Development of a New EMG Wearable Sensor for Myoelectric

Control

Clive Seguna, Steve Buhagiar, Jeremy Scerri and Kris Scicluna

Institute of Engineering and Transport, Electrical and Electronics, MCAST,

Corradino Hill Paola, Malta

Keywords: e-Health, Wireless, Wearable, Sensing, EMG, ECG, Telemetry.

Abstract: The application of wireless technology to monitor and record high quality real-time signals is playing an

important role in today`s world. Various applications such as electromyography and electrocardiography

require low-power and low-voltage portable wireless sensors for remote e-health monitoring. The use of such

technology allows patients with muscle or heart problems to be monitored from the comfort of their home.

Additionally, wireless implantable electromyogram sensing is also integrated in the design of intelligent

myoelectric control for powered prostheses. The specifications within such applications constrain the design

and development of wearable electromyographic sensors. This work presents a low-cost, portable, wireless

non-invasive 8-channel system to monitor and classify electromyographic signals related to hand or finger

movement. The proposed system operates at 1.0 V and draws a current of 1 mA in power-down mode. The

paper also discusses the hardware and software implementation details and presents various measurement

results. This work concludes through feature comparison with other similar technologies in the market.

1 INTRODUCTION

Wearable technology has been trending in healthcare

and myoelectric applications for the last decade.

Electromyography (EMG) sensors have been

succesfully used in assistive and therapeutic

healthcare. Such applications impose several

challenges on the development of such wearable

technology for the continuous daily health

monitoring; these include small form factor, minimal

power consumption, portability and extended battery

life. EMG signals are distributed in a frequency range

between 10 to 500 Hz. Additionally, EMG sensors are

also used in motion therapies in order to track patient

motion and applied forces (Nikolic, 1994), (Suster,

2007), (Cong, 2009), (Kamali, 2014).

EMG sensor which are expensive and have a large

form factor are already available in the market.

However, researchers are finding challenges in

designing and developing low-cost, low-voltage, and

small form-factor sensors that are able to detect finger

and hand movement (Nair, 2010), (Lui, 2000).

Such requirements are critical for wearable and

portable applications. Various EMG-based control

techniques apply the use of pattern recognition,

mapping techniques or models (Burke, 2004), neural

nets and time domain (Nagaraju, 2010), (Benatti,

2017), (Teng, 2014) analysis for the classification of

hand or finger movement (Cappellari, 2018),

(Berezhnoy, 2018), (Bembli, 2019), .This work

presents a new low-cost, low-voltage EMG sensor

designed to classify finger and hand movement in a

patient. Through the use of an LPC824 based

microcontroller system and the implementation of

custom signal conditioning circuitry the developed

non-invasive EMG wireless sensor is able to capture

and process 8 multiplexed EMG signals. The pre-

processed EMG data is then trasmitted wirelessly

over Bluetooth for the control and activation of a

robotic manipulator. Such features makes this sensor

suitable for various applications including muscle

movement and myoelectric control at low-cost by just

using commercial off-the shelf components.

Classification of finger and hand movement is

implemented through amplitude and time-domain

analysis (Mert et al., 2018).

Section 2 presents the circuit design for the

wireless EMG sensor. Section 3 describes the adopted

time-domain procedure for the classification and

detection of hand or finger movement. A detailed

description related with the measurement results is

given in Section 4.

160

Seguna, C., Buhagiar, S., Scerri, J. and Scicluna, K.

Development of a New EMG Wearable Sensor for Myoelectric Control.

DOI: 10.5220/0008979501600164

In Proceedings of the 13th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2020) - Volume 1: BIODEVICES, pages 160-164

ISBN: 978-989-758-398-8; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 EMG SENSOR CIRCUIT

DESIGN

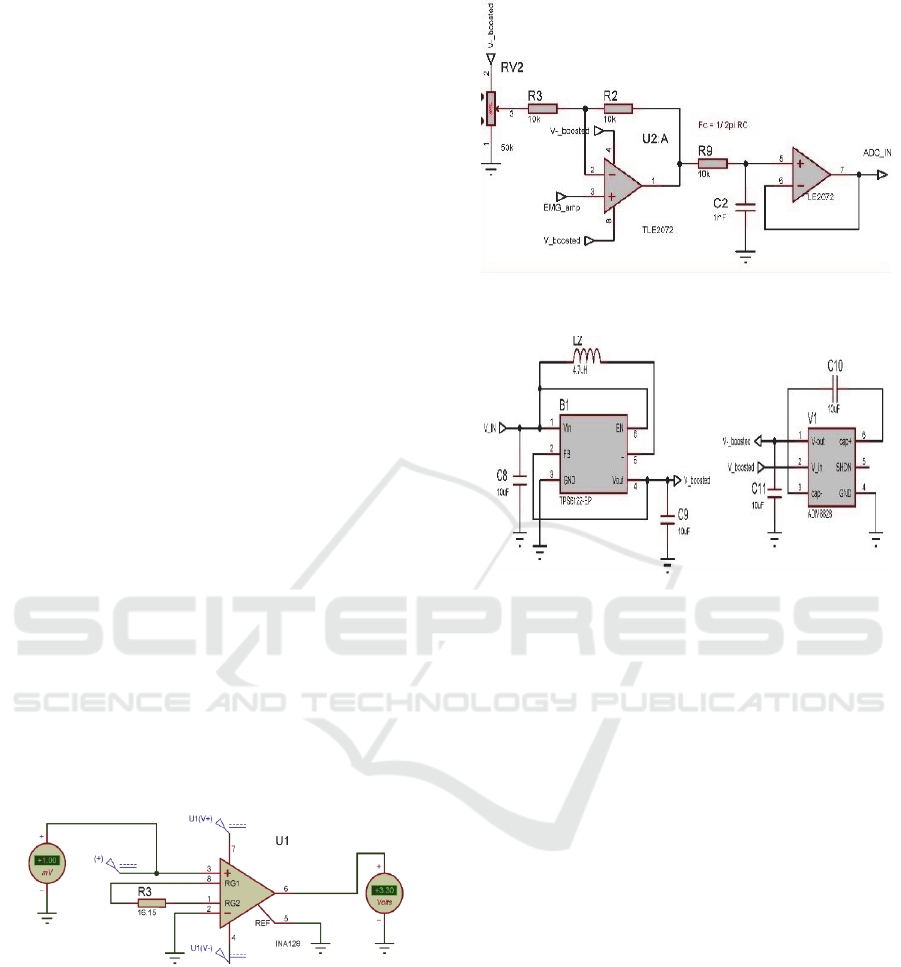

This section describes the design and implementation

details related with the developed EMG sensory

module. The acquisition of the 8-channel EMG

signals is performed through the use of wet electrodes

connected in uni-polar configuration and then to an

instrumentation amplifier (IA) with a common-mode

rejection ratio (CMRR) of 120 dB, followed by

amplification and filtering stages. This arrangement

contributes to the reduction of common mode noise

which is present on both electrodes while retaining

the signal of interest. Further reduction in circuit

design is achieved through the use of a multiplexing

circuit that allows the switching between the 8-

channel selectable electrode signals. The

instrumentation amplifier circuitry shown in Figure 1

(gain of 3300), yields a maximum output voltage of

3.3 V peak to peak. A DC offset of 1.65 V is

introduced so that the full range of the 3.3 V

Analogue-to-Digital Converter (ADC) on the

LPC824 microcontroller is used. The DC offset

circuit is followed by an first order low-pass filter

(bandwidth f

3dB

= 15 kHz) as shown in Figure 2. The

adopted LPC824 ARM based Cortex M0+

microcontroller operates through an internal RC

oscillator running at 12 MHz, pre-scaled to 30 MHz

using an internal PLL. Additionally, this

microcontroller supports Direct Memory Access

(DMA), thus enabling the processing of 14

th

order

band-pass digital filter at a sampling frequency of 1.5

kHz. The dual rail supply voltage for instrumentation

amplifier is ± 5.0 V.

Figure 1: EMG Instrumentation Amplifier Circuit.

The TPS6122 buck-boost DC-DC converter circuitry

has a minimum input voltage of 0.7 V and output

voltage range of 1.8 to 5.5 V with a quiescent current

of 5.5 µA.

The analog stage requires a dual rail supply,

therefore a buck-boost convertor (negative supply) is

used to achieve the required voltages of ± 5.0 V. The

ADM8829 charge-pump voltage inverter changes the

input voltage outputted from the TPS6122 device into

Figure 2: DC offset and Low Pass Filter circuitry.

Figure 3: Buck-Boost Converter.

a negative voltage, creating a dual rail supply voltage

for the IA and op-amps.

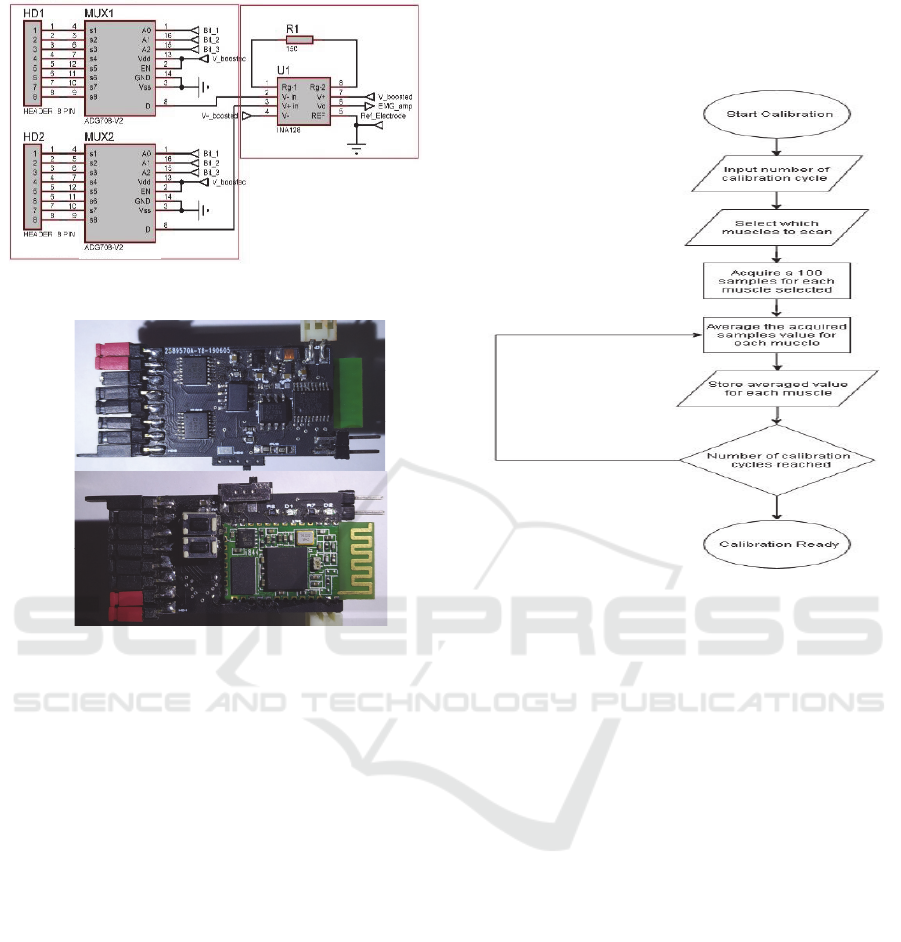

The ADG708 multiplexer is used to switch

between selectable 8-channel electrodes whose

output is to be sampled by the ADC, and then filtered

through the 14

th

order digital infinite-impulse

response (IIR) band-pass digital filter using the

LPC824 microcontroller (bandwidth f1

3dB

= 25 Hz,

f2

3dB

= 225 Hz ). The filtered EMG data is then

transmitted from the LPC824 device to the HC06

bluetooth module and then received by a wireless

client device.

The maximum switching time in between

multiplexer channels is 14 ns when running on 5 V

and a typical power consumption of 1 µA.

Figure 5 illustrates the top and bottom views for

the manufactured system with a small form-factor of

33 by 20 mm. Two switch push-buttons, are used to

program the microcontroller. The internal LPC824

direct Memory Access (DMA) module allows

transfer of digital EMG data at a high transfer rate

with the intervention of very few CPU cycles. Test

pins were included in the module so to directly

monitor and record the amplified and filtered EMG

signals through an oscilloscope.

Development of a New EMG Wearable Sensor for Myoelectric Control

161

Figure 4: INA128 and multiplexing stage.

Figure 5: Top and bottom view of the wearable EMG sensor

with dimension 33mm by 20 mm.

3 EMG SENSOR

CLASSIFICATION

Analysis of EMG signals was performed using two

pairs of electrodes placed over the forearm muscle,

which is mostly active when moving the arm wrist.

The raw EMG signal was processed through root

mean square calculation. Classification of wrist and

hand movement was done through time-domain

amplitude analysis. A system calibration procedure

shown in Figure 6 allows the recognition of wrist or

hand movement via amplitude analysis. The

implementation for amplitude analysis identifies and

configures the thresholds measured when certain

hand gesture movements are made. Calibration

process follows electrode placement. This process

consisted of contracting the wrist in three different

positions multiple times and one at a time. With each

contraction, the amplitudes acquired from all

electrodes being recorded. This process was repeated

for a pre-defined amount of repetitions so to establish

the required thresholds. The amplitude analysis is

performed prior to the signal being filtered and then

Root Mean Squared; a moving average can be applied

to the signal if needed.

Figure 6: Calibration Procedure for the classification of

hand movement.

4 MEAUREMENT RESULTS

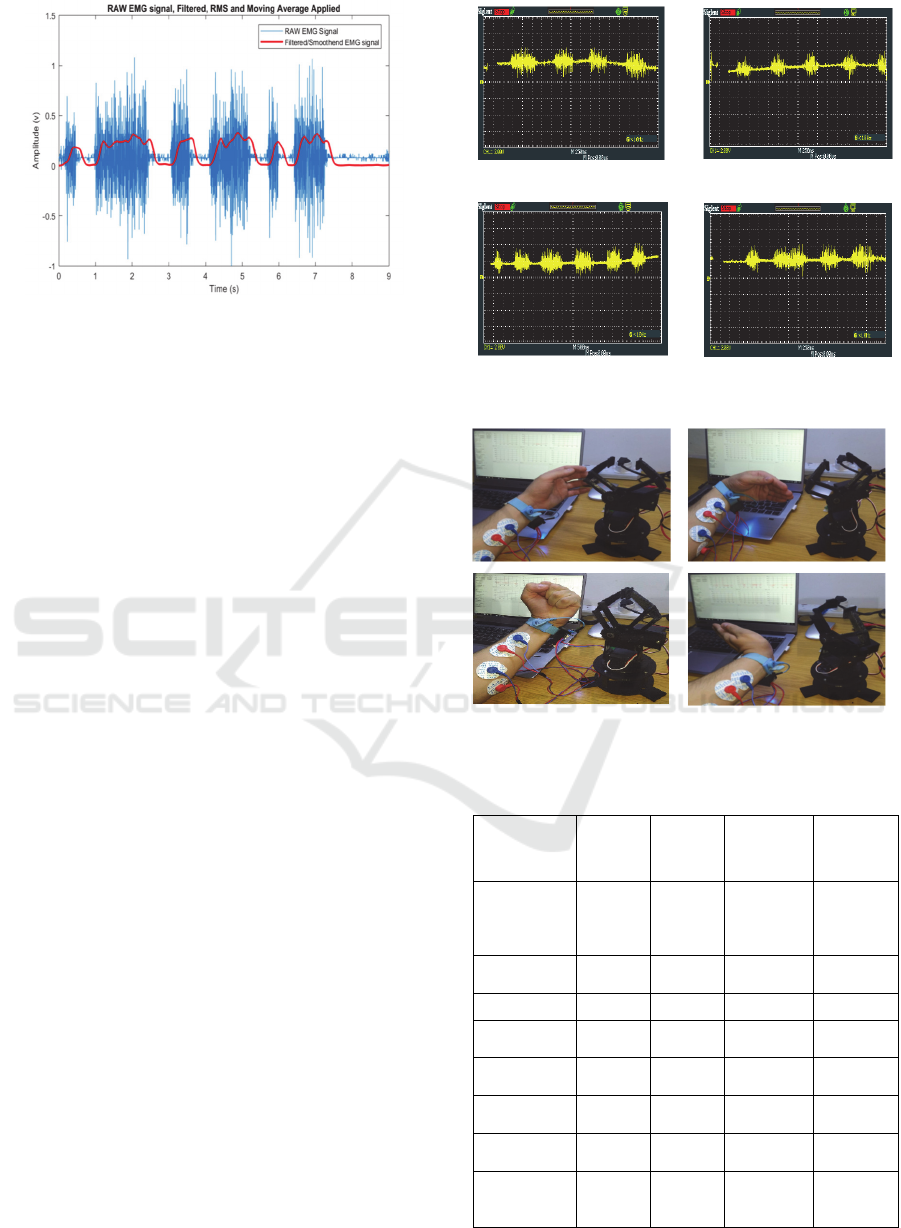

An illustration of the amplified raw, DC shifted EMG

signal for various hand movements is shown in Figure

7. This signal represents the electrical currents

generated by the muscle activity being controlled by

the nervous system and is also depended on the

anatomical and physiological properties of the

muscles. Additionally, the shown EMG signal in

Figure 7 has been filtered from noise being generated

from various tissues. For testing purposes, a 3D-

printed five degrees of freedom robotic manipulator

is to be controlled through six analogue or PWM

inputs located on the robot controller.

The acquired EMG myoelectric signals from 4

different channels are shown in Figure 8. The

calibration procedure was performed for adaptively

setting the required channel amplitude thresholds

needed for the classification of three hand

movements. Classification data is wirelessly

transmitted to a bluetooth client device located on the

robotic manipulator and controlled using an

embedded controller.

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

162

Figure 7: Amplitude response of filtered and smoothened

Raw EMG signal.

Examples of three different classified hand

motions are shown in Figure 9. The fist motion will

control the opening and closing of the claw actuation,

while two other hand movements rotates are used to

control the angular position robotic arm

that is

clockwise or counter-clockwise. The same

classification procedure has also been tested and

adopted for the classification of finger movement.

Through exstensive experimentation repetitive

measurement and performance results were noted.

5 DISCUSSION AND

CONCLUSION

In this work, the successful development of a low cost

and wearable 8-channel sEMG data acquisition

system was presented along with the implementation

of an adaptive threshold setting algorithm for the

classification and contraction detection of hand or

wrist movement. A feature comparison of the

proposed system with other similar sEMG sensors

including commercially available products in terms

of bandwidth, operating voltage, size, and contraction

detection is shown in Table 1. Such comparison,

illustrates that the developed non-invasive wearable

sEMG sensor has the smallest form factor operates

and operates at a low supply voltage of 1.0 V using

just one single-cell AAA battery. The developed

EMG sensor has also a very low weight of 6 grams,

four times less when compared to other similar work.

Additionally, through exstensive testing and from

the illustrated measurement results the threshold

setting amplitude analysis classification algorithm is

satisfactorily detects contractions and recognizes

wrist or finger movement.

Figure 8: EMG measurements for four EMG channels (mV

versus time ms).

Figure 9: Control of robotic manipulator through developed

EMG sensor.

Table 1 : Comparison with other similar Systems.

This

work

sEMG

Sensor

(Seguna,

2018

)

Myo

Armband

Hercules

(Mert, 2018)

Classification

of

Hand/Finger

Movement

Yes Yes No No

Contraction

Detection

Yes Yes No Yes

Wearable Yes Yes Yes Yes

Bandwidth

(Hz)

1200 20-589 - 20-500

Supply

Voltage

1.0 V 2.5 V 3.7 V 3.7 V

Dimensions

L x W (mm)

20 x 33 45 x 25

190 x 340 -

Weight

(grams)

6 24

93 -

Battery

Type

AAA

(x1)

-

Built-in

lithium

Ion

AA

(x2)

Development of a New EMG Wearable Sensor for Myoelectric Control

163

REFERENCES

Nikolic, R., et al.,“Instrumentation for ENG and EMG

recordings in FES systems”, IEEE Trans. Biomedical

Engineering, v. 41, nr. 7, pages 703-706, 1994.

Suster, M., et al., “A Wireless Strain Sensing Microsystem

with External RF Powering and Two-Channel Data

Telemetry Capability,” ISSCC, 2007, pages 380-381.

Cong, P., et al., “A Wireless and Batteryless 130 milligram

300μW 10-bit Implantable Blood Pressure Sensing

Microsystem for Real-time Genetically Engineered

Mice Monitoring”, ISSCC, 2009, pages 428-429.

Kamali, T., et al., ,“A multi-classifier approach to MUAP

classification for diagnosis of neuromuscular

disorders,” IEEE Trans. Neural Syst. Rehabil. Eng.,

vol. 22, no. 1, pages 191–200, Jan. 2014.

Nair, S., et al., “The application of machine learning

algorithms to the analysis of electromyographic

patterns from arthritic patients,” IEEE Trans. Neural

Syst. Rehabil. Eng., vol. 18, no. 2, pages 174–184, Apr.

2010.

Liu, W. and Humayun, M. S, “Retinal Prosthesis”, ISSCC,

2004, pages 218 – 225.

Burke, M., et al., “A micropower dry-electrode ECG

preamplifier,” Biomedical Engineering, IEEE

Transactions on, vol. 47, 2000, pages 155 –162.

Nagaraju, M., et al., “Circuit techniques for wireless

bioelectrical interfaces,” in 2010 International

Symposium on VLSI Design Automation and Test

(VLSI-DAT), 2010, pages 117 –120.

Benatti, S., et al., “A prosthetic hand body area controller

based on efficient pattern recognition control

strategies,” Sensors, vol. 17, no. 4, pages 2-17–4-17,

2017.

Teng, S., L, et al., “Programmable EXG biopotential front-

end IC for wearable applications”, IEEE Trans.

Biomed. Circuits Syst., vol. 8, no. 4, pages 543–551,

Aug. 2014.

Cappellari, P., et al., “Identifying Electromyography Sensor

Placement using Dense Neural Networks”, in

Proceedings of the 7th International Conference on

Data Science, Technology and Applications – pages

130-141, 2018.

Berezhnoy, V., Popov D., Afanasyev I. “The Hand-gesture-

based Control Interface with Wearable Glove System”,

in Proceedings of the 15th International Conference on

Informatics in Control, Automation and Robotics -

Volume 2: ICINCO, pages 458-465, 2018.

Bembli, S., et al., “A Terminal Sliding Mode Control using

EMG Signal: Application to an Exoskeleton-Upper

Limb System”, in Proceedings of the 16th International

Conference on Informatics in Control, Automation and

Robotics - Volume 2: ICINCO, pages 559-565, 2019.

Seguna, C., et al., “Development of a New Low-Cost EMG

Monitoring System for the Classification of Finger

Movement”, 2018 New Generation of CAS (NGCAS),

pp. 126-129, 2018.

Mert, E., et al., “An Embedded, Eight Channel, Noise

Cancelling, Wireless, Wearable sEMG Data

Acquisition System with Adaptive Muscle Contraction

Detection”, IEEE transactions on biomedical circuits

and systems, 2018.

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

164