Combining Evidential Clustering and Ontology Reasoning for Failure

Prediction in Predictive Maintenance

Qiushi Cao

1 a

, Ahmed Samet

2 b

, Cecilia Zanni-Merk

1 c

, Franc¸ois de Bertrand de Beuvron

2 d

and Christoph Reich

3 e

1

Normandie Universit

´

e/INSA Rouen, LITIS, 76000 Saint-

´

Etienne-du-Rouvray, France

2

ICUBE/SDC Team (UMR CNRS 7357)-Pole API BP 10413, 67412 Illkirch, France

3

Hochschule Furtwangen, 78120 Furtwangen, Germany

Keywords:

Industry 4.0, Predictive Maintenance, Ontologies, SWRL Rules, Evidential Clustering.

Abstract:

In smart factories, machinery faults and failures are detrimental to the efficiency and reliability of production

systems. To ensure the smooth operation of production systems, predictive maintenance techniques have

been widely used in a variety of contexts. In this paper, we tackle the machinery failure prediction task by

introducing a novel hybrid ontology-based approach. The proposed approach is based on the combined use

of evidential theory tools and semantic technologies. Among evidential theory tools, the Evidential C-means

(ECM) algorithm is used to assess the criticality of failures according to two main parameters (time constraints

and maintenance cost). In addition, domain ontologies with their rule-based extensions are used to formalize

the domain knowledge and predict the time and criticality of future failures. Case studies on synthetic data

sets and a real-world data set are used to validate the proposed approach.

1 INTRODUCTION

Within manufacturing processes, anomalies such as

machinery faults and failures may lead to the break

down of production lines. To avoid the outage situ-

ation and economic loss may be caused by machin-

ery faults and failures, predictive maintenance is a

vital methodology that has been widely used in dif-

ferent manufacturing processes. By collecting real-

time data from sensors and other information sources,

a predictive maintenance task tries to detect possi-

ble anomalies and hazards within different industrial

components.

To predict potential machinery failures, heteroge-

neous data are collected from multidimensional data

sources, including the machine historical data and

context data. For the analysis and management of

these data, data mining and machine learning tech-

niques are widely used for automatically discovering

knowledge from data sets. In the predictive main-

a

https://orcid.org/0000-0002-5858-0680

b

https://orcid.org/0000-0002-1612-3465

c

https://orcid.org/0000-0002-5189-9154

d

https://orcid.org/0000-0003-1324-2853

e

https://orcid.org/0000-0001-9831-2181

tenance domain, the prediction and assessment of

failure criticality is a critical issue for system users.

By obtaining criticality levels for different failures,

machine operators can prioritize maintenance actions

for higher criticality-level failures compared to lower

level ones. However, existing predictive maintenance

approaches in the manufacturing domain are limited

to the deployment of condition monitoring systems

for detecting anomalies and predicting the time of fu-

ture machinery failures, while lacking the solutions

for identifying the criticality of machinery failures

(Ansari et al., 2019). This brings obstacles to oper-

ators to perform appropriate maintenance actions by

considering different priorities. As the degradation

process of a piece of machinery often involves in-

herent randomness, techniques that can handle uncer-

tainty are required to avoid the outage situation of the

machinery and to ensure the smooth operation of the

production system.

In this paper, we propose a hybrid ontology-based

approach for the failure prediction tasks in Industry

4.0, which is based on the combined use of evidential

clustering and ontology reasoning. Since the predic-

tion of failure criticality suffers from the uncertainty

and imprecise knowledge, the ECM algorithm is used

to handle such kind of uncertainty and imprecision.

618

Cao, Q., Samet, A., Zanni-Merk, C., de Beuvron, F. and Reich, C.

Combining Evidential Clustering and Ontology Reasoning for Failure Prediction in Predictive Maintenance.

DOI: 10.5220/0008969506180625

In Proceedings of the 12th International Conference on Agents and Artificial Intelligence (ICAART 2020) - Volume 2, pages 618-625

ISBN: 978-989-758-395-7; ISSN: 2184-433X

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

On the other hand, domain ontologies with their rule-

based extensions are used to formalize the classifica-

tion results and predict the temporal constraints and

criticality of future failures.

The remainder of the paper is structured as fol-

lows. Section 2 introduces the existing solutions and

software that address the similar issues in predictive

maintenance. Section 3 gives the foundations and

background knowledge, including the introduction to

the evidence theory and ECM. Section 4 introduces

the proposed hybrid semantic approach for industry

4.0 predictive maintenance, where a domain ontology

and ontology reasoning process are presented. Sec-

tion 5 shows the experimental results we obtained on

several synthetic data sets and a real-world data set.

Section 6 concludes the paper.

2 STATE OF THE ART

In recent years, several efforts have been proposed to

facilitate the predictive maintenance in Industry 4.0.

As the manufacturing domain is becoming more dy-

namic and knowledge-intensive, several domain on-

tologies and their rule-based extensions were pro-

posed to facilitate knowledge representation and reuse

for the predictive maintenance in the industry. In this

section, we review the most relevant research works.

In (Zhou et al., 2015), an intelligent fault diag-

nosis method was proposed based on ontologies and

the Failure Mode, Effects and Criticality Analysis

(FMECA). The method was proposed to meet the de-

mands of fault diagnosis of wind turbines. In their

work, deep knowledge and the shallow knowledge

were extracted from FMECA and then modeled in the

form of ontologies. To perform failure diagnosis, the

knowledge is translated into the facts and rules for

ontology reasoning. The knowledge model for fleet

predictive maintenance, introduced in (Monnin et al.,

2011), was developed to handle contextual knowledge

within a fleet scale. In their work, semantic model-

ing techniques were used to define the context knowl-

edge and the structure of a fleet. The fleet knowledge

model has proved its practicability in the context of a

marine application.

In the manufacturing domain, there are also re-

search works considering the predictive maintenance

of production lines. In (Emmanouilidis et al., 2010),

a domain-specific ontology was developed to define

the main elements of a generic condition monitoring

system from an abstract level. The aim of the ontol-

ogy is to facilitate asset self-awareness and to support

production-level sustainable machinery operation. As

another knowledge-based approach, the prescriptive

maintenance model (PriMa) was designed for the pre-

scriptive maintenance of production systems in smart

factories (Ansari et al., 2019). Within the framework

of PriMa, ontologies and case-based reasoning are

used to build semantic learning and reasoning mod-

els. Results showed that the PriMa model enhances

two functional capabilities of production systems: the

efficient processing of heterogeneous big data, and the

effective generation of decision support measures and

recommendations for improving maintenance plans

(Ansari et al., 2019).

After examining the existing research works, we

observed that there is a missing link between the tem-

poral information of an anomaly (e.g., the occurrence

time of a future machinery failure) and the critical-

ity level of the anomaly. Also, the impact of the es-

timated economic cost of maintenance on the crit-

icality of the anomaly also remains uninvestigated.

To address these issues, we propose a novel hybrid

ontology-based approach for failure criticality predic-

tion. The prediction of failures relies on two critical-

ity descriptors: the temporal constraints of failures,

and the estimated maintenance cost for avoiding the

failures.

3 FOUNDATIONS AND

BACKGROUND KNOWLEDGE

This section introduces the foundations and theoreti-

cal background that are necessary for describing our

approach. It includes the background knowledge of

evidence theory and the ECM algorithm.

3.1 The Evidence Theory

The evidence theory (Dempster, 1967; Smets and

Kennes, 1994) is based on several fundamentals such

as the Basic Belief Assignment (BBA). A BBA m is

the mapping from elements of the power set 2

Θ

on to

[0, 1]:

m : 2

Θ

−→ [0,1],

where Θ is the frame of discernment. It is the set of

possible answers for a treated problem and is com-

posed of K exhaustive and exclusive hypotheses Θ =

{ω

1

,ω

2

,...,ω

K

}. A BBA m is written as follows:

∑

A⊆Θ

m(A) = 1

m(

/

0) ≥ 0.

(1)

Assuming that a source of information has a reliabil-

ity rate equal to (1 − α) where (0 ≤ α ≤ 1), such a

meta-knowledge can be taken into account using the

Combining Evidential Clustering and Ontology Reasoning for Failure Prediction in Predictive Maintenance

619

discounting operation introduced by(Shafer, 1976),

and is defined by:

(

m

α

(A) = (1 − α) × m(A) ∀A ⊂ Θ

m

α

(Θ) = (1 − α) × m(Θ) + α.

(2)

A discount rate α equal to 1 means that the source is

not reliable and the piece of information that is pro-

vided cannot be taken into account. On the contrary,

a null discount rate indicates that the source is fully

reliable and the piece of information that is provided

is entirely acceptable.

Within the evidence theory, several combination

rules have been introduced among which we find the

Dempster rule of combination (Dempster, 1967). As-

suming two BBAs m

1

and m

2

modelling two inde-

pendent reliable sources of information S

1

and S

2

, the

Dempster rule of combination is defined as follows:

m = m

1

⊕ m

2

, (3)

so that :

m(A) =

1

1 − m(

/

0)

∑

B∩C=A

m

1

(B) × m

2

(C) =

1

1 − m(

/

0)

m

∩

(A),

∀A ⊆ Θ,A 6=

/

0, (4)

where m(

/

0) is defined by:

m(

/

0) =

∑

B∩C=

/

0

m

1

(B) × m

2

(C) = m

∩

(

/

0). (5)

m(

/

0) represents the conflict mass between m

1

and m

2

.

The pignistic probability, denoted BetP, is pro-

posed by Smets et al. (Smets, 2005) within the Trans-

ferable Belief Model (TBM). In the decision phase,

the pignistic transformation consists in distributing

equiprobably the mass of a proposition A on its in-

cluded hypotheses. Formally, the pignistic probability

is defined by:

BetP(ω

n

) =

∑

A⊆Θ

|

ω

n

∩ A

|

|

A

|

× m(A) ∀ω

n

∈ Θ. (6)

where || is the cardinality operator.

3.2 Evidential c-means (ECM)

In the following, we present the ECM clustering ap-

proach (Masson and Denœux, 2008). The ECM al-

gorithm is based on the concept of credal partition,

which extends those of fuzzy and possibilistic ones.

To derive such a structure, we minimize the proposed

objective function:

J

ECM

(M,V ) ,

d

∑

i=1

∑

{ j/A

j

6=

/

0,A

j

⊆Θ}

c

α

j

m

β

i j

dist

2

i j

+

n

∑

i=1

δ

2

m

β

i

/

0

,

(7)

subject to:

∑

{ j/A

j

6=

/

0,A

j

⊆Θ}

m

i j

+ m

i

/

0

= 1 ∀i = 1,. ..,d, (8)

where m

i

/

0

and m

i j

respectively denote m

i

(

/

0) and

m

i

(A

j

). M is the credal partition M = (m

1

,. .. ,m

d

)

and V is a cluster centers matrix. c

α

j

is a weight-

ing coefficient and dist

i j

is the Euclidean distance. In

our case, we use the default values prescribed by the

authors in (Masson and Denœux, 2008), i.e. α = 1,

β = 2 and δ = 10.

3.3 Ontologies and SWRL Rules

In computer science, an ontology is a specification

of a representational vocabulary for a shared domain

(Gruber, 2009). Normally, it is designed to support

the sharing and reuse of domain knowledge among

different AI system components and also among sys-

tem users. An ontology consists of classes, individu-

als, relationships, functions, and other objects (Gru-

ber, 2009), which allows ontology reasoning to be

performed on individuals, for inferring new knowl-

edge.

Semantic Web Rule Language (SWRL) is based

on a combination of its sublanguages OWL DL and

OWL Lite with the RuleMarkup Language (Horrocks

et al., 2006). A SWRL rule is in the form of an impli-

cation between an antecedent (body) and consequent

(head), which can be interpreted in a way that when-

ever the conditions specified in the antecedent hold,

then the conditions specified in the consequent must

also hold (Horrocks et al., 2006). In SWRL, a rule has

the syntax: Antecedent → Consequent, where both

the antecedent (body) and consequent (head) contains

zero or more atoms.

4 THE HYBRID EVIDENTIAL

ONTOLOGY-BASED

APPROACH FOR PREDICTIVE

MAINTENANCE

This section introduces our proposed hybrid method

for failure time and criticality prediction. Fig. 1

shows the different steps within the approach. The

approach starts with the Sequential Pattern Mining

(SPM) on machine historical data (Agrawal et al.,

1995). The aim of SPM is to extract frequent sequen-

tial patterns which contain failure events as well as

their temporal information (e.g., the time stamp indi-

cating when the failure happened). Then, the ECM al-

gorithm is applied to cluster the failures according to

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

620

Figure 1: Different steps within the hybrid ontology-based approach for predictive maintenance.

their criticality, based on failure temporal constraints

and estimated maintenance cost. After the cluster-

ing, we label different clusters with criticality Low,

Medium, and High. With obtaining the results from

ECM, ontologies with its SWRL rule-based exten-

sions are used to predictive the criticality of a future

failure.

4.1 The Evidential Approach for

Failure Criticality Estimation

In our previous work (Cao et al., 2019), one ontology-

based condition monitoring method was proposed.

However, the method is based on crisp logic, and it

fails to classify the criticality of a failure into the cor-

rect category when there are uncertain situations. To

cope with this issue, an evidential approach which is

able to handle such type of uncertainty situations is

required. To do so, the times to failures described

in rules and the estimated maintenance cost are used

as training examples for ECM with 3 fixed clus-

ters/classes which represents three levels of critical-

ity: (i) high criticality, which indicates the time from

a normal condition to the failure is relatively short

and the production line should be stopped for immedi-

ate maintenance, or the estimated maintenance cost is

relatively high; (ii) medium criticality, indicating the

failure may happen after a moderate amount of time,

or the estimated maintenance cost is moderate; (iii)

low criticality, indicating the failure may happen in

the long future and machine operators will have suf-

ficient time to plan maintenance actions, or the esti-

mated maintenance cost is relatively low.

In this paper, we intend to consider two factors

to evaluate the criticality of a failure. Assuming a

prediction rule in a form R : A −−→

[t

i

,t

j

]

Failure that pre-

dicts the failure with a time interval with an Estimated

Maintenance Cost EMC. The time to failure and the

cost of the failure are valuable descriptors to assess

the criticality of a failure. Each rule R has a value of

support that evaluates its pertinence. We aim to use

both predicted maintenance cost and predicted tem-

poral constraints of the failure within a rule to assess

the criticality of a predicted failure.

Let us assume a sequence S classified by a rule R

as a failure in [t

i

,t

j

] with an EMC. A BBA is com-

puted from both parameters on the frame of discern-

ment {Low,Meduim, High} for each level of critical-

ity. Both m

S,Cost

and m

S,time

are discounted using the

support

1

of the used rule R as follows:

m

1−Sup(R)

S

= m

1−Sup(R)

S,Cost

⊕ m

1−Sup(R)

S,time

. (9)

m

1−Sup(R)

S

is the BBA obtained from the aggrega-

tion of the cost and the time to failure BBAs using

the Dempster rule of combination. 1 − Sup(R) is seen

as the reliability value used to discount the obtained

BBAs. The final level of criticality is decided upon

the use of the arguments of the maxima as follows:

4.2 The Manufacturing Failure

Prediction Ontology

To address the uncertain situations, we extend the the

ontology introduced in (Cao et al., 2019), by describ-

ing the nominal categories of classes. As a result, we

developed the Manufacturing Failure Predictive On-

tology (MFPO), within which the classes are associ-

ated with pignistic probabilities which range from 0

to 1. For example, in the ontology introduced in (Cao

et al., 2019), hasFailureCriticality is an object prop-

erty whose domain is the class Failure, and range is

the predefined individuals Low, Medium and High.

After applying the aforementioned method, this ob-

ject property is replaced by three data properties: has-

FailureCriticalityLow, hasFailureCriticalityMedium,

1

The Support is measure that evaluate the pertinence of

a rule based on its matching frequency within a database

and denoted Sup().

Combining Evidential Clustering and Ontology Reasoning for Failure Prediction in Predictive Maintenance

621

and hasFailureCriticalityHigh, and the sum of the nu-

meric values of these three data properties is 1.

H

n

= argmin

ω

n

∈Θ

BetP(ω

n

). (10)

Algorithm 1: Algorithm to transform a chronicle into a pre-

dictive SWRL rule, based on evidential c-means.

Require: S

F

: a chronicle within which the last state

(event) is a failure, E : a set of the states that are

described within a chronicle.

Ensure: R R: the SWRL rule to be constructed.

1: ls ← LastNon f ailureState(S

F

,E ) Extract

the last non-failure state before the failure within

a chronicle.

2: f ← theFailure(E) Extract the failure within a

chronicle.

3: R ←

/

0, A ←

/

0, C ←

/

0, Atom

a

←

/

0, Atom

c

←

/

0,

F

FailureCriticalityLow

= 0, F

FailureCriticalityMedium

= 0,

F

FailureCriticalityHigh

= 0.

4: for each e

i

∈ E do

5: pe ← ProceedingState(e

i

,S

F

) Extract the

proceeding state

6: se ← SubsequentState(e

i

,S

F

) Extract the

subsequent state

7: Atom

a

← pe ∧ se

8: A ← Atom

a

∧ pe ∧ se

9: end for

10: f td ← FailureTimeDuration(ls, f ) Extract the

time duration between the last non-failure state

and the failure.

11: mc ← MaintenanceCost(S

F

) Obtain the esti-

mated maintenance cost for the failure described

in this the chronicle.

12: F

FailureCriticalityLow

←

PignisticProbabilityLow( f td, mc)

13: F

FailureCriticalityMedium

←

PignisticProbabilityMedium( f td,mc)

14: F

FailureCriticalityHigh

←

PignisticProbabilityHigh( f td, mc)

15: C ← F

FailureCriticalityLow

∧ F

FailureCriticalityMedium

∧

F

FailureCriticalityHigh

∧ f td

16: R ← {A → C}

4.3 Ontology Reasoning for Failure

Time and Criticality Prediction

To predict time and criticality of future failures, we

propose SWRL rules (Horrocks et al., 2006) for on-

tology reasoning. The proposed SWRL rules reason

on the individuals in the MFPO ontology, and infer

new knowledge about failure prediction.

In this paper, we use the frequent chronicle min-

ing algorithm introduced in (Sellami et al., 2019) to

obtain chronicles, which are a special type of se-

quential patterns in a rule format. After that, SWRL

rules are proposed to formalize the mining results

and to predict failures. To enable the generation of

SWRL rules, in this work we propose a novel algo-

rithm to transform chronicles into SWRL predictive

rules. The pseudo-code of the rule transformation al-

gorithm is shown in Algorithm 1. It runs in four major

steps: i). The function LastNonfailureState extracts

the last non-failure state (event) within a chronicle,

and the function LastNonfailureState extracts the fail-

ure event within a chronicle; ii). For each time inter-

val in a chronicle, the two functions ProceedingEvent

and SubsequentEvent extract the proceeding and sub-

sequent events of it. Then the two events and this time

interval forms different atoms in the antecedent of the

rule, and they are treated as conjunctions; iii). The

ECM algorithm is applied to classify the failures ac-

cording to their criticality. The failures are classified

into three categories, and three object properties in

MFPO are used to represent the pignistic probability

to different clusters. The pignistic probabilities are

treated as a conjunction, to form the consequent of

the rule; iv). At last, a rule is constructed as an impli-

cation between the antecedent and the consequent.

5 EXPERIMENTAL RESULTS

We validate our approach on several synthetic data

sets and a real-world data set

2

. The experimentation

starts with the preprocessing of data, followed by the

chronicle mining step. The frequent chronicle mining

algorithm introduced in (Sellami et al., 2019) is used

to extract frequent chronicles.

5.1 Experimentation on Synthetic Data

Sets

The experimentation on synthetic data sets begin with

the frequent chronicle mining on synthetic data. To

do this, the synthetic data was transformed into the

form of pairs (event, time stamp), where each data

sequence finishes with a failure. With obtaining se-

quences that contain failures, the frequent chronicle

mining algorithm was used to extract the temporal

constraints among these sequential patterns. As re-

sults, frequent chronicles were obtained. Inside a

2

The source codes and data sets used in this paper

could be found at: https://github.com/caoppg/ICAART-

2020-paper-125.git

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

622

chronicle, events are ordered and temporal orders of

events are quantified with numerical bounds (Sellami

et al., 2019).

5.1.1 Classification of Failure Criticality using

ECM

After obtaining the chronicles, we then generate syn-

thetic data for the estimated maintenance cost. To do

this, the maintenance cost is generated as uniformly

distributed random numbers between [0,100]. In the

generated data, each value of maintenance cost is as-

sociated with a failure, indicating the estimated main-

tenance cost caused by the failure. In addition to the

temporal constraints of failures, maintenance cost is

considered as the second descriptor for the failure crit-

icality. The third step is to apply ECM on the syn-

thetic data set, for determining the criticality of fail-

ures based on their temporal constraints and estimated

maintenance cost. Following the evidential cluster-

ing approach introduced in Section 4.1, we obtained

the final level of criticality of the failures described

in chronicles. At last, the extracted frequent chroni-

cles are transformed into SWRL predictive rules (us-

ing Algorithm 1), and the ECM classification results

are also formalized by these rules. The following sub-

sections introduce the different steps in our experi-

mentation in details.

Table 1 shows the 10 failure chronicles (FC)

which have the highest chronicle support (CS) among

all extracted ones. In this figure, the numeric values

of the minimum time duration (Min

T D

, time unit: sec-

ond) among the last normal events and the failures,

the EMC for each chronicle, and the pignistic proba-

bility of the final criticality (PPFC) are presented. For

the classification results, the final level of a failure’s

criticality is shown inside the brackets within the last

column of the table.

5.1.2 The Generation of SWRL Rules based on

Chronicles and ECM Results

To formalize the failure classification results and to

predict the criticality of future failures, we generated

SWRL rules based on the obtained chronicles and

ECM classification results. To do this, Algorithm 1

was used to transform the failure chronicles and ECM

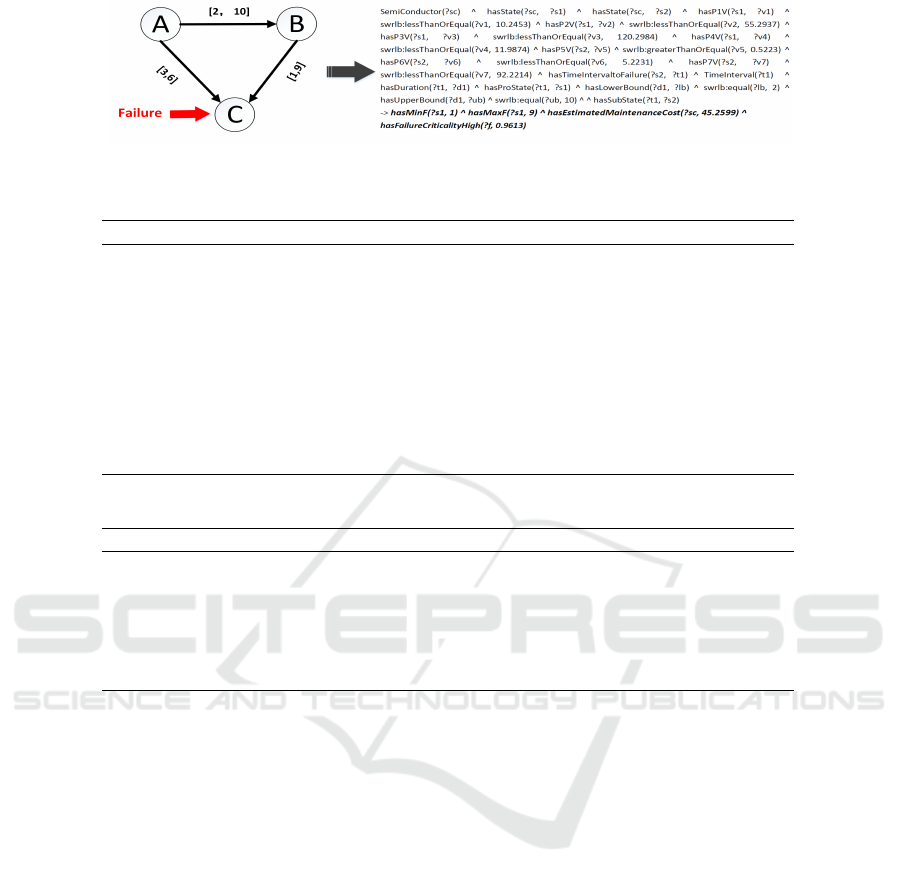

classification results into predictive SWRL rules. Fig.

2 presents an example SWRL rule that was generated

following our approach.

To evaluate the quality of the SWRL rules, two

measures are computed. The first measure is Accu-

racy. It is computed by Equation 11, where n

rc

is the

number of training examples that are covered by a rule

R and belonging to the class C. n

r ¯c

is the number of

training examples that are covered by a rule R but not

belonging to the class C. The second measure is Cov-

erage, which is computed by Equation 12. Within it,

n

¯rc

the number of training examples that are not cov-

ered by a rule R but belonging to the class C.

Accuracy(R) =

n

rc

n

rc

+ n

r ¯c

. (11)

Coverage(R) =

n

rc

n

rc

+ n

¯rc

. (12)

We use the above two equations to obtain the aver-

age value of Accuracy and Coverage for the SWRL

rules. Table 2 presents the two measures under differ-

ent chronicle support. We can observe from the table

that as the chronicle support increases, the accuracy of

rules also increases. It is reasonable since as the min-

imum threshold of extracted chronicles increases, we

obtain more relevant chronicles. On the other hand,

as the number of extracted rules decreases, the se-

quences that are covered by the rules decreases. This

is the reason why the average value of coverage shows

a downtrend.

5.2 Experimentation on a Real-world

Data Set

To evaluate the performance of the prediction and fail-

ure classification, we apply ECM on a real-world data

set. The real-world data set is called SECOM (Dua

and Graff, 2017), which contains measurements of

features of semi-conductor productions within a semi-

conductor manufacturing process.

We first compute the hard credal partition on the

SECOM data set. In total, at most 2

Θ

focal sets could

be obtained through credal partition, where Θ is the

frame of discernment. In our experimentation, Θ rep-

resents the three levels of failure criticality. For the

SECOM data set, we only use temporal constraints

of failures as the descriptor for criticality. The data

points on the empty set which have the highest masses

are removed as outliers before they are assigned to the

clusters.

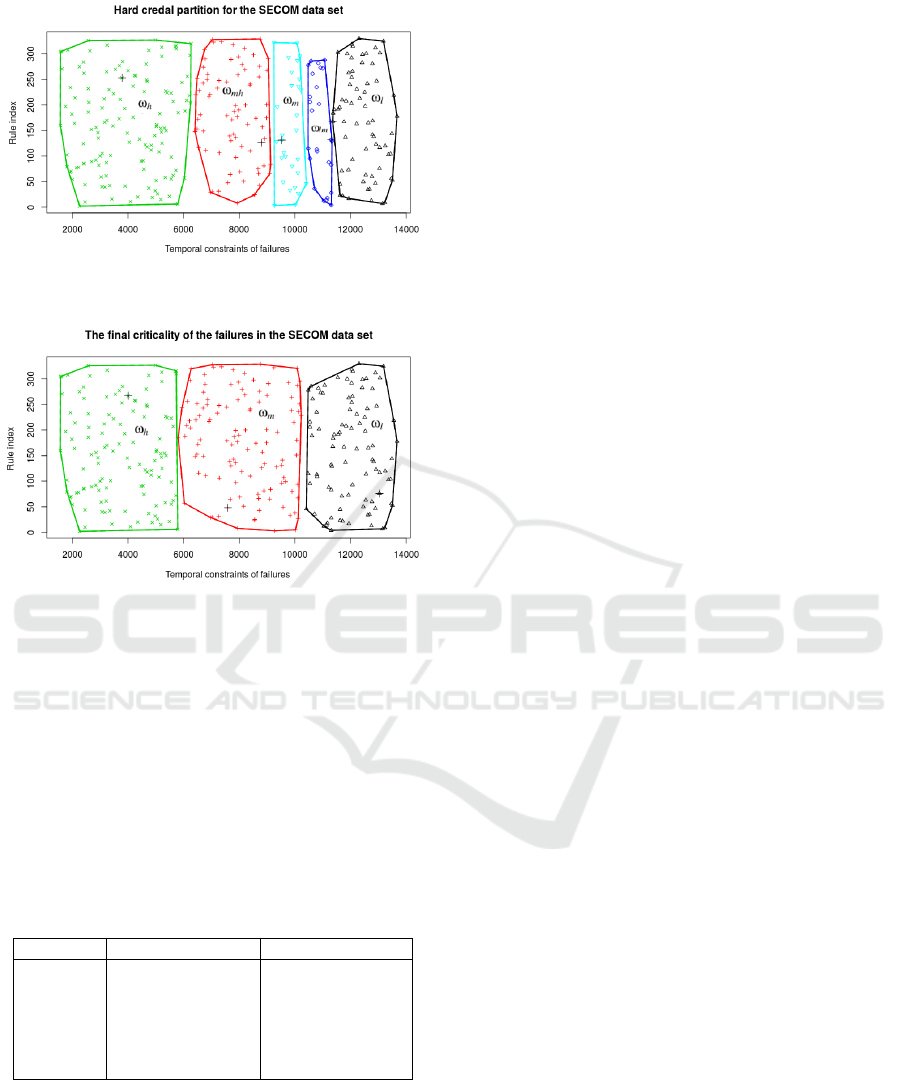

Fig. 3 shows the hard credal partition computed

on the SECOM data set with the following parame-

ters: α = 1,β = 2, δ = 10, and ε = 10

−3

. As results,

6 focal elements are obtained, including the universal

set Θ

ω

= {ω

l

,ω

lm

,ω

m

,ω

mh

,ω

h

}. Each subset of Θ

ω

is represented by the convex hull. Among them, ω

l

is the focal set representing the low criticality class,

ω

m

is the focal set representing the medium critical-

ity class, and ω

h

is the focal set representing the high

criticality class. ω

lm

is the hesitation between the ω

l

and ω

m

classes, which is {ω

l

,ω

m

}. ω

mh

is the hesi-

tation between the ω

m

and ω

h

classes, which means

Combining Evidential Clustering and Ontology Reasoning for Failure Prediction in Predictive Maintenance

623

Figure 2: An example SWRL rule generated from a chronicle.

Table 1: Failure chronicles that have the 10 highest chronicle support, and their failure classification results.

C

F

Min

T D

EMC CS PPFC

C

F1

10 33.4163 96.19% 0.6652 (Medium)

C

F2

7 50.0472 95.61% 0.5049 (Medium)

C

F3

3 14.9865 94.48% 0.6140 (High)

C

F4

4 17.3388 94.21% 0.8739 (Medium)

C

F5

21 81.8148 92.94% 0.3921 (Low)

C

F6

3 65.9605 91.06% 0.8796 (High)

C

F7

11 68.1971 90.27% 0.4722 (Medium)

C

F8

24 9.6730 90.01% 0.6871 (Low)

C

F9

10 64.8991 86.93% 0.4266 (Medium)

C

F10

18 66.6338 86.87% 0.4030 (Low)

Table 2: Two rule quality measures under different chronicle support.

Chronicle support Accuracy Coverage

0.5 76.52% 74.26%

0.6 74.14 % 75.71%

0.7 76.98 % 74.35%

0.8 79.33% 70.49%

0.9 82.56% 68.10%

1 84.45% 67.71%

{ω

m

,ω

h

}. The center of each class is marked as a

cross.

It can be observed that the ω

h

class has the highest

number of training examples, and over half of the fail-

ures are classified into the ω

h

and ω

mh

classes. As the

value of a temporal constraint increases, the critical-

ity level of the failure decreases. We can see that the

evidential-based clustering extends the fuzzy and pos-

sibilistic methods by not only assigning data points to

single clusters but also to all subsets of the universal

set Θ

ω

. In this way, ECM provides more insights into

failures than the classical clustering methods.

To obtain the final level of criticality, the pignos-

tic probability BetP and the maxima of BetP are com-

puted. After comparing the BetP of the three classes,

the class with the maximum BetP is selected to rep-

resent the final level of criticality. Fig. 4 shows

the final criticality for the training examples in the

SECOM data set. ω

l

, ω

m

, ω

h

represents the low crit-

icality class, medium criticality class, and high criti-

cality class respectively. It can be seen that there is

no hesitation among different classes, which ensures

the final criticality to be determined based on a maxi-

mum of BetP of the three classes. An example of the

ECM clustering results on the training data is shown

in Table 3. We select rule #45 and show the obtained

BBAs and the pignistic probability of the final criti-

cality (PPFC) of the failure which is described within

this rule. Since the high criticality class is assigned

with the highest PPFC, the final decision on the criti-

cality level of this failure is high.

6 CONCLUSIONS

In this paper, the issue of failure prediction is tack-

led by introducing a hybrid ontology-based approach.

The proposed approach is based on the combined use

of evidential clustering and ontology reasoning tech-

niques, where temporal constraints of failures and the

estimated maintenance cost are used as training ex-

amples to evidential clustering, and domain ontolo-

gies with their rule-based extensions are used to for-

malize the classification results and predict the future

failures.

For future work, we will work on experience capi-

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

624

Figure 3: Hard credal partition for the SECOM data set.

Figure 4: Final criticality levels of failures in the SECOM

data set.

talization, which will support the failure classification

process in case of failure. To achieve this goal, expert

rules will be proposed and launched when the initial

rule base fails to predict the machine anomalies cor-

rectly. In this way, when the next time a similar situa-

tion needs to be addressed, the rule which capitalizes

domain experts’ experience will also be launched to

predict potential failures.

Table 3: Experimental results of a training example in the

SECOM data set.

Rule index BBAs of the failure PPFC

#45 m({ω

h

}) = 0.3174

m({ω

mh

}) = 0.2219

m({ω

m

}) = 0.2929

m({ω

lm

}) = 0.0181

m({ω

l

}) = 0.0485

m({Θ

ω

}) = 0.1012

BetP(ω

h

) = 0.4683

BetP(ω

m

) = 0.4391

BetP(ω

l

) = 0.0926

ACKNOWLEDGEMENTS

This work has received funding from INTER-

REG Upper Rhine (European Regional Development

Fund) and the Ministries for Research of Baden-

W

¨

urttemberg, Rheinland-Pfalz (Germany) and from

the Grand Est French Region in the framework of the

Science Offensive Upper Rhine HALFBACK project.

REFERENCES

Agrawal, R., Srikant, R., et al. (1995). Mining sequential

patterns. In icde, volume 95, pages 3–14.

Ansari, F., Glawar, R., and Nemeth, T. (2019). Prima: a pre-

scriptive maintenance model for cyber-physical pro-

duction systems. International Journal of Computer

Integrated Manufacturing, pages 1–22.

Cao, Q., Giustozzi, F., Zanni-Merk, C., de Bertrand de Beu-

vron, F., and Reich, C. (2019). Smart condition mon-

itoring for industry 4.0 manufacturing processes: An

ontology-based approach. Cybernetics and Systems,

pages 1–15.

Dempster, A. (1967). Upper and lower probabilities in-

duced by multivalued mapping. AMS-38.

Dua, D. and Graff, C. (2017). UCI machine learning repos-

itory.

Emmanouilidis, C., Fumagalli, L., Jantunen, E., Pistofidis,

P., Macchi, M., Garetti, M., et al. (2010). Condition

monitoring based on incremental learning and domain

ontology for condition-based maintenance. In 11th

International Conference on Advances in Production

Management Systems, APMS.

Gruber, T. (2009). Ontology. Springer.

Horrocks, I., Patel-Schneider, P. F., Boley, H., Tabet, S.,

Grosof, B., Dean, M., et al. (2006). Swrl: a semantic

web rule language combining owl and ruleml, 2004.

W3C Submission.

Masson, M.-H. and Denœux, T. (2008). ECM: An eviden-

tial version of the fuzzy c-means algorithm. Pattern

Recognition, 41(4):1384–1397.

Monnin, M., Abichou, B., Voisin, A., and Mozzati, C.

(2011). Fleet historical cases for predictive mainte-

nance. In The International Conference Surveillance,

volume 6, pages 25–26.

Sellami, C., Miranda, C., Samet, A., Tobji, M. A. B., and

de Beuvron, F. (2019). On mining frequent chronicles

for machine failure prediction. Journal of Intelligent

Manufacturing, pages 1–17.

Shafer, G. (1976). A Mathematical Theory of Evidence.

Princeton University Press.

Smets, P. (2005). Decision making in the TBM : The ne-

cessity of the pignistic transformation. International

Journal of Approximate Reasoning, 38:133–147.

Smets, P. and Kennes, R. (1994). The Transferable Belief

Model. Artificial Intelligence, 66(2):191–234.

Zhou, A., Yu, D., and Zhang, W. (2015). A research on in-

telligent fault diagnosis of wind turbines based on on-

tology and fmeca. Advanced Engineering Informatics,

29(1):115–125.

Combining Evidential Clustering and Ontology Reasoning for Failure Prediction in Predictive Maintenance

625