Transgenic Genetic Algorithm to Minimize the Makespan in the Job

Shop Scheduling Problem

Monique Simplicio Viana

1a

, Orides Morandin Junior

1b

and Rodrigo Colnago Contreras

2c

1

Department of Computing, Federal University of São Carlos, Rod. Washington Luiz KM 235, São Carlos – SP, Brazil

2

Department of Computer Sciences, University of São Paulo, Av. Trabalhador São-carlense 400, São Carlos – SP, Brazil

Keywords: Job Shop Scheduling Problem, Genetic Algorithm, Transgenic Operator, Combinatorial Optimization.

Abstract: In recent years, several research studies have been conducted that use metaheuristics to calculate

approximations of solutions for solving NP-Hard problems, within this class of problems there is the Job Shop

Scheduling Problem (JSSP), which is discussed in this study. Improved solutions to problems of this type

have been created for metaheuristics in the form of additional operators. For the Genetic Algorithm (GA) the

transgenic operator has recently been created, whose operation is based on the idea of "genetically modified

organisms", with the proposal to direct some population of individuals to a more favorable solution to the

problem without removing the diversity of the population with a competitive cost of time. In this study, our

main contribution is an adaptation of the GA with transgenic operator to the JSSP. The results obtained by

the proposed method were compared with three papers in the literature that work on the same benchmark: one

using GA, one using Adaptive GA and another using Ant Colony Optimization. The results confirm that the

GA used with the transgenic operator obtains better results in a competitive processing time in comparison to

the other techniques, due to its better targeting in the search space.

1 INTRODUCTION

The job shop scheduling problem (JSSP) is a

combinatorial optimization problem defined in the

literature as in the NP-Hard class (Lu et al., 2018a).

Therefore, it is recommended the use of heuristic,

metaheuristic and stochastic algorithms to optimize

NP Hard class problems (Hasan et al., 2010).

The JSSP is part of a class of problems among the

job-based scheduling problems. This class represents

a research area of great importance in current studies,

such as flexible job scheduling problems (FJSPs),

parallel machine scheduling problems (PMSPs), test

task scheduling problems (TTSPs) and others (Lu et

al., 2018a). Specifically, in this paper, we approach

the class of combinatorial optimization problems

known as JSSP. In the following paragraphs, some

recent works are presented from a vast literature on

the use of metaheuristics in job-based problems.

Nguyen et al. (2018) proposed a study of the

dynamic flexible job shop scheduling problem with a

a

https://orcid.org/0000-0002-2960-8293

b

https://orcid.org/0000-0001-5588-100X

c

https://orcid.org/0000-0003-4003-7791

new genetic programming algorithm (GP), entitled

adaptive charting GP (ACGP), the proposed

algorithm. The ACGP can balance its exploration,

getting exploitation better than the existing surrogate-

assisted algorithm. The proposal performed better

than standard genetic programming algorithm.

Romero et al. (2018) proposed a study of the

flexible job shop scheduling problem (FJSSP) with

Lot Streaming with the Tabu Search (TS) algorithm,

the study was compared with a mathematical

programming solver, GUROBI. The algorithm

obtained better results surpassing the upper limits

found of GUROBI.

Öztop et al. (2018) proposed a study of the hybrid

flow shop scheduling problem (HFSP) using the

Iterated greedy algorithms, IG and IGALL. The

objective variable was to minimize total flow time

and has been tested in HFSP instances from the

literature. The authors emphasize that one of the main

contributions of the study was that the results of flow

Viana, M., Morandin Junior, O. and Contreras, R.

Transgenic Genetic Algorithm to Minimize the Makespan in the Job Shop Scheduling Problem.

DOI: 10.5220/0008937004630474

In Proceedings of the 12th International Conference on Agents and Artificial Intelligence (ICAART 2020) - Volume 2, pages 463-474

ISBN: 978-989-758-395-7; ISSN: 2184-433X

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

463

time criterion have been reported for the HFSP

benchmark suite for the first time.

Dao et al. (2018) proposed a study of the JSSP

with an algorithm based on parallel versions of the bat

algorithm (BA), using as objective variable

makespan. The algorithm presented better

convergence and competitive results than BA

traditional and particle swarm optimization.

Morandin, et al. (2008a) proposed a study to solve

the Production Scheduling of Manufacturing

Systems, the study has been tested in a benchmark of

the type JSSP with a traditional genetic algorithm

(GA) as a search method, using as objective variable

the makespan measure. The GA achieved competitive

results in a shorter processing time.

Morandin et al. (2008b) added an improvement in

the GA proposed in Morandin et al. (2008a), adaptive

rules were included to the algorithm, entitled adaptive

genetic algorithm (AGA). The crossover and

mutation rate are dynamically adjusted according to

the individual's fitness value. The study has been

tested in a benchmark of the type JSSP. The AGA

presented solutions with response time acceptable.

Kato et al. (2010) proposed a study to solve the

Production Scheduling of Manufacturing Systems.

The study has been tested in a benchmark proposed

in Morandin et al. (2008b). The authors use a Max-

Min Ant System algorithm as a search method. The

proposal was compared with Morandin et al. (2008b)

and obtained quality solutions in a shorter time.

In the literature, it is possible to find several recent

studies belonging to the job-based scheduling

problems class that approach the task with AG

(Asadzadeh, 2015; Kundakci and Kulak, 2016; Kurdi,

2016; Lu et al., 2018b; Peng et al., 2018;

Hosseinabadi et al., 2019).

The GA is a metaheuristic widely used in current

studies due to several advantages that this algorithm

has, but it also has some disadvantages such as not

solve complex problems easily (Guo et al., 2010). The

GA has as one of its main disadvantages the high

consumption of resources, that is, domain of large

solutions will use longer search time (Kazemi et al.,

2012; Nie et al., 2013).

Amaral and Hruschka (2014) have developed an

operator for evolutionary algorithms entitled

Transgenic Operator. This operator was inspired by

genetic engineering, in which there is the possibility

of manipulating the genetic material of individuals by

adding features that are believed to be important. This

type of approach can be understood as a strategy of

elitism focused on specific genes. The Transgenic

Operator must direct a portion of individuals of the

population for a better solution, without loss of

diversity in population and in a smaller cost of time.

The objective of this work is the application of an

alternative version of Transgenic Operator (Amaral

and Hruschka, 2014) in the job shop scheduling

problem. In this paper, we approached the reasoning

proposal used by Morandin et al. (2008a), Morandin

et al. (2008b), Kato et al. (2010), which uses the same

benchmark for the job shop problem and are solved,

respectively, by the metaheuristics GA, AGA and Ant

Colony Optimization (ACO). In this way, the

comparison of the results of our method with the

methods of such studies becomes more natural, since

we will use the same benchmark.

The remainder of this paper is organized as

follows. Section 2 contains the JSSP specification and

the fundamentals of GA and description of the

Transgenic Operator. The components of the

proposed algorithm are presented in Section 3. The

computational experiments and analyses of the

obtained results are presented in Section 4. Finally,

Section 5 presents the conclusions of the paper.

2 PROBLEM DESCRIPTION

2.1 Job Shop Scheduling Problem

In this context, in a manufacturing system, there is a

set of jobs {

,

,...,

} that are produced by

manufacturing, and such products make shared use of

a set of machines {

,

,...,

}. A job contains

a set of operations and a predetermined sequence of

machines. Each operation makes use of one of the

machines for a predetermined time interval to

complete a job. A schedule can be defined as the

assignment of operations, established by a sequence

of elements in the set =

{

,

,…,

⋅

}

, which

determine the priority order in which a job should be

processed on a machine.

For each possible operations sequence , we

associate the value

(

)

, which is the time it takes

the job

to be processed by all machines in the

respective script, which consists of the production

itinerary detailed in this same section, and thus be

considered finished according to the defined

sequence of operations at .

Thus, the makespan value of a sequence can be

defined as being the time taken for finish the

production of all the jobs, as described in the

Equation (1):

=max

(

)

.

(1)

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

464

Dao et al. (2018) do a similar and rigorous

modeling of the makespan measurement in their

work. Moreover, in this work, for each job

, a set

ℛ

of

possible scripts is considered, as defined in

Equation (2), which increases the complexity of the

task of minimizing the makespan value in the space

of operations. A script of a job determines by which

machines it should be processed and the order in

which it must occur for it to be considered finished.

Studies such as those from Morandin et al. (2008a),

Morandin et al. (2008b) and Kato et al. (2010) are

characterized by this specification.

ℛ

=

,

,

,

,...,

,

.

(2)

2.2 Search with Genetic Algorithm

Genetic Algorithms (GAs) were developed in the

1970s by Holland (Holland, 1975) with the objective

of optimizing complex and non-linear systems. This

type of technique has a strong appeal to biological

inspiration derived from the theory of evolution to

perform its operation, so that its use does not require

very elaborate mathematical theories.

Many improvements have been implemented over

the last few years (Antonio and Coello, 2017) to the

GAs that Holland formulated in his initial work

(Holland, 1975) and presented in the classic 1992

book (Holland, 1992). However, all the improved

GAs present in the specialized literature maintains as

the main sequence of steps the one originally

presented by Holland (1992) in Algorithm 1.

Algorithm 1: A Genetic Algorithm Pseudocode.

(1)

it=0;

(2) Generate initial population:

Ω

=

{

,

,…,

}

(3) Evaluate the fitness of the initial population

(4) Repeat

(5) Select individuals for crossover

(6) Apply crossover operator

(7) Apply mutation operator

(8) Evaluate new individuals

(9)

Generate a new population: Ω

it

(10)

it=it+1;

(11) Until Termination criterion is satisfied

The generation of a new population, as done in

step (9) of Algorithm 1, generally takes into account

some own insertion technique so that only the best

individuals from the iteration are maintained and do

not change the size of the population.

2.3 Transgenic Operator

In order to simulate the biological advances of genetic

engineering, Amaral and Hruschka (2014) proposed

the use of transgenic technique in GA. The concept of

transgenics is to transfer, from one generation to

another, genes that probably describe a good feature.

For example, vitamin supplementation of maize is

used in developing countries to avoid that the

population, usually with food habits based mainly on

cereals, suffers from lack of vitamins. This

supplementation can be done with the use of

transgenic planting (Naqvi et al., 2009). The addition

of this concept to GA occurs in the form of an

operator, as represented in Algorithm 2.

Algorithm 2: A Transgenic Genetic Algorithm Pseudo-

Code.

(1)

it=0;

(2) Generate initial population:

Ω

=

{

,

,…,

}

(3) Evaluate the fitness of the initial

population

(4) Repeat

(5) Select individuals for crossover

(6) Apply crossover operator

(7) Apply mutation operator

(8) Evaluate new individuals

(9)

Generate a new population: Ω

it

(10) Apply transgenic operator

(11) Evaluate modified individuals

(12)

Generate modified population: Ω

it

(13)

it=it+1;

(14) Until Termination criterion is satisfied

In Algorithm 2, two inserts of individuals are

carried out: one in the step (9) and another in the step

(12). However, only the population Ω

it

is

maintained in the process, since the population Ω

it

is an intermediate population, from which the

transgenic individuals are made in step (10). In this

way, the population Ω

it

is formed by the

individuals of Ω

it

together with the transgenic ones.

The transgenic operator codification is described

in detail in the next section.

Transgenic Genetic Algorithm to Minimize the Makespan in the Job Shop Scheduling Problem

465

3 THE PROPOSED GENETIC

ALGORITHM MODEL FOR

JSSP

3.1 Chromosome Codification

In this study, we will follow Morandin et al. (2008a)

approach to treating a subproblem within the JSSP,

which is to get the best sequence of products that must

be obeyed as a priority list when starting product

processing on each of the machines in their respective

script. Thus, the metaheuristic developed here should

not obtain an "optimal sequence of operations", but

rather an "optimal sequence of jobs".

Thus, the chromosome ( ) of the proposed

method is formulated according to Equation (3):

C=

,

,

,

,

,

,…,

,

,

,

(3)

in which,

∈

{

1,2,…,

}

,

≠

and

,

∈

ℛ

, ∀∈

{

1,2,…,

}

.

In this way, the problem chromosome is formed

by the genes

=

,

,

(

)

and hence represents

a product processing order in JSSP.

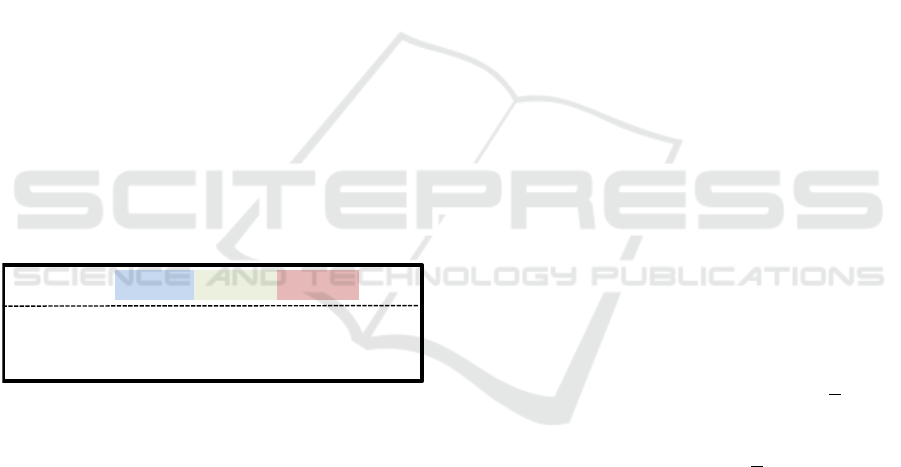

Figure 1 shows an example of chromosome and

some scripts for this modeling applied to a 3×3

JSSP.

Figure 1: Example of chromosome and scripts.

Thus, in the example shown in Figure 1, the list of

operations that the processing of jobs

,

and

must obey, following scripts

,

,

,

and

,

respectively and according to the priority sequence

defined on chromosome , would be the next:

1)

processing starts at

;

2)

processing starts at

as soon as it is vacant;

3)

processing starts at

;

4)

processing starts at

as soon as it is vacant;

5)

processing at

begins;

6)

processing starts at

as soon as it is vacant;

7)

processing starts at

as soon as it is vacant.

It is noteworthy that, by construction, the

feasibility of this modeling is maintained, as

presented by Morandin et al. (2008a).

3.2 Fitness Function

The objective function of this work is the time taken

to process the products of the JSSP, according to the

configuration given in the input chromosome. Thus,

the definition of this function is given in Equation (4):

fit

(

C

)

=MKS,

(4)

in which, MKS is the makespan value of

configuration , defined in Equation (1).

Thus, the goal of the GA developed here is to find

the configuration that has the lowest possible

makespan value.

3.3 Transgenic Operator Codification

3.3.1 Transgenic Operator

Let us suppose at this stage of the study that a set of

genes that we know carry "good features" is given,

since in this subsection we describe how the

transgenic operator works given a set of better genes.

In the next subsection we describe a most relevant

gene selection technique that we use in this paper to

define which genes should be transferred in the

transgenic operator.

We propose, in a preliminary way, that the genes

set for use in the transgenic operator are the index

genes =

,

,…,

Trans

, so that the elements

of are

Trans

index of genes

=[

,

,

] on the

set

{

1,2,...,

}

, where is the number of genes in a

chromosome and

Trans

is the number of genes to be

transferred in the operator.

In order to control the reduction of population

diversity, we propose the use of

Trans

≤

√

, since

if genes are replicated in large quantities, transgenic

individuals may present endogenous phenomena. In

this work, we take

Trans

=ceil

√

.

In order for the concept of transgenesis to be

maintained, we propose to transfer genes from a

model individual, which is the individual with the

best fitness, to the worst individuals. That is, in each

generation , we take the best individual

∗

and

transfer its genes, whose indices belong to , to the

Trans

worst individuals of the same generation.

Thus, the transgenic individual will have the index

genes belonging to in the same coordinates

(positions) in which they are arranged in the best

individual. And the remaining genes will occupy the

remaining coordinates respecting the order in which

they were in the individual before suffering

transgenics. An operation scheme of the transgenic

0

1,1

=

(

1

,

2

,

3

)

2

,

1

=

(

1

,

3

)

3,2

=

(

2

,

1

)

=

1

,

1,1

2

,

2,1

3

,

3,2

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

466

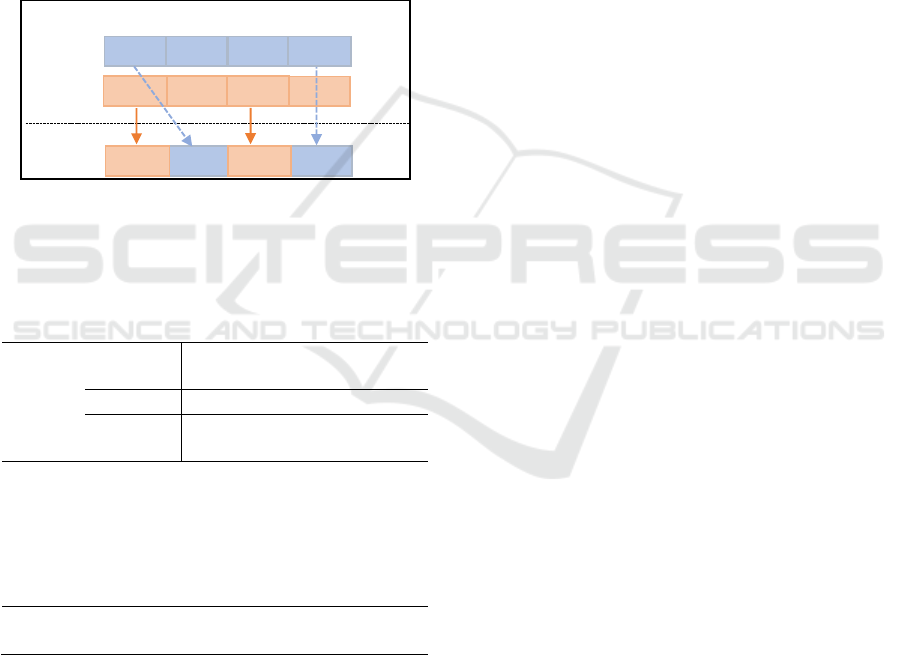

operator is shown in Figure 2, given a set of indices

, a subject

∗

considered as an individual with

good features, and an individual that will receive

transgenic genes, it is possible to construct a

transgenic individual ̂.

Thus, the transgenic operator is modelled

according to the function trans

∗

(

⋅

)

presented in

Equation (5).

trans

∗

(

)

=trans

∗

,

,

,…,

,

,

=trans

∗

,…,

(5)

=

,…,

∗

,…,

∗

,…,

Tran

s

∗

,…,

,

in which,

∗

=(

∗

,

∗

,…,

∗

) is the best individual

in the current generation.

Figure 2: Transgenic operator application example.

In this way, the transgenic operator is defined in

detail in Algorithm 3 below.

Algorithm 3: Transgenic operator.

Input:

Trans

Number of individuals to

get transgenics

Ω

Current population

Index of genes to be

transferred

(1)

∗

≔ Individual with best fitness on Ω

(2)

,

,…,

Trans

≔ The

Trans

worst

individuals in Ω

(3)

For =1 to

Trans

do:

(4)

≔trans

∗

(

)

(5) End

Output:

,

,…,

Trans

Transgenic

individuals

It is worth noting that the chromosomes generated

by the transgenic operator have their feasibility

guaranteed by Equation (5), that is, the operator is

also feasible by construction, since the genes (jobs)

chosen to be transferred by transgene (set ) will

already have their guaranteed position in the

chromosomes generated, which is the position

established by the best individual in the population,

while the genes that do not belong to the set will

receive the position in which they present themselves

in the worst individuals.

In the next subsection, a method for determining

the most significant genes is presented. In other

words, we have established how to construct the set

so that the indices of the genes selected to be

transferred by the transgenic operator transfer good

features to the affected individuals.

3.3.2 Method to Find More Significant

Genes

A necessary step to perform the Genetic Algorithm

with Transgenic Operator is to determine which genes

are the most significant to the problem, ie, which

genes will be transmitted from the best individual to

other individuals in the population in order to direct

the worst individuals to the best solutions.

In this work we propose a method to determine the

most significant genes, this method uses as a principle

of weighted average and simulation, the latter being

the concept of applying repeatedly the metaheuristic

developed in the JSSP scenario we wish to solve

before actually applying the algorithm to a given

problem.

Specifically, the elaborated method simulates the

behavior of GA with Transgenic operator, in which

each gene individually must be simulated as the most

significant through the Transgenic operator and such

simulations are performed over

generations. In

each simulation, the difference between the fitness

value of an individual prior to the use of the

Transgenic operator and after the use of the

Transgenic operator is saved over this generations, so

that it is possible to evaluate some improvements in

individuals by applying certain genes in the

Transgenic stage.

In each simulation performed, the improvement of

the modified individuals is stored during the

generations of the Transgenics process. Improvement

is measured by the difference between an individual's

fitness value before using Transgenics and after using

Transgenics. Thus, in a simulation that the gene

=

[

,

,

] is the most significant, a vector

∈ℝ

×

storing the average improvement between the

individual fitness values before and after transgenic

application is created. At the end of all generations of

the fixed gene simulation, the difference matrix is

defined, as shown in Equation (6) below.

=

|||

…

|||

.

(6)

=

{

2,4

}

∗

=

4

,

4,1

3

,

3,2

2

,

2,2

1

,

1,2

̂

=

4

,

4

,

1

3

,

3

,

1

2

,

2

,

2

1

,

1

,

3

=

3

,

3,1

2

,

2,5

4

,

4,2

1

,

1,3

Transgenic Genetic Algorithm to Minimize the Makespan in the Job Shop Scheduling Problem

467

After the simulation and generation step of the

improvement matrix , a weighted average is used to

calculate which genes are most significant. For each

column

the measures of mean , standard

deviation and largest difference are calculated.

These measurements are included in the calculation

of the weighted average W, given by Equation (7),

which is a vector score containing a coordinate for

each gene in the chromosome. The higher the score

of a gene in W, the more significant we consider it.

W

(

)

=

(

)

+2⋅

(

)

+3⋅

(

)

6

.

(7)

All measures used in the weighted average

calculation were chosen for certain purposes.

Standard deviation was applied to verify the

convergence speed of the possible improvements

obtained. Mean was applied to assess whether a

given gene influences a high or low improvement

over all generations. Largest difference was applied

by determining which genes contribute to great

instantaneous improvement, representing the

influence of a given gene on a generation. The weight

values used for each statistical property used in the

Weighted Average Measurement presented were

obtained through evaluations of a grid search.

3.4 Basic Operators

The genetic algorithm we developed is based on the

genetic algorithm of Morandin et al. (2008a) used in

the resolution of JSSPs of size 9×9 and the main

contribution of this work is the adaptation of the

transgenic operator for use in JSSP and the evaluation

of this in larger problems. In this way, all the standard

operators of our GA, such as crossover and mutation,

are the same operators described by Morandin et al.

(2008a). For the selection operator, we use the

technique of roulette wheel and for insertion operator

we use elitism.

4 RESULTS AND DISCUSSION

4.1 Experimental Settings and

Benchmark Specification

As this work was developed using a modeling similar

to the one used by Morandin et al. (2008a), Morandin

et al. (2008b) and Kato et al. (2010), so the

evaluations are performed on a similar benchmark

used by the authors of the referred works, which

consists of specialized scenarios for the used

modeling. In this way, the scenarios evaluated are of

similar or more complex dimensions to the

dimensions of the most commonly used state-of-the-

art base instance configurations, such as Lawrence

(1984), which were not used in this paper because it

has only one script per job and fixed size, thus

presenting great distinction to the experiments

performed in the works used for comparison.

However, the scenarios evaluated in this experiment

have dimensions equivalent to those in Lawrence's

bases.

The method described in this paper was evaluated

in a specific job shop scheduling problem of size 9 ×

9, which consists of a problem of =9 jobs and

=9 machines, which was found and detailed by

Kato et al. (2009). Two more complex JSSP scenarios

were generated to test the scope of the method and its

direction in the search space. A specific job shop

scheduling problem of size 20×8 and a job shop

scheduling problem of size 100×40, which were

generated following the same rules as the 9×9

scenario.

Specifically, the times at which jobs take to be

processed by machines were randomly generated

following a uniform distribution within the time range

[400,500]. For each product, 2 to 5 scripts were

randomly generated, containing 5 to 7 machines per

script, as detailed in Table 1. Each of these scenarios

was generated before all evaluations were performed.

Thus, the metaheuristics compared here acted on the

same JSSP scenarios, so that the tests were as honest

as possible.

Table 1: Benchmark specification.

Scenario 1 Scenario 2

Jobs

9 20 100

Machines

9840

Production

time

[400,500] [400,500] [400,500]

Scripts per

job

2

{

2,3,4,5

}

{

2,3,4,5

}

Machines

per script

{

5,6,7

}

{

5,6,7

}

{

5,6,7

}

The number of evaluations was set to 35 for each

technique in order to use the non-parametric

Wilcoxon tests (Veldhuizen and Lamont, 2000) to

determine if our method presents competitive results

to the compared metaheuristics. In addition, the

statistical properties presented by the tests can be

viewed in box plots visualizations.

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

468

All the algorithms tested were coded in Matlab

software. All tests were run on a notebook with i7

processor and 16GB RAM.

4.2 Results of the Proposed Algorithm

and Comparisons with Other

Works

In order to compare the efficiency of the proposed

method (GA-Trans), we implemented some

metaheuristics already successfully used in JSSP: GA

(Morandin al., 2008a); Adaptive GA (AGA)

(Morandin et al., 2008b); and Ant Colony

Optimization (ACO) (Kato et al., 2010).

We try to follow as closely as possible the settings

presented in each work for honest results. However,

the configurations of our method are more similar to

GA and AGA metaheuristics configurations, which

makes sense, since these algorithms differ only in the

use of specific operators. Thus, the configurations of

the GA, AGA and GA-Trans techniques are presented

in Table 2 and the configurations used by the ACO

are set out in Table 3.

Table 2: State-of-the-art configuration on GAs.

GA AGA GA-Trans

Number of

chromosomes

30 30 30

Crossover

Rate

0.8 0.8 0.8

Mutation Rate

0.05 0.05 0.05

Iterations

200 200 200

Trans

- -

12

Stopping

Criterion

Iterations Iterations Iterations

Table 3: State-of-the-art configuration on ACO.

Number of Ants

50

1

2

10

0.25

Evaporation

0.02

Iterations

75

Stopping Criterion Iterations

In addition, we apply the methodology described

in section 3.3.2 to determine which genes should be

used ( ) in the transgenic operator. The genes

obtained are shown in Table 4.

Table 4: More significant genes.

Scenario Genes

×

[

2,4,7

]

×

[

1,4,10,13,18

]

×

[

5,21,33,49,53,68,72,80,93,100

]

4.2.1 Results Comparison

Scenario ×.The first scenario evaluated is the

used by Morandin et al. (2008a), Morandin et al.

(2008b), Kato et al. (2009) and Kato et al. (2010). The

35 tests are show in Table 5. So, the maximum value

obtained by each technique is colored red and the

minimum value is colored blue.

Table 5: Results of 35 Tests.

ACO GA AGA GA-Trans

1

4632 4698 5015 4670

2

4669 4936 4677 4944

3

4977 4752 4673 4632

4

4945 4956 4640 4635

5

4929 4694 4741 4691

6

4872 4996 4718 4929

7

4746 4917 4944 4848

8

4754 4981 4688 4632

9

4693 4954 4989 4688

10

4901 5051 4632 4848

11

4968 4848 4659 4635

12

4736 4991 4934 5019

13

4688 4705 4921 4688

14

4956 4718 4956 4635

15

4895 4988 4925 4929

16

4734 4725 4945 4635

17

4788 5042 4880 4860

18

4782 4945 4848 4632

19

4704 4934 4956 4688

20

4899 5068 4945 4677

21

4752 4891 4848 5051

22

4785 4669 4951 4670

23

4752 4951 4919 4776

24

4929 4958 5006 4656

25

4860 4848 4968 4691

26

4763 4710 4693 4718

27

4688 4925 4705 4670

28

4642 4898 4984 4979

29

4688 4848 4759 4635

30

4909 4945 4944 4635

31

4693 4848 4735 4670

32

4692 4679 4635 4654

33

4898 5168 4929 4929

34

4646 4705 4956 4635

35

4946 4901 4632 4677

Analyzing Table 5 and Table 6, it can be

concluded that the proposed technique presented, on

Transgenic Genetic Algorithm to Minimize the Makespan in the Job Shop Scheduling Problem

469

average, makespan values that are smaller than the

other techniques. In addition, GA-Trans presented the

smallest makespan (4632) when considering the 35

evaluations conducted. In addition, GA-Trans

presents as the most often occurring value the value

4635, which is a makespan value that is less than the

minimum value presented by the GA and a value that

is very close to the minimum makespan presented by

the other methods.

Table 6: Statistical Measures.

ACO GA AGA GA-Trans

Mean

4797.4 4881.2 4838.5 4741.7

Standard

Deviation

110.3 130.1 134.3 131.3

Minimum

Value

4632 4669 4632 4632

Maximum

Value

4977 5168 5015 5051

Mode

4688 4848 4956 4635

Average

of time (s)

6.62

1.12 1.66 1.53

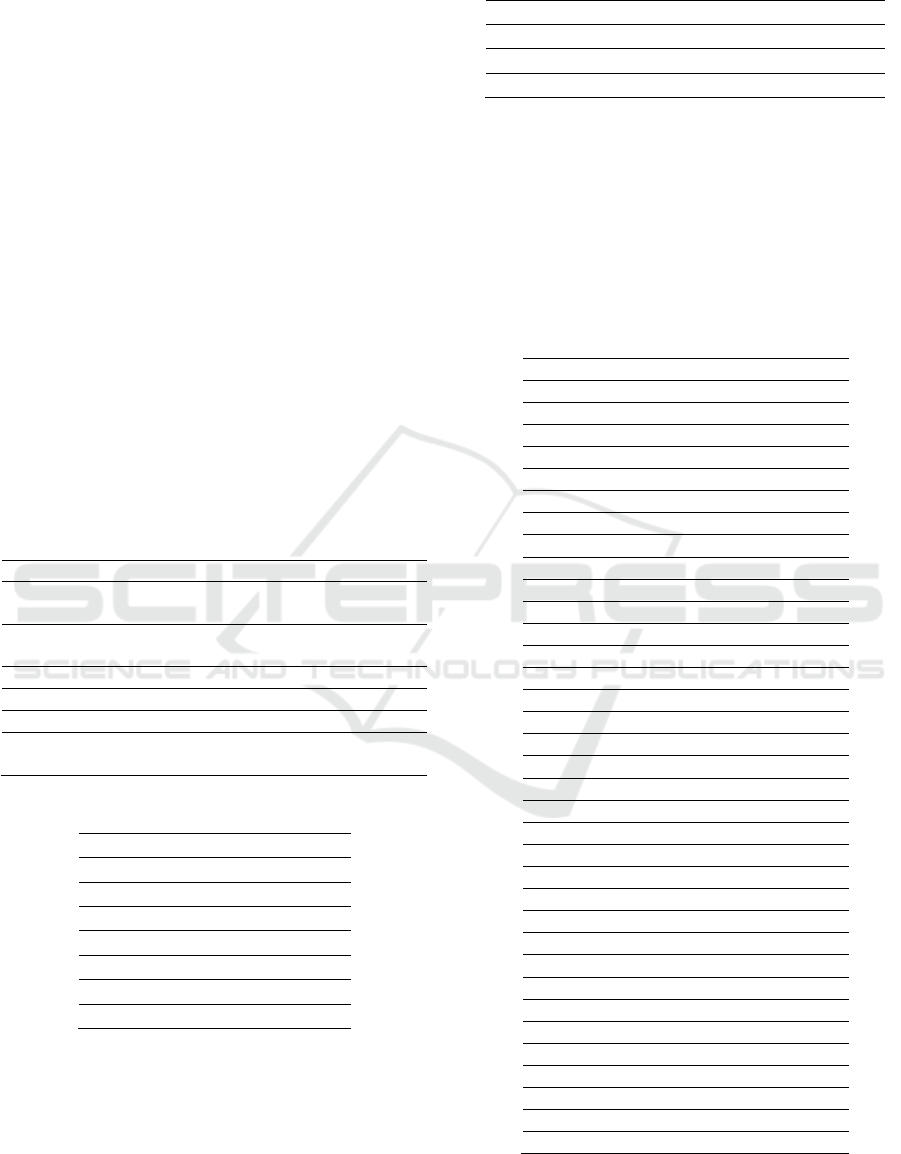

With respect to the average time of the GA-Trans,

it can be affirmed that it is very competitive to GA-

like methods and usually takes only 23,11% of the

time spent by the ACO, as can be observed in more

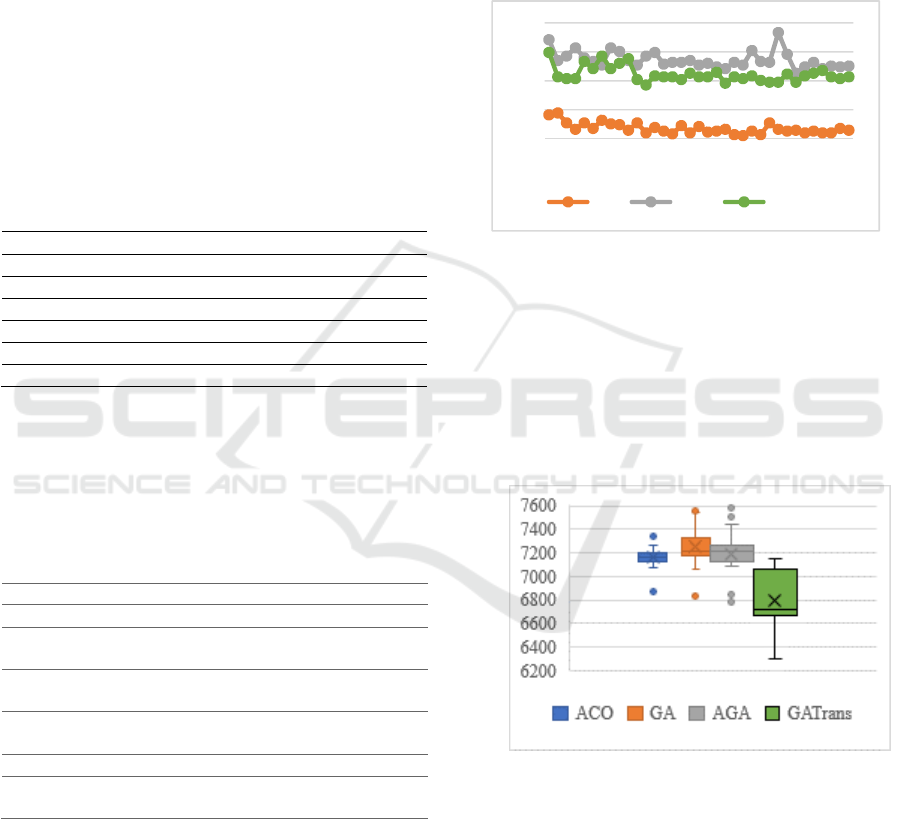

detail in Figure 3.

Figure 3: Time taken in 35 tests for each technique.

Although GA-Trans does not present the smallest

worst makespan, it can be observed in the box plot of

Figure 4 that it is a discrepant value of the technique.

In fact, we can see that GA-Trans is the method that

usually presents the best results in comparison with

the other techniques.

Figure 4: Box plot of the methods’ results.

Convergence graphs were constructed of the

proposed algorithm and the three algorithms tested, to

evaluate the evolution of the entire population of the

algorithm when iterations of the method are

advanced. Specifically, all methods were used to

generate a solution, and all individuals involved in the

process were evaluated. In this way, graphically, the

-axis shows the average of all of the makespan

values reached by the individuals (chromosomes or

ants) of a population along the iterations of each

technique, and the -axis shows its number of

iterations (generation). The purpose of these graphs is

to demonstrate how fast or slow the algorithm is in

finding an optimal solution. As seen in the

convergence graphs of the algorithm, the GA with the

transgenic operator shown in Figure 5, which is being

directed through the application of transgenics of the

most significant genes, has a convergence that

requires fewer iterations if compared to a simple GA,

to an Adaptive GA or to an ACO. With this finding,

we note the advantage in a faster convergence that a

GA with a transgenic operator can offer. Furthermore,

according to the graph, there is no consensus among

ACO ants in the observed evaluation, since the ants

that find the minimum makespan do not significantly

change the mean of the whole population.

Figure 5: Mean fitness function of a chromosome or ant

population over 75 iterations of each method.

0

2

4

6

8

1 3 5 7 9 11131517192123252729313335

ACO GA AGA GATrans

4600

4900

5200

5500

5800

6100

6400

1 6 11 16 21 26 31 36 41 46 51 56 61 66 71

ACO GA AGA GATrans

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

470

The Wilcoxon test is used to infer if two samples

come from the same distribution and, if they are not,

the test also classifies which sample is composed of

statistically lower values. Thus, we use this statistical

test to decide whether GA-Trans is statistically

equivalent to some other metaheuristic evaluated. As

observed in Table 7, assuming as initial hypothesis

(

) that GA-Trans is equal to some other

metaheuristic, the Wilcoxon test presents zero or

almost zero -values (0.0026 and 0.0072), which

means that the initial hypothesis must be discarded as

it is very unlikely. Similarly, assuming that GA-Trans

has makespan values statistically lower than the

values presented by other metaheuristics, the

Wilcoxon test presents -values equal to or very close

to 1, which guarantees that GA-Trans presents

statistically lower values.

Table 7: Wilcoxon test.

-Value

Confidence Level

GA-Trans=GA

0 95%

GA-Trans<GA

1 95%

GA-Trans=GA

0.0026 95%

GA-Trans<GA

0.9987 95%

GA-Trans=GA

0.0072 95%

GA-Trans<GA

0.9965 95%

Scenario ×. The parameter settings of the

methods were the same as the previous test, Table 2-

4. In Table 8, some statistical measures extracted

from the 35 evaluations on the 20×8 scenario are

presented.

Table 8: Statistical Measures.

ACO GA AGA GA-Trans

Mean

7164.8 7252.3 7193.6 6799.0

Standard

Deviation

76.3 169.3 198.1 197.7

Minimum

Value

6870 6829 6788 6301

Maximum

Value

7342 7584 7583 7146

Mode

− 7254 7221 6688

Average

of time (s)

17.35 2.07 3.26 3.01

As we can see in Table 8, the results obtained in

the 20×8 scenario by the proposed technique are, on

average, smaller than the values presented by the

other techniques. In addition, GA-Trans presented the

smallest makespan (6301) of all of the techniques

discussed when considering the 35 evaluations

conducted in each. In addition, GA-Trans presents as

the most often occurring value the value 6688, which

is a makespan value that is less than the minimum

value presented by the ACO, GA and AGA.

With respect to the average time of the GA-Trans,

it can be affirmed that it is very competitive to GA-

like methods and usually takes only 17,34% of the

time spent by the ACO, which makes the time spent

by the ACO a noncompetitive time, so we present in

Figure 6 a comparison between the times spent by the

compared GA-like techniques.

Figure 6: Time taken in 35 tests for each technique.

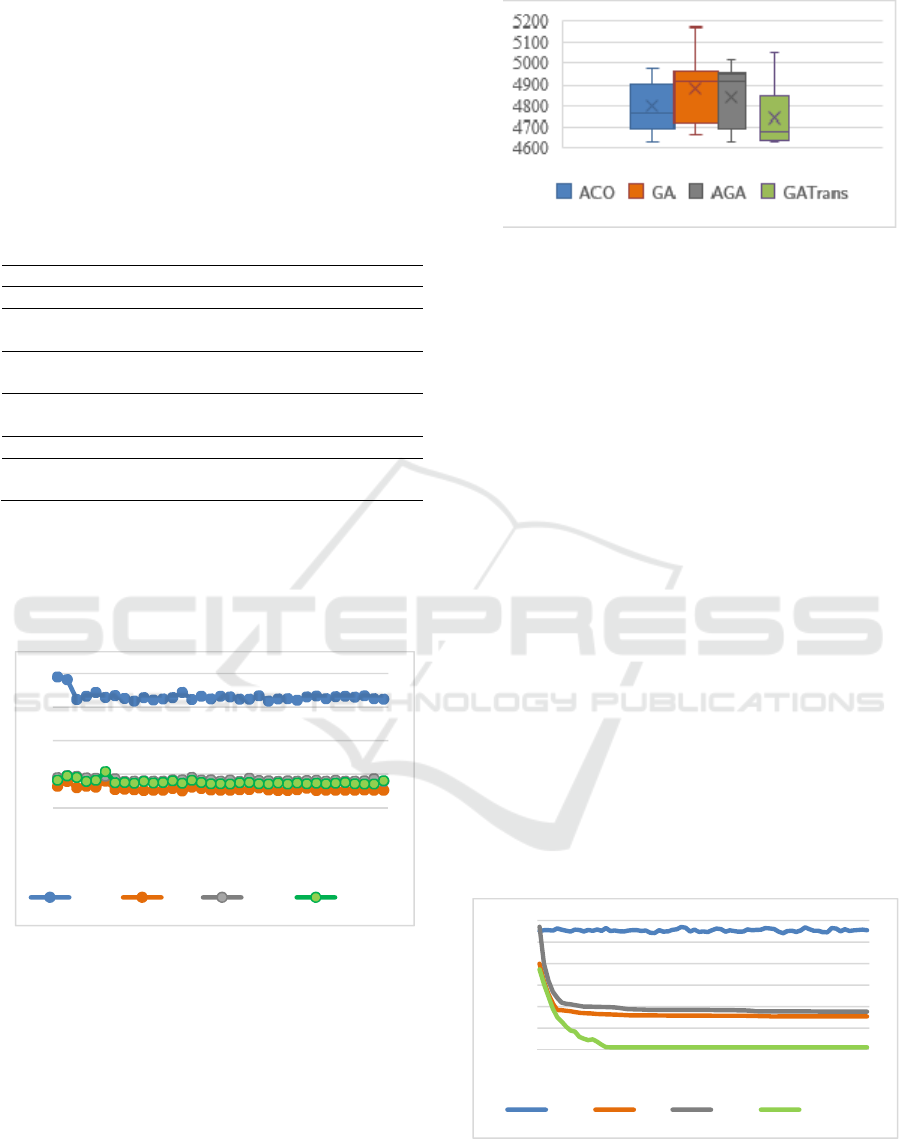

It can be observed in the box plot of Figure 7 that

GA-Trans presents significantly better results than

the other methods. In fact, the increase in the

complexity of the scenario increased the differences

presented by the comparative techniques and made

GA-Trans stand out among the others. Using the

Wilcoxon test would be redundant in stating that GA-

Trans gives the best results.

Figure 7: Box plot of the methods’ results.

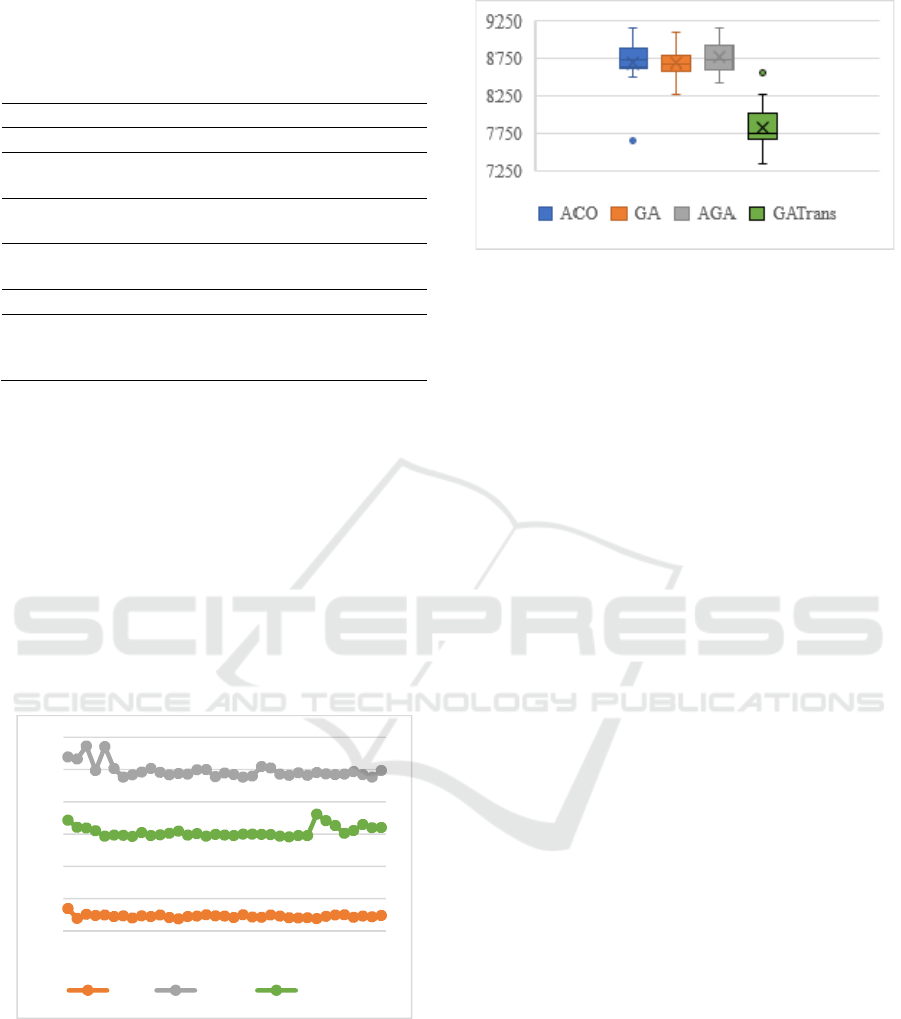

Scenario ×. The parameter settings of the

methods were the same as the previous test, Table 2-

4. Similar to the other scenarios, as we can see in

Table 9, GA-Trans presented even more promising

measures than in the other less complex scenarios. In

the case, GA-Trans presented the smallest makespan

( 7348) of all of the techniques discussed when

considering the 35 evaluations conducted in each. In

addition, GA-Trans presents as the most often

occurring value the value 8016, which is a makespan

1,9

2,4

2,9

3,4

3,9

1 4 7 101316192225283134

GA AGA GATrans

Transgenic Genetic Algorithm to Minimize the Makespan in the Job Shop Scheduling Problem

471

value that is less than the minimum value presented

by the GA and AGA.

Table 9: Statistical Measures.

ACO GA AGA GA-Trans

Mean

8682.7 8677.3 8757.8 7830.1

Standard

Deviation

350.0 164.7 192.0 254.3

Minimum

Value

7643 8274 8423 7348

Maximu

m Value

9162 9105 9162 8569

Mode

8793 8667 − 8016

Average

of time

(s)

115.37 13.91 22.93 19.14

With respect to the average time of the GA-Trans,

it can be affirmed that it is very competitive to GA-

like methods and usually takes only 16.59% of the

time spent by the ACO, as it can be observed in more

detail in Figure 8.

In Figure 9 it is possible to observe that GA-Trans

maintained its good search direction, achieving much

better results than the compared methods. Moreover,

the difference between the compared techniques is so

great in these last two scenarios that the use of the

Wilcoxon test has become redundant, as the box plot

show that GA-Trans statistically gets lower makespan

values than the other techniques addressed.

Figure 8: Time taken in 35 tests for each technique.

With the obtained results it is possible to verify

that the proposed method obtains good results in

scenarios of less complexity and the results are more

evident in the ones of greater complexity. Besides, the

proposal was able to find better makespan results in a

competitive processing time.

Figure 9: Box plot of the methods’ results.

5 CONCLUSION

The objective of the paper was to develop an

alternative version of the transgenic operator

proposed by Amaral and Hruschka (2014) to reduce

the makespan in job shop scheduling problem. The

proposal was evaluated, and the results obtained were

compared to other approaches proposed in related

work (Morandin et al., 2008a; Morandin et al., 2008b;

Kato et al., 2010), using as an evaluation criteria the

minimization of the makespan value and the time to

obtain the response. The Transgenic operator

proposed in this work is an altered and adapted

version of the original operator proposed by Amaral

and Hruschka (2014), in this way it is a new operator

that was inspired by the original operator with the

focus of obtaining a better performance in the specific

problem. Some changes were proposed in the original

operator with the purpose of a simplification of the

method and a better use in the JSSP. Therefore, the

fundamental contribution of this work is this new

operator that translates into efficiency in the

optimization of the JSSP and also the significant

improvement of the results obtained in a scenario

present in the literature with a competitive time.

The first JSSP scenario that was evaluated (9×

9), comparing the makespan values obtained, there

was a tendency of improvement of the proposed

algorithm in 82.86% of the cases in comparison to

the results obtained with the GA and in 71.43% with

the AGA. In comparison with the ACO technique,

there was a tendency to improve the proposed

algorithm in 65.71% of the cases. The mean

execution time of the proposed algorithm was 1.53

seconds, while the mean time spent by the GA was

1.12 seconds; the Adaptive GA used 1.66 seconds,

and the ACO used 6.62 seconds, i.e., there was an

increase of 36.6% when the proposed technique was

compared with GA, and there was a reduction in the

13

15

17

19

21

23

25

1 3 5 7 9 11131517192123252729313335

GA AGA GATrans

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

472

processing time of the proposed algorithm of 7.83%

with respect to the AGA and a reduction of 76.89%

with respect to the ACO. In addition, by comparing

the values of the makespan obtained for the problem

addressed, it is possible to conclude by means of the

Wilcoxon statistical test, with 95% confidence, that

the proposed method will have better results than the

results obtained by the GA, Adaptive GA and ACO.

With respect to the last two evaluated scenarios,

the box plot visualization showed that the GA-Trans

technique presented much better results than the other

techniques approached, statistically outperforming

them and it was useful to confirm the versatility of the

proposed method.

The genetic algorithm with a transgenic operator

is promising in solving the JSSP. Thus, it is

convenient that in future studies, the proposed

algorithm is applied in problems similar to the JSSP,

since the GA with transgenic operator obtained more

significant results when compared to other

metaheuristics. In this way, it is possible to work

equivalently when applied to other combinatorial

problems. It would also be interesting to study

possible alternative techniques to determine the most

significant genes that are passed in the transgenics.

REFERENCES

Amaral, L. R., & Hruschka Jr, E. R. (2014). Transgenic: An

evolutionary algorithm operator. Neurocomputing, 127,

104-113.

Antonio, L. M., & Coello, C. A. C. (2017). Coevolutionary

multiobjective evolutionary algorithms: Survey of the

state-of-the-art. IEEE Transactions on Evolutionary

Computation, 22(6), 851-865.

Asadzadeh, L. (2015). A local search genetic algorithm for

the job shop scheduling problem with intelligent agents.

Computers & Industrial Engineering, 85, 376-383.

Dao, T. K., Pan, T. S., & Pan, J. S. (2018). Parallel bat

algorithm for optimizing makespan in job shop

scheduling problems. Journal of Intelligent

Manufacturing, 29(2), 451-462.

Guo, P., Wang, X., & Han, Y. (2010). The enhanced genetic

algorithms for the optimization design. In 2010 3rd

International Conference on Biomedical Engineering

and Informatics (Vol. 7, pp. 2990-2994). IEEE.

Hasan, S. K., Sarker, R., & Essam, D. (2010). Evolutionary

scheduling with rescheduling option for sudden

machine breakdowns. In IEEE Congress on

Evolutionary Computation (pp. 1-8). IEEE.

Holland, J. (1975). Adaptation in natural and artificial

systems: an introductory analysis with application to

biology. Control and artificial intelligence.

Holland, J. H. (1992). Adaptation in natural and artificial

systems: an introductory analysis with applications to

biology, control, and artificial intelligence. MIT press.

Hosseinabadi, A. A. R., Vahidi, J., Saemi, B., Sangaiah, A.

K., & Elhoseny, M. (2019). Extended genetic algorithm

for solving open-shop scheduling problem. Soft

computing, 23(13), 5099-5116.

Kato, E. R., Morandin, O., & Fonseca, M. A. S. (2009). Ant

colony optimization algorithm for reactive production

scheduling problem in the job shop system. In 2009

IEEE International Conference on Systems, Man and

Cybernetics (pp. 2199-2204). IEEE.

Kato, E. R., Morandin, O., & Fonseca, M. A. S. (2010). A

Max-Min Ant System modeling approach for

production scheduling in a FMS. In 2010 IEEE

International Conference on Systems, Man and

Cybernetics (pp. 3977-3982). IEEE.

Kazemi, A., Mohamed, A., Shareef, H., & Zayandehroodi,

H. (2012). An Improved Power Quality Monitor

Placement Method Using MVR Model and Combine

Cp and Rp Statistical Indices. Journal of Electrical

Review, 88, 205-209.

Kundakcı, N., & Kulak, O. (2016). Hybrid genetic

algorithms for minimizing makespan in dynamic job

shop scheduling problem. Computers & Industrial

Engineering, 96, 31-51.

Kurdi, M. (2016). An effective new island model genetic

algorithm for job shop scheduling problem. Computers

& operations research, 67, 132-142.

Lawrence, S. (1984). Resouce constrained project

scheduling: An experimental investigation of heuristic

scheduling techniques (Supplement). Graduate School

of Industrial Administration, Carnegie-Mellon

University.

Lu, H., Shi, J., Fei, Z., Zhou, Q., & Mao, K. (2018a).

Analysis of the similarities and differences of job-based

scheduling problems. European Journal of Operational

Research, 270(3), 809-825.

Lu, P. H., Wu, M. C., Tan, H., Peng, Y. H., & Chen, C. F.

(2018b). A genetic algorithm embedded with a concise

chromosome representation for distributed and flexible

job-shop scheduling problems. Journal of Intelligent

Manufacturing, 29(1), 19-34.

Morandin, O., Kato, E. R., Deriz, A. C., & Sanches, D. S.

(2008a). A search method using genetic algorithm for

production reactive scheduling of manufacturing

systems. In 2008 IEEE International Symposium on

Industrial Electronics (pp. 1843-1848). IEEE.

Morandin, O., Sanches, D. S., Deriz, A. C., Kato, E. R. R.,

& Tsunaki, R. H. (2008b). An adaptive genetic

algorithm based approach for production reactive

scheduling of manufacturing systems. In 2008 34th

Annual Conference of IEEE Industrial Electronics (pp.

1461-1466). IEEE.

Naqvi, S., Zhu, C., Farre, G., Ramessar, K., Bassie, L.,

Breitenbach, J., ... & Christou, P. (2009). Transgenic

multivitamin corn through biofortification of

endosperm with three vitamins representing three

distinct metabolic pathways. Proceedings of the

National Academy of Sciences, 106(19), 7762-7767.

Nguyen, S., Zhang, M., & Tan, K. C. (2018). Adaptive

charting genetic programming for dynamic flexible job

shop scheduling. In Proceedings of the Genetic and

Transgenic Genetic Algorithm to Minimize the Makespan in the Job Shop Scheduling Problem

473

Evolutionary Computation Conference (pp. 1159-

1166). ACM.

Nie, L., Gao, L., Li, P., & Li, X. (2013). A GEP-based

reactive scheduling policies constructing approach for

dynamic flexible job shop scheduling problem with job

release dates. Journal of Intelligent Manufacturing,

24(4), 763-774.

Öztop, H., Tasgetiren, M. F., Eliiyi, D. T., & Pan, Q. K.

(2018). Iterated greedy algorithms for the hybrid

flowshop scheduling with total flow time minimization.

In Proceedings of the Genetic and Evolutionary

Computation Conference (pp. 379-385). ACM.

Peng, C., Fang, Y., Lou, P., & Yan, J. (2018). Analysis of

double-resource flexible job shop scheduling problem

based on genetic algorithm. In 2018 IEEE 15th

International Conference on Networking, Sensing and

Control (ICNSC) (pp. 1-6). IEEE.

Romero, M. A. F., García, E. A. R., Ponsich, A., &

Gutiérrez, R. A. M. (2018, July). A heuristic algorithm

based on tabu search for the solution of flexible job

shop scheduling problems with lot streaming. In

Proceedings of the Genetic and Evolutionary

Computation Conference (pp. 285-292). ACM.

Veldhuizen, D. A. V., & Lamont, G. B. (2000). On

measuring multiobjective evolutionary algorithm

performance. In Proceedings of the 2000 Congress on

Evolutionary Computation. CEC00 (Cat. No.

00TH8512) (Vol. 1, pp. 204-211). IEEE.

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

474