Low Temperature Plasma Vacuum Sterilization of Medical Devices

by using SterAcidAgent

®

: Description and Distinctive Characteristics

Aleksei E. Zhdanov

1a

, Ilya M. Pahomov

2

, Alexey I. Ulybin

2

and Vasilii I. Borisov

1b

1

Ural Federal University, Institute of Radio Electronics and Information Technology-RTF, Mira Str., Yekaterinburg, Russia

2

Lidkor LLC, Posadskaya Str., Yekaterinburg, Russia

Keywords: Low Temperature Plasma, Atmospheric-pressure Plasmas, Sterilization, RF Discharge, UV Radiation,

Diffusion, Exposition, Peroxide, Organic Acid, Sterilized Agent.

Abstract: This article presents a description and distinctive characteristics of the new method of low-temperature

sterilization. This method based on using a mixture which is consists of peroxide and organic acid as the

sterilized agent (SterAcidAgent

®

). This study shows that SterAcidAgent

®

composition has reduced the

concentration of hydrogen peroxide, it also has increased bactericidal property of the mixture. We conducted

studies of the sterilizing activity of 5-carboxylic low molecular weight acids, investigated the effect of basicity

and hydroxyl group in the alpha position on sterilizing activity, and proposed a potential composition for a

new line of sterilizing agents.

1 INTRODUCTION

The low-temperature plasma sterilization method is

used as an alternative to gas sterilization based on

ethylene oxide or formaldehyde vapor (Zhao and Li,

2018). High toxicity of ethylene oxide is a reason for

its increasing usage limitation as well as the strict

requirement of subsequent prolonged ventilation of

sterilized products (Dianfeng, 2016).

Plasma sterilization is carried out at low

temperatures (up to 60 °C) in a dry atmosphere

(Plewa and Yousfi, 2014). A pair of a 60% hydrogen

peroxide aqueous solution (peroxide) H

2

O

2

and its

low-temperature plasma is used as a sterilizing agent

(Xaplanteris and Filippaki, 2019). This combination

of these factors provides the sterilization process

estimated time to be reduced to 35-45 minutes.

According to manufacturers, a vast scope of

instruments and medical devices are not

recommended or eligible to be sterilized in high

temperature and humidity conditions (Suanpoot and

Sornsakdanuphap, 2016). These tools include

surgical, traumatological, ophthalmic, dental

(excluding burs), microsurgical instruments, optical

fibers, laser and optical fibers, electrical cords and

cables, electrical and electronic devices (Li and Hang,

a

https://orcid.org/0000-0002-8594-7660

b

https://orcid.org/0000-0003-0486-7552

2016), electrophysiological catheters (Esmond and

Winfrey, 2016), pens instruments (Ahn and Chae,

2016), breathing circuits, plastic containers and many

other. Implementation of plasma sterilizer appears to

be a decent option to such tools, especially effective

in sterilization of heat-sensitive materials products

and materials prone to active corrosion. Also, the

plasma sterilization method could be used to sterilize

hard-to-reach and finished surfaces. However, wear

and maintain performance of instruments with thin

and sharp working parts could be reduced through

plasma sterilization in a longer period in comparison

to autoclave sterilization method (Smolyakov and

Romadanov, 2015).

Using this method makes it possible to sterilize

the internal surfaces of the channels of medical

devices, such as endoscopes (diameter up to 1 mm

and length up to 3000 mm). Plasma sterilization cause

no harm to the environment since hydrogen peroxide

leaves only non-toxic components (oxygen and

water) after utilization.

The method of low-temperature plasma

sterilization is embodied in the line of low-

temperature plasma sterilizers represented by

Steriplaz

®

models manufactured by Lidkor LLC.

86

Zhdanov, A., Pahomov, I., Ulybin, A. and Borisov, V.

Low Temperature Plasma Vacuum Sterilization of Medical Devices by using SterAcidAgent

R

: Description and Distinctive Characteristics.

DOI: 10.5220/0008934500860093

In Proceedings of the 13th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2020) - Volume 1: BIODEVICES, pages 86-93

ISBN: 978-989-758-398-8; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

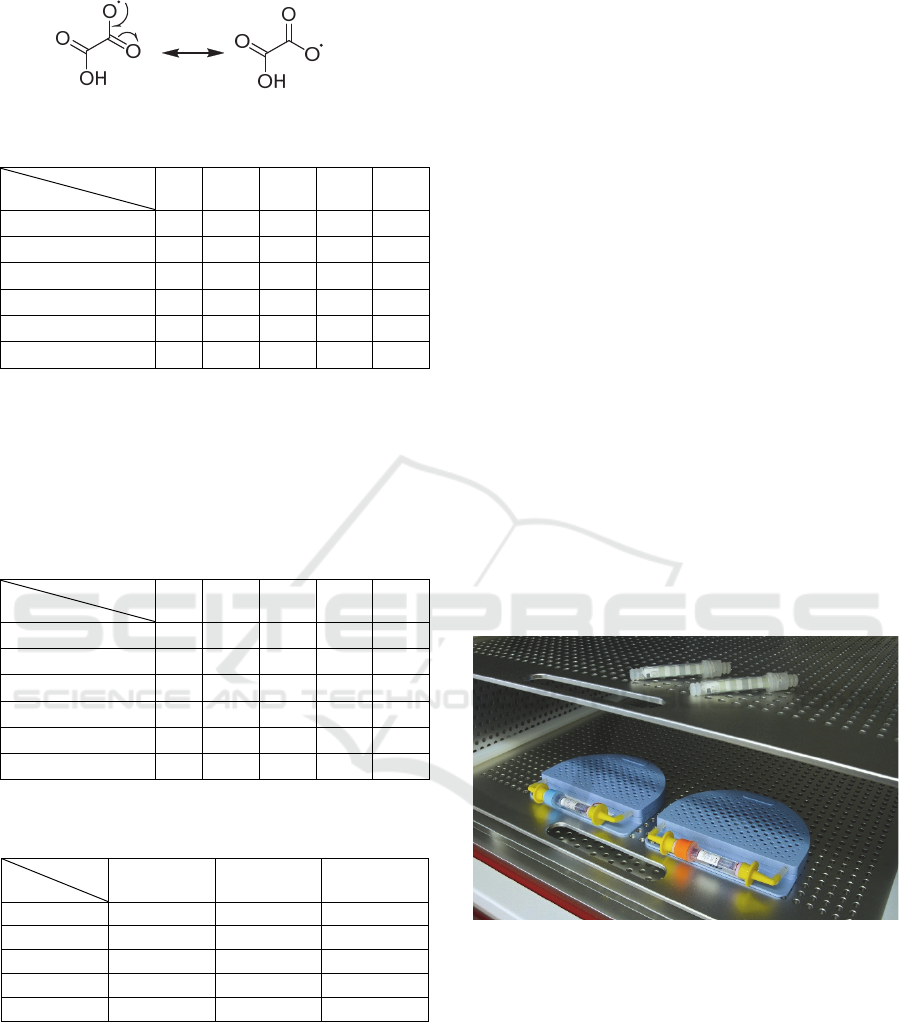

These sterilizers have usable volumes of sterilization

chambers of 50, 80 and 126 litters (Fig.1).

Figure 1: Model Line of Steriplaz

®

.

Limitation of plasma technology is based on the

evaluation of technology itself in numerous system

configurations (Oshita and Kawano, 2015). Thus,

there is an explanation of increased interest in the

plasma used for the microorganism inactivation as a

substitute for other non-thermal sterilization

procedures (Suanpoot and Han, 2015). Publications

(Jeništa, 2016) evidence this fact and highlight

several advantages (Yang and Yan, 2015) and

disadvantages (Gil'man, 2003) (for example, the need

for extensive research to determine the most plasma-

resistant microorganisms (Deilmann and Thei, 2008))

associated with method (Xu and Wang, 2019). This

article summarizes the results of plasma sterilization

using SterAcidAgent

®

. The microbiological

assessment shows the effectiveness of

microorganism’s inactivation technology based on

SterAcidAgent

®

.

2 METHODS

2.1 Technical Implementation of

Developed Sterilization Method

All acids are water-soluble, prepared in non-

explosible concentrations, and stored in accordance

with peroxide storage rules. All reagents were

purchased by Lidkor LLC. The experiments were

performed on a Steriplaz-120 brand sterilizer, and

bactericidal tests were performed on biological and

chemical indicators manufactured by Lidkor LLC.

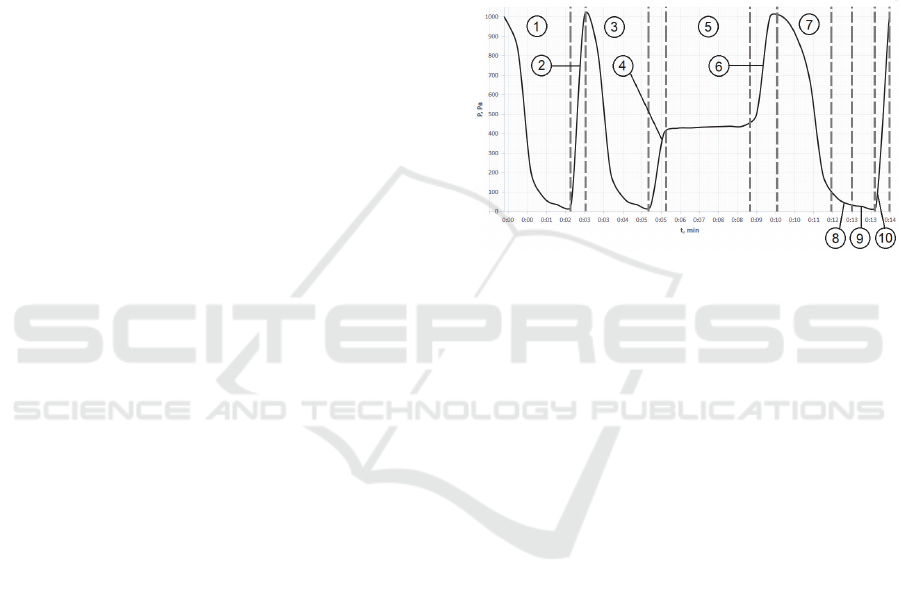

Fig.2 shows a simplified diagram of a plasma

sterilization device, where:

1 - a sterilization chamber;

2 - a sterilizing agent evaporator;

3 - a vacuum pump;

4 - a high-frequency generator;

5 - a container with a sterilizing agent;

6 - a pump of sterilizing agent;

7 - a sterilizing agent measuring cup;

8 - valve for injection of a sterilizing agent;

9 - valve of a vacuum pump;

10 - atmospheric valve;

11 - chamber walls;

12 - concentration equalization slit.

The designed method may be divided into 7 main

stages, which are described below and referred to the

elements of a simplified diagram of the plasma

sterilization device (Fig. 2) and an influence of

sterilization chamber pressure on time (Fig.3).

Figure 2: Simplified Diagram of a Plasma Sterilization

Device.

2.1.1 Evacuation

The sterilization chamber and evaporator heating

initiate the start of operation of the sterilization

device. Sterilization chamber (Fig. 2, 1) is heated in

the range from 45 to 50 degrees Celsius and of the

sterilizing agent (Fig. 2, 2) is heated to 110 degrees

Celsius. When the device is ready for sterilization, the

operator places the object into the chamber and fills

the container with a sterilizing agent (Fig. 2, 1).

Atmospheric pressure valve (Figs. 2, 10) closing

and vacuum pump starting proceed automatically,

providing the first target pressure (at least 25 Pa)

(Figs. 2, 3).

At this stage, pressure reduces linearly to the

value of at least 200 Pa. After reaching that point, the

pressure inside the chamber decreases exponentially

to the first target pressure value. The evacuation

process shown in curve 3 may be divided into two

parts. The first part is a low vacuum (linear), where

the main influence is caused by the chamber volume.

The second part is high vacuum (nonlinear), where

the vacuum time depends on the inner surface area of

Low Temperature Plasma Vacuum Sterilization of Medical Devices by using SterAcidAgent

R

: Description and Distinctive Characteristics

87

the sterilization chamber. The inside chamber

pressure is represented on curve 3 (Fig.3, 3).

Camera pre-drying cycle is displayed on curves 1

and 2. Curve 1 shows evacuation to 100 Pa, after

which the RF generator is turned on to the maximum

vacuum value. Curve 2 shows the opening of the

atmospheric valve and increasing the pressure to

atmospheric value. If additional camera drying is

required the user can select the camera pre-drying

cycle manually.

2.1.2 Injection of a Sterilizing Agent

Hydraulic pump operation start provides the supply

of the sterilizing agent in the measuring cup (Fig. 2,

6), after which the sterilizing agent is injected into the

evaporator (Fig. 2, 2) by the opening of the measuring

cup valve (Fig. 2, 8).

Curve 4 (Fig.3, 2) shows the change in pressure

inside the chamber (Fig.2, 1) when opening the

atmospheric valve (Fig.2, 10). An immediate increase

in pressure up to no more than 400 Pa occurs as a

result of the injection valve opening (Fig.2, 8) since

the measuring cup (Fig.2, 7) has connection with the

atmosphere.

2.1.3 Diffusion of the Sterilizing Agent

In the evaporator (Fig.2, 2), the sterilizing agent

changes its aqueous state of aggregation to gaseous.

Using the concentration equalization slit (Fig.2, 12) is

essential to reach the sterilizing agent concentrations

alignment between the evaporator (Fig.2, 2) and the

chamber (Fig.2, 1) (or the penetration of the

sterilizing agent into the chamber (Fig. 2, 1)).

Diffusion initiates with the sterilizing agent

subside on the sterilized object. The diffusion process

of an organic acid-based sterilizing agent is presented

in more detail in the second paragraph described

below.

Concentration gradient and sterilizing agent

diffusion inside the chamber (Fig.2, 1) are the reason

for the alignment of concentrations between the

chamber and the evaporator as shown in Curve 5

(Fig.3, 5). Initially, the pressure increases

exponentially due to the pressure gradient inside the

chamber. The linear part of the curve corresponds to

the sterilizing agent evaporation and an increase in

the temperature inside the chamber as a result.

2.1.4 Opening of the Atmospheric Valve and

Subsequent Diffusion of the Sterilizing

Agent

Some of the objects, like endoscopes and tubular

systems, have cavities inaccessible for penetration of

the sterilizing agent. Thus, an increase in pressure to

1000 Pa occurs by opening the atmospheric valve for

penetrating the sterilizing agent into the tubular

systems (Fig.2, 10) and allow the sterilizing agent to

persist action on bacteria on the surface of the

sterilized object.

Figure 3: Graph of the Pressure Versus Time of the Plasma

Sterilization Process.

The change in pressure inside the chamber (Fig.2,

1) when opening the atmospheric valve (Fig.2, 10) is

represented on curve 6 (figure 3).

The engagement of the RF generator (Fig.2, 4)

generates a short-term increase in pressure associated

with the transfer of plasma energy to condensed

water, thereby contributing to the evaporation

process.

The effect of radiofrequency discharge on a

sterilizing agent is presented in more detail in the

third paragraph, described below.

The evacuation process is shown in curve 7

(Fig.3) is similar to the process in curve 3.

The introduction into the plasma chamber

promotes a brief increase in pressure, shown in curve

8 (Fig.3). The plasma inside the chamber can

effectively destroy any pathogen present in the

working area (Qi-Kang and Si-Jing, 2019). As

reported in recent studies (Stulić and Vukušić, 2019),

it is known that atmospheric pressure plasma is highly

destructive towards microorganisms (Li and Zhou,

2019), which makes it an object of potential use for

various biological and medical purposes.

The optimal pressure range for an effective

breakdown of the spark gap lays between 30 to 100

Pa. This increasing pressure step in sterilization

process is displayed on the curve 8 (Fig.3). However,

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

88

the breakdown of the gaseous medium relies on

assorted factors. Pressure, temperature, and

composition of the working mixture and the distance

between the electrodes makes the contribution into

breakdown properties.

2.1.5 Exposition

The RF generator is disabled by the control unit

(Fig.2, 4). The plasma burns out during plasma

exposure occurring in chamber. The mechanism of

the UV-radiation formation is presented in more

detail in the fourth paragraph, described below.

2.1.6 Opening the Atmospheric Valve

This stage returns an atmospheric pressure to the

chamber. Pressure equalization between the

atmosphere and the chamber is realized due to the

concentration gradient. An abrupt increase in pressure

to atmospheric is displayed on curve 10 (Fig. 3).

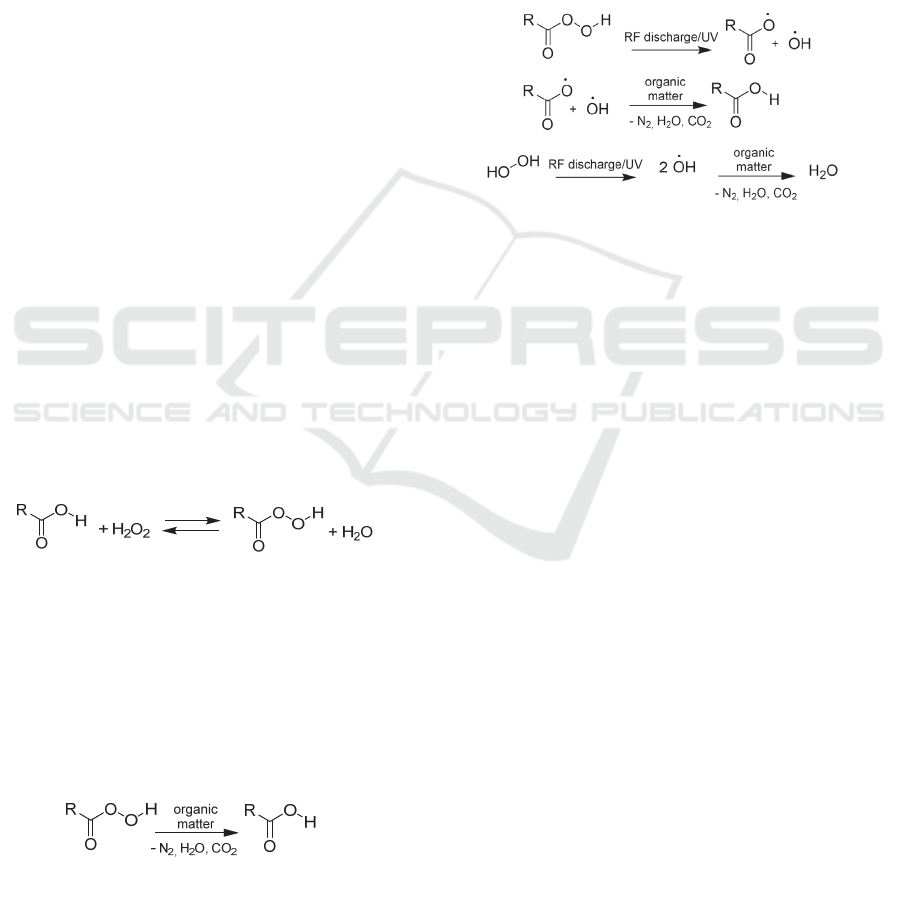

2.2 Diffusion Process of an Organic

Acid-based Sterilizing Agent

Since the second half of the twentieth century, a wide

scope of oxidation reactions is realized through the

organic peracids action (Ki and Masur, 2019).

Currently, organic peracids are regularly used in

diverse bleaching and cleaning products and

disinfectants (Li and Ma, 2019). Organic peracids

could be obtained by the reversible reaction of

hydrogen peroxide with organic acids (1), but the

yields do not exceed 10% without catalyst.

(1)

Substituent R in α-position to carboxyl group

determines the oxidizing potential of organic

peracids. Higher oxidative activity, in comparison to

hydrogen peroxide, and, as a result, more effective

sterilization, is provided by more powerful electron-

withdrawing substituent R. The peracids affect

organic matter similarly to other strong oxidizing

agents, which means the carbon dioxide, nitrogen,

and water in reaction products. Original carbon acid

is regenerated through the oxidation process (2).

(2

)

2.3 The Effect of RF Discharge on a

Sterilizing Agent

All proceeding reactions undergo the same reaction

centre – peroxyl group, prone to homolytic

decomposition, making effect of RF Discharge on

peracids and hydrogen peroxide similar. The O-O

bond cleavage proceeds when exposed both to RF

discharge as well as UV radiation produced. Obtained

radicals are significantly more active oxidants

comparing to starter compounds, which leads to

increased sterilization activity (3).

(3)

It’s noteworthy, that obtaining radicals are

highly unstable, that provides not only effective

oxidative sterilization but also self-oxidation to

carbon dioxide and water, which has a positive

influence on sterilization camera cleanness.

2.4 The Mechanism of UV Radiation

Formation

Inactivation or removal of biological contaminants

(pathogens) under influence of non-thermal plasma

has been reported in papers (McEvoy and Rowan,

2019). Thus, moderate processes for gentle biological

deactivation could be realized through plasma action

as reported for sensitive products (Homola and

Pongrac, 2019), medical instruments (Chumakov and

Taranchuk, 2018) and implants (Souza and Ferreira,

2012). UV radiation has a lower antimicrobial effect

than direct plasma treatment (George and Barrett,

2019). Moreover, biological deactivation using non-

thermal plasma can include processes involving

active radicals or ions (Vasilets and Gutsol, 2009).

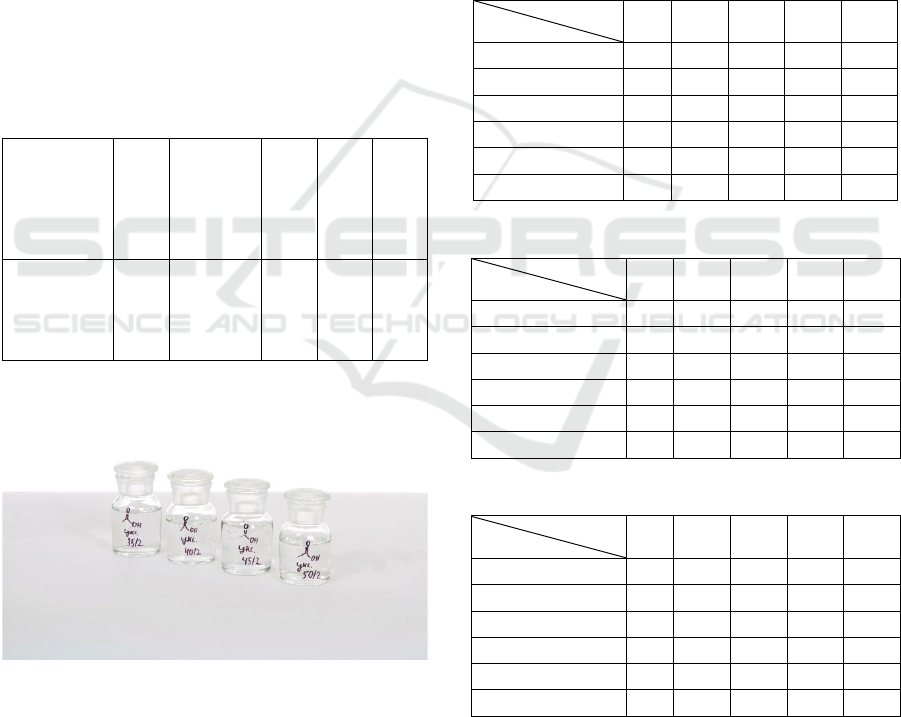

3 RESULTS AND DISCUSSION

Chemical indicators CI PCD and biological indicators

BI PCD with a class G culture (Stearothermophilus

culture of Lidkor LLC) were used for effectiveness

evaluation of the sterilizing agent. For each

sterilization iteration, two chemical and two

Low Temperature Plasma Vacuum Sterilization of Medical Devices by using SterAcidAgent

R

: Description and Distinctive Characteristics

89

biological indicators were used. Result was

considered as a successful in the case of positive

results of both biological indicators.

A portion of acid and the required amount of

water was added to 60% hydrogen peroxide to

prepare solutions with given mass concentrations.

The resulting solutions were kept in the dark for 10

days to form a sufficient amount of peracids.

As part of the study, a set of low molecular weight

carboxylic acids including acetic, propionic, lactic,

oxalic and citric acid were selected for the

experiments. During the study, the concentration of

acids ranged from 5 to 15% in increments of 2.5%,

the concentration of hydrogen peroxide changed from

50 to 20% in increments of 5% and from 20 to 10%

in increments of 2%.

The critical concentrations at which sterilization

was possible (the minimum acid concentration at the

minimum peroxide concentration) are shown in Table

1.

Table 1: Critical Concentrations.

Acid

Acetic

Propionic

Lactic

Oxalic

Citric

Acid/

Peroxid,

%

12.5/20

15/20

15/16

15/20

15/10

Figure 4: Selection of the Optimal Composition.

Obtained results for chosen original carbon acids are

provided in Tables I-VI. Each table represents the

sterilization activity of carbon acid and hydrogen

peroxide mixture (Fig.4). “Plus” and “minus” signs in

the table cells mean effective and ineffective

sterilization respectively based on indicator response.

Sterilization is considered complete if both results

are “plus”. It is noteworthy that hydrogen peroxide

aqueous solution without carbon acids persist

effective sterilization only in concentrations above

52,5%.

The results of the experiments on the selection of

the optimal composition and a comparative table are

shown in Table 2-7.

Sterilization activity should be associated with

peracid oxidative potential; hence it should be

determined by the carboxyl group substituent.

Actually, an increase in sterilization activity

correlates with an increase of the electron-

withdrawing group influence for the series of

propionic, acetic and lactic acids.

Table 2: Propionic Acid Sterilization Potential.

Acid

Peroxi

d

5,0 7,5 10,0 12,5 15,0

45 +/+ +/+ +/+ +/+ +/+

40 +/+ +/+ +/+ +/+ +/+

35 +/- +/+ +/+ +/+ +/+

30 -/- +/+ +/+ +/+ +/+

25 -/- -/- +/+ +/+ +/+

20 -/- -/- -/- +/- +/+

Table 3: Oxalic Acid Sterilization Potential.

Acid

Peroxi

d

5,0 7,5 10,0 12,5 15,0

45 +/+ +/+ +/+ +/+ +/+

40 +/+ +/+ +/+ +/+ +/+

35 +/- +/+ +/+ +/+ +/+

30 -/- +/+ +/+ +/+ +/+

25 -/- -/- +/+ +/+ +/+

20 -/- -/- -/- +/- +/+

Table 4: Acetic Acid Sterilization Potential.

Acid

Peroxi

d

5,0 7,5 10,0 12,5 15,0

45 +/+ +/+ +/+ +/+ +/+

40 +/+ +/+ +/+ +/+ +/+

35 +/+ +/+ +/+ +/+ +/+

30 +/+ +/+ +/+ +/+ +/+

25 -/- +/- +/+ +/+ +/+

20 -/- -/- -/- +/+ +/+

Almost similar results for oxalic and acetic acids

could be explained with oxalic radical increased

stability due to resonance structures set (4). The

highest efficiency was performed by lactic and citric

acids in accordance with the assumption.

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

90

(4

)

Table 5: Lactic Acid Sterilization Potential.

Acid

Peroxi

d

5,0 7,5 10,0 12,5 15,0

45 +/+ +/+ +/+ +/+ +/+

40 +/+ +/+ +/+ +/+ +/+

35 +/+ +/+ +/+ +/+ +/+

30 +/+ +/+ +/+ +/+ +/+

25 -/- +/- +/+ +/+ +/+

20 -/- -/- -/- +/+ +/+

Thus, we divide the acid set into two groups,

applicable and non-applicable for further

investigations as a sterilization agent. Propionic and

oxalic acids are considered to be non-applicable due

to propionic acid poor efficiency and oxalic acid

higher toxicity in comparison with acetic acid.

Table 6: Citric Acid Sterilization Potential.

Acid

Peroxi

d

5,0 7,5 10,0 12,5 15,0

45 +/+ +/+ +/+ +/+ +/+

40 +/+ +/+ +/+ +/+ +/+

35 +/+ +/+ +/+ +/+ +/+

30 +/+ +/+ +/+ +/+ +/+

25 +/+ -/- +/- +/+ +/+

20 -/- -/- -/- +/- +/+

Table 7: Lactic, Citric and Acetic Acid Sterilization

Potential in Conditions of Low Peroxide Concentration.

Acid

Peroxi

d

Lactic, 15% Citric, 15% Acetic, 15%

18 +/+ +/+ -/-

16 +/+ -/- -/-

14 -/- -/- -/-

12 -/- -/- -/-

10 -/- +/+ -/-

Most substantial results are recorded for citric

acid, even with unexplainable at this moment's gaps

in sterilization facilities. Also, a high activity in low

peroxide concentration was performed by acetic and

lactic acids which could lead to the decreased

corrosive effect on glass parts of medical equipment.

That makes acetic, lactic and citric acid regarded as

possible compounds for an agent of commercial use.

Moreover, no papers or patents content citric acid as

a possible sterilization agent, which makes it a very

interesting object of further investigations.

A method for experimental mixtures effectiveness

evaluation was developed and consist in usage of pair

of chemical and biological indicators (Fig.5). The

chemical indicator is a test strip with five applied

layers of the active colored substance. Upon

successful sterilization, all colored strips change their

color to pale yellow, a special table for color

comparison is provided. Evaluation of the

sterilization effectiveness using chemical sterilizers is

approximate, but express. Thus, it has the role of a

rapid detector of errors that could possibly occur

during the sterilization process. The biological

indicator represents a combination of a plastic capsule

containing a G. Stearothermophilus bacterial culture

(ATCC 7953) and incubator. This indicator is more

accurate and is used for the final assessment of

sterilization efficiency, but incubation time requires

24 hours to complete.

A pair of biological and chemical indicators are

placed in both sterilizer compartments for

experimental sterilizing agent testing. After leak-

proof covers are removed, the capsule with a

biological indicator is placed into a Teflon lumen load

with a silicone hose 1000 mm long and 1 mm in

diameter, simulating endoscopes.

Figure 5: Pairs of Chemical and Biological Indicators.

After the sterilization cycle is complete, the glass

ampoule is crushed, providing a nutrient medium

access to oxygen. A broken ampoule, along with a

control broken ampoule are instantly placed in an

incubator for 24 hours at a temperature of 55 degrees

Celsius (Fig.6). Successful sterilization provides the

growth of a bacteriological culture causing a chemical

indicator to turn pale yellow under the influence of

the bacteria waste products. Sterilization is

considered successful only if both biological

indicators persist in their color.

Low Temperature Plasma Vacuum Sterilization of Medical Devices by using SterAcidAgent

R

: Description and Distinctive Characteristics

91

4 CONCLUSIONS

This article presents a new method of low-

temperature plasma sterilization using a mixture of

hydrogen peroxide and low molecular weight

carboxylic acids as a sterilizing agent as well as a

method for the bactericidal activity evaluation based

on combination of chemical and biological indicators.

The sterilization process includes both chemical

oxidative and physical effects due to low-temperature

plasma and ultraviolet radiation, determining the

complex nature of the method. The carboxylic acid

usage in the composition of sterilizing agents allowed

a 5-6-fold reduction in the working concentration of

a hydrogen peroxide solution, thereby reducing the

corrosive effect on the glass components of expensive

medical equipment.

Figure 6: Biological Indicator Incubator.

Bactericidal activity of hydrogen peroxide and

carbon acid mixtures was investigated, results are

provided in Table 2-7. Final monitoring of sterilizer

effectiveness was carried out by the bacteriological

method, consisting in biotests based on the

deactivation of test culture spores. This paper

represents the results based on the germination of

crops in an incubator. However, additional

bacteriological tests required as a part of the

validation of a new type of Steriplaz

®

sterilizer.

ACKNOWLEDGEMENTS

We are grateful Lidkor LLC represented by Alexey I.

Ulybin for the providing of the equipment and

chemical reagents for the experiments. We commend

for the support provided by the employees of Lidkor

LLC Gleb A. Sudakov and Alexey N. Roznin. The

MathLab software used for data analysis was

provided by Ural Federal University.

REFERENCES

J. Zhao, W. Li, L. Zou, H. Fu, "Analysis of Oilfield

Wastewater Treatment Effect Based on Low

Temperature Plasma Treatment Process", IOP Conf.

Series: Earth and Environmental Science, vol. 170,

№032099, 2018.

Z. Dianfeng, "The Feasibility of Applying AC Driven Low-

Temperature Plasma for Multi-Cycle Detonation

Initiation", Plasma Science and Technology, vol. 18

(11), pp. 1110-1114, 2016.

J. Plewa, M. Yousfi, C. Frongia, O. Eichwald, B.

Ducommun, N. Merbahi, V. Lobjois, "Low-

temperature plasma-induced antiproliferative effects on

multi-cellular tumor spheroids", New Journal of

Physics, vol. 16, №043027, 2014.

C.L. Xaplanteris, E.D. Filippaki, J.K. Christodoulakis,

M.A. Kazantzaki, E.P. Tsakalos, L.C. Xaplanteris,

"Low temperature atmospheric plasma applications and

codification of its' influence on micro-organisms",

CHAOS 2014 - Proceedings: 7th Chaotic Modeling and

Simulation International Conference, pp. 533-549,

2019.

P. Suanpoot, J. Sornsakdanuphap, H. S. Uhm, G. Cho and

E. H. Choi, "Using plasma propagation speed model for

investigation of electron temperature of AR/N2 in non-

thermal atmospheric pressure indirect-plasma jet,"

2016 IEEE International Conference on Plasma Science

(ICOPS), Banff, AB, 2016, pp. 1-3.

X. Li, Y. Hang, J. Wu, S. Jia and A. B. Murphy, "Roles of

metalions and plasma radiation in the interactions

between a capillary discharge plasma and propellants,"

2016 IEEE International Conference on Plasma Science

(ICOPS), Banff, AB, 2016, pp. 1-2.

M. J. Esmond and A. L. Winfrey, "Review of past, present,

and future plasma models for electrothermal plasma

discharge simulation," 2016 IEEE International

Conference on Plasma Science (ICOPS), Banff, AB,

2016, pp. 1-3.

S. Ahn, J. Chae, H. Kim, K. H. Kim and S. Y. Jung,

"Modeling of reduced air plasma reactions for

nanosecond-pulse dielectric barrier discharge," 2016

IEEE International Conference on Plasma Science

(ICOPS), Banff, AB, 2016, pp. 1-4.

A. Smolyakov, I. Romadanov, W. Frias, A. Koshkarov, A.

Y. Raitses and I. Kaganovich, "Instabilities and

transport in plasmas with EXB drift," 2015 IEEE

BIODEVICES 2020 - 13th International Conference on Biomedical Electronics and Devices

92

International Conference on Plasma Sciences (ICOPS),

Antalya, 2015, pp. 1-4.

T. Oshita, H. Kawano, T. Takamatsu, H. Miyahara and A.

Okino, "Temperature Controllable Atmospheric

Plasma Source," in IEEE Transactions on Plasma

Science, vol. 43, no. 6, pp. 1987-1992, June 2015.

P. Suanpoot, G. Han, J. Sornsakdanuphap, H. S. Uhm, G.

Cho and E. H. Choi, "Plasma Propagation Speed and

Electron Temperature in Slow Electron Energy Non-

thermal Atmospheric Pressure Indirect-Plasma Jet," in

IEEE Transactions on Plasma Science, vol. 43, no. 7,

pp. 2207-2211, July 2015.

J. Jeništa et al., "Investigation of mixing of plasma species

in argon-water arc discharge," 2016 IEEE International

Conference on Plasma Science (ICOPS), Banff, AB,

2016, pp. 1-1.

L. Yang, H. Yan, X. Qi, S. Zhao and C. Ren, "Geometry

Effects of SDBD Actuator on Atmospheric-Pressure

Discharge Plasma Airflow Acceleration," in IEEE

Transactions on Plasma Science, vol. 43, no. 10, pp.

3653-3661, Oct. 2015.

A. B. Gil'man, "Low-temperature plasma treatment as an

effective method for surface modification of polymeric

materials", High Energy Chem., vol. 37, no. 1, pp. 17-

23, Jan. 2003.

M. Deilmann, S. Thei, P. Awakowicz, "Pulsed microwave

plasma polymerization of silicon oxide films:

Application of efficient permeation barriers on

polyethylene terephthalate", Surf. Coat. Technol., vol.

202, no. 10, pp. 1911-1917, Feb. 2008.

J. Xu, Z. Wang, C. Chang, C. Song, J. Wu, W. Shang, P.

Tao, T. Deng, "Electrically Driven Interfacial

Evaporation for High-Efficiency Steam Generation and

Sterilization", ACS Omega 2019, Sep. 2019.

P. Qi-Kang, L. Si-Jing, H. Huan, X. Jing-Fei, Z. Li, F. Zhi,

W. Chuan, "Sterilization effect of an atmospheric low

temperature plasma jet on Candida albicans biofilm",

V. Stulić, T. Vukušić, A.R. Jambrak, V. Bačun-Družina, D.

Popović, J. Mrvčić, Z. Herceg, "Quantitative microbial

assessment for Escherichia coli after treatment by high

voltage gas phase plasma", Innovative Food Science

and Emerging Technologies, vol. 53, pp. 26-35, 2019.

X. Li, R. Zhou, B. Zhang, R. Zhou, K. Ostrikov, Z. Fang,

"Design and characteristics investigation of a miniature

low-temperature plasma spark discharge device",

Plasma Science and Technology, vol. 21 (5), 054005,

2019.

S.H. Ki, K. Masur, K.Y. Baik, E. Ha Choi, "Effects of

humidity on room disinfection by dielectric barrier

discharge plasma", Journal of Physics D: Applied

Physics, vol. 52 (42), 425204, 2019.

J. Li, C. Ma, S. Zhu, F. Yu, B. Dai, D. Yang, "A Review of

Recent Advances of Dielectric Barrier Discharge

Plasma in Catalysis", Nanomaterials (Basel), vol. 9

(10), 1428, 2019.

B. McEvoy, N.J. Rowan, "Terminal sterilization of medical

devices using vaporized hydrogen peroxide: a review of

current methods and emerging opportunities", Journal

of Applied Microbiology, vol. 127 (5), pp. 1403-1420,

2019.

T. Homola, B. Pongrac, M. Zemanek, M. Simek,

"Efficiency of Ozone Production in Coplanar Dielectric

Barrier Discharge", Plasma Chemistry and Plasma

Processing, vol. 39 (5), pp. 1227–1242, 2019.

V. Chumakov, A. Taranchuk, V. Stetsiuk and V. Michan,

"A New Technology of Bactericidal Processing of

Koch's Bacillus on the Basis of Pulsed Electromagnetic

Radiation," 2018 IEEE 38th International Conference

on Electronics and Nanotechnology (ELNANO), Kiev,

2018, pp. 271-276.

J. H. C. d. Souza and J. L. Ferreira, "G. stearothermophilus

Spores' Inactivation by a Single Dielectric Barrier

Discharge in Air at Atmospheric Pressure," in IEEE

Transactions on Plasma Science, vol. 40, no. 12, pp.

3482-3484, December 2012.

J. George and J. Barrett, "A Steam Sterilizable Plastic-

Encapsulated Wireless Sensor Module," in IEEE

Transactions on Components, Packaging and

Manufacturing Technology, vol. 9, no. 4, pp. 770-778,

April 2019.

V. N. Vasilets, A. Gutsol, A. B. Shekther, A. Fridman,

"Plasma medicine", High Energy Chem., vol. 43, no. 3,

pp. 229-233, May 2009.

Low Temperature Plasma Vacuum Sterilization of Medical Devices by using SterAcidAgent

R

: Description and Distinctive Characteristics

93