Ontology-based Open Multi-agent Systems for Adaptive Resource

Management

Petr Skobelev

1,2 a

, Alexey Zhilyaev

3b

, Vladimir Larukhin

1,3 c

, Sergey Grachev

1,3 d

and Elena Simonova

4e

1

Samara State Technical University, Molodogvardeyskaya Str., 244, 443100 Samara, Russia

2

Institute for the Control of Complex Systems of Russian Academy of Sciences, Sadovaya Str., 61, 443020 Samara, Russia

3

«Knowledge Genesis» Group of companies, Bolshoi bulvar, Office 1680, 42/1, Skolkovo Innovation Center,

129085, Moscow, Russia

4

Samara National Research University, Moskovskoye Shosse, 34, 443086, Samara, Russia

grachev@smartsolutions-123.ru, simonova.elena.v@gmail.com

Keywords: Resource Management, Ontology, Knowledge Base, Multi-agent Technology, Planning, Adaptability,

Flexible Production.

Abstract: The paper describes an ontological model of a planning object, which provides flexible configuration of multi-

agent resource management systems. The authors propose using the basic ontology of resource planning and

then building it up for significantly different domains. The key concept here is “Task”. A relatively universal

agent can be created thanks to formalized description of various classes of tasks based on this concept. It can

also be customized to a specific domain area. Based on the ontology, an enterprise knowledge base is created.

It contains instances of concepts and relations. The paper also introduces new classes of agents for demand

and resource networks. The authors then propose a new method of multi-agent planning using this knowledge

base. This approach has been already successfully applied in several domain areas through the developed

software package. The paper demonstrates that the use of ontologies can improve the quality and efficiency

of planning by taking into account multiple factors in real time, thus reducing the cost of creating and

maintaining multi-agent systems, as well as development times and risks.

1 INTRODUCTION

With the increasing complexity of tasks, the ability of

a business to quickly adapt to changes becomes the

most important characteristic that determines

economic efficiency of the enterprise (Zhong, R. Y.,

2016). We can distinguish adaptability of the first

type, in which plans of enterprises change taking into

account new unforeseen events, and adaptability of

the second type, when changes affect the knowledge

underlying decision-making processes for planning

activities of enterprises, for example, products,

technological processes, capabilities of available

resources, etc. The combination of all knowledge and

a

https://orcid.org/0000-0003-2199-9557

b

https://orcid.org/0000-0003-4522-5257

c

https://orcid.org/0000-0002-5720-3111

d

https://orcid.org/0000-0003-1879-3208

e

https://orcid.org/0000-0003-2638-2572

data about the production object and the enterprise

itself is increasingly called the “digital twin” of the

product and the enterprise (Tao, F., 2017).

In these conditions, enterprise management

requires new approaches to automating solution of

planning problems, which should gradually become

more operational and flexible, rather than strategic

and long-term. In fact, production plan becomes the

necessary part of the enterprise "digital twin", along

with other parameters, such as the state of its

warehouses and machines at any given time.

However, high complexity and dynamics of

event-driven production processes lead to the fact that

traditional batch, centralized and sequential

Skobelev, P., Zhilyaev, A., Larukhin, V., Grachev, S. and Simonova, E.

Ontology-based Open Multi-agent Systems for Adaptive Resource Management.

DOI: 10.5220/0008896301270135

In Proceedings of the 12th International Conference on Agents and Artificial Intelligence (ICAART 2020) - Volume 1, pages 127-135

ISBN: 978-989-758-395-7; ISSN: 2184-433X

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

127

computational models, methods and algorithms of

combinatorial or heuristic types cannot effectively

solve these problems with acceptable quality and

within decent time (Leitao, P., 2016). In this regard,

the task of searching for rational methods providing

for adaptive event-based restructuring of plans in real

time becomes extremely relevant and significant.

At the same time, experience in solving practical

problems (Rzevski, G., 2014) shows that the key

factor affecting the quality and efficiency of planning

is the professional knowledge of specialists who

determine semantics of the domain area and content-

related features of the tasks being solved.

These challenges make digitalization of

knowledge relevant and significant, especially in the

form that allows for computer processing, in

particular, for use in automation systems for planning

production resources.

2 PROBLEM STATEMENT

One of the promising approaches to creating

automated resource management systems is the use of

multi-agent technology (Rzevski, G., 2014).

The proposed approach to creating multi-agent

systems (MAS) for resource management is

associated with the use of demand and resource

networks (DR-networks) (Vittikh, V. A., 2003,

Skobelev, P., 2015). This approach allows us to move

from the usual “centralized” vision of management,

where one single interest and one objective function

of the “whole” are dominating - to distributed

solution of management problem, where interests of

all participants are represented, valued and taken into

account.

Moreover, solution to any complex problem is

formed evolutionarily, from the roughest and most

particular solutions to more complete and accurate

ones. In general, this process can be considered as a

non-deterministic process of agent self-organization,

since each agent itself makes the decision to establish

or break the links at a previously unknown time

(reviewing decisions made earlier is a typical step in

this method). At the same time, all the agents are in

the state of continuous identification and resolution of

conflicts with other agents. Conflict resolution is

implemented through various types of negotiation

protocols and mutual concessions with

compensations based on satisfaction functions, as

well as bonuses and fines (Mayorov, I., 2015). The

result of these processes is not a completely globally

optimal solution, which is often not possible to

obtain, but a rational (locally optimal) one, which has

the ability to quickly adapt to events in real time.

The papers (Shoham, Y., 2009, Easley, D., 2009)

show a number of important properties of such

methods and algorithms for planning and

optimization, which not only reduce combinatorial

enumeration of options and sometimes provide an

optimal solution, but are also intuitive, better

parallelized, resistant to changes in the problem

statement and have other advantages to become a new

tool for solving NP-hard problems.

At the same time, development of MAS still

remains more an art than a technology, and requires

great efforts from developers both at the design and

development stages, and at the implementation and

operation stages, as it is necessary to take into account

a variety of individual characteristics, preferences and

limitations of both participants of the planning

process and the actual enterprise objects (products,

machines, materials, etc.), which directly affect the

quality and efficiency of planning. The principal

thing here is that the structure and composition of

these requirements is difficult to determine in

advance, since they relate to “unconscious”

knowledge, and their next change is actually another

type of event to be processed by the planning system.

The basic principles for constructing multi-agent

systems based on ontologies were previously

formulated in the works of G. Rzevski and P.O.

Skobelev (Rzevski, G., 2014). In particular, the paper

(Skobelev, P. O., 2013) shows the structure of a

typical multi-agent system for resource planning, the

data model of which is based on ontology.

The proposed research considers the developed

principles of creating a basic planning ontology and

developing models and methods of decision-making

for resource management, as well as implementing a

set of software tools in which ontologies can not only

expand the set of limitations taken into account, but

also reconfigure the planning system for solving new

problems.

3 PROPOSED ONTOLOGICAL

APPROACH TO PROBLEM

SOLVING

3.1 Requirements for Building an

Ontology for Resource Planning

In order to solve the problem of formalizing

knowledge about individual characteristics of domain

objects and processes, it is proposed to create a set of

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

128

tools based on the principle of separating the planning

logic and describing the domain area of the specific

problem to be solved.

Such an approach should make it possible to tune

the system to the field of application, describing the

enterprise model in a formalized way as an object of

planning with the help of a basic set of concepts and

relations of the domain ontology. Further, this

formalized description, which is an ontological model

of the management object (technical object or

production enterprise), will be uploaded into the

planning MAS for constructing a plan and its further

adaptive adjustment based on events. In this case,

each order or resource will be associated with its own

software agent and a variant of its behavior, which

will be adjusted to the specifics of its owner from the

knowledge base that describes, for example,

qualifications of a worker or specific features of a

technological process.

The knowledge base is used for accumulation and

formalization in planning of those knowledge quanta,

the storage of which in corporate systems is currently

not provided. Such a knowledge base that already

contains instances of objects instead of classes can be

built based on the domain ontology in the form of a

semantic network of classes of concepts and relations.

The scheduling tasks have similar features,

highlighting which, we can create a basis of concepts

and relations sufficient to describe objectives,

preferences and limitations of system agents.

Thus, any work plan of an enterprise is built on

the basis of orders put into production, each of which

is characterized by applicable technological or

business processes, preconditions for starting task

implementation and the expected result (product or

service) for each task, as well as resource preferences,

and time standards for performing the work.

The planning task consists in calculating the

schedule for executing orders, which determines

distribution of resources by tasks and the exact time

of their fulfillment from the point of view of the

following performance indicators:

• fulfillment of orders as early as possible or in

time;

• increasing resource utilization;

• minimizing the average or maximum delays for

orders, etc.

The resulting solution must satisfy the

performance and resource schedule limitations. For

example, an unshared resource can be used by only

one operation at a time. If there are several valid

schedule options, it is necessary to choose the one that

is closest to optimal, since due to dimension of the

solution space or completely different criteria used at

different stages of planning, obtaining the optimal

result can be difficult and unjustified in terms of the

time spent.

Compared to the well-known and closest tasks of

constructing a schedule for Project Scheduling and

Job Shop Scheduling for machines (Shoham, Y.,

2009), the described problem statement has a number

of additional requirements, the most important of

which is growth of the number of individual criteria,

preferences and restrictions for each object, as well as

the need for adaptive schedule recalculation due to

events that change both availability of resources and

materials, and technological processes for execution

of orders.

3.2 Overview of Existing Ontologies of

Production Resources

Creation of ontologies for managing production

resources has been the subject of a number of studies.

One of the first known production ontologies was

the Process Specification Language (PSL) ontology,

which was developed as an independent language of

knowledge representation about the production

process and used for integration of various

applications (Gruninger, M., 2003).

In 2006, the Manufacturing’s Semantics Ontology

(MASON) was published, designed to simulate the

production process and calculate costs associated

with it. The main classes of concepts in it were

resources (including materials and personnel) and

operations (Lemaignan, S., 2006).

Borgo and Leitao (Borgo, S., 2007) proposed their

version of production ontology based on one of the

top-level public ontologies (DOLCE) and expanding

it with domain-dependent concepts. The resulting

ontology determines taxonomy of products and

components, materials, orders, and production

processes.

In the paper (Cândido, G., 2007), the authors were

among the first ones to use the ontological approach

for automating the assembly line management

process, creating a MAS in which resource agents

registered their capabilities in the system, while

agents of processes selected the necessary resources.

Advantages of using ontologies in agent-based

resource management systems have been

demonstrated in (Vrba, P., 2009). The described

ontology focuses on such concepts as order, product,

production process and enterprise structure (grouping

of equipment into production cells, description of

product movement routes between cells).

Ontology-based Open Multi-agent Systems for Adaptive Resource Management

129

The paper (Usman, Z., 2011) proposes a

production ontology of the upper level, which can

combine the stages of design and production.

In paper (Wautelet, Y., 2012) the authors focused

on using ontology to match resources’ offer and

demand through the concepts of functionality and

competency. In (Minhas, S., 2014), application of

knowledge bases is considered in the context of

assisting dispatchers in planning of the production

process. One of the latest works (Sormaz, D., 2019),

proposes an ontology based on representation of

production process in three dimensions: structural

(relationship between processes and the used

equipment and tools, etc.), temporal (sequence of

operations), variative (ability to choose between

alternative processes, equipment and tools). A

detailed analysis of the current trends and the future

of industrial knowledge bases based on ontologies

was published in (Chandrasegaran, K., 2013).

Analysis shows that most ontologies are focused

on a specific area of production and mainly serve to

integrate knowledge from various information

systems or to simulate production processes.

Whereas, the aim of this paper is to develop the basic,

domain-independent planning ontology that helps

apply accumulated knowledge about the production

process in automated MAS for planning.

3.3 Structure of Ontology for Resource

Management

The main purpose of ontologies and knowledge bases

built on their basis is to formalize the domain

knowledge in order to more accurately specify

requirements that must be taken into account in

applied systems, as well as to separate this

information from the system source code to enable its

editing and expansion. The ontology development

process consists in classifying domain concepts and

defining the format for knowledge representation in

the form of a finite set of concepts and domain

relations.

At the first most abstract level, the concepts

defined in the RDFS and OWL standards are used. At

the next level, it is proposed to use the planning

ontology, which consists of the most common and

reusable concepts, while details depending on the

domain area would be fixed in specialized ontologies

that extend the basic one. Thus, a separate

manufacturing ontology can be created to describe the

domain area of machine-building production. The

hierarchy of concepts can be specified in the more

specialized ontologies down to the level of a

particular enterprise. On the basis of the domain

ontology, an ontological model of the enterprise is

constructed, consisting of instances of the previously

described concepts including the enterprise

organization, description of products and

technological processes, equipment, people and tools

used (Fig. 1).

Enterprisemodel

Manufactur in gontology

Planningontology

RDFSandOWLcon cepts

Figure 1: An example of ontology representation with

multiple layers.

Advantages of using this approach include:

• creation of a single basis in which knowledge is

described. This helps systematize and unify the ways

of representing knowledge;

• possibility of making changes to the structure of

knowledge representation;

• visibility and accessibility of large volumes of

complex structured information for users;

• ability to integrate heterogeneous sources of

information.

3.4 Basic Planning Ontology

In order to “explain” to the planning system how to

work with the domain area, it is necessary to connect

its concepts and relations with the already known

ones (interpreted by the system and built into its

source code). A set of these concepts and relations

forms the “planning ontology”, in which all

abstractions for operation of the planning system can

be collected.

For the basic concepts and relations of the domain

ontology, it is advisable to choose those that

correspond to the main agents of the demand and

resource network, used for adaptive planning based

on multi-agent technology. Such concepts are: order,

task, resource and product (Fig. 2).

Resource

Convertible

resource

Providingresource

Resou rcegroup

Partof

Producedprod uct Consumedproduct

Product

Order

Requires

creation

Task

Follows

Produce

Consum e

Grouptask

Atomictask

Resource

requirement

Use

Use

Availability

Available

Available

Servicerule

Requires

maintenance

Connectedto

Partof

Changeoverrule

Requires

rea djustment

Hasprevious

Hasnext

Storage

requirement

0..n

0..n

Partof

0..n

0..n

0..n

0..n

0..n

1

0..n

0..n

0..n

1..n

1..n

0..n

0..n

0..n

0..n

1..n

0..n

0..1

0..1

0..n

0..n

0..n

0..n

0..n

Figure 2: Basic planning ontology.

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

130

In general, to form an enterprise model, it is

necessary to create instances of the following concepts:

1) Range of products used and manufactured (raw

materials, semi-finished products, information

products, documents, products, etc.). Description of

each type of product can be refined using additional

relations and attributes.

2) Composition and structure of used resources

(personnel, machines, tools, etc.). The following

properties are set for resources: productivity; work

calendar; rules for scheduled preventive repairs and

maintenance, depending on the operating time or the

output volume; readjustment rules determining

duration of transition to production of another type of

product; additional attributes and relations.

3) Technological processes for obtaining

products, which are an ordered list of operations. For

operations, standards of lead time are indicated: fixed

or depending on the volumes of products involved in

the transformation and resources necessary for its

implementation (by setting the necessary properties).

The time taken to complete the operation may depend

on the performance of the selected line.

4) List of orders containing information about the

manufactured product, its quantity and deadlines.

3.5 Domain-specific Ontologies

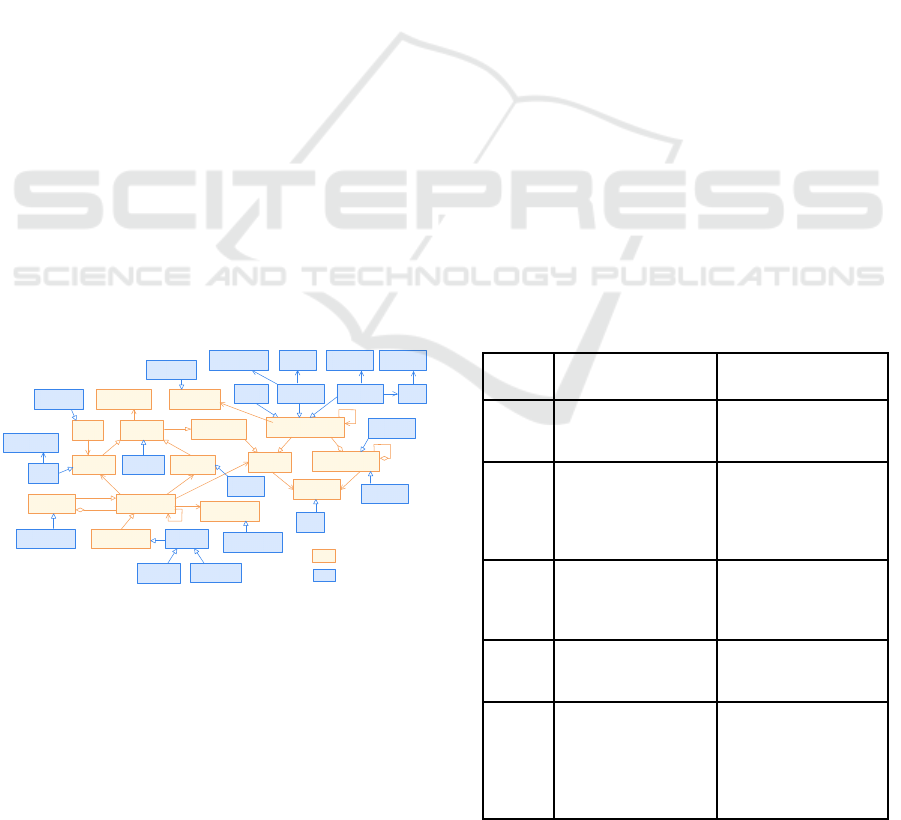

Applied ontologies contain classes of concepts and

relations that are specific for this domain, for

example, manufacturing ontology describes such

classes as “product”, “technological process”,

“workshop”, “equipment”, etc. (Fig. 3).

Workshop

Resource

Convertible

resource

Providingresource

Resourcegroup

Produced

product

Consumed

product

ProductOrder

TaskGrouptask

Atomictask

Resource

requirement

Availability

Servicerule

Storage

requirement

Service

operation

Calibration

operation

Operation

Tech nological

process

Production

order

Article

Modification

Calibration

Production

area

Worker Skill

Profession

Skillgroup

Manufacturer

Equipment

Model

Tooling

Assembly

unit

Daily

Worker

require nment

Material

Planningontology

Man ufact uringontology

Figure 3: Extension of the planning ontology to the field of

manufacturing.

Some of these classes refer to the basic ones given

in the planning ontology, for example, the “Providing

resource” at the level of ontology of manufacturing is

represented by the classes “Tooling” and

“Equipment”. Additionally, classes of the general

purpose are indicated. These are not inherited from

the basic ones, but only participate in relations with

them, allowing users to describe properties of the

domain area concepts (equipment model, employee

competencies, etc.).

4 DEVELOPMENT OF A

MULTI-AGENT

ONTOLOGY-BASED

PLANNING METHOD

To solve the planning problem, it is proposed to use a

multi-agent approach, which is based on juxtaposition

of ontological entities of domain area and software

agents acting on their behalf.

Each agent is able to make decisions and interact

with other agents, which altogether form the multi-

agent system. Behavior of the MAS is not regulated

by any centralized algorithm, but, on the contrary,

arises from the local interactions of the agents

forming it. Each agent has a set of behaviors that

determine its response to messages from other agents,

or to changes in external conditions (events).

In the proposed approach, the schedule is built via

self-organization of software agents of the demand

and resource network with competition and

cooperation in the virtual market. The basic types of

agents are agents of orders, tasks, resources, products,

as well as the scene agent.

Objectives and limitations of these agents are

shown in Table 1.

Table 1: Objectives and limitations of agents.

Type

Objectives and

preferences

Limitations

Order

agent

To be fully completed

in the specified time,

with minimum cost

Timing, volume,

marginal cost

Task

agent

To be performed on a

suitable resource within

the specified timeframe

in the shortest time

Characteristics of the

required resources and

products, start and end

dates, relations with

other tasks

Resource

agent

To be as occupied as

possible, minimize

downtime and

changeovers

Work calendar,

unavailability intervals,

service and readjustment

rules, performance

Product

agent

To provide its storage,

minimize retention

Storage requirements,

delivery or production

time, consumption time

Scene

agent

Identification of

bottlenecks in the

schedule, managing

activity of system

agents, interaction with

external systems

Time allocated for

planning, depth of

permutation chains in

the schedule

Ontology-based Open Multi-agent Systems for Adaptive Resource Management

131

Objectives and preferences of each agent are

determined through the satisfaction function, which is

a weighted sum of components that meet various

criteria. Depending on the value of satisfaction

function, an agent is automatically assigned a bonus

(or penalty), the amount of which is determined by

the bonus and penalty function set for this agent

(Mayorov, I., 2015).

The agent-based planning method is built on the

conflict analysis mechanism that provides the ability

to rearrange conflicting tasks in the schedule through

agent negotiations (by exchanging messages

according to specified rules). As a result, an

acceptable locally optimal solution is achieved, which

is further adaptively corrected in the “sliding mode”

on the given planning horizon.

The following is an algorithm for the planning

method:

1) In accordance with the current state of the

scene, agents of orders, resources and products are

created. The scene agent sends a signal about the start

of planning to one or more order agents.

2) The order agent reads the technological process

for the related product and generates task agents

corresponding to the technological process and

operations arranged in a hierarchy.

3) The top-level task agent reads the concept of

the given task in the knowledge base and checks for

the presence of products used in the task, evaluates

resource requirements and selects a combination of

them based on assessment of its duration. The

procedure for finding placement options includes

analyzing the required resources, comparing

requirements of tasks and capabilities of resources,

coordinating times of availability of all resources, and

choosing the best combination of performers.

Moreover, as resources are selected, the system

determines a set of orders interfering with placement

on the selected resources (the conflicting set). The

procedure for determining a conflicting set of orders

depends on the type of resource under consideration:

an unshared resource fixes a conflict in case of

intersection of time intervals used by two tasks, while

the shared resource fixes a conflict if the total amount

of the resource used by the tasks exceeds the limit

value. After selecting a placement option, the group

task agent sends a planning request to the agents of

child tasks.

4) Agents of child tasks recursively search for

placement options taking into account limitations

determined by the parent task. Planning results are

reported to the top-level task agent, which clarifies its

placement or invites child tasks to schedule at another

time.

5) The top-level task agent informs the order agent

about parameters of the selected placement.

6) The order agent proposes conflicting orders to

find another slot in the schedule, reporting their losses

in comparison with the basic (initial for the current

thread) version of the schedule. As a result, a chain of

permutations of tasks and orders is determined,

values of objective functions of those entities affected

by changes in the plan are calculated, and based on

this, the final value of the objective function of the

whole system is refined as the normalized sum of

objective functions of its constituent agents. A

permutation chain is successful (permissible) if the

value of objective function of the system is higher,

and the order agent can compensate for the loss of

other entities involved in this variant of permutations.

If these conditions are met, the changes in the

schedule are approved. Otherwise, another placement

option is determined.

7) After placement, the order agent checks

availability of products related to it by the “Produced”

relation and notifies their agents of the delivery time

to the warehouse.

8) This process continues until the condition is

fixed where no agent can improve its state

(satisfaction function).

9) The scene agent determines the agent with the

worst criteria for the system as a whole. The selected

worst agent is instructed to break ties with related

products and resources. The selected agent receives

an increased importance coefficient of the worst

criterion in the satisfaction function, so that agents

choose other options during the next rescheduling.

10) The agent tries to be scheduled again - if

successful, the process goes on to the next criterion

and the corresponding agent. If not, the agent reports

the amount of compensation that it lacks to achieve

the new criterion value.

11) The scene agent evaluates availability of the

currency in the system and if necessary, adds virtual

currency to this agent. As a result, the worst agents

iteratively “tighten” their criteria for the new values,

compensating for the losses of other agents via virtual

budget.

12) The process ends if the time allotted for

building the schedule is over, or if there is no more

room for improvement.

4.1 Support Tools

To implement the proposed approach, a software

package was developed, which includes a

management module, a user interface, an editor of

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

132

ontologies, models and scenes, as well as a planning

module (Fig. 4).

Backend

Planning module

User interface

Editor of

ontologies,

models and

scenes

Ontology

Model

Scene

Knowledge base

Figure 4: Architecture of the software package.

The management subsystem is the server part of

web application that implements its business logic.

The editor of models, ontologies and scenes provides

creation, editing and storage of a digital model of the

planning object, providing a software interface for

access to available information. The data warehouse

is physically divided into two parts: ontological and

relational. The ontological part contains descriptions

of all used ontologies and models in the form of

triplets, while the relational part contains data about

all objects entered into the system (resources, orders,

tasks, etc.). This division allows users to combine

advantages of rigid, normalized and dynamically

extensible data structures stored in various DBMSs:

PostgreSQL and Mongo.

The main objective of the planning module is

formation and adaptive restructuring of the order

execution plan taking into account resource

limitations. The module creates and configures

instances of system agents based on the ontological

description of the planning object, provides a multi-

threaded environment for their implementation,

determines the order and algorithm of their

functioning. The module is built on Akka framework

that implements a low-level mechanism for

asynchronous messaging and thread-scheduling in a

concurrent environment. It allows creating thousands

of agent instances on a limited number of threads. All

created agents correspond to the base concepts from

the planning ontology and can be directly executed

without manual code insertion because all

communication protocols have been already

implemented.

The user interface is the client part of the web

application that runs in the browser and implements

graphical interface for accessing the object model and

planning results.

5 USING THE TOOLS FOR

SOLVING APPLIED

PROBLEMS

The developed methods and tools were applied to

solve the following problems:

• production planning for an aircraft

manufacturing enterprise;

• planning for truck assembly;

• planning a well drilling process.

Despite significant differences in the statements,

all these problems were solved using one software

package with some improvements related, primarily,

to visualization of domain-dependent processes. At

the same time, all changes in the planning module

were not “tied” to a specific domain area and only

increased its general capabilities, which allows us to

make the conclusion that the product can be gradually

stabilized and can later be offered to system

integrators as a regular service.

In each case, the basic planning ontology was

used, on the basis of which domain-specific

ontologies and enterprise models were created. In the

case of aggregate assembly of trucks, it was possible

to reuse the ontology of manufacturing, expanding it

to the specific case of robotic tools. At the same time,

based on the needs arising in solving applied

problems, the basic planning ontology was being built

up and the logic of agents' work was modified.

General information about the number of entities in

the knowledge base, agents in the planning module,

as well as approximate terms of completion of the tool

complex is given in Table 2 (the number of agents

depends on the number of orders entered, the table

shows average values).

Based on the analysis, the following main

advantages of the developed approach can be

distinguished, since it helps to:

• significantly reduce the complexity and labor

intensity of creating a MAS for resource

management;

• increase the number of factors for decision

making;

• configure the logic of MAS without involvement

of programmers;

• reduce the costs of creating and maintaining the

described systems;

• use the same source code for different tasks,

reducing the number of errors and risks associated

with development.

Ontology-based Open Multi-agent Systems for Adaptive Resource Management

133

Table 2: Indicators of the use of a set of tools for solving

applied problems.

Applied

task

Size of

basic

ontology

Size of

domain

ontology

Size of

enterprise

model

N

umber

of

agents

Time for

completion

(man/month)

KB

Planning

module

Aircraft

assembly

61

152 925 > 350 3 5.5

Truck

assembly

89 382 > 520 1 2

Well

drilling

85 441 > 5000 2 3.5

In practice, it becomes possible to systematize,

accumulate, and formalize the specific knowledge of

enterprises that could not previously be separated

from the source code and which can now receive

additional value. In the future, it will enable us to

consider the emerging knowledge base as another

asset of the enterprise.

6 CONCLUSIONS

The paper proposes the basic ontology of resource

planning and possibilities of its expansion in domain

areas, making it possible to use the same set of DR-

network agents to manage enterprises in significantly

different domains. An extension of the multi-agent

planning method based on the ontological enterprise

model stored in the knowledge base is presented. The

paper also presents examples of using this approach

to control assembly of aircrafts, robotic assembly of

cars and the drilling process.

The proposed approach makes it possible to build

formal ontological models of DR-networks of

enterprises and flexibly configure multi-agent

systems of resource management without labor-

intensive reprogramming in order to take into account

specific features of their work. The created

ontological models of enterprises can be the basis for

creating ontological "digital twins" of enterprises,

applicable both for operational management and for

modeling the processes of development and

modernization of enterprises.

ACKNOWLEDGEMENTS

Research has been carried out and financed within the

Program of fundamental research of the Russian

Academy of Sciences in priority areas determined by

the RAS Presidium #7 «New developments in

promising areas of energetics, mechanics and

robotics».

REFERENCES

Zhong, R. Y., Xu, X., Klotz, E., et al., 2016. Intelligent

Manufacturing in the Context of Industry 4.0: A

Review. In Frontiers of Mechanical Engineering. P.

616-630.

Tao, F., Cheng, J., Qi, Q., et al, 2017. Digital twin-driven

product design, manufacturing and service with big

data. In International Journal of Advanced

Manufacturing Technology. P. 3563-3576.

Leitao, P., Karnouskos, S., Ribeiro, L., et al, 2016. Smart

Agents in Industrial Cyber-Physical Systems. In

Proceedings of the IEEE. № 104 (5). P. 1086-1101.

Rzevski, G., Skobelev P., 2014. Managing complexity. WIT

Press. Boston.

Vittikh, V. A., Skobelev, P. O., 2003 Multiagent Interaction

Models for Constructing the Needs-and-Means

Networks in Open Systems. In Automation and Remote

Control. 64(1). P. 162-169.

Skobelev, P. Multi-Agent Systems for Real Time Adaptive

Resource Management, 2015. In Industrial Agents:

Emerging Applications of Software Agents in Industry.

P. 207-230. Elsevier.

Mayorov, I., Skobelev, P., 2015. Towards thermodynamics

of real timescheduling. In International Journal of

Design & Nature and Ecodynamics. Vol. 10. Is. 3. P.

213-223. WIT Press.

Shoham, Y., Leyton-Brown, K., 2009. Multi-agent systems:

Algorithmic, Game Theoretic and Logical Foundations.

Cambridge University Press.

Easley, D., Kleinberg, J., 2010. Networks, Crowds, and

Markets: Reasoning about a Highly Connected World.

Cambridge University Press.

Skobelev, P. O., 2013. Situational management and multi-

agent technology: collective search for coordinated

solutions in a dialogue. In Ontology of Designing. №2

(8). P. 26-48. (In Russian)

Gruninger, M., Menzel, C., 2003. The process specification

language (PSL) theory and applications. In AI

Magazine. Vol. 24(3). P. 63-74.

Lemaignan, S., Siadat, A., Dantan, J. Y., 2006. MASON: A

proposal for an ontology of manufacturing domain. In

Proc.of DIS 2006. P. 195-200. IEEE.

Borgo, S., Leitão, P., 2007. Foundations for a Core

Ontology of Manufacturing. In Ontologies. Integrated

Series in Information Systems. P. 751-775.

Cândido, G., Barata, J., 2007. A mutliagent control system

for shop floor assembly. In Holonic and Multi-Agent

Systems for Manufacturing. P. 293-302.

Vrba, P., Radakovič, M., Obitko, M., 2009. Semantic

Extension of Agent-Based Control. In The Packing Cell

Case Study. P. 47-60.

Usman, Z., Young, R., Chungoora, N., et al., 2011. A

Manufacturing Core Concepts Ontology for Product

Lifecycle Interoperability. In Enterprise

ICAART 2020 - 12th International Conference on Agents and Artificial Intelligence

134

Interoperability. IWEI 2011. Lecture Notes in Business

Information Processing. Vol 76. P. 5-18.

Wautelet, Y., Heng, S., Kolp, M., 2012. A Usage-Based

Unified Resource Model. In The 24th International

Conference on Software Engineering and Knowledge

Engineering. P. 299-304.

Minhas, S., Berger, U., 2014. Ontology Based

Environmental Knowledge Management - A System to

Support Decisions in Manufacturing Planning. In Proc.

of 6th International Conference on Knowledge

Engineering and Ontology Development. P. 397-404.

Sormaz, D., Sarkar, A., 2019. SIMPM – Upper-level

ontology for manufacturing process plan network

generation. In Robotics and Computer Integrated

Manufacturing. Vol. 55. P. 183-198.

Chandrasegaran, K., Ramani, K., Sriram, R. D., 2013. The

evolution, challenges, and future of knowledge

representation in product design systems. In Computer-

Aided Design. Vol. 45(2). P 204-228.

Ontology-based Open Multi-agent Systems for Adaptive Resource Management

135