Physical Characterization of Red Palm Oil Emulsion

Vallerina Armetha

1a

, Purwiyatno Hariyadi

1,2 b

, Azis Boing Sitanggang

1,2 c

and Sri Yuliani

3d

1

Department of Food Science and Technology, Faculty of Agricultural Engineering and Technology, IPB University,

Bogor 16680, Indonesia

2

Southeast Asian Food and Agricultural Science and Technology Center, IPB University, Bogor 16680, Indonesia

3

Indonesian Center for Agricultural Postharvest Research and Development,

Indonesian Agency for Agricultural Research and Development, Bogor 16122, Indonesia

Keywords: Emulsion Stability, Red Palm Oil, Separation Index, Whey Protein Concentrate, Whey Protein Isolate.

Abstract: The oil/water emulsion is widely studied as a carrier system of oil-soluble bioactive components. This study

aimed to investigate the formation of a whey protein-based red palm oil (RPO) emulsion system and its

stability during long-term storage. The RPO emulsion utilizing three different emulsifiers (WPCa, WPCb,

and WPI) with three different emulsifier concentrations (i.e., 2.5, 5, 10, and 15% w/v) in the aqueous phase

was prepared. A mixture of whey protein solution containing 30% (v/v) of RPO was prepared and

emulsification was performed with two-steps homogenization processes. Emulsions produced were stored at

ambient temperature and evaluated for their physical stability by determining the qualitative rating of

destabilization and oil droplet viability and measuring its separation index (SI, %). The results showed that

the type and concentration of emulsifiers affected the emulsions' stability during long-term storage at ambient

temperature. The system emulsified with WPCa and WPCb was found to be more stable with a lower SI value

than that of WPI. Furthermore, emulsions with higher emulsifier concentrations were found to be more stable,

with lower SI values. The RPO emulsion with 15% of WPCb was the most stable system, having SI of 0%

after 105 days of storage.

1 INTRODUCTION

The oil-in-water (O/W) emulsion is one of the carrier

systems widely reported increasing the stability of the

fat-soluble food bioactive components

(Aswathanarayan & Vittal, 2019; Banasaz, Morozova,

Ferrentino, & Scampicchio, 2020; Gasa-Falcon,

Odriozola-Serrano, Oms-Oliu, & Martín-Belloso,

2020; D. J. McClements, Decker, & Weiss, 2007;

David Julian McClements, 2010; Özbek & Günç

Ergönül, 2017; Wang, Neves, Isoda, & Nakajima,

2015). The O/W system is known to provide a

protection mechanism for the entrapped components

by forming a "wall" composed of the emulsifier (D. J.

McClements et al., 2007; Wang et al., 2015). The

ionic interaction and repulsive forces exerted by the

emulsifier and other constituent components of the

a

https://orcid.org/0000-0003-2461-8756

b

https://orcid.org/0000-0001-5677-2163

c

https://orcid.org/0000-0002-1378-5367

d

https://orcid.org/0000-0001-5151-3840

emulsion (i.e., co-emulsifier, co-solvent, or other

stabilizers) can also enhance the protection

mechanisms provided by the system (Wilde, Mackie,

Husband, Gunning, & Morris, 2004). The "wall"

defines the entrapped oil portion from interactions

with environmental factors that can reduce its

stability (i.e., oxygen, light, or metal cations).

Red palm oil (RPO) is a type of edible oil rich in

natural fat-soluble bioactive micronutrients (Chong et

al., 2018; Dauqan, Sani, Abdullah, Muhamad, & Md.

Top, 2011; Loganathan, Subramaniam,

Radhakrishnan, Choo, & Teng, 2017; Nagendran B.,

Unnithan U., Choo, Sundram, 2000; Scrimshaw,

2000). RPO contains high levels of carotenoids with

potential natural antioxidants and pro-vitamin A

activity. RPO also contains high levels of vitamin E

in the form of tocotrienols and tocopherols, and other

food bioactive compounds in a considerable amount

Armetha, V., Hariyadi, P., Sitanggang, A. and Yuliani, S.

Physical Characterization of Red Palm Oil Emulsion.

DOI: 10.5220/0010641200003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 185-190

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

185

(phytosterols, ubiquinone, and squalene). RPO is

potential to be used as a source of natural fat-soluble

bioactive micronutrients based on its rich nutritional

value. However, the RPO tends to be less stable to

oxidation during storage (Ayu, Andarwulan,

Hariyadi, & Purnomo, 2016; de ALMEIDA, Viana,

Costa, Silva, & Feitosa, 2019; Sohail, Ahmed,

Akhtar, Durrani, & Section, 2010). This has led RPO

has not been intensively used as a source of fat-

soluble bioactive micronutrients. Therefore, there is a

need to enhance the stability of RPO during storage

to improve its utilization as a source of fat-soluble

food bioactive compounds.

The formation of the O/W system has the potential

to be used to increase the stability of fat-soluble

bioactive micronutrients in RPO. In this study, we

studied the production of RPO-in-water emulsion

system. Emulsions stabilized with natural emulsifiers

could provide additional functional value to the

system (i.e., nutritional value) (Adjonu, Doran,

Torley, & Agboola, 2014). Concerning the current

trend in using natural emulsifiers (i.e., protein, pectin,

gum, or other biopolymer compounds) in emulsions

(Charoen et al., 2011; Matalanis, Jones, &

McClements, 2011; David Julian McClements, 2009;

Qian & McClements, 2011; Wilde et al., 2004), we

considered that whey protein has good potential as a

single emulsifier in the RPO emulsion system. To the

best of our knowledge, emulsion systems with whey

protein as single emulsifiers have never been reported

to be an emulsifier in RPO emulsion systems. A

stable whey protein-based RPO emulsion system is

needed to increase the stability of RPO emulsified as

well as to maintain the emulsion stability.

This study then aimed to investigate the formation

of a whey protein-based RPO emulsion system and its

physical stability during long-term storage. Three

types of commercially available whey protein were

used as the single emulsifier in our RPO emulsion

system.

2 MATERIALS AND METHODS

2.1 Materials

RPO was obtained from the Indonesian Oil Palm

Research Institute (IOPRI). Whey Protein

Concentrate (WPCa) (Avonlac

TM

180) had a total

protein of >78 %, water ≤5.0 %, fat <12.0 %, mineral

<5.0 %, and sugar 5.0. Whey Protein Concentrate

(WPCb) (OptiSol

R

1007) had a total protein >76 %,

water <6.0 %, fat <13.5 %, mineral <6.0 %, and sugar

5.0. Whey Protein Isolate (WPI) 90 (Provon 190) had

a total protein >90 %, water <5.0 %, fat <0.7 %,

mineral <3.5 %, and sugar 0.7. These whey protein

products were obtained from Glanbia Nutritionals

Singapore Pte Ltd., Singapore. The deionized water

was obtained from Hach Lange GmbH, Germany.

Sodium azide (NaN

3

) (pro-analysis grade) was

purchased from Merck KGaA, Darmstadt, Germany.

2.2 Emulsification of Whey

Protein-based RPO Emulsions

The WPI, WPCa, or WPCb (2.5, 5, 10, 15 %; w/v)

were dissolved in deionized water containing 0.02 %

(w/v) NaN

3

and

stirred (IKA C-MAG HS7, Staufen,

Germany) for one hour at ambient temperature. The

whey protein solutions were then stored overnight

(±18-20 h) at 4±1 °C to allow protein hydration.

Whey protein-based RPO emulsions were prepared

by combining phase inversion technique and rotor-

stator homogenization. Whey protein solution was

added gently to RPO to produce a mixture containing

30 % (v/v) of RPO. Emulsification was carried out

with two-steps homogenization. Initially, the rotor-

stator homogenizer (Silverson L4r, Silverson

Machines, Ltd, Bucks, UK) was set to 9000 rpm for

two minutes and followed by an increased speed at

18000 rpm for five minutes. The emulsions was

produced in duplicate

2.3 Physical Stability of Emulsion

A 40 mL of RPO/W emulsion was transferred

immediately to a 50-mL measuring cylindrical glass

(Iwaki Pyrex) after emulsification and stored at

ambient temperature. The stability of emulsions was

analysed by visual observation and was expressed in

as three categories. For the first category, the

emulsions destabilisation was rated into

discontinuing values (0 to 6) defined in Table 1 and

noted as rating of destabilisation (RoD). Second

category was focused on the oil droplet viability

(ODV) on the surface of the emulsion system,

expressed in zero to six scale (i.e., 0 = oil separation

was not identified, and 6 = high amount of oil

creamed at the surface. In the third category, the

emulsion stability was evaluated based on the

separation index (SI, %). SIs of the stored emulsions

were evaluated on the 1

st

, 7

th

, 14

th

, and 105

th

days of

storage. SI was calculated by measuring the ratio of

separated portion volume (H

S

) to the volume of total

system (H

E

) (Equation 1).

SI

ሺ

%

ሻ

=

H

s

H

E

×100

(1)

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

186

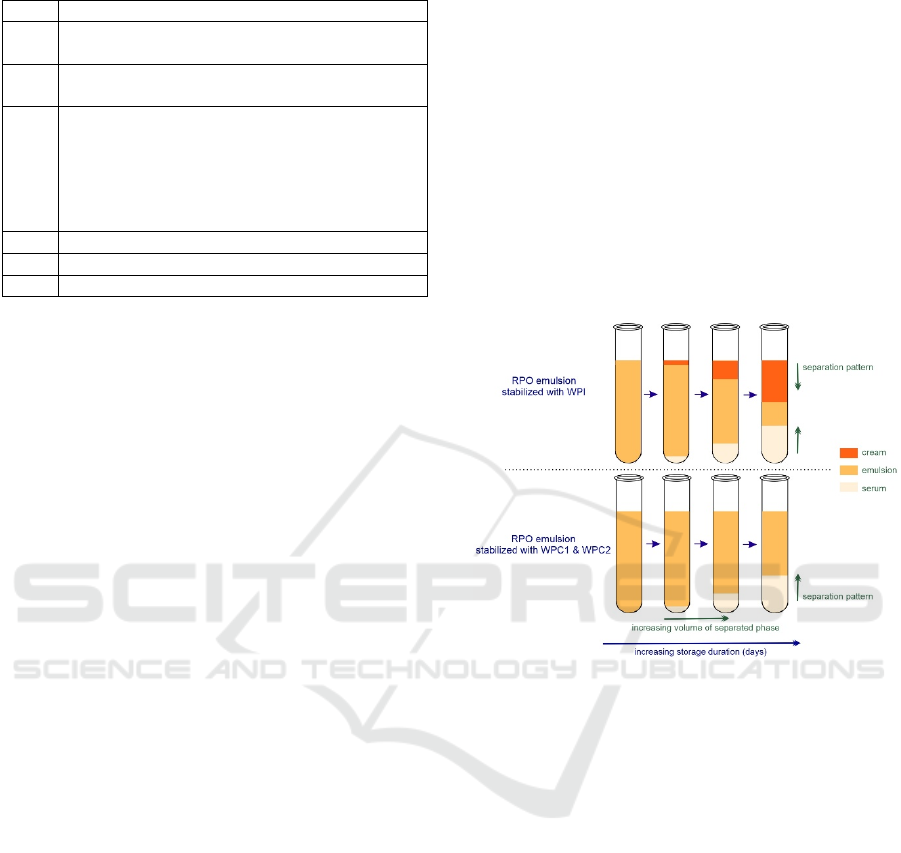

Table 1: Description of emulsion destabilisation score.

RoD Descri

p

tion

1

Emulsion was visually stable; no change or

separation was observe

d

2

Emulsion started to separate, identified by a

visuall

y

thin color

g

radation

3

Emulsion experienced one type of separation;

such as creaming development (at the top layer

of emulsion) or oil droplet separation (at the top

surface of emulsion) or serum separation (at the

bottom layer of emulsion) or formation of whey

p

owder sediments

(

at the bottom of emulsion

)

.

4 Emulsion ex

p

erienced two t

yp

es of se

p

aration.

5 Emulsion experienced three types of separation.

6 Emulsion experienced four types of separation.

3 RESULTS AND DISCUSSIONS

The RPO emulsion emulsified with whey protein

formed by two-step homogenization employing rotor-

stator homogenizer. Previously, we performed a

preliminary study to estimate the required amount of

whey protein used. Based on preliminary research

results, whey protein started at 2.5% concentration in

the continuous phase showed good performances on

the initial physical appearances of the emulsions.

Therefore, the RPO emulsion was fabricated utilizing

a whey protein at 2.5-15% in the continuous phase. The

emulsions with emulsifier concentrations of 2.5% and

5% had relatively small amounts of cream droplets on

the top surface as soon as the emulsification process

finished. There were 12 variants of RPO emulsions

produced and showed a yellowish visual appearance

and were either dense or not translucent. The RPO

emulsions emulsified with WPI had a more dilute

consistency than those with WPCa and WPCb.

3.1 SI (%) of the Whey Protein-based

RPO Emulsions

The whey protein-based RPO emulsions showed

different destabilization phenomena influenced by the

type of emulsifier. RPO emulsion emulsified with WPI

was observed to experience a different destabilization

phenomenon compared to RPO emulsion emulsified

with WPCa and WPCb. The visually observed

destabilization phenomenon is presented in Figure 1.

The RPO emulsion emulsified with WPI experienced

destabilization in the form of splitting the system into

three noticeable parts, whereas the RPO emulsion

emulsified with WPC experienced separation into only

two noticeable parts. Several previous studies also

reported differences in the appearance of phase

separation due to destabilization into two parts or three

separate parts with different emulsifiers and system

composition (Anvari & Joyner (Melito), 2017; Zhang

et al., 2019). The separation of the emulsion prepared

with WPI could be identified in the form of cream,

emulsion, and serum; whereas the separation of RPO

emulsions emulsified with WPCa and WPCb was

indicated by the formation serum (see Figure 1). The

destabilization phenomena were differed presumably

due to the inherent emulsifier's physicochemical

characteristics (i.e., protein concentration, charge,

structures). WPI with higher protein concentration is

considered to have more intense protein intermolecular

interactions in the resulting emulsion system. Herein,

the creaming process is noticeable.

Figure 1: Destabilisation pattern observed on the whey

protein-based RPO emulsions during storage.

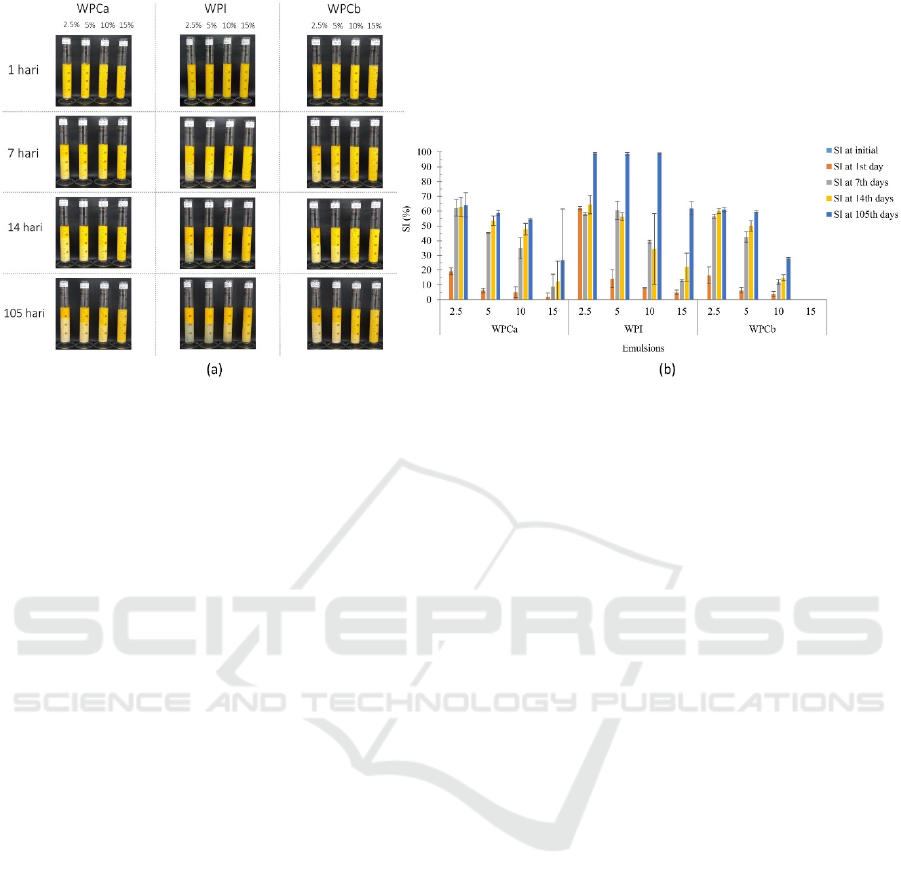

The stability of the whey protein-based RPO

emulsion was evaluated based on the separation index

(SI, %). Based on the destabilization phenomena

described previously, we propose the use of SI to

describe the stability characteristics of a protein-

based emulsion system based on visual observation.

Generally, a creaming index (CI, %) is used to

describe emulsion stability in evaluating visual

observations over long-term storage (David Julian

McClements, 2007). However, the CI value could not

indicate the system's differences in destabilization

when the separation of the cream and serum phases

(the emulsion separated into three parts) was

noticeable, or the separation of the serum layer was

unnoticeable even though the separation of the cream

layer was observed (the emulsion separated into two

parts). SI value defined in this study was calculated

based on the ratio of the separated parts' volume to the

total system's volume (see Equation 1). SI values and

the documentation of the whey-protein based RPO

emulsion are shown in Figure 2.

Physical Characterization of Red Palm Oil Emulsion

187

Figure 2: The documentation of physical appearance (a) and SI (%) (b) of the whey protein-based RPO emulsions after 1, 7,

14, and 105 days of storage at ambient temperature.

The results showed that the systems emulsified

with WPCa and WPCb had lower SI values than the

ones emulsified with WPI. The systems prepared with

WPCa and WPCb had relatively similar SI values. The

systems emulsified with WPI experienced increased SI

values respective to the storage time. On the other

hand, SI values for the systems emulsified with WPCa

and WPCb did not change significantly after

experiencing separation. The systems emulsified with

WPCa and WPCb experienced separation after 14 days

of storage. At longer storage time (i.e., more than 14

days), these systems did not show significant changes.

The concentration of whey protein used also

influenced the stability of the emulsion. Emulsions

with higher emulsifier concentrations were found to be

more stable, as indicated by lower SI values. The

system with an emulsifier concentration of 15% was

observed to have the best stability among the

concentrations tested for each type of emulsifier tested.

The results showed that a system stabilized with WPCb

at 15% showed the best stability with a separation

index value of 0% after 105 days of storage. At

extended storage, the RPO emulsion system emulsified

with 15% WPCb emulsifier was stable for up to 5.5

months. RPO emulsion prepared with WPCb was more

stable than that of WPCa at 15% concentration. This

was presumably due to differences in fat and mineral

content in WPCb and WPCa. The differences in whey

protein' physicochemical characteristics can result in

differences in repulsive forces and ionic interactions,

shown through the emulsion's physical stability (Abd

El-Salam, El-Shibiny, & Salem, 2009; Adjonu et al.,

2014; Dybowska, 2011; Ravindran, Williams, Ward,

& Gillies, 2018).

3.2 Destabilization and Oil Droplet

Viability of the Whey Protein-based

RPO Emulsions

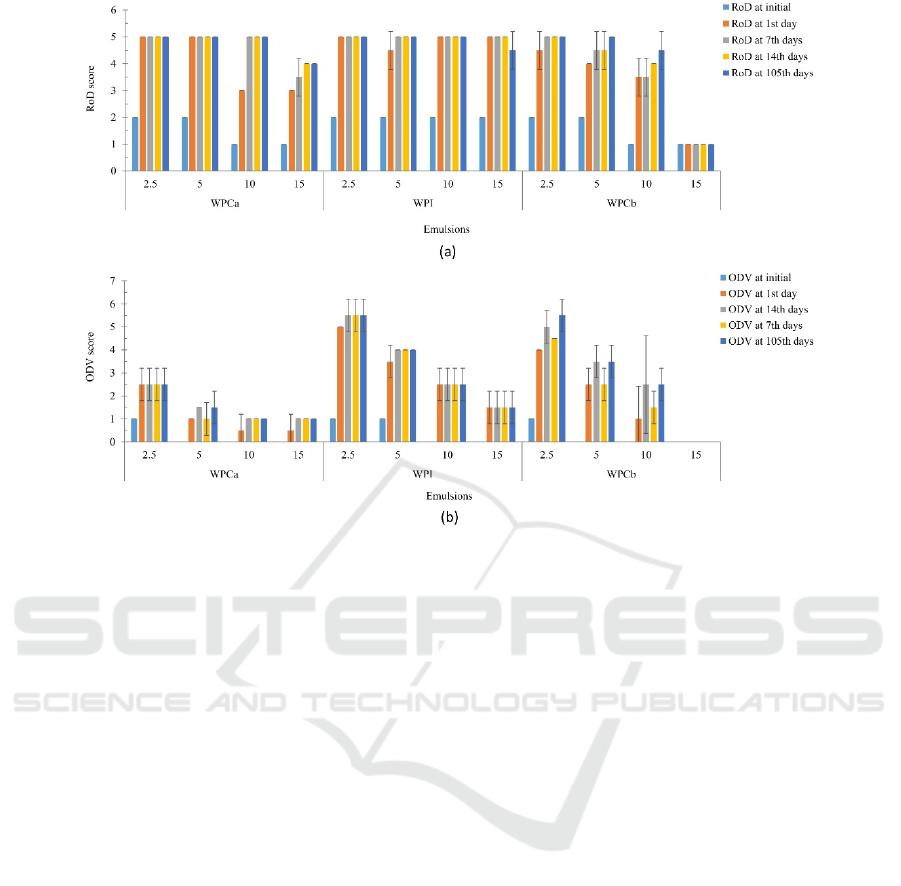

The destabilization of whey protein-based RPO

emulsions was also evaluated based on the rating of

destabilization (RoD) and the rating of oil droplet

viability (ODV) at the top of emulsions. The system

was evaluated for the appearance of destabilization at

the beginning of storage and also after 1

st

, 7

th

, 14

th

,

and 105

th

days of storage. RoD and ODV scores of

the whey protein-based RPO emulsion are presented

in Figure 3. The results confirm the findings

described in section 3.1 that the twelve whey protein-

based RPO emulsions had varying stability.

A whey protein-based RPO emulsion system with a

higher emulsifier concentration was observed to be

more stable on storage. There is a trend that shows the

type of emulsifier affects the stability of the emulsion

system. The difference in stability was perceived

from the destabilization that first occurred in the

system with WPI, namely the separation in the form

of cream formation (shown in Figure 1). In fresh

emulsions, systems with higher emulsifying

concentrations, such as 10% and 15%, were observed

to be more stable with no appearance of cream

droplets on the top surface except in the emulsion

emulsified with WPI. Emulsion emulsified with WPI

was observed to experience complex destabilization

earlier than the system with WPC; the higher rating

of destabilization system indicates this since the

beginning of storage.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

188

Figure 3: The rating of destabilisation (a) and oil droplet viability (b) of the whey protein-based RPO emulsions produced

during storage.

The whey protein-based RPO emulsion system

was not observed to undergo a large amount of oil

phase separation. Oil separation was observed in the

form of oil droplets that did not form an oil layer. This

was due to the characteristic of protein that can absorb

oil in the emulsion system. The WPI-stabilized

emulsion was observed to have more separated oil

droplets than that of WPCa and WPCb. This results

are corresponding to the findings we described earlier

that the systems emulsified with WPCa and WPCb

were more stable than the ones emulsified with WPI.

The systems with lower emulsifying concentration

were observed to have more oil droplets separated.

Therefore, the whey protein-based RPO system had

better stability to oil droplet separation when the

concentration used was high (i.e., 15%).

4 CONCLUSIONS

Whey protein-based RPO emulsion was produced

with a rotor-stator in this study. The emulsion's

stability was investigated based on visual

observation. Whey protein emulsifier type and its

concentration were found to influence the stability of

RPO emulsion. A stable emulsion system was

obtained by having WPCb as the emulsifier at 15%

concentration. Conclusively, WPCb is proposed as a

potent emulsifier for producing RPO emulsion with

better stability.

ACKNOWLEDGEMENTS

This study was funded by The Indonesian Ministry of

Research and Technology/National Research and

Innovation Agency through a PMDSU research grant.

We are thankful to Glanbia Nutritionals for providing

commercially available whey proteins.

REFERENCES

Abd El-Salam, M. H., El-Shibiny, S., & Salem, A. (2009).

Factors affecting the functional properties of whey

protein products: A review. Food Reviews

International, 25(3), 251–270. https://doi.org/10.1080/

87559120902956224

Adjonu, R., Doran, G., Torley, P., & Agboola, S. (2014).

Whey protein peptides as components of

nanoemulsions: A review of emulsifying and biological

functionalities. Journal of Food Engineering, 122(1),

15–27. https://doi.org/10.1016/j.jfoodeng.2013.08.034

Anvari, M., & Joyner (Melito), H. S. (2017). Effect of

formulation on structure-function relationships of

concentrated emulsions: Rheological, tribological, and

microstructural characterization. Food Hydrocolloids,

Physical Characterization of Red Palm Oil Emulsion

189

72, 11–26. https://doi.org/10.1016/j.foodhyd.2017.04.0

34

Aswathanarayan, J. B., & Vittal, R. R. (2019).

Nanoemulsions and their potential applications in food

industry. Frontiers in Sustainable Food Systems,

3(November), 1–21. https://doi.org/10.3389/fsufs.20

19.00095

Ayu, D. F., Andarwulan, N., Hariyadi, P., & Purnomo, E.

H. (2016). Photodegradation kinetics of chlorophyll,

tocopherol , and carotenoid in red palm oil. Agritech,

36(2), 117–127.

Banasaz, S., Morozova, K., Ferrentino, G., & Scampicchio,

M. (2020). Encapsulation of Lipid-Soluble Bioactives

by Nanoemulsions. Molecules. https://doi.org/10.3390/

molecules25173966

Charoen, R., Jangchud, A., Jangchud, K., Harnsilawat, T.,

Naivikul, O., & McClements, D. J. (2011). Influence of

biopolymer emulsifier type on formation and stability

of rice bran oil-in-water emulsions: Whey protein, gum

arabic, and modified starch. Journal of Food Science,

76(1), E165–E172. https://doi.org/10.1111/j.1750-

3841.2010.01959.x

Chong, W. T., Tan, C. P., Cheah, Y. K., Lajis, A. F. B.,

Dian, N. L. H. M., Kanagaratnam, S., & Lai, O. M.

(2018). Optimization of process parameters in

preparation of tocotrienol-rich red palm oil-based

nanoemulsion stabilized by Tween80-Span 80 using

response surface methodology. PLoS ONE, 13(8), 1–

22. https://doi.org/10.1371/journal.pone.0202771

Dauqan, E., Sani, H. A., Abdullah, A., Muhamad, H., &

Md. Top, A. G. (2011). Vitamin E and beta carotene

composition in four different vegetable oils. American

Journal of Applied Sciences, 8(5), 407–412.

de ALMEIDA, D. T., Viana, T. V., Costa, M. M., Silva, C.

D. S., & Feitosa, S. (2019). Effects of different storage

conditions on the oxidative stability of crude and

refined palm oil, olein and stearin (Elaeis guineensis).

Food Science and Technology, 39, 211–217.

https://doi.org/10.1590/fst.43317

Dybowska, B. E. (2011). Whey protein-stabilized emulsion

properties in relation to thermal modification of the

continuous phase. Journal of Food Engineering,

104(1), 81–88. https://doi.org/10.1016/j.jfoodeng.20

10.11.030

Gasa-Falcon, A., Odriozola-Serrano, I., Oms-Oliu, G., &

Martín-Belloso, O. (2020). Nanostructured lipid-based

delivery systems as a strategy to increase functionality

of bioactive compounds. Foods, 9(3).

https://doi.org/10.3390/foods9030325

Loganathan, R., Subramaniam, K. M., Radhakrishnan, A.

K., Choo, Y. M., & Teng, K. T. (2017). Health-

promoting effects of red palm oil: Evidence from

animal and human studies. Nutrition Reviews, 75(2),

98–113. https://doi.org/10.1093/nutrit/nuw054

Matalanis, A., Jones, O. G., & McClements, D. J. (2011).

Structured biopolymer-based delivery systems for

encapsulation, protection, and release of lipophilic

compounds. Food Hydrocolloids, 25(8), 1865–1880.

https://doi.org/https://doi.org/10.1016/j.foodhyd.2011.

04.014

McClements, D. J., Decker, E. A., & Weiss, J. (2007).

Emulsion-based delivery systems for lipophilic

bioactive components. Journal of Food Science.

https://doi.org/10.1111/j.1750-3841.2007.00507.x

McClements, David Julian. (2007). Critical review of

techniques and methodologies for characterization of

emulsion stability. Critical Reviews in Food Science

and Nutrition, 47(7), 611–649. https://doi.org/10.1080/

10408390701289292

McClements, David Julian. (2009). Biopolymers in Food

Emulsions. In Modern Biopolymer Science (pp. 129–

166). Elsevier Inc. https://doi.org/10.1016/B978-0-12-

374195-0.00004-5

McClements, David Julian. (2010). Emulsion Design to

Improve the Delivery of Functional Lipophilic

Components. Annual Review of Food Science and

Technology, 1, 241–269. https://doi.org/10.1146/annu

rev.food.080708.100722

Nagendran B., Unnithan U., Choo, Sundram, K. (2000).

Charasteristics of red palm oil, a carotene-and vitamin

E- rich refined oil for food uses. Food and Nutrition

Bulletin, 21(2), Food and Nutrition Bulletin. 21(2):189.

https://doi.org/10.1177/156482650002100213

Özbek, Z. A., & Günç Ergönül, P. (2017). A review on

encapsulation of oils. Celal Bayar Üniversitesi Fen

Bilimleri Dergisi, 13(2), 293–309. https://doi.org/10.1

8466/cbayarfbe.313358

Qian, C., & McClements, D. J. (2011). Formation of

nanoemulsions stabilized by model food-grade

emulsifiers using high-pressure homogenization:

Factors affecting particle size. Food Hydrocolloids,

25(5), 1000–1008. https://doi.org/10.1016/j.foodhyd.2

010.09.017

Ravindran, S., Williams, M. A. K., Ward, R. L., & Gillies,

G. (2018). Understanding how the properties of whey

protein stabilized emulsions depend on pH, ionic

strength and calcium concentration, by mapping

environmental conditions to zeta potential. Food

Hydrocolloids, 79, 572–578. https://doi.org/10.1016/

j.foodhyd.2017.12.003

Scrimshaw, N. S. (2000). Nutritional potential of red palm

oil for combating vitamin A deficiency. Food and

Nutrition Bulletin, 21(2), 195–201. https://doi.org/

10.1177/156482650002100214

Sohail, M., Ahmed, T., Akhtar, S., Durrani, Y., & Section,

F. B. (2010). Effect of sunlight on quality and stability

of dietary oils and fats, 43(3), 123–125.

Wang, Z., Neves, M. A., Isoda, H., & Nakajima, M. (2015).

Preparation and Characterization of Micro / Nano-

emulsions Containing Functional Food Components

*

. Japan Journal of Food Engineering, 16(4), 263–276.

Wilde, P., Mackie, A., Husband, F., Gunning, P., & Morris,

V. (2004). Proteins and emulsifiers at liquid interfaces.

Advances in Colloid and Interface Science, 108–109,

63–71. https://doi.org/10.1016/j.cis.2003.10.011

Zhang, Y., Yang, N., Xu, Y., Wang, Q., Huang, P.,

Nishinari, K., & Fang, Y. (2019). Improving the

stability of oil body emulsions from diverse plant seeds

using sodium alginate. Molecules. https://doi.org/

10.3390/molecules24213856

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

190