Learning-based Material Classification in X-ray Security Images

Benedykciuk Emil

a

, Denkowski Marcin

b

and Dmitruk Krzysztof

c

Institute of Computer Science, Maria Curie-Sklodowska University, Lublin, Poland

Keywords:

X-ray Imaging, Material Classification, Machine Learning Algorithms.

Abstract:

Although a large number of papers have been published on material classification in the X-ray images, rel-

atively few of them study X-ray security raw images as regards of material classification. This paper takes

into consideration the task of materials classification into four main types of organics and metals in images ob-

tained from Dual-Energy X-ray (DEXA) security scanner. We adopt well-known methods of machine learning

and conduct experiments to examine the effects of various combinations of data and algorithms for generaliza-

tion of the material classification problem. The methods giving the best results (Random Forests and Support

Vector Machine) were used to predict the materials at every pixel in the testing image. The results motivate

a novel segmentation scheme based on the multi-scale patch classification. This paper also introduces a new,

open dataset of X-ray images (MDD) of various materials. The database contains over one million samples,

labelled and stored in its raw, original 16-bit depth form.

1 INTRODUCTION

Automatic baggage inspection systems using com-

puter vision techniques have not been common for

general threat detection in X-ray images yet. A sig-

nificant obstruction is a difficulty of collecting large

datasets of different materials with pixel-leveland ob-

ject labelling. To automate the X-ray scanners inspec-

tion a couple of problems such as material discrimina-

tion, image segmentation, object detection and finally

threats identification should be resolved. Most of the

security scanners use the dual-energy X-ray absorp-

tion techniques (DEXA). These devices apply radia-

tion generated in two ranges classified as high energy

(HE) and low energy (LE) X-rays. These two energies

give two different absorption readings for the scanned

objects that create one two-channel image with 16 bits

per pixel. This makes the data unique if they are com-

pared to the classic RGB images. Hence, this requires

developinga different approach and considering some

of the features of information obtained from the X-ray

images.

A major contributionof our paper is to propose the

best of the most-common machine learning methods

to solve the problem of classification of the materials

in the X-ray scans. We perform some experiments to

a

https://orcid.org/0000-0002-1542-6747

b

https://orcid.org/0000-0002-2491-091X

c

https://orcid.org/0000-0003-1464-5822

examine the effects of various combinations of data

obtained from the DEXA scanners for generalization

of the material classification problem. For this pur-

pose different machine learning algorithms and train-

ing data sizes on the subregions (patches) of the full

scene image are investigated. Further, we build clas-

sification results on on our patch and demonstrate si-

multaneous material recognition as well as initial seg-

mentation of a full resolution DEXA scan by the naive

sliding window approach. In addition, we have built

a large dataset, called the Materials in DEXA Scans

Database (MDD) with about 1 million samples. The

dataset has samples in five material classes. The entire

dataset is discussed in more detail in section 3. MDD

gives us the opportunity to train the above-mentioned

machine learning algorithms and validate its effec-

tiveness and accuracy.

In summary, we make two main contributions:

• conclusions regarding the data representation and

selection of the machine learning methods, giving

the best results for the problem of material classi-

fication in the X-ray images for simultaneous ma-

terial recognition and initial segmentation;

• introduction of a new material dataset MDD for

the DEXA images with a simple crowdsourcing

pipeline for efficient acquisition of other millions

of labelled patches.

284

Emil, B., Marcin, D. and Krzysztof, D.

Learning-based Material Classification in X-ray Security Images.

DOI: 10.5220/0008951702840291

In Proceedings of the 15th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2020) - Volume 4: VISAPP, pages

284-291

ISBN: 978-989-758-402-2; ISSN: 2184-4321

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 PRIOR WORK

2.1 X-ray Images Databases

The increase in the popularity of data-based methods

has led to the creation of many datasets, including

those with X-ray images. X-Ray scanners provide

images based on a different level of radiation absorp-

tion for different materials. As a service to the X-

ray testing and computer vision communities, Mery

et al. (Mery et al., 2015) collected more than 19400

X-ray images for the development, testing and eval-

uation of image analysis and computer vision algo-

rithms. Unfortunately, these images have been made

available in the form of classic grayscale 8-bit images,

thus preventing the use of DEXA methods for mate-

rial recognition. In the domain of luggage inspection,

many papers are focused on object detection. This

leads to creating some datasets like ALERT Datasets

(ALERT, 2019). ALERT has four active datasets of

CT scans available to the research community that

has developed out of transition tasks. One of the col-

lections contains approximately 900 objects fully seg-

mented from 62 luggage datasets to span the spectrum

of packing, density, arrangement, orientation, and size

difficulty. Another important dataset that should be

mentioned in the context of materials recognition is

MINC (Materials in the Context Database) (Bell et al.,

2014) but this is a collection of samples of materials

from the conventional images. There are also many

public medical X-ray image databases but such im-

ages contain very limited and specific materials com-

pared to the huge variety of materials and their com-

binations in security the X-ray images.

Unfortunately, there are no large X-ray images

datasets of different materials with pixel or patch level

labelling. Therefore, to fill this gap, we have created

our own dataset. Our X-ray scans dataset MDD will

allow us to verify different material recognition meth-

ods in the X-ray images which should help analyzing

and interpreting X-ray scans and detecting threats.

2.2 Material Classification in the X-ray

Images

X-Ray scanners provide images based on different

levels of absorption of radiation of different materials.

Such raw X-ray images are not always easy to ana-

lyze and interpret. Some image processing methods

like object detection, frequency resolution increase

or pseudocolouring are used (Dmitruk et al., 2015;

Dmitruk et al., 2018). There are four main colors used

widely in X-ray scanners to label material classes. In

the newer generation of X-ray scanners, six classes

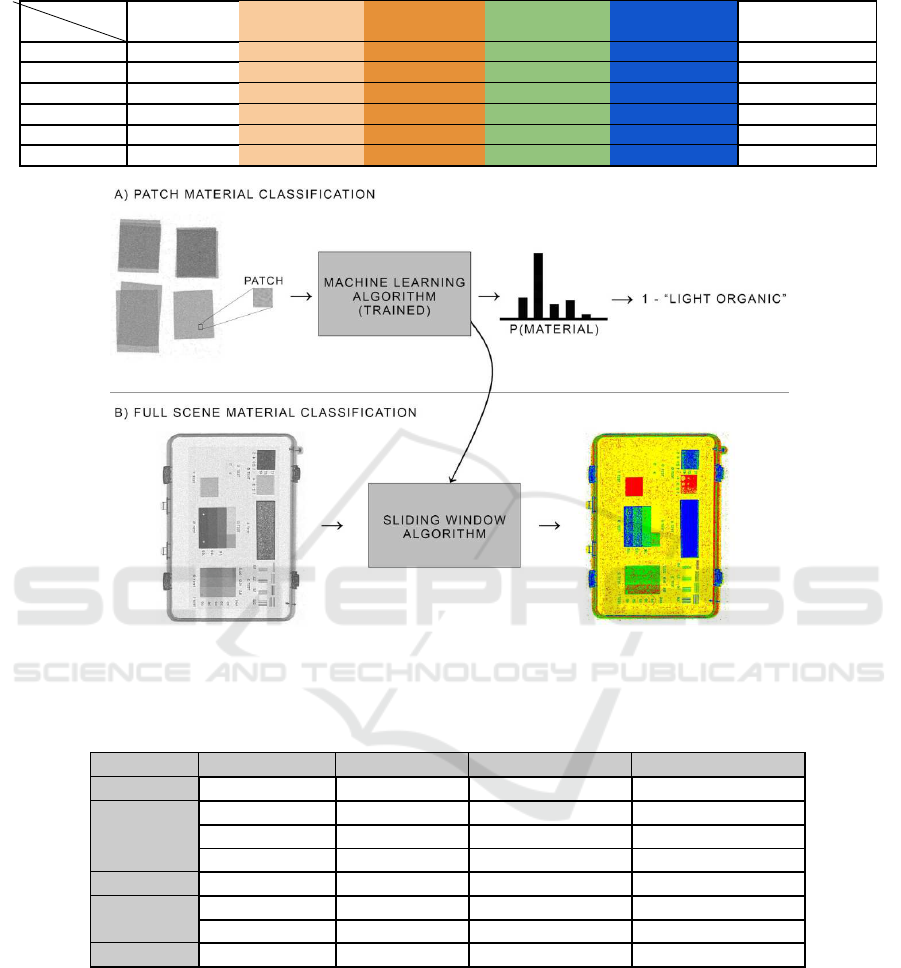

are often used to differentiate materials (see Figure 1).

Nevertheless, the best solution would be to provide a

specific type of material or an average value of the

atomic number from which the material is made. The

main problem in discriminating materials of a given

object from its single projection image is to determine

its thickness, density and composition itself. Two

very different materials (e.g. steel and water) can give

identical readings on the X-ray detectors if they have

different densities and/or thicknesses. For this rea-

son, multi-energy techniques are used that allow such

a distinction for a single material. Dual-energy X-ray

imaging is a such well-knowntechnique. These X-ray

scanners provide two images based on different levels

of radiation absorption of different materials. In or-

der to determine approximately the material class of

the object being studied, the coefficient k (equation 1)

is used (Watabiki et al., 2013; Rebuffel and Dinten,

2007):

k =

µ

mL

µ

mH

(1)

where: µ

mL

is the mass absorption coefficient for low

energy scans and µ

mH

is the mass absorption coef-

ficient for high energy scans. However, the classic

material discrimination methods used for the dual-

energy X-ray scans do not cope well with determin-

ing the type of material when there are many layers

of different types of material at a given point. As

discussed in (Alvarez and Macovski, 1976; Lehmann

et al., 1981; Chuang and Huang, 2000; Rebuffel and

Dinten, 2007), the unambiguous definition of a ma-

terial class for a composite of more than three sub-

stances is not obtainable in the case of a fixed X-ray

tube system.

Figure 1: Material pseudo-colours and its classes used

widely in the X-ray security scanners.

Dual-energy techniques allow simply to recognize

a type of material only for a homogeneous object,

regardless of its thickness. For an object composed

of various materials, the obtained information is the

averaged absorption value for all materials and their

Learning-based Material Classification in X-ray Security Images

285

thicknesses on the radiation line. But the biggest chal-

lenge is the case where the materials with a very dif-

ferent X-ray radiation absorption are assembled in a

given place of the scan. Such a case can indicate

a possible thread in the process of luggage control,

ie. when light objects (e.g. dry bulk goods like

drugs or tobacco products) are placed on the back-

ground or inside the objects made of heavy materi-

als (e.g. fire extinguisher). To overcome these dif-

ficulties, the community tries to use machine learn-

ing methods. In (Ko et al., 2011; Nedjar et al., 2015;

Mehta and Sebro, 2019) the authors applied a random

forest classifier or support vector machine (Elmasri

et al., 2016; M.S. Kavitha et al., 2012; Sivakumar and

Chandrasekar, 2013) to achieve fast and accurate clas-

sification task. Additionally, there are many works

where machine learning methods have been used for

material recognition in the conventional images (Ca-

puto et al., 2005; Bhattacharjee et al., 2015). This

allows to conclude that the methods also work for the

problem presented in this paper giving satisfactory re-

sults. On the other hand, using machine learning in

material discrimination in the X-ray scans is still in

its initial form as for now and this problem has not

thoroughly investigated by the computer vision com-

munity.

3 MATERIAL DEXA DATASET

(MDD)

3.1 X-ray Samples

In out studies we use an ARIDA X-ray scanner

(Arida, 2019), equipped with a Metrix SAX 1712A

(Metrix, 2019) X-ray lamp and a strip of eight DT

X-DAQ 0.8 DualEnergy detectors (DetectionTechnol-

ogy, 2019) giving 1024 pixels of data in a single line

of scan. All scans were made for the following X-ray

beam setting: 130kV × 0.86mA = 112W.

The scans of all samples are raw, two-channel im-

ages where the pixel value in each channel is rep-

resented by a 16-bit integer with the values from 0

to 65536. The materials were classified into three

main groups: organic materials, mixed materials, and

heavy metals. The collection of organic materials

for practical reasons has been divided into two sub-

groups: light organic materials and heavy organic ma-

terials. For the first group of materials we selected the

following liquids: water, ethanol, and slightly heavier

vegetable oil. We have completed the first group with

sugar, CD, and plexiglass from the set of solid and

light substances. In addition, a set of samples was

supplemented with two types of wood. The approxi-

mate atomic number Z for organic light materials does

not exceed 8 so the substances from this group have

absorption values similar to those of explosives, e.g.

C-4, TNT, Sentex. Paper and plasticine were selected

from heavy organic materials. They give readings

analogous to the specific type of dangers like pow-

dery drugs, i.e. heroin or cocaine. Their approximate

atomic number Z ranges from 8 to 10. Characteris-

tic examples of materials with the average mass ratio

values - non organic class, also called light metals,

are aluminum and salt. In this group, there is also a

kind of threats. The approximate atomic number of

these substances is from 10 to 17. This is similar to

that of gunpowder or heavy fuel. Whereas steel and

brass belong to the group of substances called heavy

metals, the approximate value of the atomic number

Z is greater than 17. This material class represents

those listed in section 2, metals and heavy metals.

The reason for this simplification is the lack of a suf-

ficient amount of substances with a very large atomic

number Z. In addition, the impact on creation of one

class of the two in our lamp settings will not affect

readings on the detectors too much. Similarly to the

previous classes of materials in this group there are

many threats. The most common items in this group

are the objects such as white weapons, firearms, car-

tridges, and high-value smuggling materials i.e. silver

and gold. For all materials samples of different thick-

nesses were prepared.

To avoid overfitting and the ’leakage’ of knowl-

edge about the test data an additional test data set was

created. It consists of selected common items and the

specialized test case scans. Thus, we have expanded

the MDD with an additional test set. Moreover, for

the correct training process, we split our training sam-

ples and created a validation data set which contains

20% of all samples. The validation set helps us avoid

overfitting and determines the accuracy of the classi-

fier during the learning process.

3.2 Patches

The type of annotations or labels to collect for train-

ing is guided to a large extent by the tasks we wish

to generate training data for. For some tasks such

as scene recognition, whole-image labels can suffice

(Xiao et al., 2014; Zhou et al., 2015). For object de-

tection, the labelled bounding boxes as in PASCAL

are often used (Everingham et al., 2010). For seg-

mentation or scene parsing tasks, the per-pixel seg-

mentations are required (Russell et al., 2008; Gould

et al., 2009). Each style of annotation comes with a

cost proportional to its complexity. For the materials

VISAPP 2020 - 15th International Conference on Computer Vision Theory and Applications

286

in the X-ray scans we decided to focus on one prob-

lem – patch material classification.

For training different types of classifiers, it is use-

ful to have data in the form of fixed-sized patches. We

use a patch center and a patch scale to define the im-

age subregion that makes a patch. Further in Section

5, we justify our choice with experiments that vary the

patch scale for the test suitcase scan. We generated

about 1 million patches from all materials scans. The

patches have the following sizes: 3x3, 5x5, 7x7, 9x9,

15x15. Table 1 shows the exact number of patches

that make up each class of materials for learning and

testing the dataset. It is worth mentioning that the

samples are very noisy which is characteristic of X-

ray images.

4 METHODS AND

METHODOLOGY

Our goal is to create a system that will identify materi-

als for each pixel of the scan. The result of the system

will be an initial segmented image. For full-resolution

segmentation of the image, the exact definition of the

edge and noise removal will be missing. However,

our initial segmentation is a solid input for the full

segmentation method that simplifies and/or changes

the representation of an image into something that is

more meaningful and easier to analyze.

Among the algorithms and parameter variations

we tested the best performing and the most common

machine learning algorithms:

1) (LDA) – Linear Discriminant Analysis,

2) (LR) – Logistic Regression,

3) (NB) – Naive Bayesian,

4) (SVM) – Support Vector Machine,

5) (CART) – Decision Tree,

6) (RF) – Random Forests,

7) (KNN) – k-Nearest Neighbours,

8) (MLP) – Simple Multilayer Perceptron,

that produce a single prediction for a given input

patch. Then the one that gives the most efficient pre-

dictions for all sizes of the input patches is chosen.

After analyzing the performance in each stage our

classifier is transformed into a sliding window and

materials on a grid across the image are predicted.

We do this with multiple scales of patches and then

their simple arithmetic mean is computed. The above

allows to predict the material class for every pixel of

the scan.

Figure 2 gives the overview of our method for si-

multaneously initial segmenting and recognizing the

material class. Given an estimator that can classify

individual points in the image, based on the pixel dif-

ferent size regions, we use it for the naive sliding win-

dow approach. This way of initial segmentation of a

full resolution DEXA scan allows to present transi-

tional steps of full scan material classification. The

probability of each of the material classes in a given

pixel of the scan can be presented. The input image

can be any size, depending on the size of the patch,

the corresponding number of pixels on the edges is

copied. It should be noted that increasing the patch

size reduces the resolution of the results. Therefore

for prediction of the pixel material class, we use the

results of a given classifier for different sizes of the

pixel region. Finally, depending on the probability of

each material class, we select the colour of class with

the greatest probability.

5 EXPERIMENTS AND RESULTS

5.1 Mean Classification Accuracy

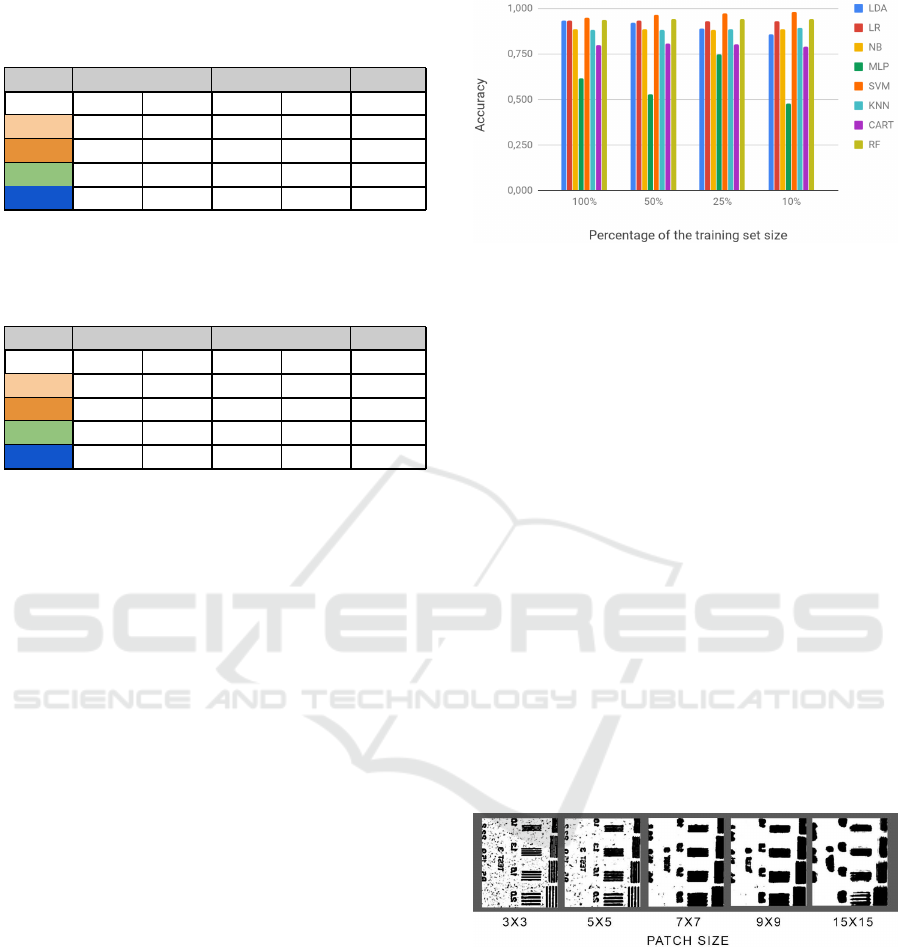

Table 2 presents the patch material classification re-

sults on our dataset during the learning process and

for the additional test scans. The input data images

for all algorithms are three-channel images with the

following composition: the first channel is high en-

ergy, the second channel is low energy and the last

channel is filled by zeros.

The algorithms that obtained the best results for

the validation set (i.e. accuracy above 90 percent) are

KNN, RF and SVM. We can try to choose an algo-

rithm based on the results for a test set but we have to

be careful because this may lead to matching the algo-

rithm to the test set. This situation is called overfitting

(see Section 4). The choice based only on the results

for the test set would suggest that the LDA and LR al-

gorithms are a good choice. However, a close look at

the results for the validation set shows that this is not

the case. This suggests that the algorithm does not

generalize the problem sufficiently. The algorithms

that obtain the most stable and best results are random

forest (RF) and support vector machine (SVM).

For a more detailed comparison of these two al-

gorithms in Tables 3 and 4 the accuracy of the al-

gorithms for each class and patch size is presented.

Comparing these two tables, we can conclude that

the SVM algorithm gets better results particularly for

larger patches where the decision is made for a larger

number of image features. Due to the fact that the dif-

ferences in accuracy of these two algorithms are not

too big and because the scanning of the luggagehas to

be carried out very quickly (see Section 1) the RF al-

gorithm is considered to ba a better solution because

RF is a much faster method in the learning process

Learning-based Material Classification in X-ray Security Images

287

Table 1: MDD training/testing data set - number of patches for all material classes.

Patch size

Material

Background Light organic Heavy organic Light metals Heavy metals Total

3× 3 82526/29538 210028/15940 152082/3186 109376/7406 89374/11216 643386/67286

5× 5 29436/10382 73966/5690 54176/1120 38716/2614 31432/3894 227726/23700

7× 7 14852/5352 37000/2860 27400/550 19390/1326 15826/1982 114468/12070

9× 9 8902/3198 21822/1664 16344/342 11574/778 9388/184 68030/7166

15× 15 3108/1112 7258/578 5776/110 3862/270 3170/368 23174/2438

Total 138824/49582 350074/26732 255778/5308 182918/12394 149190/18644 1076784/112660

Figure 2: Pipeline for full scan material classification. WHITE - background, YELLOW - light organic, RED - heavy organic,

GREEN - light metals, BLUE - heavy metals.

Table 2: Mean accuracy for all materials and patch sizes for different machine learning algorithms trained and tested on MDD.

The performance of all algorithms was verified using a computer equipped with AMD Ryzen 7 2700x.

Algorihtm Validation Set Test Set Learning time [s] Prediction time [s]

LDA 0.666 (0.027) 0.931 (0.044) 4.43 0.04

LR 0.743 (0.012) 0.931 (0.010) 30.77 0.04

NB 0.565 (0.005) 0.885 (0.005) 0.23 0.14

MLP 0.549 (0.230) 0.614 (0.347) 177.65 0.08

SVM 0.925 (0.030) 0.950 (0.049) 17776.42 182.82

KNN 0.965 (0.012) 0.882 (0.011) 2.50 27.65

CART 0.889 (0.018) 0.797 (0.027) 27.30 0.03

RF 0.965 (0.008) 0.935 (0.017) 177.72 0.88

as well as in the test process compared to SVM, as

shown in Table 2.

As we approve the RF as the best solution for

our problem, it is worth nothing that the efficiency

of the classifier is the smallest for the class of heavy

organic materials. This is probably due to the fact

that this class mixes with that of light metals very

much. Unfortunately, the random forest algorithm

separates these two groups of materials poorly. In ad-

dition, it can be deduced that the accuracy for these

classes changes along with the change in the size

of the patches. The effectiveness value for the light

metal class increases with the increasing patch area

because most of the patches from both groups are rec-

ognized as a heavier material. If time was not an im-

portant attribute of material prediction, the SVM al-

gorithm would be a much better solution of this prob-

lem. Also noteworthy is the signal to noise ratio for

all pixels in the patch which affects the prediction in

these both algorithms. For the RF algorithm, this is

VISAPP 2020 - 15th International Conference on Computer Vision Theory and Applications

288

Table 3: Random forest accuracy for each class and patch

size. Material classes: 0 – background, 1 – light organic, 2

– heavy organic, 3 – light metals, 4 – heavy metals.

Class 3x3 5x5 7x7 9x9 15x15

0 0.975 0.999 0.978 0.971 1.000

1 0.937 0.985 0.997 0.999 1.000

2 0.897 0.952 0.782 0.509 0.455

3 0.805 0.909 0.941 0.943 1.000

4 0.797 0.804 0.818 0.785 0.810

Table 4: Support vector machine accuracy for each class

and patch size. Material classes: 0 – background, 1 – light

organic, 2 – heavy organic, 3 – light metals, 4 – heavy met-

als.

Class 3x3 5x5 7x7 9x9 15x15

0 0.953 0.980 0.971 0.970 1.000

1 0.905 0.950 0.974 0.992 1.000

2 0.379 0.629 0.913 0.994 1.000

3 0.664 0.816 0.919 0.892 1.000

4 0.891 0.963 1.000 1.000 1.000

evident for heavy material classes. The heavier mate-

rials have more noisier samples which can be seen in

the accuracy results. On the other hand, the ratio of

noise to all pixels is larger for smaller patches which

is clearly evident in the effectiveness of the SVM that

achieves less accuracy for smaller patches. Our ob-

servations are consistent with what was discussed in

(Ogorodnikov et al., 2002). The authors note that the

discrimination error increases for lower mass thick-

ness because there is no sufficient contrast between

the low and high energy images, and for larger mass

thickness due to the decreasing signal-to-noise ratio.

5.2 Training Dataset Size

We have also verified the impact of the size of the

training database on the predicition accuracy. We

checked the dataset containing 100%, 50%, 25% and

10% of all MDD training samples (see Table 1). The

results of the mean accuracy of the algorithms for dif-

ferent amounts of training data are presented in Fig-

ure 3.

Evaluation of the classifiers results shows that a

decrease in accuracy can be noted for only LDA. Pre-

diction decreases as the training set decreases. The re-

verse situation is for SVM and RF because algorithms

are overfitted. A much larger accuracy difference be-

tween 100% and 10% of the training set can be seen

for SVM. This depends on the selected penalty pa-

rameter C and kernel parameters. Even though SVM

is an approximate implementation of a bound on the

generalization error, that depends on the margin, but

is independent of the dimensionality of the feature

Figure 3: Impact of the training set size on the predictions

accuracy for test set.

space. So in principle, SVMs should be highly resis-

tant to over-fitting but in practice this depends on the

careful choice of C and the kernel parameters (Caw-

ley and Talbot, 2007; Cawley and Talbot, 2010).

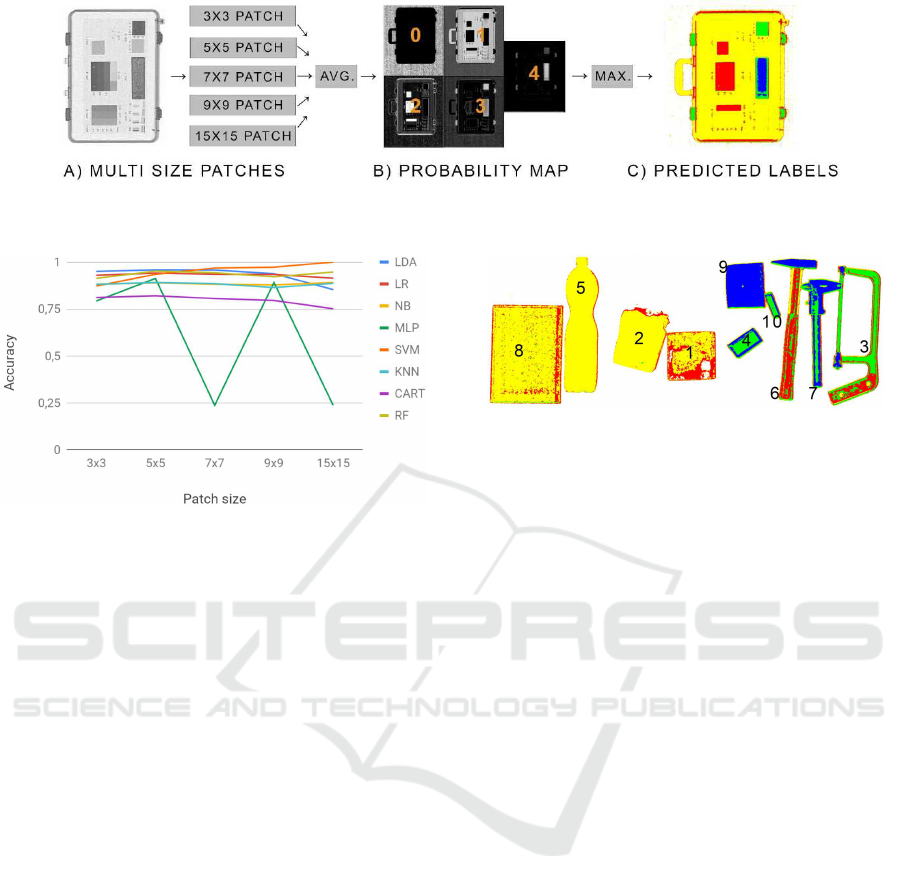

5.3 Patch Material Classification

To classify a point in an image we must decide how

large context to include around it. The context, ex-

pressed as an area of the pixel, is the patch size.

A priori, it is not clear which scale is best since

small patches have a better spatial resolution but large

patches have more contextual information. The visual

impact of patch scales is shown in Figure 4. As you

can see in this figure, the smaller size of the patch is

a better reflection of the shape of objects appearing

on the scan. Unfortunately, this is not an ideal solu-

tion as is largely susceptible to the previously men-

tioned noise appearing in the X-ray images. On the

other hand, too large patches cause loss of informa-

tion about details.

Figure 4: Visualization of the impact of patches size on the

recognition of material classes (presented in the gray back-

ground). We present the probability of occurrence of the

light organic class (using a gray scale) for the scan of spe-

cial test suitcase fragment.

Good information can be the fact that with such

patch sizes the accuracy of most of the tested clas-

sifiers is not very different (Figure 5). However, at-

tention should be paid to the lack of stability of the

MLP algorithm whose results come from its simple

architecture, which made it impossible to generalize

the classification process.

Learning-based Material Classification in X-ray Security Images

289

Figure 6: Pipeline for full scan material classification. Each colour indicates a specific type of material: WHITE (0) –

background, YELLOW (1) – light organic, RED (2) – heavy organic, GREEN (3) – light metals, BLUE (4) – heavy metals.

Figure 5: Accuracy as a function of a patch size for the

tested machine learning algorithms on the test dataset and

[LE, HE, zeros] input image.

5.4 Initial Full Scan Material

Segmentation

The scheme of the image initial segmentation process

is shown in Figure 6. Presentation of the probability

of each material class is very important to determine

the certainty of the receivables of each pixel. It also

allows different presentations of the estimator results.

We decided that the initial segmentation of the scans

is based on selecting the class that is most likely for

all patch sizes. As for now, the procedure is quite sim-

ple. We get all patches size for each pixel scan (Fig-

ure 6A). Then the average probability of the class for

each pixel is calculated (Figure 6B). This generates

probability maps for all classes. The last step is to

choose the class with the greatest probability (Figure

6C). Figure 7 presents some results for the classifier

which obtained the best results in the previous tests.

6 CONCLUSIONS

Material recognition in the X-ray images is a long-

standing, challenging problem. We introduce a new

large, open, material database – MDD that includes

a diverse range of materials, and this is the first such

dataset. Using this large database we conduct an eval-

uation of recent machine learning algorithms for si-

Figure 7: Full scan material classification examples: test

set predictions by our method based on the random forest

classifier. Each colour indicates a specific type of material

as stated in Figure 1.

multaneous material classification and initial segmen-

tation. We have proved that training on a dataset

which includes the surrounding context is crucial for

material classification in the DEXA scans. Many fu-

ture avenues of work remain. Expanding the dataset

to a broader range of categories will require new ways

to mine images that have more variety, and new an-

notation tasks that are cost-effective. We also be-

lieve that further exploration of the material and ob-

ject classification will be successful and lead to im-

provements in both tasks. Another issue that we want

to deal with in the future study is to propose an orig-

inal algorithm that will provide a faster learning pro-

cess and better predictions. In addition, the improve-

ment of deep convolutional neural networks suggests

that the solutions will also work for the problem pre-

sented in this paper. The issue that can be solved by

machine learning or deep learning algorithms is the

unnatural separation of material classes. We believe

that the clusters’ algorithms would enforce the classes

more naturally, based on the data set because, as we

can see, the unnatural division of classes can cause

classification errors.

REFERENCES

ALERT (2019). Alert datasets. http://www.north

eastern.edu/alert/transitioning-technology/alert-

datasets/, (accessed: 2019-08).

Alvarez, R. and Macovski, A. (1976). Energy-selective

reconstructions in x-ray computerized tomography.

Physics in Medicine and Biology, 21:733–744.

VISAPP 2020 - 15th International Conference on Computer Vision Theory and Applications

290

Arida (2019). Arida systems sp. z o.o. http://arida.pl/ in-

dex.php#products, (accessed: 2019-10).

Bell, S., Upchurch, P., Snavely, N., and Bala, K. (2014).

Material recognition in the wild with the materials in

context database. in IEEE CVPR.

Bhattacharjee, T., Wade, J., and Kemp, C. C. (2015). Mate-

rial recognition from heat transfer given varying initial

conditions and short-duration contact. In Robotics:

Science and Systems.

Caputo, B., Hayman, E., and Mallikarjuna, P. (2005). Class-

specific material categorisation. In Tenth IEEE Inter-

national Conference on Computer Vision (ICCV’05)

Volume 1, volume 2, pages 1597–1604 Vol. 2.

Cawley, G. and Talbot, N. (2007). Preventing over-fitting

during model selection via bayesian regularisation of

the hyper-parameters. Journal of Machine Learning

Research, 8:841–861.

Cawley, G. and Talbot, N. (2010). On over-fitting in

model selection and subsequent selection bias in per-

formance evaluation. Journal of Machine Learning

Research, 11:2079–2107.

Chuang, K.-S. and Huang, H. (2000). Comparison of four

dual energy image decomposition methods. Physics

in Medicine and Biology, 33:455–466.

DetectionTechnology (2019). Dt x-daq 0.8 dualenergy de-

tector documentation. http://www.datvision.co.kr/ up-

load/DT

20121019132944.pdf, (accessed: 2019-10).

Dmitruk, K., Denkowski, M., Mazur, M., and Mikoajczak,

P. (2018). Sharpening filter for false color imaging

of dual-energy x-ray scans. Signal, Image and Video

Processing, 11(4):613–620.

Dmitruk, K., Mazur, M., Denkowski, M., and Mikolajczak,

P. (2015). Method for filling and sharpening false

colour layers of dual energy x-ray images. IFAC-

PapersOnLine, 48:342–347.

Elmasri, K., Hicks, Y., Yang, X., Sun, X., Pettit, R., and

Evans, W. (2016). Automatic detection and quantifi-

cation of abdominal aortic calcification in dual energy

x-ray absorptiometry. 20th International Conference

on Knowledge-Based and Intelligent Information and

Engineering Systems 5-7 September 2016, 96:1011–

1021.

Everingham, M., Gool, L., Williams, C., and J. Winn,

A. Z. (2010). The pascal visual object classes (voc)

challenge. International Journal of Computer Vision,

1(2):303–338.

Gould, S., Fulton, R., and Koller, D. (2009). Decomposing

a scene into geometric and semantically consistent re-

gions. pages 1 – 8.

Ko, B., Kim, S., and Nam, J.-Y. (2011). X-ray image classi-

fication using random forests with local wavelet-based

cs-local binary patterns. Journal of digital imaging :

the official journal of the Society for Computer Appli-

cations in Radiology, 24(6):1141–1151.

Lehmann, L. A., Alvarez, R. E., Macovski, A., Brody,

W. R., Pelc, N. J., Riederer, S. J., and Hall, A. L.

(1981). Generalized image combinations in dual kvp

digital radiography. Medical Physics, 8(5):659–667.

Mehta, S. and Sebro, R. (2019). Random forest clas-

sifiers aid in the detection of incidental osteoblas-

tic osseous metastases in dexa studies. International

Journal of Computer Assisted Radiology and Surgery,

14(5):903–909.

Mery, D., Riffo, V., and Lobel, H. (2015). Gdxray: The

database of x-ray images for nondestructive testing.

Journal of Nondestructive Evaluation, pages 34–42.

Metrix (2019). Metrix sax 1712a lamp documentation.

http://metrixndt.com/generators-brochures/SAXG

%201712A%20v1%20LR.pdf, (accessed: 2019-10).

M.S. Kavitha, A. A., Taguchi, A., Kurita, T., and Sanada,

M. (2012). Diagnosis of osteoporosis from dental

panoramic radiographs using the support vector ma-

chine method in a computer-aided system. BMC Med

Imaging, 12:1011–1021.

Nedjar, I., EL HABIB DAHO, M., Settouti, N., Sad, M.,

and Chikh, M. (2015). Random forest based classifi-

cation of medical x-ray images using a genetic algo-

rithm for feature selection. Journal of Mechanics in

Medicine and Biology, 15(2):1540025.

Ogorodnikov, S., Petrunin, V., and Vorogushin, M. (2002).

Radioscopic discrimination of materials in 1-10 mev

range for customs applications. pages 2807–2809.

Rebuffel, V. and Dinten, J.-M. (2007). Dual-energy

x-ray imaging: Benefits and limits. Insight -

Non-Destructive Testing and Condition Monitoring,

49:589–594.

Russell, B., Torralba, A., Murphy, K., and Freeman, W.

(2008). Labelme: A database and web-based tool for

image annotation. International Journal of Computer

Vision, 77.

Sivakumar, S. and Chandrasekar, C. (2013). Lung nodule

detection using fuzzy clustering and support vector

machines. International Journal of Engineering and

Technology (IJET).

Watabiki, H., Takeda, T., and Mitani, S. (2013). Develop-

ment of dual-energy x-ray inspection system. Anritsu

Technical Review, (20):60–61.

Xiao, J., Ehinger, K., Hays, J., Torralba, A., and Oliva, A.

(2014). Sun database: Exploring a large collection of

scene categories. International Journal of Computer

Vision, 119(1):3–22.

Zhou, B., Lapedriza, A., Xiao, J., Torralba, A., and Oliva,

A. (2015). Learning deep features for scene recogni-

tion using places database. Advances in Neural Infor-

mation Processing Systems, 1:487–495.

Learning-based Material Classification in X-ray Security Images

291