An Innovative Approach towards Incorporating the End User to the NMES

Wearable System Development

Anelise Ventura

1a

, João Marcos Peron Bataglia

2b

, Leonardo Mendes Ribeiro Machado

4c

,

Jorge Vicente Lopes da Silva

4d

, Renato Varoto

2,3 e

and Alberto Cliquet Jr.

1,2,3 f

1

Bioengineering Post Graduate Course, University of São Paulo (USP),

Avenida Trabalhador São Carlense 400, São Carlos, Brazil

2

Electrical & Computer Engineering Department, University of São Paulo (USP),

Avenida Trabalhador São Carlense 400, São Carlos, Brazil

3

Orthopedics & Traumatology Department, Faculty of Medical Sciences, State University of Campinas (UNICAMP),

Cidade Universitária Zeferino Vaz, Campinas, Brazil

4

Renato Archer Information Technology Center, Dom Pedro I Highway (SP-65) Km 143.6, Campinas, Brazil

Keywords: Parametric Design, NMES, Tetraplegia, Upper Limbs, Wearable System Design.

Abstract: This work presents a portable and customized wearable system design towards applying Neuromuscular

Electrical Stimulation (NMES) to tetraplegics´ upper limbs patients, from creation to production, with users’

participation into the design process. The rehabilitation system protocol for reach and grasp movements

developed by an academic research group, currently applied to patients, has already proven to be effective.

However, the current system and recently published researches, demonstrate proposals distancing from those

who will use and manipulate it, with limitations and failures evidenced. The propose wearable system

integrates electrodes and electronic components activated by a smartphone app to improve the performance

of upper limb movements and optimize the system, making it more functional for your users. The

methodology includes (1) Design Thinking process, (2) Parametric Design process and three dimensional

production, (3) Reduction of the electronic circuits, (4) Development of Android application for setting NMES

protocols and (5) Workbench tests and users experimentation. The methodology in this new approach of

development proved to be feasible and effective. Results have shown that including the end users and health

professionals in the design process to develop wearable system is a promising strategy to overcome the

limitations of the NMES systems.

1 INTRODUCTION

According to the World Health Organization (World

Health Organization, 2013), Spinal Cord Injury (SCI)

affects between 250,000 and 500,000 people

worldwide every year. It is a complex dysfunction

that has major physical, psychological and social

repercussions. Apart from the negative impact on the

quality of life for many individuals, SCI makes it

difficult to perform many activities of daily living

(ADL) and affects negatively on the motor and

a

https://orcid.org/0000-0002-8491-9959

b

https://orcid.org/0000-0001-7596-2296

c

https://orcid.org/0000-0002-3531-9471

d

https://orcid.org/0000-0002-2347-5215

e

https://orcid.org/0000-0001-5333-7123

f

https://orcid.org/0000-0002-9893-5204

sensory functions of the upper and lower limbs of

tetraplegic and paraplegic patients. Paralysis at

different levels and parts of the body, as well as

changes in sensitivity and comorbidities (Eng &

Miller, 2009), are the consequences of SCI, which is

divided into tetraplegia and paraplegia.

It is known that Neuromuscular Electrical

Stimulation (NMES) is an effective rehabilitation tool

applied to tetraplegics’ upper limbs, to perform

reaching and grasping movements (Varoto,

Barbarini, & Cliquet, 2008) (Peckham et al, 1988).

192

Ventura, A., Bataglia, J., Machado, L., Lopes da Silva, J., Varoto, R. and Cliquet Jr., A.

An Innovative Approach towards Incorporating the End User to the NMES Wearable System Development.

DOI: 10.5220/0009095401920199

In Proceedings of the 13th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2020) - Volume 1: BIODEVICES, pages 192-199

ISBN: 978-989-758-398-8; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

The NMES employed to intact motor neurons allows

the resumption of movements that have been lost or

altered by the spinal cord injury and promote muscle

strengthening of the limbs (Varoto & Cliquet Jr,

2015). Nevertheless, stimulation parameters should

be carefully adjusted in consonance with the desired

goal, injury level, and muscle response under the

supervision of healthcare professionals (Benton,

1981). In biomedical systems, there are a number of

complexities that need to be addressed in an

integrated manner, including not only electrical and

electronic devices and disease-specific constraints,

but also the many users involved who need to deal

with the proposed product, such as patients, family

and health professionals. Including users early in

process development involves concerns about

ergonomics, appropriate materials used in the

product, user usability and acceptance. In this type of

integrated process, unforeseen problems can be

solved, leading the project to a better resolved final

product. Therefore, healthcare product development

involves a multidisciplinary team working with an

interdisciplinary way (Romero M., Perego P.,

Andreoni G., 2010)

Wearables are different in their nature and

application, so each of them is related to a different

type of a design and ergonomic criteria. The

ergonomics of a product or a system is related to

providing safety, health, comfort and performance to

the user. In this context, some rehabilitation

technology devices have been developed aiming at

upper limb motor rehabilitation, such as Handmaster

System (Snoek, Ijzerman, In ’t Groen, Stoffers, &

Zilvold, 2000), INTFES (Malesevic et al., 2012) and

the Wearable Multi-Site (Crema et al., 2018). This

work presents a new approach for the development of

wearable system towards applying NMES to

tetraplegic patients, including them from the

beginning of creation using the Design Thinking,

Parametric Design and File-to-Factory process to

achieve better results. A portable wearable system

was developed to be individually fitted to the upper

limb, to improve the performance of reach and grasp

movements for functional rehabilitation therapy. At

the same time makes the work of the health

professional more agile.

2 MATERIAL AND METHODS

The NMES rehabilitation for repetitive task training

of reach and grasp movement, currently applied to

patients with C5-C7 injury level, includes a computer

in which the stimulation signal parameters and the

protocol are defined for the rehabilitation program, a

4-channel electronic stimulator that creates stimuli

and commercial self-adhesive surface electrodes

(Fig. 1). Four active electrodes are manually

positioned on the upper limb to generate elbow

extension, extension and flexion of the fingers and

thumb opposition. Straps ensure adherence between

the electrode and the skin (Castro & Cliquet Jr.,

2001). Although the rehabilitation system and

program have already proven to be effective, self-

adhesive electrodes placement demands a longer

implementation time in each training session and

depends on the healthy professional experience for

finding the accurate position. The adhesive film on

the surface of the electrodes is highly adherent when

new, with frequent use this film loses its grip,

preventing its use. In addition, computer- based

system and cables that can interfere in the movements

impose certain limitations.

In order to minimize these inaccuracies and

benefit users, the NMES System currently applied to

tetraplegic patients has been completely redesigned

with a focus on end users and healthcare

professionals, since the actual system it only takes

into account the efficiency of electrostimulation, thus

presenting inaccuracies and failures regarding

ergonomics and the use itself.

Figure 1: The picture of the left shows the current NMES

system applied to the patient of the outpatient department

from the Clinic Hospital (HC), of the State University of

Campinas (Unicamp), Brazil versus the picture of the right

that shows the proposed novel wearable system.

This wearable system composes of three

integrated parts that cover the hand, forearm and arm

with commercial self-adhesive electrodes

incorporated, a smartphone application (app) and the

stimulation unit. The healthy professional can set

protocols for NMES via smartphone application. The

digital data are sent to the stimulation unit attached to

the wearable through Wi-Fi, which generates the

stimulation signal. Commercial surface electrodes

integrated to the wearable are used for applying

NMES to the patient.

An Innovative Approach towards Incorporating the End User to the NMES Wearable System Development

193

2.1 Wearable System Design

Interdisciplinary Design Process

This project approved by the ethics committee was

devised by researchers from the Bioengineering Post

Graduate Course and Electrical & Computer

Engineering Department of University of São Paulo

(USP), composed of architect, designer and

engineers. The team that participated in all stages of

the development of this project is composed of that

researchers, the patients and the health professionals,

these last two from the outpatient department of the

Clinic Hospital, of the Unicamp.

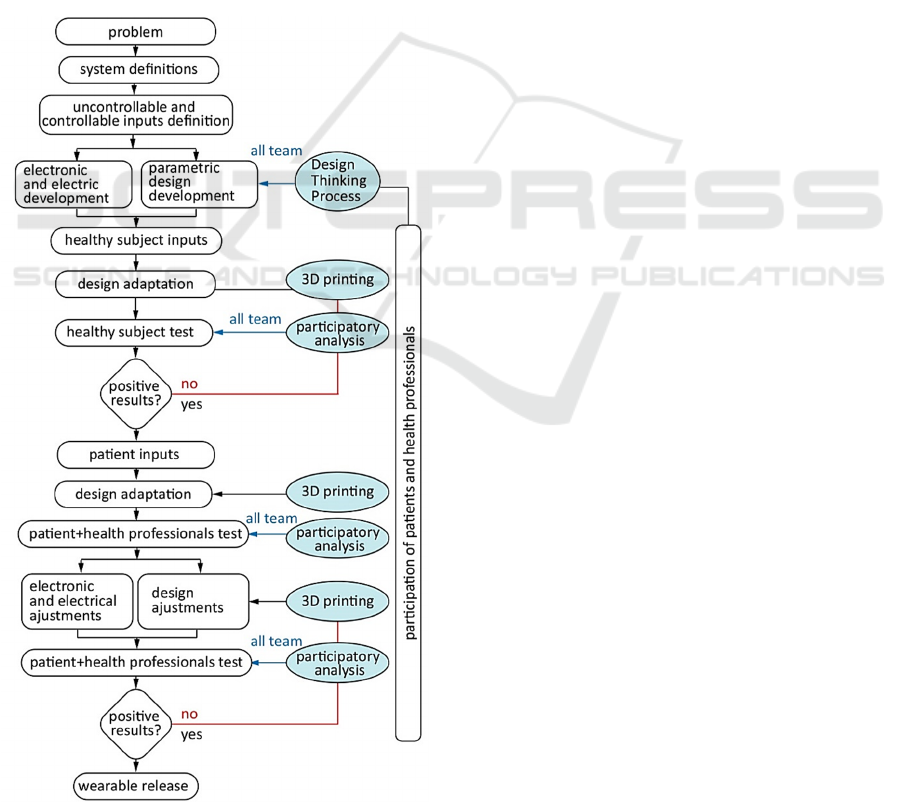

From flowchart

presented by Maximiliano Romero (Romero M.,

Perego P., Andreoni G., 2010), an adapted version

was created to clarify the interdisciplinary process

that involves the wearable system development

(Ventura, Varoto, & Cliquet Jr, 2018) (Fig. 2).

Figure 2: Interdisciplinary proposed flowchart.

The proposed flowchart shows that the

participation of the entire team occurs at the

beginning of the design process and at various times

throughout product development. Team integration is

the moment when everyone observes, evaluates and

discusses what was produced.

To get closer to the realities of the rehabilitation

routine and improving the current system, the Design

Thinking process was applied. The major goal is to

explore possibilities and to create options in a

divergent process of ideas without judgments or

limits, and then make choices, through the convergent

process (Brown, 2009), resulting in three-

dimensional models and prototypes.

After the Design Thinking stage, the parametric

design methodology was developed. In parallel, a

scanning protocol of the upper limbs was elaborated

and the results of the 3D scanning of a healthy

individual and a patient were inserted in the

generative algorithm inputs, for verification and

adjustments of the created methodology. The patient

participated in the product development of the healthy

individual from the point of view of wearable shape,

aesthetic acceptance and material malleability. The

health team evaluated the placement of the electrodes

in the wearable, their handling and the ease of placing

the product on the upper limb.

With positive results, the healthy subject's inputs

will be replaced by the patient's inputs. The wearable

will be 3D printed, and quantitative movement and

qualitative comfort assessments will be performed.

Parametric Design and File-To-Factory

Process

Wearable are devices designed to fit different moving

bodies so that they can be controlled and operated

without interruption or limiting the movements of the

users (Mann, 1997). The wearable shape, their active

relationship with the human anatomy and other

components must act in an integrated way for proper

secondary functioning and use. Specifically, for this

work, the anthropometric characteristics of the upper

limbs are very different from one patient to another

due to deformities resulting from the SCI. Thus, it

arises the need for individually fitted wearables, and

design and ergonomics criteria based on Design

Wearability Guidelines (Gemperle, Kasabach,

Stivoric, Bauer, & Martin, 1998).

According to ergonomic criteria and because it is

a highly complex product, the creation of wearable

involved the development of a Parametric Design

Methodology using generative algorithms, a 3D

scanning protocol for patient's upper limb and a file-

to-factory 3D printed product.

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

194

The production of complex geometries of this

order is associated with file-to-factory process, with a

direct relationship between design and production. It

involves direct transfer of data from a 3D modeling

software to a 3D printing machine (Kolarevic, 2009).

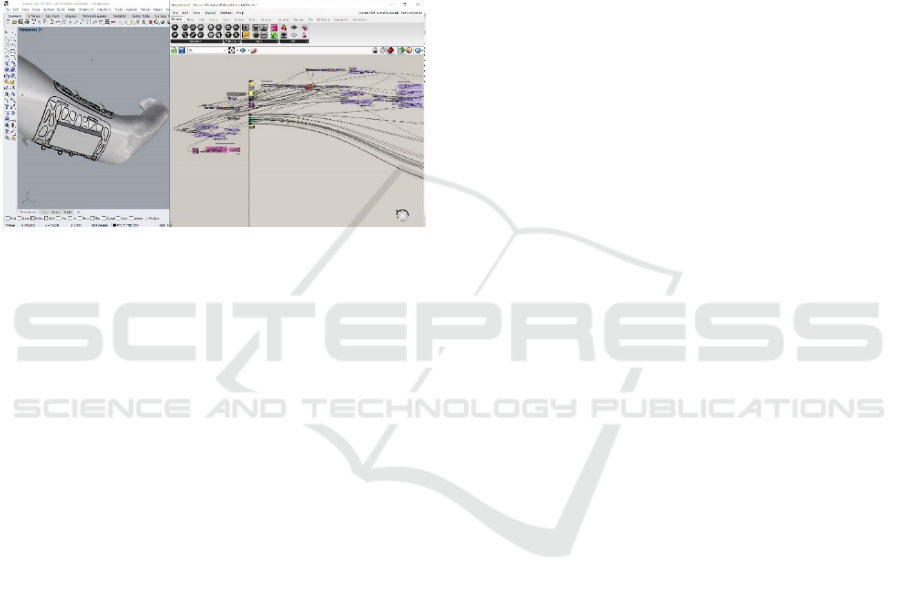

The wearable model was performed in Rhinoceros 3D

(TLM Inc., Seattle, WA, USA), which is a CAD tool,

and an algorithmic logic has been developed in

Grasshopper, which is a generative algorithm editor

for Rhinoceros, so that the design is completely

automated (Fig. 3). The input data changes according

to the individuality of each patient.

Figure 3: 3D model automated with generative algorithm.

According to the ergonomic criteria the inputs

required for the construction of wearable were

divided into primary (uncontrollable):

anthropometric data and the electrode points on the

muscle groups, and secondary (controllable): position

that the wearable will occupy on the arm, size of the

electrodes, tubes that will embed the cables,

stimulation unit position, wearable clearance, weight

of the wearable and ventilation. The resulting

wearable shape is achieved according to the

relationships of the primary and secondary

parameters.

The protocol scan created considerate the

wheelchairs and restricted upper limb movement of

the patient. It was simulated the environment and the

conditions of the patients to scan the dominant upper

limb of the healthy subject. The 3D scan of the

dominant upper limb resulted in an anthropometric

data, and it was collected with 3D iSense Scanner (3D

Systems, Rock Hill, SC, USA) with Skanect 3D

Scanning Software (Occipital, Inc., San Francisco,

CA, USA).

According to the developed model, the wearable

was printed by Fused Deposition Modelling (FDM)

process with flexible ABS material.

Electronic Apparatus and Smartphone

Application

The ESP32 DeviKit V1 Development Board

(Shenzhen Doctors of Intelligence & Technology Co.

Ltd, Shenzhen, Guangdong, China) provides an

interface between the smartphone app and the

stimulation unit, presenting Wi-Fi and Bluetooth Low

Energy (BLE) connectivity.

Powered with 6V by one 18650 rechargeable

lithium ion battery (4.2V, 9.8Ah) connected to an

adjustable booster power supply module with

XL6009 DC-DC step up module (Shanghai Xinlong

Semiconductor Technology Co. Ltd, Pudong,

Shanghai, China), the ESP32 operates as a custom-

made monophasic square waveform generator,

creating the stimulation signal with following

parameters: number of pulses for each burst: 4; pulse

width: 100s; period between pulses: 100s and burst

frequency: 25Hz.

The microcontroller module was programmed

using language and Integrated Development

Environment (IDE) of Arduino (Arduino S.r.l,

Scarmagno, TO, Italy) with extension packages for

ESP32. Ports D13, D12, D14, D27, D26, D25, D33

and D32 were configured as outputs, corresponding

to the stimulation channels 1 to 8, respectively.

In the stimulation unit, the generated signal is

transmitted to the isolation circuitry, which uses

optical coupling. In order to adequate the signal for

the amplification circuitry, an inverter buffer operates

at the optocoupler output.

A potentiometer, an N-Channel Power MOSFET

and a pulse transformer compose the amplification

circuitry, designed for output up to 100V.

The same strategy - previously described - is used

to power the stimulation unit, but the booster module

output has been set to 12V.

The stimulation unit is electrically coupled to the

patient via self-adhesive surface electrodes.

Communication between the microcontroller and

the Android app occurs using a Wi-Fi router (there is

no need of internet access). In relation to the router, a

static local IP address and a port number were

assigned for microcontroller connection, which

works as a network server. The app connects to the

same Wi-Fi router as a network client, requesting

permission to exchange data with the microcontroller.

The smartphone app written in Java Programming

Language was designed using Android Studio

(Google LLC, Mountain View, CA, USA). The user

interface was done through FIGMA online design

tool (Figma Inc., San Francisco, CA, USA) and

presents three tabs.

An Innovative Approach towards Incorporating the End User to the NMES Wearable System Development

195

Four strings are written to adjust the channels and

to define the NMES protocol. The first one is

dedicated to the stimulation channels tuning; the

stimulation signal is provided on the selected channel

for one minute. This period allows the health

professional to adjust the signal amplitude - via

stimulation unit - according to the patient's motor

responses.

NMES protocol has up to 12 phases that

correspond to the planned movements of the upper

limb. For each phase, up to three channels can be

activated during the specified period (up to 12s with

resolution of 400ms). This information is gathered in

the second string. In the rehabilitation program, this

protocol can be repeated. Thus, the third string

determines the number of cycles (up to 300) along the

program. The fourth string contains an indicator to

initiate the process.

Workbench Tests

The workbench tests were done to verify the

electronic apparatus performance, including the

temperature variation of some components. Using a

TDS2024 Digital Storage Oscilloscope (Tektronix

Inc, Beaverton, OR, USA), the stimulation signal was

characterized in terms of time and amplitude at the

output of ESP32, optocoupler, inverter buffer and

amplification circuitry. A resistor played a role of

electrodes and biological tissue (impedance

equivalent to 1k). Battery autonomy was estimated

for the 100V amplitude stimulation signal. Thus, a

channel powered by a fully charged battery was

activated uninterrupted until the amplitude reached at

least 90% of this voltage.

Users Experimentation

The health professional inserted the electrodes into

the wearable in the space designed for them; new and

reused electrodes were tested. Then, the wearable was

placed in the healthy subject's hand, forearm and arm,

and the channels were adjusted according to their

motor response to perform effective wrist and elbow

extension movements and effective flexion and

extension of the fingers. The amplitude was gradually

increased until reaching the excitability threshold of

each muscle group. The NMES protocol was adapted,

since the stimulus sensitivity of the healthy individual

is higher.

3 RESULTS

The relevant and unanimous concepts extracted as a

result of Design Thinking dynamics for wearable

design were safety and confidence in the movement,

agility of the process during NMES therapy and the

possibility to do it at home with healthy professional

supervision.

As a result of the methodology developed with the

Grasshopper plug-in the full automation of the project

was achieved and the developed method confirmed to

be efficient regarding the substitution of the

parameters from one individual to the other, although

the generative algorithm editor had limitations

regarding the modeling flexibility over double

curvature geometries, such as topographic features of

the upper limbs.

The solution found for the loss of electrode

contact with the user's skin over time due to decreased

electrode film adhesion and its precise location on

muscle groups was the print of the wearable with

embossed markings, positioned exactly at the

locations of the muscle groups to be stimulated, with

the shape and size of the electrodes. The high relief

promoted the integral contact of the surface of the

electrodes to the individual's skin, so that the reach

and grip functions were achieved even with the loss

of the adherent film. In addition, the solution found

for the fixation of the electrodes on the werarable

were double sided tapes. The double-sided tape was

suitable for its fixation to the werarable and for the

fixation of the electrodes to it.

Figure 4: Left wearable inside with the electrodes and right

without the electrodes.

Regard file-to-factory process the printing was

faithful to the 3D modeling data. The characteristics

of the flexible ABS material allow the wearable

surfaces to have flexibility without losing their

original shape and allow the health professional to

easily place the product on the patient. In addition,

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

196

flexible ABS features a comfortable texture to the

touch.

In relation to users’ experimentation, appropriate

results were achieved with new and reused electrodes.

The wearable system design resulted in efficiency

of the projected areas for the electrodes, and its

position and emboss surface provided better adhesion

to the electrodes on the skin surface, resulting in

effective NMES (Fig. 4). The extension and flexion

movements of the wrist, fingers and elbow were

efficient performed with stimuli of approximately

10V (for 1k equivalent impedance). The electronic

circuit was designed to provide up to 100V. However,

10V was sufficient for the healthy subject.

The physical access and manipulation of the

wearable by the health professional was intuitive. The

anthropometric characteristics of the 3D model were

faithful to the real ones, facilitating the wearable

placement in the correct position. There was no

readjustment in the wearable position to perform

efficient movements.

Figure 5: Printed wearable and stimulation unit.

The tubes that embed the electrode cables were

strategically positioned in the wearable avoiding their

disconnection and flow close to the stimulation unit

solving the problems with the dimension of the

cables.

Regard the Android app, called “Stimulator”, on

the “Setting Channels Up” tab, each channel can be

selected to tune the stimulation intensity. The “NMES

Protocol” tab is dedicated to configure the phases.

When the phase button is tapped, the “Phase Settings”

screen pops up, so up to three channels can be

selected and a slider allows adjustment of the

activation period. The last tab- “Rehabilitation

Activities”-summarizes the phases configuration and

shows the slider to select the number of cycles of the

rehabilitation activity, indicating the total time

(Fig. 5). Tapping the send button on this tab, a status

screen of the communication process appears, and

then the rehabilitation activity is started.

Figure 6: Stimulator android app.

The generated signal achieved the timing

characteristics (pulse width, period between pulses

and burst frequency) and provided four pulses for

each burst, from ESP32 to amplification circuitry

output. General-purpose input/output (GPIO) of

ESP32 operates with analog voltage ranging from 0

to 3.3V. Thus, the stimulation signal was generated

with amplitude of 3.24V. On the analog circuit, this

signal was inverted, reaching -4.72V according to the

5V power supply. Amplified to 8.08V at the inverter

buffer output, the stimuli range from 0 to about 100V

for 1k impedance. Battery autonomy was

approximately 65 minutes.

4 DISCUSSION

It is considered that one of the major obstacles in the

development of the wearable system in this work is

the product to meet the varied anthropometries of the

upper limb of the spinal cord injured patient and the

system to function properly. Current computing

technologies have proven to be able to handle these

complexities.

Using parametric design produced with the file-

to-factory process, including end-user participation

throughout the product development process and

being faithful to upper limb anthropometry, has

allowed preliminary testing to be performed on a

healthy individual. It contributed to verify the

strengths and weaknesses of the proposed wearable.

Problems were minimized during product

development without the patient being overwhelmed

in the preliminary phase of the patient's wearable

impression.

According to the concepts discussed in Design

Thinking process - safety, confidence and agility- the

wearable shape provided robustness, towards a safety

physical constitution, although light (177,21 g),

without limiting the range of motion. In contrast to

the current system the stimulation unit has

An Innovative Approach towards Incorporating the End User to the NMES Wearable System Development

197

considerably decreased its size. However, it was

heavy to be coupled to the wearable (401,6 g).

The inconvenient of the double-sided tape for

attaching the electrodes to the wearable was that it left

material residue on the product when removed from

it.

The wearable was designed to be produced by the

file-to-print method with 3D printing, without having

to be finalized by the industry. This optimizes the

design and production process.

Filament deposition printing (FDM) showed

flaws mainly in the final shape of the fastening parts

and the wearable finish. However, its malleability and

tactile comfort characteristics were achieved.

According to the literature review the commercial

product Handmaster (Snoek et al., 2000), in terms of

performance, presented functional benefits to

patients. In terms of product design, it did not present

ergonomic for all sizes of forearms tested, and among

ten product units, three did not serve patients because

of its small size. Among the three examples

presented, both Handmaster as INTFES (Malesevic et

al., 2012) and The Wearable Multi-Site System

(Crema et al., 2018) proved to be effective in relation

to NMES functionality, although they have

anthropometric constraints. Furthermore, the last two

examples do not suggest the end-user and health team

participation until the presented stage of

development, which may have generated the

mentioned results in relation to the particularities of

each patient. This means that if users are ignored

early in the stimulation system development process,

incompatibilities between this system and the end

product tend to occur more easily. In addition,

recurring failures in ergonomics, usability, handling

and user acceptance of the product will be detected

and new issues will need to be fixed. Thus, users,

product design, electronics, and assembly

manufacturing must be developed simultaneously by

an interdisciplinary team.

An advantage of using an app and the

microcontroller other than a fixed apparatus (such as

a computer) to set up the NMES, is the fact that a

single device containing the app is capable, with

minor adjustments, to be used for multiple patients at

the same time. After the stimulation has been sent

from the app to the microcontroller, the app is no

longer in charge of the stimulation, been possible to

operate in another person. This feature has the

potential to increases the amount of patients that can

receive the treatment at a time with the same amount

of health professionals, therefore creating a more

accessible treatment to the public.

The possible limitations of the present study are

that a designer with programming knowledge it is

necessary to alter the parameters for the development

of a new wearable to a new patient, using the same

method and the product has been designed for a

particular stimulation protocol, if new muscle groups

need to be stimulated, the inputs must be reformulated

and a new wearable printed.

5 CONCLUSIONS

The results demonstrated that including the end user

and the health professionals from the development of

the concept design to the wearable production can be

a promising alternative to reconciling the

complexities involved in a NMES wearable system to

overcome its shortcomings and limitations. To

achieve these results, the use of Design Thinking,

Parametric Design and File-to-Factory processes

proved to be feasible and effective.

The next steps for this work include system

development for the patient and performance analysis

with the motion imaging system.

ACKNOWLEDGEMENTS

The authors would like to thank the support by grants

from São Paulo Research Foundation (FAPESP),

Brazilian Federal Agency for Support and Evaluation

of Graduate Education (Capes) and National Council

for Scientific and Technological Development

(CNPq).

REFERENCES

Benton, L. A.; Baker, L. L.; Bowman, B. R.; Waters, R. L.

(1981) Functional Electrical Stimulation - A Practical

Clinical Guide, 2 ed., Rancho Los Amigos

Rehabilitation Engineering Center, California.

Brown, T. (2009). Change by Design. How Design

Thinking Transforms Organizations and Inspires

Innovation. HarperBusiness.

Castro, M. C. F. De, & Cliquet Jr., A. (2001).

Neuromuscular Electrical Stimulation and Electron-

tactile Stimulation in Rehabilitation of Artificial

Prehension and Proprioception in Tetraplegic Patients.

Acta Ortop. Bras., 9(3), 19–28.

Crema, A., Maleševi, N., Furfaro, I., Raschellà, F.,

Pedrocchi, A., & Micera, S. (2018). A Wearable Multi-

Site System for NMES-Based Hand Function

Restoration. IEEE Transactions on Neural Systems and

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

198

Rehabilitation Engineering, 26(2), 428–440.

https://doi.org/10.1109/TNSRE.2017.2703151

Eng, J. J., & Miller, W. C. (2009). Rehabilitation: From

Bedside To Community Following Spinal Cord Injury

(SCI). SCIRE Spinal Cord Injury Rehabilitation

Evidence: Version 2.0, (1). Retrieved from

www.icord.org/scire C:%5CEMH%5CScannede art

ikler referanser%5CRefMan4265.pdf

Gemperle, F., Kasabach, C., Stivoric, J., Bauer, M., &

Martin, R. (1998). Design for Wearability. In Digest of

Papers. Second International Symposium on Wearable

Computers (Cat. No.98EX215) (pp. 116–122). IEEE.

Kolarevic, B. 2009. Architecture in the digital age: design

and manufacturing. New York; London: Taylor &

Francis.

Malesevic, N. M., Popovic Maneski, L. Z., Ilic, V.,

Jorgovanovic, N., Bijelic, G., Keller, T., & Popovic, D.

B. (2012). A multi-pad electrode based functional

electrical stimulation system for restoration of grasp.

Journal of NeuroEngineering and Rehabilitation, 9(1),

66. https://doi.org/10.1186/1743-0003-9-66

Mann, S. (1997). An historical account of the `WearComp’

and `WearCam’ inventions developed for applications

in `Personal Imaging’. In PISWC ’97 Proceedings of

the 1st IEEE International Symposium on Wearable

Computers (pp. 66–73). Cambridge, MA, USA: IEEE.

https://doi.org/10.1109/ISWC.1997.629921

Peckham, P.H., Keith, M.W.; Freehafer, A. A. (1988).

Restoration of functional control by electrical

stimulation in the upper extremity of the quadriplegic

patient. J Bone and Joint Surg 70-A(1):144-148.

Romero M., Perego P., Andreoni G., C. F. (2010). New

Strategies for Technology Products Development in

Health Care, New Trends in Technologies: Control,

Management, Computational Intelligence and Network

Systems. (Meng Joo E, Ed.). Meng Joo Er.

https://doi.org/DOI: 10.5772/293

Snoek, G. J., Ijzerman, M. J., In ’t Groen, F. A. C. G.,

Stoffers, T. S., & Zilvold, G. (2000). Use of the NESS

Handmaster to restore handfunction in tetraplegia:

Clinical experiences in ten patients. Spinal Cord, 38(4),

244–249. https://doi.org/10.1038/sj.sc.3100980

Varoto, R., Barbarini, E. S., & Cliquet, A. J. (2008). A

Hybrid System for Upper Limb Movement Restoration

in Quadriplegics. Artificial Organs. Thoughts and

Progress, 32(9). https://doi.org/10.1111/j.1525-

1594.2008.00597.x

Varoto, R., & Cliquet Jr, A. (2015). Experiencing

Functional Electrical Stimulation Roots on Education ,

and Clinical Developments in Paraplegia and

Tetraplegia With Technological Innovation. Artificial

Organs, 39(ii). https://doi.org/10.1111/aor.12620

Ventura, A., Varoto, R., & Cliquet Jr, A. (2018). Wearable

Technology: Healthcare Product Design For

Participation Of Tetraplegics In Society. In Blucher

Design Proceedings. https://doi.org/10.5151/sigradi

2018-1726

World Health Organization. (2013). Spinal cord injury.

Retrieved March 12, 2019, from https://www.who.int/

news-room/fact-sheets/detail/spinal-cord-injury

An Innovative Approach towards Incorporating the End User to the NMES Wearable System Development

199