Clothing Category Classification using Common Models Adaptively

Adjusted to Observation

Jingyu Hu

1,∗

, Nobuyuki Kita

2

and Yasuyo Kita

2

1

Technology Platform Center, IHI Corporation Technology & Intelligence Integration, Japan

2

Intelligent Systems Research Institute, National Institute of Advanced Industrial Science and Technology (AIST),

Tsukuba, Japan

Keywords:

Clothing Categorization, Active Recognition, Recognition of Deformable Objects, Automatic Handling of

Clothing, Robot Vision.

Abstract:

This paper proposes a method of automatically classifying the category of clothing items by adaptively ad-

justing common models subject to each observation. In the previous work(Hu and Kita, 2015), we proposed a

two-stage method of categorizing a clothing item using a dual-arm robot. First, to alleviate the effect of large

physical deformation, the method reshaped a clothing item of interest into one of a small number of limited

shapes by using a fixed basic sequence of re-grasp actions. The shape was then matched with shape potential

images of clothing category, each of which was configured by combining the clothing contours of various

designed items of the same category. However, there was a problem that the shape potential images were too

general to be highly discriminative. In this paper, we propose to configure high discriminative shape potential

images by adjusting them subject to observation. Concretely, we restrict the contours used for potential images

according to simply observable information. Two series of experiments using various clothing items of five

categories demonstrate the effect of the proposed method.

1 INTRODUCTION

As home and rehabilitation robots are expected to

play an important role in an aging society, it will

become necessary for robots to automatically han-

dle daily objects including clothing items. The large

deformation of clothing items that is accompanied

by complex self-occlusion makes it more difficult to

recognize items. There have been many studies on

the recognition for handling clothes, such as those

on classification(B. Willimon and Walker, 2013)(Stria

and Hlavac, 2018), and automatic folding (J. Maitin-

Shepard and Abbeel, 2010)(S. Miller and Abbeel,

2011)(Y. Kita and Kita, 2014)(P. Yang and Ogata,

2017).

The present paper focuses on the automatic classi-

fication of clothing items into a category (e.g., shirts,

trousers) using a dual-arm robot without flattening the

items on a table. Unlike most existing methods, we

aim at a method that can work with general mod-

els of the category without requiring preregistration

of the clothing items to be recognized. Considering

the almost infinite variation in clothing shape, it is

∗

Was a student in the Department of Intelligent Interaction

Technologies of the University of Tsukuba, Tsukuba, Japan

extremely difficult to make the model of each cat-

egory that is highly discriminating among different

categories and at the same time is tolerant of intra-

category shape variation. To overcome this problem,

in the previouswork(Hu and Kita, 2015) we proposed

a two-stage method to separately deal with the shape

variation due to design variation of a category from

that caused by physical deformation. First, to lessen

the effect of physical deformation, the item of inter-

est is reshaped into one of a small number of limited

shapes in the air. Then, to absorb the shape varia-

tion of each limited shape due to the different size,

design and material within the category, we match the

shape with a potential image, which is made by com-

bining contours of clothing items of various design

and material. The feasibility tests of the work demon-

strated a high potential of the strategy. However, we

also found the defect of the shape model represented

by the potential image: while the model can cover

variation caused by large individual size, design and

materials, it has low discriminative power.

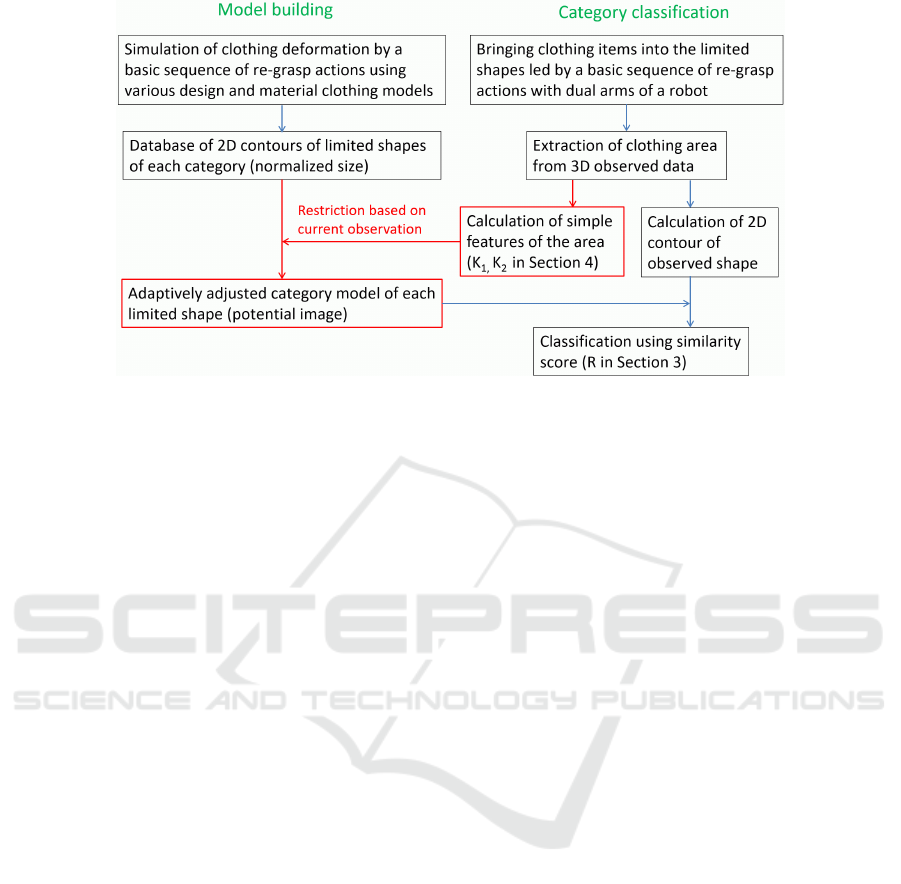

To overcome this weak point, this paper proposes

to add a feedback process from observation to the

model building process, as illustrated in Fig. 1. Al-

though we, human, naturally do such feedback, few

310

Hu, J., Kita, N. and Kita, Y.

Clothing Category Classification using Common Models Adaptively Adjusted to Observation.

DOI: 10.5220/0008936903100317

In Proceedings of the 15th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2020) - Volume 5: VISAPP, pages

310-317

ISBN: 978-989-758-402-2; ISSN: 2184-4321

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: Strategy for clothing category classification: parts colored by red are the contribution of this paper.

works take this approach: most works prepare the

model at the first and just directly use it to match with

observations.

The contribution of the present paper is to build

discriminating common models in response to each

observation. Owing to this improvement, the pro-

posed method well classifies clothing category with-

out requiring either the preregistration of individual

clothing information or a learning stage using huge

training data.

This paper is organized as follows. After survey-

ing related works in Section 2, in Section 3, we briefly

explain a base two-stage method. Section 4 describes

how to configure potential images that are adjusted

to each observed case. Section 5 presents the results

of experiments conducted using both a manual setting

and a humanoid system, and then finally, the paper is

concluded with discussions of the current status and

future direction of research in Section 6.

2 RELATED WORK

Miller et al. (S. Miller and Abbeel, 2011) used pa-

rameterized models as general models for the analysis

of clothing items flattened on a desk. However, flat-

tening an item itself is not an easy task, as shown in

other studies (e.g., (B. Willimon and Walker, 2011)),

and requires extra procedures.

Classifying the category of clothing items held

in the air has also been studied from the early

days(Hamajima and Kakikura, 2000)(F. Osawa and

Kamiya, 2007). Recently, many researchers ap-

plied a learning approach for handling clothing

items, some of which are dealing with hang-

ing clothes(A. Doumanoglou, 2014)(I. Mariolis

and Malassiotis, 2015)(Stria and Hlavac, 2018).

Doumanoglou et al. (A. Doumanoglou, 2014) used

3D features extracted from depth images of cloth-

ing items to classify the clothing category and to

detect the position to hold according to the random

forests algorithm. Although they obtained good re-

sults even for items different from those used in the

learning stage, their methods require approximately

30,000 observation data for training to achieve the re-

sults. It is uncertain if the learned classifier still works

when the situation (i.e., the robots and 3D sensors)

changes. Mariolis et al. (I. Mariolis and Malassio-

tis, 2015) applied a deep learning approach to auto-

matically extract efficient features from 3D clothing

shapes, aiming at classifying the pose and category

of clothing. They reduced the burden of the learning

stage using a synthetic database obtained by physics

based simulation. In the learning stage, however, the

method requires the model of the individual clothing

item to be recognized and does not target the general

categorization of arbitrary items. Stria et al. (Stria

and Hlavac, 2018) proposed to use 3D point clouds

of the whole circumference of a garment held by a

robot hand as input for category classification. They

extracted auto-encoder features from the point clouds

using a convolutional neural network (CNN) and use

the features for SVM classification of garment cate-

gories. When using the 3D shape of a garment after

grasping its lowest part, high success ratio was re-

ported. However, the shape held by only one hand

originally shows small difference between different

categories especially in the case of garments made of

soft materials. In addition, the output of their method

is just a type of category and does not indicate any in-

formation of the clothing state. Before taking specific

Clothing Category Classification using Common Models Adaptively Adjusted to Observation

311

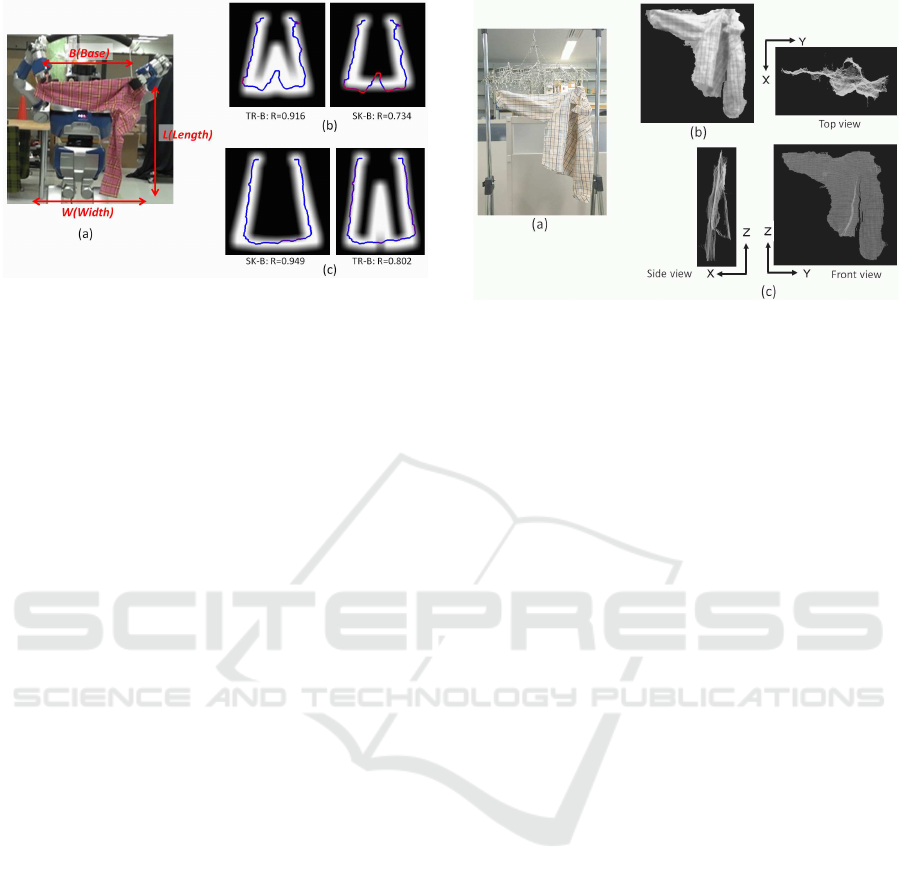

Figure 2: Two-stage method for overcoming two types of

shape variations of clothing.

handling actions such as folding and spreading, an ad-

ditional method to recognize the state is required.

For the purpose of classification of category at the

same time of recognizing the clothing state, we take

the two-stage approach shown in Fig. 2, where a

clothing item of interest is first brought into one of a

small number of limited shapes and the type of limited

shape is then recognized. Osawa et al. (F. Osawa and

Kamiya, 2007) proposed a method that re-grasps the

lowest point of clothing items twice to limit the phys-

ical deformation. The difference between their way

and ours is that we bring clothing items into more dis-

criminative shapes by finding a proper grasping posi-

tion.

3 BASE METHOD

3.1 Bringing an Item into a Limited

Shape

Fig. 2 shows the flow of our two-stage method. To

bring any item into a shape that is as discriminating

as possible without prior knowledge of the item, we

select the following sequence of actions: 1. Pick up

an item at an arbitrary point; 2. Grasp the lowest

point and release the first hand; 3. Grasp the con-

vex point closest to the currently grasped point and

spread the item. After the application of this basic se-

quence of actions, an item of any category is brought

into one of a few types of shapes. We refer to such

possible shapes as the set of limited shapes. In the

case of the five categories that we deal with in this pa-

per, all categories are brought into two types of lim-

ited shapes. Figure 3(a)–(d) shows the two limited

shapes of four of the five categories, namely long-

sleeve shirts, trousers, skirts and half-sleeve shirts,

where pink and green points illustrate the two grasp-

ing points after the sequence is executed. We refer to

Figure 3: Limited shapes of various categories.

a limited shape as, for example, “Shape A of a long-

sleeve shirt”, abbreviated as LS-A as shown in Fig. 3.

For A types, left-right symmetrical shapes also exist.

These actions are automatically done by a dual-

arm robot by the method proposed in (Hu and Kita,

2015). To detect the convex point of items such as

shoulder of shirts stably, a sequence of 3D depth im-

ages from different view directions are used to track

possible convex points during the sequential observa-

tion.

3.2 Potential Image for Representing

Intra-category Shape Variation

After bringing the clothing item of interest into one of

the set of limited shapes, the proposed method classi-

fies the type of limited shape, such as LS-A in Fig. 3,

according to the shape of the observed clothing area.

To absorb variations of the contour shape of a type

of limited shape depending on the size, design and

softness of clothing items in the category, we use a

potential image to represent each limited shape.

First, several typically designed clothing models

are built for each category. For this, we take the

shapes from different clothing items on the Inter-

net. The clothing model is represented by a simpli-

fied planar surface that deforms three-dimensionally.

As examples, pictures of long-sleeve shirts from the

Internet and the models built manually from their

shapes are shown in Fig.4(a). Limited shapes of each

category are then physically simulated using these

models by manually giving two holding positions.

For this simulation, we use the “n-cloth” function in

Maya(GOULD, 2004). To consider different fabrics

of clothing, we also change parameters of the softness

in the models, such as stretch resistance of dynamic

properties. Fig.4(b) show examples of 3D shapes for

Shape A of long-sleeve shirts obtained after the simu-

VISAPP 2020 - 15th International Conference on Computer Vision Theory and Applications

312

Figure 4: Building a database of 3D shapes (long-sleeve

shirts (LS-A)): (a) pictures of long-sleeve shirts from the

Internet and the models built from their shapes; (b) limited

shapes physically simulated using the models and different

elastic property.

Figure 5: Calculation of potential images: (a) collection of

different contours in an image; (b) smoothing of the possi-

ble shape.

lations. The two-dimensional (2D) contours extracted

from the projection of the simulated 3D shapes are

normalized based on the distance between two grasp-

ing points and integrated on a image as shown Fig.

5(a). Then the area enclosed by the contours are filled

with the value of 1.0 (the middle figure of Fig.5(b))

for the purpose of compensating the small number of

samples for infinite shape variation. Then the poten-

tial image is obtaining by smoothing the image using

a Gaussian filter (the right figure of Fig.5(b)). We re-

fer to the calculated image as the “potential image of

limited shape”. P(i, j), where (i, j) is the 2D coordi-

nates of the image.

In the observation stage, the contour of the cloth-

ing area in an observed depth image is extracted and

Figure 6: Ambiguity of potential images considering all

possible variations: (a) Shape B of trousers (TR-B); (b)

Shape B of skirts (SK-B).

normalized in the same way as the model building

process. The consistency between the extracted con-

tour and the potential image of each limited shape is

then measured using R:

R =

∑

N

n=1

P(i

n

, j

n

)

N

, (1)

where N is the number of pixels of the observed

contour and (i

n

, j

n

) denotesthe coordinatesof contour

point n(n = 1,...,N).

4 ADAPTIVE ADJUSTMENT OF A

POTENTIAL IMAGE

The potential image described above can represent

large intra-category variations in each limited shape,

but on the other hand, its generality weakens the abil-

ity to discriminate from other categories. Figure 6

shows an example, an ambiguity of potential images

between Shape B of trousers (TR-B) and Shape B of

skirt (SK-B). Because the potential image of TR-B

covers a large area owing to the high variance of the

ratio of the width and the length of trousers for chil-

dren and adults, contours of limited shapes other than

TR-B also have a high value of R (shown under each

figure) in the matching with it, and the recognition

thus becomes unreliable.

Here, we propose to feedback observed informa-

tion to the model-building process for obtaining more

discriminating models. Some information obtained

from observation using simple image processing can

lead the constraint of shape variation. Model contours

that is inconsistent to the constraint can be removed

Clothing Category Classification using Common Models Adaptively Adjusted to Observation

313

Figure 7: Potential image adjusted to observation: (a) stable

simple features specifying the clothing region; (b) improve-

ment gained using adjusted potential images.

from candidates. Concretely, we measure the three

lengths as shown in Fig. 7(a): B (base) is the horizon-

tal distance between two holding positions; L (length)

is the vertical distance between a holding position and

the lowest point of the observed item;W (width) is the

horizontal distance between the leftmost and right-

most points of the observed item. The simple ratios

between them are calculated:

k

1

= L/B, k

2

= W/B.

For each 2D model contour, m, obtained in

the process described in Section 3.2, (k

1m

,k

2m

) is

calculated and recorded in advance. When catego-

rizing an observation, (k

1

,k

2

) of the observed item

is calculated and only the model contours that are

consistent with these ratios are integrated into one

potential image. Considering the length variation

caused by the difference in how strongly stretched the

clothing item, some allowable differences, L

d

,W

d

,

from observed values of L,W are introduced. A

2D model contour m is selected only if its ratio,

(k

1m

,k

2m

), satisfies

(L− L

d

)/B < k

1m

< (L+ L

d

)/B

(W −W

d

)/B < k

2m

< (W +W

d

)/B.

(2)

Figure 7(b) and (c) shows examples of potential

images built using L,W calculated from the observa-

tion of Fig. 6(a) and (b), respectively. Through this

adjustment, potential images become more specific,

resulting discriminating against different categories,

while still absorbing intra-category shape variations.

We see the values of R of incorrect potential images

become low, while ones of correct potential images

keep high.

In all experiments of this paper, we assume the

length variation affected by the strength of pulling as

+- 3.5cm and set both L

d

and W

d

at 7 cm.

Figure 8: Observation setting for Experiments using man-

ual setting: (a) observed image; (b) 3D data of the clothing

item.

5 EXPERIMENTS

We conducted two types of experiments to separately

examine the performance of the classification method

using adjusted potential images and the practical po-

tency of the two-stage strategy using the classification

method. In both experiments, we deal with clothing

items of five categories: long-sleeve shirts, trousers,

skirts, half-sleeve shirts and towels. Because clothing

of each category is brought into two limited shapes

after the basic sequence of actions described in Sec-

tion 3.1, the task of the experiments is classification

of clothing items into one of 10 limited shapes.

In advance of the experiments, a database of 2D

contours of various limited shapes was built as ex-

plained in Section 3.2. Specifically, we chose nine

items of different design and size for each category

from pictures on the Internet and gave two types of

softness to each shape, resulting in 18 different con-

tours for each limited shape besides the towel. Be-

cause the towel has less variation in design, only 12

contours were used. Therefore, the database consists

of (18 (contours) × 4 (categories) + 12 (contours for

the towel)) × 2 (limited shapes) = 168 contours. As

we noted in Section 4, the potential images are adap-

tively calculated after observation.

5.1 Experiments using Manual Setting

We conducted experiments with different clothing

items by manually setting the items into limited

shapes. Specifically, a clothing item was hung by

being pinched at two points as shown in Fig. 8(a).

The 3D data of clothing items were obtained using a

trinocular vision system (Ueshiba, 2006) as shown in

Fig. 8(b) and (c) for the texture-mapped 3D data and

VISAPP 2020 - 15th International Conference on Computer Vision Theory and Applications

314

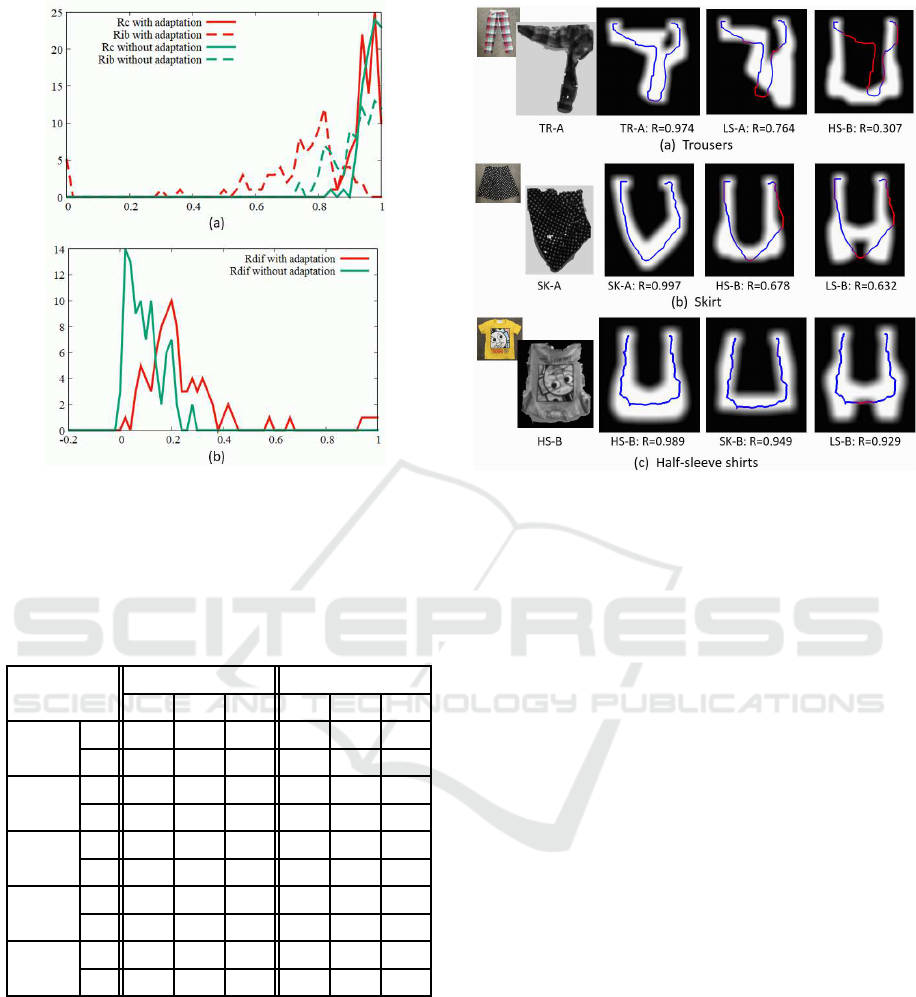

Figure 9: Variance of R

c

and R

ib

:(a) comparison of the dis-

tribution of R with (red) and without (green) model adjust-

ment; (b) distribution of the difference between R

c

and R

ib

with/without model adjustment.

Table 1: Classification results for a manual setting: the

number of success, failure and confusing (conf.) cases

when using potential images non-adjusted P(i, j) and ad-

justed P(i, j) respectively.

Limited non-adjusted adjusted

shape Success Failure Conf. Success Failure Conf.

L-sleeve A 10 0 0 10 0 0

shirts B 10 0 10 10 0 1

Trousers A 10 0 7 10 0 0

B 10 0 3 10 0 0

Skirts A 10 0 1 10 0 0

B 10 0 1 10 0 0

H-sleeve A 10 0 1 10 0 0

shirts B 3 7 3 10 0 2

Towel A 4 1 4 5 0 1

B 5 0 1 5 0 0

the 3D observed points (gray dots).

In this experiment, we used 10 long-sleeve shirts,

10 pairs of trousers, 10 skirts, 10 half-sleeve shirts

and five towels. We formed two limited shapes for

each piece of clothing, and a total of 90 observations

were thus made. The experimental results are sum-

marized in Table 1. To evaluate the effect of model

adjustment, experiments without the adjustment pro-

cess (i.e., using all contours of the database to make

potential images) were also conducted; these results

are listed in the column “non-adjusted”.

Figure 10: Results of Experiment using manual setting: the

potential image of the limited shapes with the three highest

R of (a) Shape A of trousers, (b) Shape A of skirt and (c)

Shape B of half-sleeve shirt.

The diagram of Fig. 9(a) shows the distributions

of R of the correct type, R

c

and the largest R among

the incorrect types, R

ib

. The former and latter are

plotted with solid and dashed lines respectively, while

the color red/green indicates the result with/without

model adjustment. In contrast to the result that the

distribution of R

c

does not change greatly with model

adjustment, the distribution of R

ib

largely shifted to

lower values. Figure 9(b) shows the distribution of

the difference between R

c

and R

ib

with/without the

model adjustment (red/green). The difference clearly

became large with the adjustment; the average of the

distribution increases from 0.165 to 0.238. The im-

provement in discriminant efficiency is also clearly

shown in Table 1. In all experiments, the correct

types of the limited shape were successfully selected

as shown in the column “adjusted”.

Three examples of classification results are shown

in Fig.10. The first and second columns of Fig.10

show the clothing item and the 3D observation data

of its limited shape. The last three columns show

the potential image of the limited shapes with the

three highest R in descending order. The blue and

red colored lines superposed on the potential images

show the contour extracted from the observation data.

The RGB color of each contour point (i, j), (R, G, B),

is determined as ((1 − P(i, j)),0.0,P(i, j)); contour

points with higher P(i, j) are colored more blue, while

those with lower P(i, j) are colored more red. The

Clothing Category Classification using Common Models Adaptively Adjusted to Observation

315

consistency R calculated for each potential image is

shown under the image. As shown in the examples of

Shape A of trousers (TR-A, Fig.10 (a)) and Shape A

of skirt (SK-A, Fig.10 (b)), R of the correct type was

clearly the largest in most cases. The column “con-

fusing (conf.)” in Table 1 shows the number of cases

where the difference between the largest and second

largest R is less than 0.05. There were four confusing

cases of the proposed method. Two were ambiguity

between Shape B of half-sleeve shirts (HS-B) with

very short sleeves and Shape B of skirts (SK-B) as

shown in Fig.10(c).

Owing to inaccurate 3D observation data around

the boundary of clothing regions, extracted contours

are not so smooth even after several dilation/erosion

image processes. Insensitivity to such disturbance is

one advantage of using potential images. The compu-

tational time for adaptively configuring potential im-

ages is 0.2 s (using an Intel Xeon 3.47-GHz proces-

sor) on average, which is sufficiently short for real-

time processing.

5.2 Experiments using a Humanoid

System

We examined the practical potency of the total strat-

egy, using the humanoid robot HRP-2 (Kaneko et al.,

2004) and the same trinocular vision system as used

in the first experiment set in front of the robot at a

distance of 3 m. In this experiment, we used six long-

sleeve shirts, five pairs of trousers, six skirts, seven

half-sleeve shirts and eight towels. By using some of

the items multiple times, 52 trials were done in total.

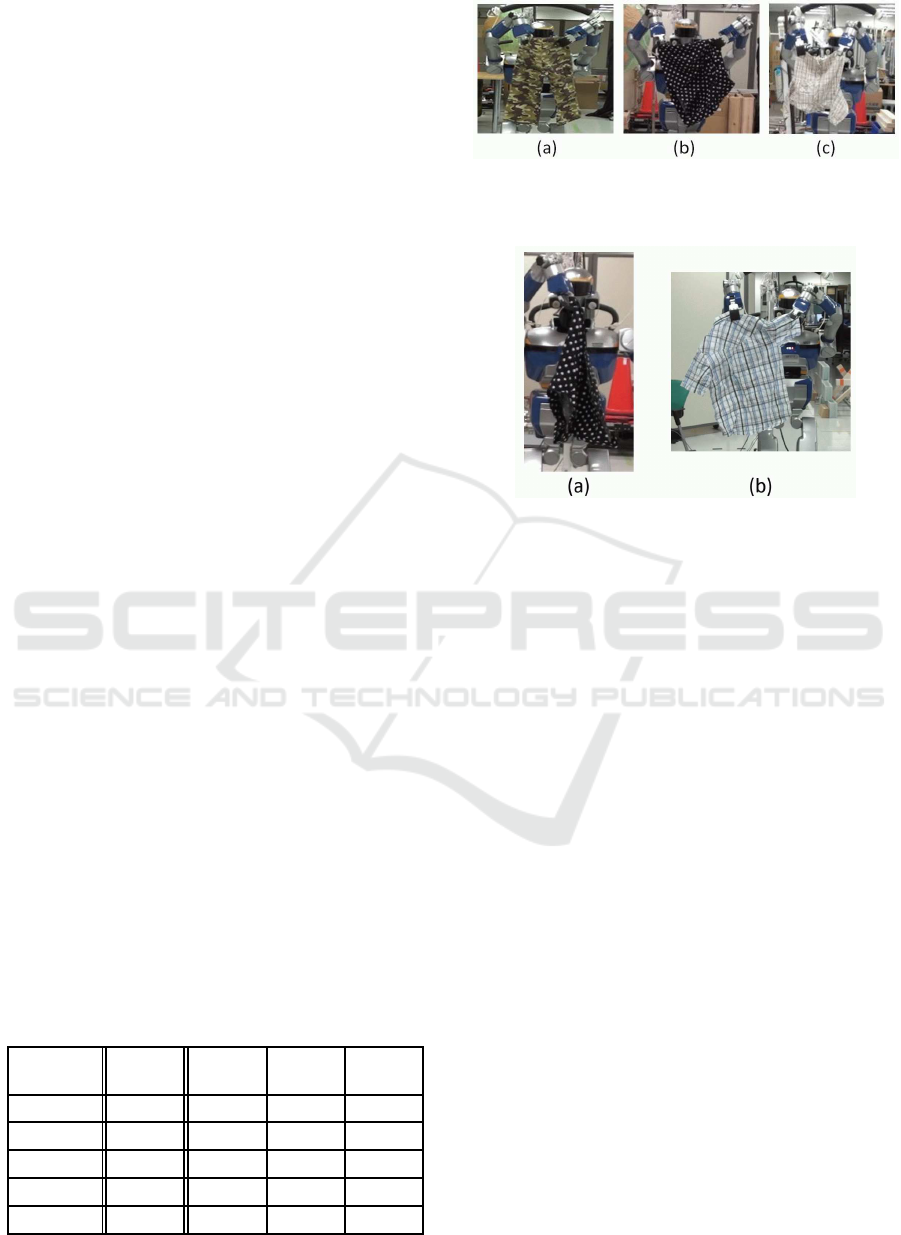

Figure 11 shows some examples of the case where

items were successfully reshaped into one of the lim-

ited shapes and then correctly classified. All experi-

mental results are summarized in Table 2. From the

third to the fifth columns, the denominator and nu-

merator are the number of experiments and success-

ful cases respectively, whereas the third, fourth and

fifth columns give the results of detection of the close

convex point, spreading the item using the detected

points, and classification using the spread shapes.

Table 2: Experimental results using a humanoid.

Category Num.

of expt.

Selection SpreadingClassifi-

cation

LS shirts 10 7/10 7/7 7/7

Trousers 11 9/11 9/9 9/9

Skirts 11 6/11 6/6 5/6

HS-shirts 10 6/10 5/6 4/5

Towels 10 6/10 4/6 4/4

Figure 11: Examples of successful spreading in Experi-

ment using a humanoid system: (a) Shape B of trousers;

(b) Shape A of skirts; (c) Shape B of long-sleeve shirts.

Figure 12: Examples of failures in Experiment using a hu-

manoid system: (a) spreading failure of a skirt; (b) classifi-

cation failure due to unexpected shape deformation.

The overall success rate of reshaping an item into

one of the limited shapes was not high, 60% (31/52).

Most of failures happened in the case of skirts, half-

sleeve shirts and towels, because we just applied the

reshaping method developed for the other two cate-

gories, long-sleeve shirts and trousers. Figure 12(a)

shows an example of the failure in detecting close

convex point of skirts. Although the current method

detects only convex points at a planar part, waist parts

of skirts were often spread into a round shape, causing

detection failures.

Once clothing items were successfully spread into

one of the limited shapes, the items were successfully

classified into the correct type of limited shape except

in the two in 31 cases. Fig 12(b) shows one failure

case: a half-sleeve shirt was spread into a perfectly

flattened shape by chance, which is not expected as

typical shapes. In this case, even the largest R became

very low and indicative of such special situation.

6 CONCLUSION

We proposed a method of clothing category classifi-

cation that builds discriminating common models us-

ing the feedback from current observation. Under the

framework where a dual-arm robot first reshapes a

clothing item into one of a small number of limited

VISAPP 2020 - 15th International Conference on Computer Vision Theory and Applications

316

shapes, two series of experiments using many dif-

ferent clothing items of five clothing categories were

conducted. Although the method of bringing cloth-

ing items into one of the limited shapes is still in a

stage of development, the classification is highly cor-

rect once the items are successfully reshaped into a

limited shape. Though we need more thorough exper-

iments for assertion, the current results showed that

the feedback of observed information to model build-

ing process enables common category models that is

highly discriminating among different categories and

at the same time is tolerant of intra-category shape

variation.

Because, in the proposed framework, the state of

the clothing item is also known at the same time as

the classification, such as Shape A of trousers in Fig.

10(a), the method can be directly connected to sub-

sequent actions for specific tasks such as folding or

spreading into a fixed shape. The results also have

high affinity with the model-drivenmethod of (Y. Kita

and Kita, 2014) to perform further tasks.

ACKNOWLEDGEMENTS

The authors thank Dr. Y. Kawai, Mr. T. Ueshiba

for their support of this research. This work was

supported by a Grant-in-Aid for Scientific Research,

KAKENHI (16H02885).

REFERENCES

A. Doumanoglou, A. Kargakos, T.-K. K. S. M. (2014). Au-

tonomous active recognition and unfolding of clothes

using random decision forests and probabilistic plan-

ning. In International Conference in Robotics and Au-

tomation (ICRA) 2014, pages pp.987–993.

B. Willimon, S. and Walker, I. (2013). Classification of

clothing using midlevel layers. ISRN Robot, pages pp.

1–17.

B. Willimon, S. B. and Walker, I. (2011). Model for un-

folding laundry using interactive perception. Int’l

Conf. on Intelligent Robots and Systems (IROS11), pp.

4871–4876.

F. Osawa, H. S. and Kamiya, Y. (2007). Unfolding of mas-

sive laundry and classification types by dual manip-

ulator. Journal of Advanced Computational Intelli-

gence and Intelligent Informatics, Vol. 11, No.5:457–

463.

GOULD, D. A. D. (2004). Complete Maya Programming.

Morgan Kaufmann Pub.

Hamajima, K. and Kakikura, M. (2000). Planning strat-

egy for task of unfolding clothes (classification of

clothes). Journal of Robotics and Mechatronics, Vol.

12, No.5:pp. 577–584.

Hu, J. and Kita, Y. (2015). Classification of the category

of clothing item after bringing it into limited shapes.

In Proc. of International Conference on Humanoid

Robots 2015, pages pp.588–594.

I. Mariolis, G. Peleka, A. K. and Malassiotis, S. (2015).

Pose and category recognition of highly deformable

objects using deep learning. In International Confer-

ence in Robotics and Automation (ICRA) 2015, pages

pp.655–662.

J. Maitin-Shepard, M. Cusumano-Towner, J. L. and Abbeel,

P. (2010). Cloth grasp point detection based on

multiple-view geometric cues with application to

robotic towel folding. In Proc. of IEEE Int’l Conf.

on Robotics and Automation (ICRA ’10).

Kaneko, K., Kanehiro, F., Kajita, S., Hirata, M., Akachi, K.,

and Isozumi, T. (2004). Humanoid Robot HRP-2. In

Proc. of IEEE Int’l Conf. on Robotics and Automation

(ICRA ’04), pages pp.1083–1090.

P. Yang, K. Sasaki, K. S. K. K. S. S. and Ogata, T. (2017).

Repeatable folding task by humanoid robot worker us-

ing deep learning. IEEE Robotics and Automation Let-

ters, Vol. 2:pp.397–403.

S. Miller, M. Fritz, T. D. and Abbeel, P. (2011). Parameter-

ized shape models for clothing. In Proc. of IEEE Int’l

Conf. on Robotics and Automation (ICRA ’11), pages

pp. 4861–4868.

Stria, J. and Hlavac, V. (2018). Classification of hang-

ing garments using learned features extracted from

3d point clouds. In Proc. of Int. Conf. on Intelligent

Robots and Systems (IROS 2018), pages pp.5307–

5312.

Ueshiba, T. (2006). An efficient implementation tech-

nique of bidirectional matching for real-time trinocu-

lar stereo vision. In Proc. of 18th Int. Conf. on Pattern

Recognition, pages pp.1076–1079.

Y. Kita, F. Kanehiro, T. U. and Kita, N. (2014). Strategy for

folding clothing on the basis of deformable models. In

Proc. of International Conference on Image Analysis

and Recognition 2014, pages pp.442–452.

Clothing Category Classification using Common Models Adaptively Adjusted to Observation

317