Robustness Improvement in Optical Deformation Analysis by

Matching a Motion Field to Stress Imposed on a Surface

Jun Takada

*

and Masahiko Ohta

*

NEC Corporation, 1753, Shimonumabe, Nakahara-ku, Kawasaki-shi, Kanagawa 211-8666, Japan

Keywords: Motion Field, Deformation Analysis, Non-destructive Testing, Crack Opening Displacement.

Abstract: A denoizing and compression method for motion field data is proposed to improve the robustness and

efficiency of optical deformation analysis. The proposed method estimates stress change over time imposed

on a captured surface based on displacements and strains derived from motion fields obtained by optical flow.

The method then finds the best least squares approximation of the motion components due to the stress time

series from the motion time series at each coordinate. This process decomposes motion fields into stress and

response vectors while removing disturbances. Experimental results confirm that the proposed method

significantly reduces noise in visualizing crack opening displacements on a bridge beam under traffic loads,

as well as the size of the motion field data.

1 INTRODUCTION

In recent decades, ensuring safety of aging civil

structures in many developed countries has become

an important global issue. However, performing

frequent contact inspections of such structures is

difficult; therefore, various technologies have been

developed to support remote and automatic

inspection and assessment. There are many types of

structural properties that can be evaluated remotely,

such as surface crack densities, temperatures, and

dynamic behaviors (e.g., bridge deflections). Fatigue

crack density is one of the most popular statistics used

to assess concrete structures. Generally, fatigue

cracks form and propagate owing to repeated cyclic

loading on structures. Once the fatigue cracks reach

steel wires inside the reinforced concrete, moisture

penetration induces steel wire corrosion, which

decreases structural strength significantly. Therefore,

the early detection and limited repair of such cracks

are important for safety and economic reasons.

Traditionally, many automatic crack detection

methods involving high-resolution digital imaging

have been developed for this purpose. However,

many of these methods attempt to detect cracks from

a single image; thus, they cannot instantly determine

whether a crack is propagating, and they cannot

suggest information about a crack’s depth.

*

https://www.nec.com/

Therefore, approaches based on video analysis

have emerged recently. Video analysis-based

methods measure and visualize the dynamic behavior

of cracks. In the material and structural mechanics

field propagating cracks demonstrate an opening and

closing motion under dynamic loading on structures,

and deeper cracks show larger motions. These video-

based methods attempt to measure such minute crack

motions using video analysis techniques to produce

information about crack progression risks.

Nevertheless, many of those are only used in indoor

experiments and suffer robustness difficulties in real

outdoor environments. In addition, video data of the

entire structure are too large to handle at reasonable

cost.

Therefore, in this paper, we propose an efficient

denoizing and compression method for the motion

field of stress-imposed structure surfaces so that

motion-based crack severity assessment methods can

be used to evaluate real outdoor structures.

2 RELATED WORK

2.1 Still Image-based Approaches

Many conventional crack assessment methods that

attempt to find cracks from a single image based on

Takada, J. and Ohta, M.

Robustness Improvement in Optical Deformation Analysis by Matching a Motion Field to Stress Imposed on a Surface.

DOI: 10.5220/0008944007670774

In Proceedings of the 15th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2020) - Volume 4: VISAPP, pages

767-774

ISBN: 978-989-758-402-2; ISSN: 2184-4321

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

767

the characteristic texture appearance along cracks

have been described in literature. A survey on the

recent image-based crack assessment methods for

concrete- and asphalt-based civil infrastructure (Koch

et al., 2015) has introduced various methods for this

approach, e.g., wavelet-based (P. Kohut, 2012) and

SVM classifier-based (Liu et al., 2002) methods.

This approach generally assumes that all cracks

are visible in a single image and attempts to assess

crack severity using static information, e.g., crack

length, width, and density. However, depending on

illumination or imposed stress conditions, cracks are

often invisible in the early stage of propagation. In

addition, crack propagating risks often appear in

dynamic behaviors. For example, crack opening

motions imply stress transmission to the crack, which

relates to future propagating risk. The expansion of

opening motion implies deeper crack propagation,

which causes damage risks to steel wires. Therefore,

still image-based methods can miss risk information

about crack indication and propagation.

2.2 Motion-based Approaches

Video-based methods have emerged to compensate

the shortcomings of the still image-based approach.

The basic idea is to use the motion field around cracks

as additional information for assessment. Digital

image correlation (DIC) and optical flow are often

used to obtain the motion field. Most structure

surfaces, e.g., concrete, have natural textures; thus, a

pixel-wise motion field can be acquired easily using

such image tracking methods.

For example, a defect classification method based

on surface motion patterns has been proposed (Imai,

2016). First, this method estimates out-of-plane

global motions from the motion field, and then it

extracts in-plane stress field information from the

motion field by subtracting an apparent motion vector

component due to global motion. Experimental

results obtained on stress-imposed soft materials

demonstrate the possibilities of classifying internal

defects (e.g., cracks, peeling, and cavities) from stress

field patterns.

Another experimental study applied this type of

method to real outdoor bridges (Imai, 2017). To

evaluate accuracy, crack opening displacements by

DIC were compared using a clip-on gauge sensor.

The results indicate they have similar variation ranges

but different graph shapes in displacement time

series.

Pixel-wise motion vectors tend to be less accurate

than pixel intensities; thus, many postprocessing

methods have been developed. For example, a spatial-

temporal nonlinear filtering method combined with

conditional random fields has been proposed

(Chaudhury, 2017). The results of indoor experiments

with concrete material demonstrate improved crack

detection accuracy, particularly in the early stages

where cracks are not yet visible without imposed

stress.

Motion-based methods have high potential to

provide additional information about crack severity

compared to still image-based methods. However,

many such motion-based methods remain limited to

laboratory investigations and are not yet feasible for

real outdoor environments, primarily due to their

insufficient accuracy. The difficulties in measuring

real outdoor structure motions compared to indoor

experiments are assumed to be smaller material

deformation due to its solidity, smaller apparent

displacements due to far shooting distance, and

undesired apparent displacements caused by heat

haze.

In addition, the data size problem will arise in

practical applications. For example, 4K (3840x2160)

video at 60 fps with an 8-bit pixel value consumes 498

MB/s of bandwidth and storage. In addition, video

compression techniques, e.g., H.265/HEVC, cause

compression noise, which reduces motion accuracy;

thus, this trade-off should be considered carefully.

Note that the size of motion field data will become

even larger. If in-plane displacements are represented

as two 32-bit values, the output data bandwidth

increases to 3981 MB/s. Most video compression

formats do not support such pixel formats, e.g., 32-bit

floating point; thus, efficient compression will

become even more difficult. Simply scaling down the

spatial resolutions of the result vectors can be a

solution; however, even with 16 × 16 downscaling,

15.6 MB/s of data will be produced, which is still

impractical for outdoor use.

2.3 Thermographic Approach

A thermoelastic stress analysis method has been

proposed to detect and assess cracks remotely. Here,

the basic idea is to capture minute temperature shifts

induced by stress using an infrared thermography

video camera. Such temperature shifts occur around

crack tips; thus, this method is expected to be suitable

for detecting micro cracks in the early initiation

stages or those with future propagating risks.

However, the temperature shift induced by stress

is generally too small to be identified clearly in

thermal images, particularly in outdoor

environments. To reduce noises in thermal images,

VISAPP 2020 - 15th International Conference on Computer Vision Theory and Applications

768

the self-reference lock-in thermography technique

has been developed (Sakagami, 2016).

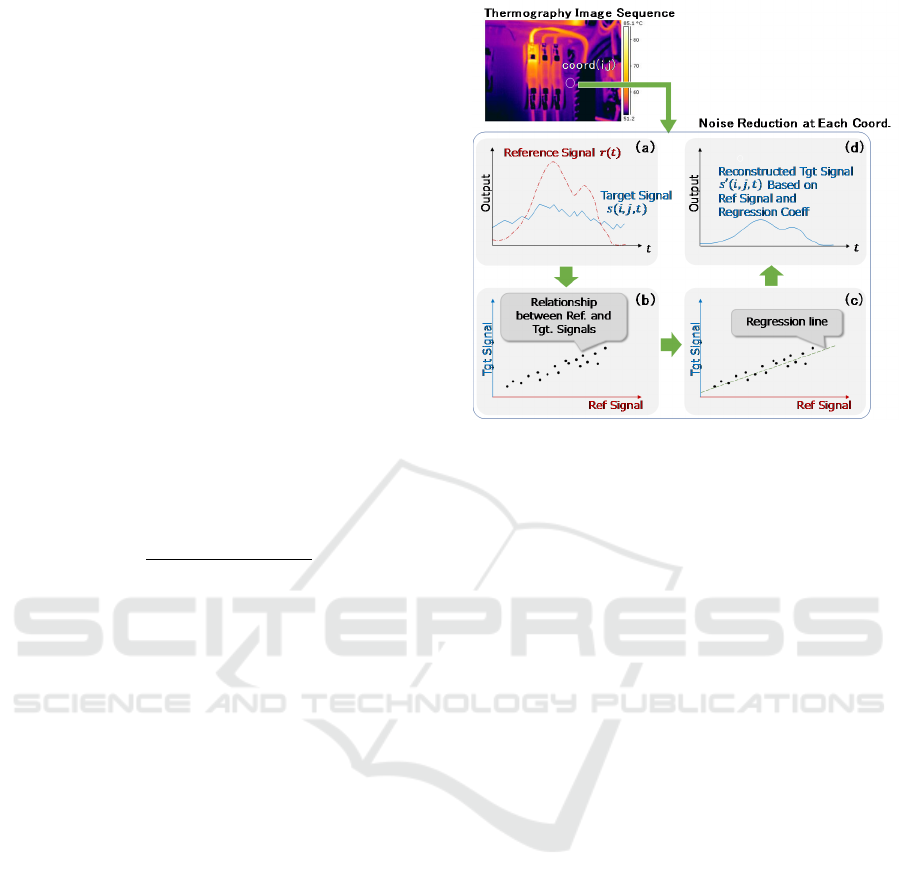

Figure 1 shows an outline of the self-reference

lock-in thermography method. In this case, we show

the noise reduction process for input signals

,,

based on predetermined reference signals

, where

and are the spatial coordinates in the image, and

is a frame number.

a) Reference signal time series

are selected out

of

,,

at an arbitrary position that gives

relatively large temperature change caused by

stress, e.g., near crack tips. The method then

extracts

,,

for each spatial coordinate

,

.

b) The method forms the relationship between

and

,,

at the coordinate.

c) The method uses the regression model

,,

,

∙

, at each

coordinate

,

. Here,

represents

,

represents

,,

, and f represents the number

of data for convenience. Then, regression

coefficient

,

is expressed as follows.

,

∑

∑

∑

∑

∑

(1

)

d) Finally, the method derives the denoized signal

time series

,,

at the coordinate as follows.

′

,

,

,

∙

(2

)

By applying the above process to each coordinate,

components that correlate with

are extracted

from

,,

, and uncorrelated components are

removed as noise. This method is suitable for real

structures, e.g., bridges, because the process works

without additional information for shaping signals. In

contrast, traditional lock-in methods require a known

reference signal pattern, e.g., periodical thermal

emission. The experimental results in the literature

demonstrate that self-reference lock-in thermography

method can clearly visualize temperature shift at

crack tips on real steel bridges under load.

However, this method faces some difficulties

relative to wide-scale deployment. For example, it

requires costly equipment, such as cooled

thermography cameras, and manual specification of

the reference point. In many cases, we cannot know

the crack tip position in advance; thus, manually

selecting an appropriate position is unrealistic in

practical applications.

Figure 1: Self-reference lock-in thermography method.

3 PROPOSED METHOD

3.1 Noise Reduction

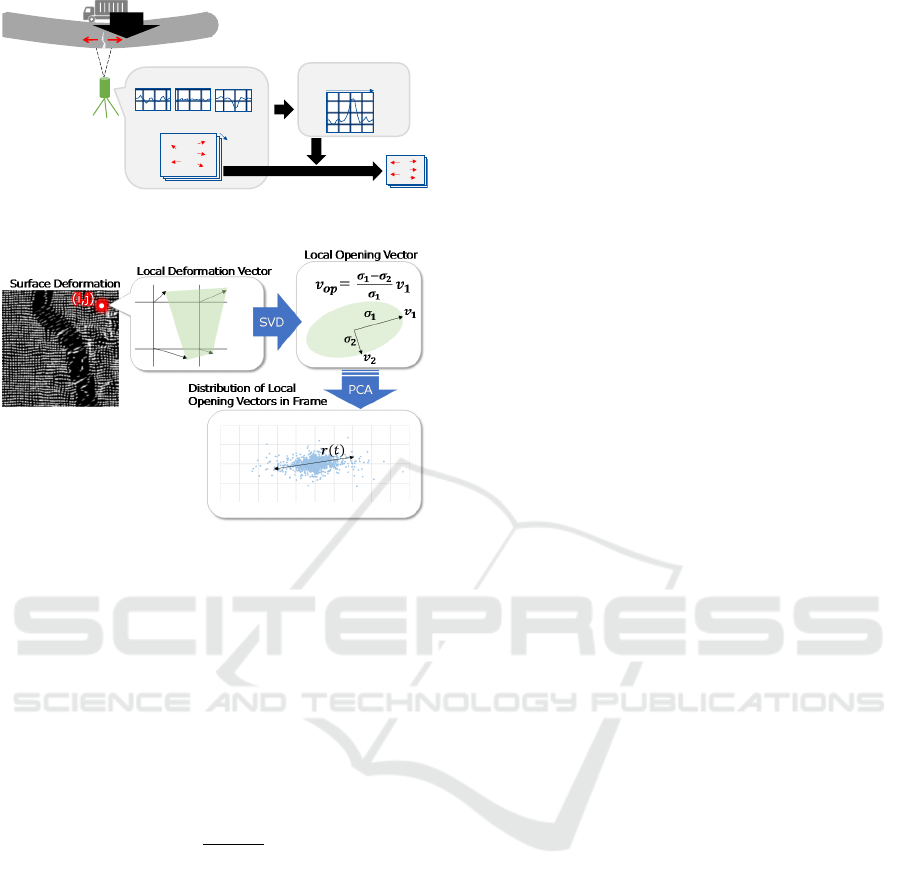

Inspired by self-reference lock-in thermography, we

have developed a new denoizing method for a motion

field (Figure 2). First, the proposed method estimates

the stress change imposed on the captured plane for

each frame based on the global 3D motion and 2D

deformation motion of the plane. Then, the proposed

method applies a lock-in calculation to the

deformation vector for each coordinate using the

stress change time series as reference signals.

To estimate the stress change from motion

vectors, we propose two derivation methods. Unlike

self-reference lock-in thermography, deformation

vector time series at one representative coordinate

will not correspond directly to the imposed stress. The

simplest way to estimate stress on the surface is to

reference a global motion component for the normal

direction of the plane. In a bridge application,

essentially, the motion of deflection is assumed to be

proportional to the amount of external force imposed.

However, this component does not always accurately

match the surface stress due to various factors, e.g.,

structural mechanics and camera self-vibration.

Therefore, we also propose to derive the imposed

stress based on the surface strain. Figure 3 shows the

derivation process.

Robustness Improvement in Optical Deformation Analysis by Matching a Motion Field to Stress Imposed on a Surface

769

Figure 2: Outline of the proposed method.

Figure 3: Reference signal generation by strain.

1. The process first extracts local deformation

vectors for each coordinate, which are

calculated as the differences of adjacent vectors.

2. The process then applies singular value

decomposition to the local deformation vectors

and derives singular values (

,

:

) and

singular vector

|

|

1 , which

corresponds to

. With the values

,

, and

, the local opening vectors

,, are

derived as follows.

,

,

(3)

3. Finally, the process applies principal component

analysis to the local opening vectors

,,

in frame to acquire reference signal

as the

square root of the eigenvalue of the first main

component. When greater stress is imposed, the

opening vectors will vary along one direction

(e.g., the beam tensile direction); thus, the stress

reflects the reference signal

.

3.2 Compression

With the proposed method, all denoized motion

vectors

,,

can be reconstructed from

,

and

, as shown in Equation (2). This means that

motion field ′ can be decomposed into the

regression coefficients and reference signal time

series , as shown in Equation (4), where is the

number of pixels in each frame, and is the number

of frames.

′

′

′

⋯′

⋮⋱⋮

′

⋯′

,

⋯

,

⋯

(4)

This decomposition process drastically reduces

the number of coefficients to be handled. Here, is

derived for the x- and y-axes, each coefficient is

represented as a 32-bit floating-point value, and the

data are coded using (6432) bits, which means

that motion fields for a 4K resolution video sequence

can be coded with 66 MB of data. With downscaling

to 16 × 16, the data are compressed to 259 kB, which

is sufficient for practical outdoor application.

In addition, if further compression is required,

image and audio compression formats that support

floating-point values, e.g., JPEG-XR and MPEG4-

ALS, can be applied.

4 EVALUATION

4.1 Implementation

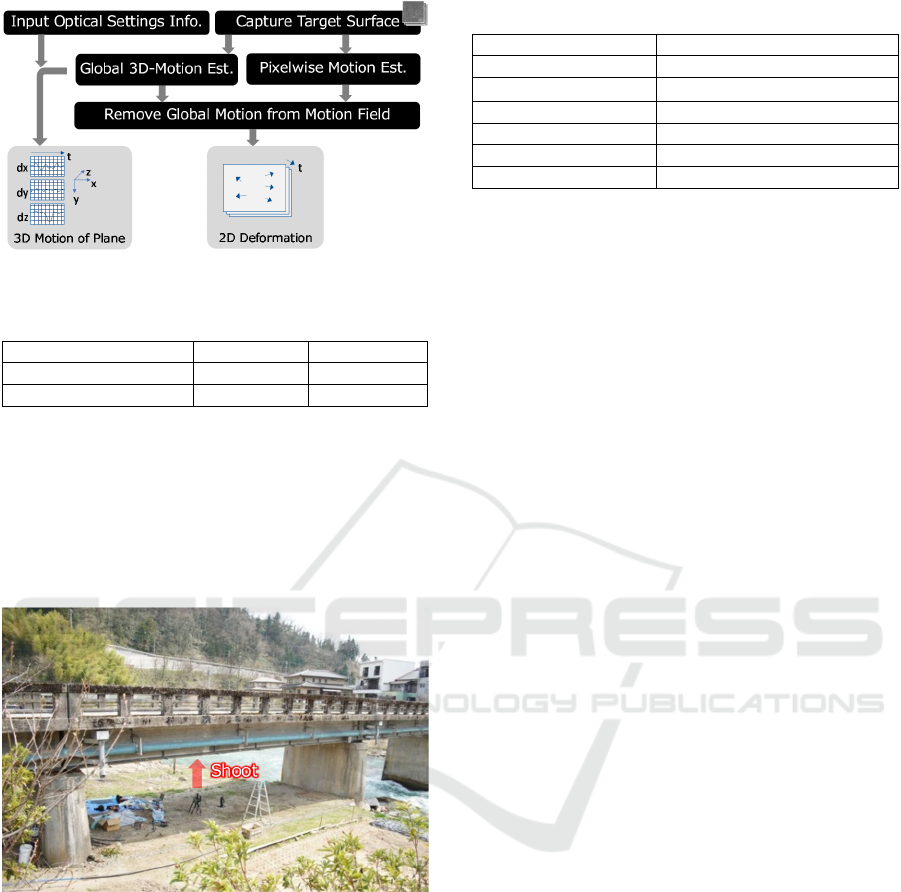

We implemented the motion estimation process

shown in Figure 4. First, users are requested to set up

optical parameters, such as shooting distance, lens

focal length, sensor resolution, pixel pitch on sensor,

and frame rate. Then, the system captures the target

surface and estimates the global 3D motion of the

plane against a predetermined reference frame in the

sequence. The estimated global motion is converted

to a physical scale based on the optical parameters.

The system also estimates the pixel-wise motion from

the captured video. By subtracting the apparent vector

components due to the global motion from the pixel-

wise motion, the system finally acquires 2D in-plane

displacements, which represent surface deformation.

Incidentally, minute self-motions of the camera are

removed in the final process.

We implemented a region-based matching

algorithm (Shimizu, 2004) for global 3D motion

estimation and dense optical flow (Brox, 2004) for

pixel-wise motion estimation with exhaustive

optimization for both Intel and nVidia architectures.

Typical processing times for a 4112x3008 pixel frame

are shown in Table 1.

In-plane 2D Motion

3D Motion of Whole Plane

Stress Change

on Surface

Est.

Lock-in

t

Load

Monocular

Videocam

t

Img based Motion Retrieval

VISAPP 2020 - 15th International Conference on Computer Vision Theory and Applications

770

Figure 4: Outline of motion estimation process.

Table 1: Typical processing time per frame [ms].

i7-8086k GTX1080ti

Global 3D motion 20 6

Pixel-wise motion 120 9

4.2 Experimental Setup

To evaluate crack opening displacement accuracy, we

conducted a dynamic loading test with a heavy

vehicle on a real bridge with reinforced concrete (RC)

beams in Japan (Figure 5) using a contact type crack

gauge sensor for reference.

Figure 5: Overview of experimental field.

Table 2 summarizes the experimental

configuration. The crack gauge was installed

beforehand at a known crack on the bottom side of the

RC beam. The monocular camera was fixed to a

tripod on the ground just below the crack to shoot the

surface perpendicularly. Here, we used two lenses

(i.e., 75 and 180 mm) to examine reproducibility. The

gauge and camera could not be synchronized

electrically; thus, we performed manual adjustments

based on the maximum value of each measurement.

We also measured the deflection of the beam using a

laser range finder with 0.5-mm repeatability for

reference.

Table 2: Experimental configuration.

Camera MC124MG-SY (+Tripod)

Pixel Resolution 4112 x 3008

Pixel Pitch on Sensor

3.45

μm

Lens Focal Length 75mm / 180mm

Shooting Speed 25fps

Shooting Distance 2.70m

Loading Weight 20t (178kN)

The crack opening displacements were measured

by the motion difference between two reference

points located across the crack. For performance

comparison, four motion denoizing methods were

tested. For each method, we visualized strain maps,

which show the local strain on each coordinate

derived as the larger singular value decomposed from

the local deformation.

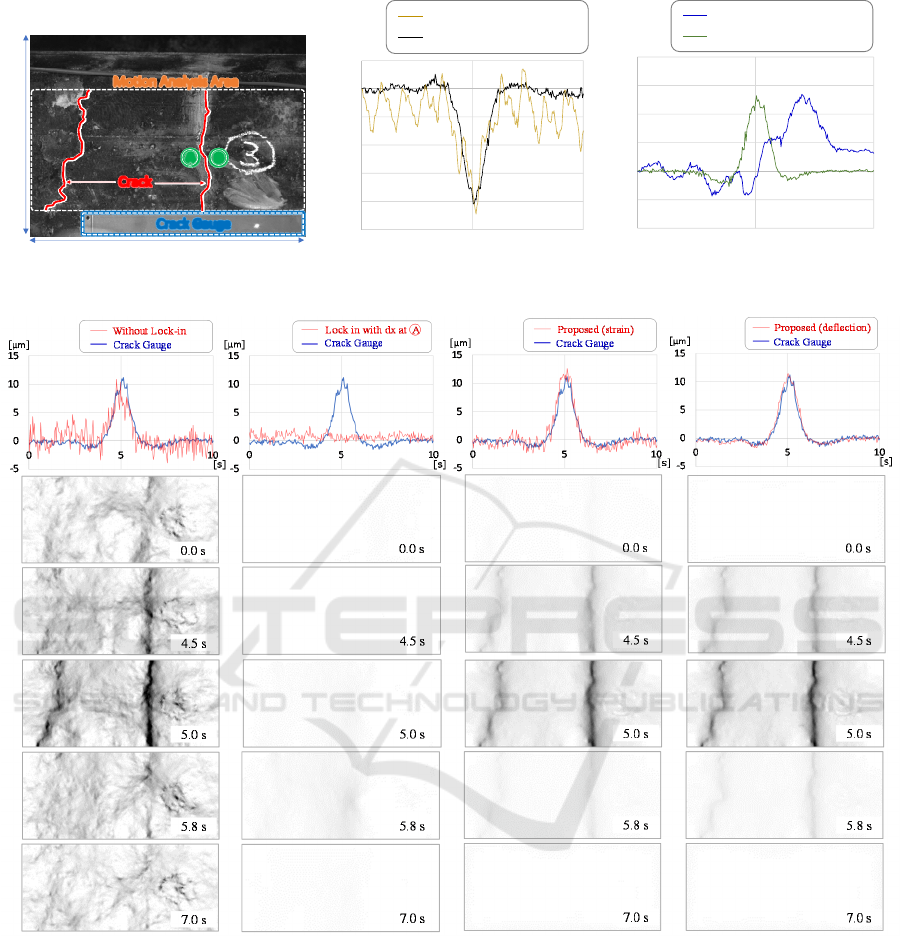

4.3 Results

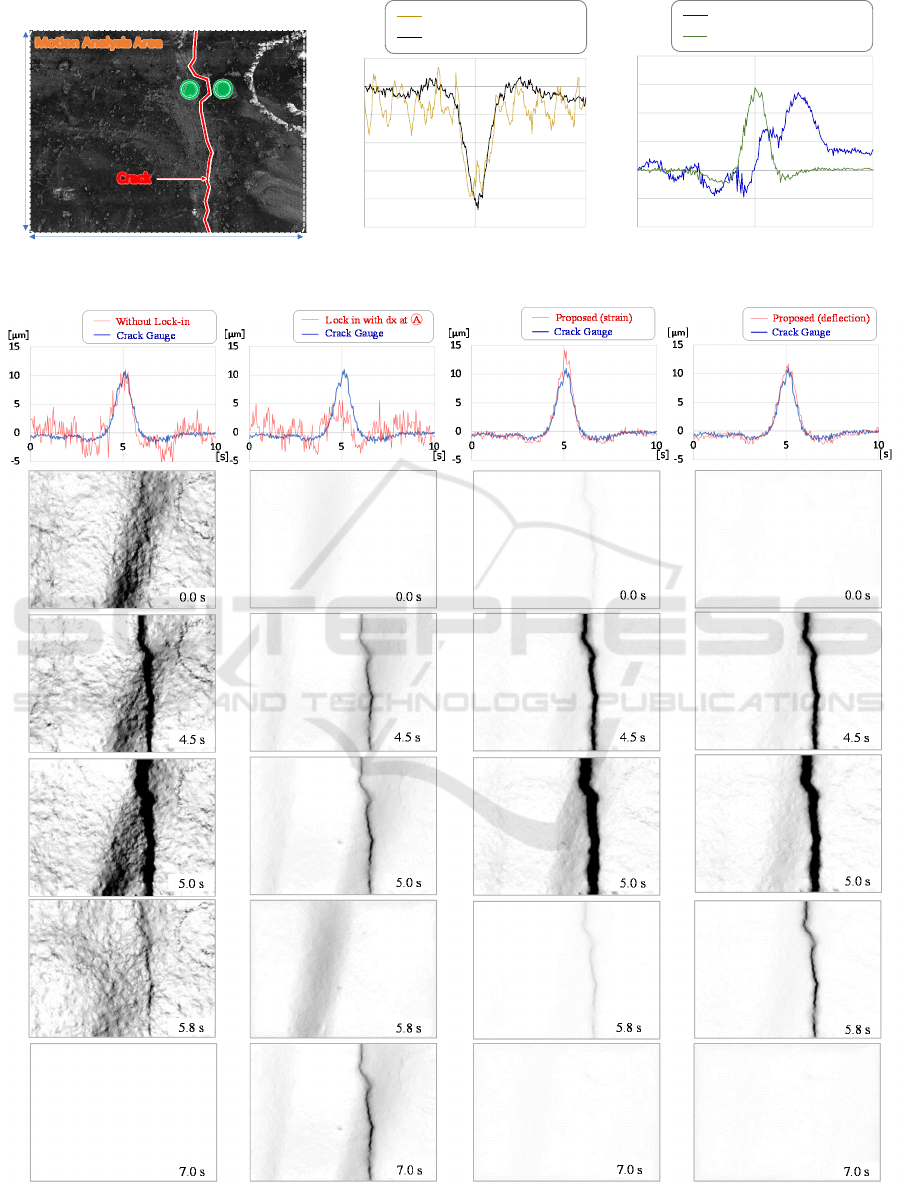

Figure 6 shows a 75-mm shot image with the ground

truth crack position and global 3D motion time series

estimated by image. We performed motion estimation

for the region in the rectangle (Figure 7) to exclude

objects other than the concrete surface. The crack

gauge sensor was set to measure the crack on the right

side of the image, and the two reference points for the

image-based crack opening measurement were set to

A and B.

The global motion graphs show deflection (depth

in the image), bridge axial motion (horizontal in the

image), and bridge-axis perpendicular motion

(vertical in the image). The deflection graph shows

the time series of the bridge beam bending while the

vehicle passed, with a maximum deflection of

approximately 800 μm.

Figure 7 shows the time series of the crack

opening displacement and strain maps for a 75-mm

shot with each denoizing method. From top to

bottom, measured time series compared with the

crack gauge sensor, strain map at the time-stamp of

0.0, 4.5, 5.0, 5.8, and 7.0 s in the video sequence.

From left to right, no lock-in, lock-in with horizontal

displacement at reference point A, lock-in with strain,

and lock-in with deflection are shown.

The results of strain and deflection-based lock-in

demonstrate significant improvements in graph shape

and crack visibilities compared to the other methods.

The graph of deflection-based lock-in shows slightly

better matches with the crack gauge sensor than the

strain-based one. The raw result appears noisy, and

locking-in with the motion near crack does not look

effective to improve graph shape nor crack visibility.

Robustness Improvement in Optical Deformation Analysis by Matching a Motion Field to Stress Imposed on a Surface

771

Figure 6: 75-mm shot image and global motion estimation results by region-based matching.

Figure 7: Crack opening displacements and strains measured and visualized by each method for 75-mm shot.

Figure 8 shows a 180-mm shot image with the

ground truth crack position and global 3D motion

time series estimated by image. Figure 9 shows the

time series of the crack opening displacement and

strain maps for the 180-mm shot with each denoizing

method. Compared to the 75-mm shot, the

implications of the results are similar, with slight

improvement in most of the graph shapes and strain

images, which is likely due to the substantially higher

resolution of the input images. Nevertheless, the raw

results still contain noise, which implies that simply

upscaling image resolution cannot solve the outdoor

noise problem.

Table 3 shows quantitative evaluation results

comparing the value of the crack gauge sensor and

image-based measurement of each method in root

mean square error (RMSE). As can be seen,

deflection-based lock-in demonstrates the best

performance among the tested algorithms. Strain-

based lock-in gives a value that is close to that

obtained by the deflection-based method; thus, the

strain-based method can be an alternative if deflection

‐1000

‐800

‐600

‐400

‐200

0

200

0510

‐100

‐50

0

50

100

150

200

0510

BridgeAxis

MotionAnalysisArea

CrackGauge

Crack

A

B

374mm

511mm

[μm]

[s]

Bridge-axis perpendicular

Deflection

Bridge-axial

[μm]

Laser range finder

[s]

VISAPP 2020 - 15th International Conference on Computer Vision Theory and Applications

772

Figure 8: 180-mm shot image and global motion estimation results by region-based matching.

Figure 9: Crack opening displacements and strains measured and visualized by each method for 180-mm shot.

‐1000

‐800

‐600

‐400

‐200

0

200

0510

‐100

‐50

0

50

100

150

200

0510

MotionAnalysisArea

Crack

A

B

156mm

213mm

BridgeAxis

[μm]

[s]

[s]

Bridge-axis perpendicular

Deflection

Bridge-axial

[μm]

Laser range finder

Robustness Improvement in Optical Deformation Analysis by Matching a Motion Field to Stress Imposed on a Surface

773

is unreliable as a stress index due to structural or

shooting conditions.

Finally, with lock-in applied, the data size of the

motion fields at one shot area was reduced to 446 kB

for the 4112x3008 pixel frame with 16 × 16

downscaling, including various metadata, e.g.,

shooting conditions.

Table 3: RMSE between crack gauge values and crack

opening displacements measured by each method for 75-

mm and 180-mm shots.

Method 75mm 180mm

Raw output (without lock-in) 1.87 1.78

Lock-in with motion near crack 2.88 2.64

Lock-in with strain 1.01 0.82

Lock-in with deflection 0.58 0.69

5 CONCLUSIONS

We have proposed a denoizing and compression

method for the motion field of stress-imposed

surfaces. Experimental results confirmed that the

proposed method significantly reduces the noise and

data size of a motion field acquired in outdoor

environments. This method decomposes the motion

field into a stress time series and response map under

certain stress on the surface while removing

disturbances. Related studies have demonstrated the

possibility of classifying internal defects using stress

field patterns; thus, this response map will help

identify internal defects. Furthermore, this

representation reduces dataset dimensionality;

therefore, it will facilitate the application of learning-

based pattern recognition methods to defect

classification. In future, we plan to further extend

motion-based structure assessment based on the

proposed method.

ACKNOWLEDGMENTS

We are grateful to Research Association for

Infrastructure Monitoring System

1

for sharing the

concrete crack dataset. This work was partly

supported by Strategic Innovation Promotion

Program (SIP), a Japanese project led by the Cabinet

Office’s Council for Science, Technology and

Innovation.

1

http://www.raims.or.jp/en/

REFERENCES

C. Koch, K. Georgieva, V. Kasireddy, B. Akinci, and P.

Fieguth, 2015. A review on computer vision based

defect detection and condition assessment of concrete

and asphalt civil infrastructure. Advanced Engineering

Informatics, 29(2):196–210.

P. Kohut, K. Holak and T. Uhl, 2012. Monitoring of civil

engineering structures supported by vision system,

European Workshop on Structural health monitoring,

1575-1582.

Z. Liu, S. Azmin, T. Ohashi and T. Ejima, 2002. Tunnel

crack detection and classification systems based on

image processing, Society of Photo-Optical

Instrumentation Engineers (SPIE) Conference Series,

4664, 145–152.

M. Imai, M. Ohta, K. Tsuyuki, H. Imai, S. Miura, K. Murata

and J. Takada, 2017. Video image-based dynamic

behavior analysis of concrete structures by using digital

image correlation method, JofJSCE 2017, 5(1), 246-

251.

S. Chaudhury, G. Nakano, J. Takada and A. Iketani, 2017.

Spatial-temporal motion field analysis for pixelwise

crack detection on concrete surfaces, WACV 2017.

336-344.

H. Imai, M. Ohta and K. Murata, 2016. Structural internal

deterioration detection with motion vector field image

analysis using monocular camera, EI 2016, 3DIPM-

410.

T. Sakagami, Y. Izumi, D. Shiozawa, T. Fujimoto, Y.

Mizokami and T. Hanai, 2016. Nondestructive

Evaluation of Fatigue Cracks in Steel Bridges Based on

Thermoelastic Stress Measurement, Procedia Structural

Integrity Vol.2, pp. 2132-2139.

M. Shimizu, T. Yano and M. Okutomi, 2004, Precise

simultaneous estimation of image deformation

parameters, CVPR 2004, 2, 954-961.

T. Brox, A. Bruhn, N. Papenberg and J. Weickert, 2004.

High-accuracy optical flow estimation based on a

theory for warping, ECCV 2004. LNCS, 3021, 25-36,

Springer, Heidelberg (2004).

VISAPP 2020 - 15th International Conference on Computer Vision Theory and Applications

774