Characterization of Edible Film Made of Pectin from Nutmeg and

Palmitic Acid

Payung Layuk, Meivie Lintang and Stevie Karouw

North Sulawesi Assessment Institute for Agricultural Technology, Jl. Kalasey-Minanga, Malalayang Dua,

Kec. Malalayang, Manado, North Sulawesi, Indonesia

Keywords: Nutmeg, Pectin, Edible Film.

Abstract: The development of biopolymers as a packaging material is increasingly needed to reduce environmental

pollution due to the use of synthetic plastics which are biologically difficult to break down. Nutmeg contains

pectin which can be used as a base for making edible films. The aim of the study was to determine the

characterization of the edible film from the pectin of nutmeg with the addition of palmitic acid and glycerol

as a plasticizer. The results showed that the increase in the concentration of pectin and palmitic acid tended

to significantly increase the thickness of the edible film, the elongation rate and the tensile strength of the

film, but it could decrease the water vapor transmission rate and the film solubility. The best treatment was a

concentration of 30% wet pectin (w / v) and palmitic acid 0.04% (w / w) which resulted in the lowest water

vapor transmission rate of 2.39 (g / mm / m

2

hour).

1 INTRODUCTION

Packaging is one way to protect food from the

influence of internal and external factors that cause

damage. Thus the role of packaging materials is very

important.Plastic is the most widely used for

packaging material, but plastic have weaknesses such

as non-biodegradable properties, which remain in the

environment for long periods of time, they remain

threats to the environment (Krochta and Johnston

1997).

The need for packaging materials for developed

countries reaches 250 kg / per capita / year, while for

countries that are starting to develop and are poor, is

5 kg / capita / year. Approximately 30% of the total

residential solid waste is packaging material and 13%

of this amount is plastic waste. In other words, plastic

waste reaches 4% of the total residential solid waste.

The biggest demand for packaging is in the form of

flexible packaging which reaches 42% of total sales.

Followed by Paper Board Packaging 28%, Rigid

Plastic Packaging 14%, Woven Polyolefin Sack 6%,

Metal Can Packaging 5%, Glass Container Packaging

3% and others 2%. Due to the nature of plastic which

is difficult to break down naturally, its existence starts

to pollute the environment. However, plastic has the

advantages of being lightweight, strong and

economical. With these superior properties, it is

estimated that if the plastic is not replaced with other

packaging materials, it is estimated that the weight of

packaging waste will increase by 100%, the volume

will increase by 250% and the cost will increase by

250%. Therefore, it is necessary to develop other

packaging materials that have superior properties

such as plastic which is strong, lightweight and

economical as well as being biodegradable and even

edible.

In developed countries such as America, it has

responded to this challenge by developing edible

films using organic biopolymers from agricultural

products (Dumat, 1999). Edible film is a thin material

that covers a food ingredient and is safe for

consumption. Edible film serves as a barrier against

the transfer of water vapor, aroma, oxygen and gases

as well as protecting against microbial attack.

Usually, the function of edible films is enhanced by

adding antioxidants, antimicrobials, nutrients and

other food additives. The basic ingredients for

making edible films are biopolymers of agricultural

products including waste products such as protein

(corn, milk, wheat, soybeans) while carbohydrates

(starch, pectin, alginate) and fat. The use of

carbohydrates as a basic material for making edible

films is based on relatively cheap costs, abundance of

materials, and thermoplastic properties (Renata et al.,

Layuk, P., Lintang, M. and Karouw, S.

Characterization of Edible Film Made of Pectin from Nutmeg and Palmitic Acid.

DOI: 10.5220/0010565500003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 171-177

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

171

2014). One of the sources of carbohydrates is pectin.

The results of the research by Layuk, 2001 reported

that the old nutmeg contains 21.54% pectin so that it

has the potential to be used as a base for making

edible films. The edible film made from nutmeg

pectin does not experience damage (moldy) after

being stored at room temperature due to the presence

of polyphenols in the nutmeg which can inhibit the

growth of fungi on the edible film. Edible films made

from carbohydrates such as pectin, starch and alginate

have disadvantages, including easy hydration,

expands quickly and tears easily. To overcome this, it

is necessary to add fatty acids (McHugh and Krochta

1994). Edible film requires a plasticizer. Plasticizer

can flex and prevent the brittleness of the edible film.

Glycerol is a plasticizer, which is commonly used in

making edible films (Han, 2005). Glycerol contains

relatively small hydrophilic molecules and easily

inserted between the polymer chains of the base

material. This condition causes structural

modification of the molecules making up the edible

film. Glycerol molecules will disrupt the polymer

cohesiveness of the base material by reducing

intermolecular interactions and increasing polymer

mobility thereby improving the flexibility and

extensibility of the edible film.

Permeability concerns the process of transferring

solution and diffusion when the solution moves from

one side of the film and then diffuses to the other side

of the film. The thicker the edible film produced, the

better the ability of the edible film to hold water

vapor. Fatty acids such as glycerol and palmitic acid

have hydrophilic groups that reduce molecular

density so that they can form free space in the film

matrix which facilitates diffusion of water vapor

(Ruan et al. 1998). Several studies have combined

two types of materials to improve the quality of edible

films such as; breadfruit and chitosan (Setiani et al.,

2013), whey protein concentrate and / or with

mesquito gum / sodium alginate / caragenate

(Villagomez-Zavala, et al., 2008), pectin and tapioca

(Layuk, 2001), sago starch and carrageenan

(Anggraini 2012). Nutmeg pectin and sago starch

(Layuk, et al, 2019), lindur fruit starch with

carrageenan (Jacoeb, 2014), soybean and tapioca

extract (Sinaga et al, 2013), Dangke and Agar (Fatma,

et al, 2015), starch sweet potato with glycerol (2018)

and nutmeg pectin and sago starch (Layuk, et al,

2019).

The research aimed to develop nutmeg pectin as a

raw material for making edible films with the addition

of plasticizers (palmitic acid) in various

concentrations and their effects on the characteristics

of the films produced.

2 MATERIALS AND METHODS

2.1 Materials and Tools

The materials used in the study were nutmeg, palmitic

acid, glycerol, calcium chloride (CaCl2), distilled

water, HCl and alcohol. The tools used is a digital

scale, beaker glass, measuring cup, hot plate stirrer,

magnetic stirrer, thermometer, glass plate measuring

8 x 7 x 2 cm, oen, Ioyid Instrument, micrometer and

other auxiliary equipment.

2.2 Research Methods

The research was carried out at the Laboratory of the

North Sulawesi Agricultural Technology Study

Center and the Laboratory of the Faculty of

Agricultural Technology, UGM Yogyakarta, from

March to December 2019. The stages of the research

included the isolation of pectin, making edible film

and the characteristics of the edible film.

2.3 Pectin Isolation (Layuk 2001)

Nutmeg pectin is obtained through several stages.

Ripe nutmeg is washed and cut in half to separate the

seeds and pulp. The pulp of the nutmeg is then cut

into 2 x 2 cm cubes. Then blanched for 5 minutes in

boiling water to activate the enzyme. Then dried in an

oven at 50 C for 8-12 hours until the moisture content

reaches 10-11%. Dried nutmeg is ground with a

fineness level of 50 mesh. Then the nutmeg powder

was extracted using HCl pH 2.0 at a temperature of

80 C for 2 hours. The schematic of pectin extraction

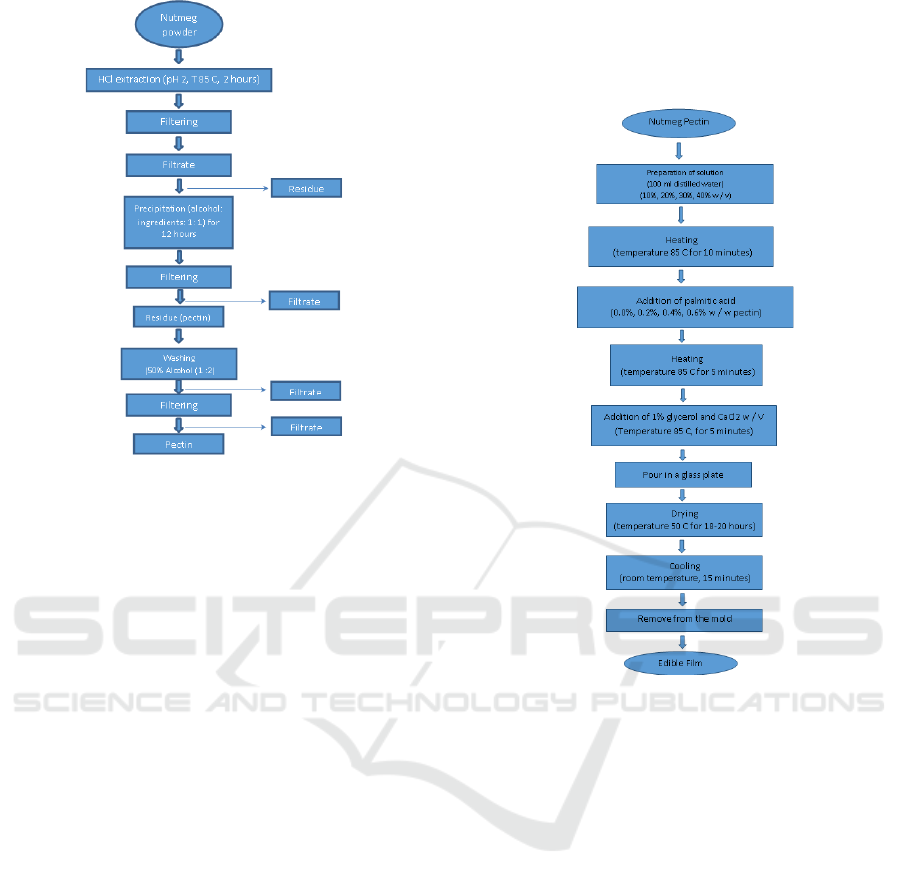

and isolation is shown in Figure 1.

2.4 Edible Film Making

Nutmeg pectin with concentrations of 10% (A1), 20%

(A2), 30% (A3) and 40% (A4) w / v and palmitic acid

0% (B0), 0.02% (B1), 0, 04% (B2) and 0.06% w / w

pectin. The solution is made by adding pectin to 100

ml of distilled water which already contains 2% sago

starch. , then heated at a temperature of 85 C for 15

minutes while stirring with a magnetic stirrer. After

that the temperature was lowered to 40 C, then added

palmitic acid and glycerol. The heating was continued

again until the temperature was 85 C while stirring

with magnetic stirrer for 10 minutes until the solution

was homogeneous. The solution is then poured into a

glass plate mold measuring 8 x 7 x 2 cm (length x

width x thickness), dried at 50 C for 10-12 hours

(Figure 2). The film was then removed from the mold

and stored in a plastic container filled with silica gel

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

172

.

Figure 1: Pectin isolation.

for 12 hours. Relative humidity in a plastic container

is around 40-50%. The film is then cut into pieces

according to the parameters to be tested. Tensile

strength and elongation tests were 3 x10cm, for

WVTR a circle was made with a diameter of 7 cm.

The solubility is 2 cm x 2 cm. Before taking

measurements, the film was conditioned for 24 hours

in a plastic container containing silica gel.

The experiment used was factorial completely

randomized with three replications (Gomez and

Gomez, 1995)

2.5 Data Analysis and Collection

Procedure

Measurement of water content, ash content and

protein content (AOAC, 1984), methoxyl and

polygalaruronic concentrations (Rangana, 1977).

Testing thickness, tensile strength and elongation

(Gontard, et al, 1992) tensile strength and elongation

were measured using a Universal Testing Machine

(LIoyd Instrument), while film thickness was

measured using a micrometer ( accuracy 0.001 mm).

2.6 Film Solubility (Gontard et al, 1992)

The percentage of film solubility was determined by

heating the film at 100 C for 24 hours with two pieces

of edible film with a size of 2 x 2 cm. Weighed then

immersed in 50 ml of water containing 0.02% sodium

azide.

The immersed edible film was stored at 20 C for

24 hours. Then the film was taken and dried at 100 C

for 24 hours. To determine the solubility of the edible

film, it was calculated by subtracting the initial weight

minus the insoluble dry weight multiplied by 100%.

Figure 2: Edible film making.

2.7 Water Vapor Transmission Rate

WVTR Testing (ASTM, 1980)

The water vapor transmission rate (WVTR) using the

gravimetric method was determined using the ASTM

procedure (1980). The film to be tested is glued to a

bowl made of acrylic with an outer diameter of 8 cm,

an inner diameter of 7 cm and a thickness of 2 cm,

then filled with 50 ml of water. The acrylic bowl is

then stored in a jar containing silica gel. Relative

humidity 20%. The water vapor that diffuses through

the film will be absorbed by the silica gel, the amount

of which can be found by calculating the reduced

weight of the bowl filled with water at the time of

measurement. Weighing was done at intervals,

1,2,3,4,5,6 and 7 hours. All tests were carried out

twice. Changes in bowl weight and time are then

plotted on a graph where the y-axis is the weight of

the plate (g) when weighed and the x-axis is time

(from this graph a regression line equation will be

generated where the resulting slope is the rate of

weight gain per unit (g / hour). WVTR is calculated

Characterization of Edible Film Made of Pectin from Nutmeg and Palmitic Acid

173

by dividing the slope by the area of the film, so that

the WVTR unit is g / m2h.

3 RESULTS AND DISCUSSION

3.1 Nutmeg Pectin Identification

The results of the composition analysis and

identification of pectin are as shown in Table 1. The

results showed that the pectin obtained was high

methoxyl pectin. Towle and Chistinsesn (1973) stated

that pectin which has a methoxyl count of 7-14% is a

high methoxyl pectin. Meanwhile, if the methoxyl

content is 0 -7%, it is a low methoxyl pectin. The

galacturonic content obtained was 84.18% and

compared to the commercial pectin the level was

83.78%, it can be said that the pectin produced has a

level of purity. This is supported by the low ash

content of 1.49%. High methoxyl and

polygalacturonic content and low ash content indicate

the level of purity of pectin and the factors that play a

role in the gel formation of a pectin. The presence of

protein content can also support the success of

nutmeg pectin as a basic material for making edible

films.

Table 1: Nutmeg pectin composition with commercial

pectin.

Composition Nutmeg

p

ectin *

Commercial

p

ectin **)

Yield (%)

Water content (%)

Ash content (%)

Protein Content (%)

Methoxyl content

(%)

Polygalacturunoate

content

(

%

)

21,54

8,95

1,49

4,37

11,48

84.17

-

11,05

3,42

1,95

11,42

83.78

3.2 Film Thickness

The thickness of the films obtained ranged from 0.03

to 0.07 mm. The highest thickness was obtained at 3%

pectin concentration and 0.6% palmitic acid (A3B3).

In Figure 3, it can be seen that the higher the

concentration of pectin and palmitic acid, the thicker

the film produced. This occurs because the increasing

number of film-forming components, resulting in the

thicker film produced. The thickness of the film is

influenced by the amount of solids in the film forming

solution and the thickness of the mold. With the

addition of glycerol as a plasticizer, it can reduce the

thickness and force density between pectin molecules

so that the chain movement is good and the resulting

film is more flexible and smoother. This is possible

because glycerol is a small hydrophilic molecule that

can easily enter between pectin chains and form

bonds (Gontard et al, 1992, Layuk et al, 2019). The

same thing was reported by Sinaga et al, (2013) that

the addition of plasticizers such as glycerol has an

effect on the thickness of the edible film, elongation

and tensile strength of the film.

Figure 3: Edible film thickness at various concentrations of

pectin and palmitic acid.

3.3 Elongation

Film elongation is a mechanical property related to

the chemical structure of the film. Film elongation is

the change in the maximum elongation experienced

by the film during the tensile strength test at the time

the film is torn (Hay, 1968). According to Gontard

and Gilbert (1993), the mechanical properties of films

depend on the type of material, especially the

structural cohesion properties. This property is a

result of the polymer's ability to form strong

molecular bonds. The results of variance can be seen

that there is a very significant effect between the

pectin concentration on the percentage of film

elongation. The palmitic acid concentration of 0.2%

and without the addition of palmitic acid had a high

elongation compared to other treatments, both at

10%, 20% and 30% pectin concentrations. This is

because palmitic acid has anti-plasticizer properties

against pectin edible film. Gontard and Gulbert

(1993) said that fatty acids have anti-plasticizing

properties in films made from gluten. The same thing

was reported (Layuk, 2001 and Layuk et al, 2019) that

the anti-plasticizing properties of palmitic acid in

pectin were caused by the formation of a

galacturonic-fatty acid complex which will add to the

three-dimensional network integrity of the polymer

film, thereby reducing the elongation rate of the film.

Meanwhile, Min Lai and Hucy (1997) reported that

palmitic acid can act as a plasticizer that can change

the mechanical characteristics of edible films. The

addition of palmitic acid will be able to increase the

0

0,05

0,1

Film Thickness (mm)

Palmitic acid concentration

Pectin

concentration

10%

20%

30%

40%

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

174

0

5

10

15

Film elongation (%)

Palmitic acid concentration

Pectin

concentration

10%

20%

30%

40%

0

20

40

Tensile Strength (KPa)

Palmitic acid concentration

Pectin

concentration

10%

20%

30%

40%

90

92

94

Film solubility (%)

Palmitic acid concentration

Pectin

concentration

10%

20%

30%

40%

tensile strength of the film breaking. When it reaches

a critical point, the addition of palmitic acid (Park et

al., 2004) and glycerol (Fantasari et al) will decrease

the elongation and tensile strength of the film.

Figure 4: Edible film extension at various concentrations of

pectin and palmitic acid.

3.4 Tensile Strength

Tensile Strength is a mechanical property related to

the chemical structure of the film. Tensile strength is

defined as the maximum tensile stress that the sample

can accept. The mechanical properties of the edible

film depend on the film-forming material, especially

the structural cohesion properties.

This property is a

result of the polymer's ability to form strong

molecular bonds Gontard and Gulbert (1993). In

Figure 5, it can be seen that the higher the

concentration of pectin and palmitic acid the higher

the resulting tensile strength. The highest tensile

strength occurred in the treatment with pectin

concentration of 30% and palmitic acid 0.6%, which

is 8.71 kPa. This is because the galacturonic-palmitic

acid complex can add to the polymer integration of

the edible film so that the resulting tensile strength is

higher. The addition of palmitic acid and glycerol can

improve the mechanical properties of the film where

the film is stronger, more compact and flexible. The

addition of palmitic acid also increases the number of

carbons and functional groups in the matrix chain

thereby increasing the tensile strength and elongation

(Donhowe and Fennema 1994).

3.5 Edible Film Solubility

Solubility in a solution is one of the determining

factors in choosing edible film as a packaging

material. Figure 6 shows that the solubility of the film

decreases as more palmitic acid is added. This is due

to palmitic acid which has a high C chain (C16)

making it difficult to dissolve in water. According to

Koelsch and Labuza (1992), palmitic acid can dissolve

in polar and non-polar organic solvents. The ability to

Figure 5: Tensile strength of edible films at various

concentrations of pectin and palmitic acid.

Figure 6: Edible film solubility at various concentrations of

pectin and palmitic acid.

dissolve in water is influenced by the C chain. The

longer the C chain of fatty acids, the more difficult

their solubility in water is.

3.6 Water Vapor Transmission Rate of

Film (WVTR)

The ability of the film to withstand the water vapor

transmission rate can be seen in Figure 7. The

resulting water vapor transmission rate ranges from

2.39 g / mm / m2 / hour - 5.10 g / mm / m2 / hour.

The highest WVTR was obtained at treatment

concentrations of pectin 40% and palmitic acid 006%.

The high WVTR is due to the increasing number of

hydrophilic components in the film which causes

water absorption on the film and increases the weight

of the film during the WVTR measurement. This

proves that biodegradable films require hydrophobic

materials to reduce the rate of water vapor

transmission through the film. While the lowest was

at the pectin concentration of 30% and palmitic acid

0.4%. According to Hui (2006), palmitic acid can act

as a plasticizer that can change the mechanical

characteristics of edible film, which can increase

hydrogen bonding thereby reducing water vapor

transmission rates. However, when it reaches a

critical point the addition of palmitic acid will reduce

hydrogen bonding and increase the intermolecular

space which will increase the flexibility of the film

and provide a cavity that allows diffusion of penetrant

Characterization of Edible Film Made of Pectin from Nutmeg and Palmitic Acid

175

molecules (Layuk 2001 and Slade and Levine, 1991).

This is also due to the presence of glycerol which

causes the speed of water vapor and gas transmission

through the film to increase (Gontar et al., 1983) and

due to reduced molecular density so that free space is

formed in the film matrix so as to facilitate the

diffusion of water and gas. The same thing was found

in this study where the palmitic acid concentration of

0.6% both at 10%, 20% and 30% pectin

concentration, resulted in increased WVTR and the

resulting film surface was rather rough.

Figure 7: Water vapor Transmission Rate Edible film at

various concentrations of pectin and palmitic acid.

4 CONCLUSIONS

Nutmeg pectin can be used as material for

making edible films.

Increasing the concentration of pectin and

palmitic acid can increase the thickness,

elongation and tensile strength of the film, but

can reduce WVTR and film solubility.

The best treatment was pectin concentration of

30% and palmitic acid 0.4% where the smallest

water vapor transmission rate was 2.39g / mm /

m2 / hour.

REFERENCES

AOAC. 1984. Official Method of Analysis of Association

of Official Analytical Chemists, 14thEd. AOAC Inc.,

Arlington,Virginia.

ASTM. 1980. Standart Test Methods for Water Vapor

Transmission Of Materials. ASTM Book of Standards

Anggraini 2012. Characteristics of Edible Film from Sago

Starch with the Addition of Glycerol and Carrageenan.

Journal of Food and Agroindustry 1: 12-1

Bourtoom T. 2008. Review article edible films and

coatings: characteristics and properties. Journal

International Food Research 15(3):237-248.

Donhowe,G. and O. Fennema. 1994. Edible film and

Coting: Characteristics Formation, Definitions and

Testing Methods: Krochta, J.M., E.A.

Baldwin, and M.O.Nisperos-Carriedo (eds). Edible

Coatings and Films to Improve Food Quality.

Tecnomic Publ.Co.,Inc.,Lancaster, USA.

Dumat, 1996. Making edible films from a mixture of rubber

seed protein with casein. Postgraduate Thesis.Master

Program in Food and Science Technology. Faculty of

Agricultural Technology UGM.

Fatnasari, A. K. A. Nocianitri and I Putu Suparthana. The

Effect of Glycerol Concentration on The Characteristic

Edible Film Sweet Potato Starch (Ipomoea batatas L.).

Scientific Journal Of Food Technology Vol. 5, No.1, 27

- 35, March 2018.

Fatma, Ratmawati Malaka and Muhammad Taufik.2015.

Characteristics of Edible Film Made from Dangle

Whey and Agar Using Different Percentage of

Glycerol. JITP Vol. 4 No. 2, Page 63-69, July 2015

Fennema O, Donhowe IG, Kester JJ. 1994. Lipid type and

location of the relative humidity gradient influence on

the barrier properties of lipid to water vapor. Journal

of Food Engineering 22(1):225-239

Gontar, N. Guilbert and J.L. Cug. 1992. Water and

Glycerol as Plasticizer affect mechanical and water

vapor barrier properties of edible film wheat gluten

film. J. Food Sci: 58(1): 206-210

Gontard, N. and Gulbert,S. 1993. Bio Packaging.

Technology and properties of edible film and

biodegradable material of agricultural origin. In M.

Methiouthi. Food packaging and preservation. The AVI

Publ.Inc. Westport Connecticut.

Han, 2005. Innovations in Food Packaging. Department of

Food Science University of Manitoba Wiminpeg,

Manitoba Canada.

Hay,P.M. 1968. Properties and Methods of Identification of

Commercial Films. In O.J. (ed) .The Science and

Technology of Polymer Film, London.

Hui, Y. H. 2006. Handbook of Food Science, Technology,

And, Engineering Volume I. Crc Press. USA.

Jacoeb M. A. Roni Nugraha, Siluh Putu Sri Dia Utari. 2014.

Edible Film from Lindur Fruit Starch with Addition of

Glycerol and Carrageenan. JPHPI 2014, Volume 17

No 1.

Koelsch C.M. and Labuza, T.P. (1992). Functional

physical and morphological properties of methyl

cellulose and fatty acid-based edible barriers. Lebensm

Wiss U-Technol 25:404-411.

Krochta JM and Johnston CDM. 1997. Edible and

Biodegradable Polymer Film. Journal of Food

Technology 52(2): 1-20.

Layuk, P. 2001. Characterization of Nutmeg Pectin

Composite Edible Film with Tapioca.

PostgraduateThesis.Master Program in Food and

Science Technology. Faculty of Agricultural

Technology UGM

Layuk P . Sondakh J. Marietje P. Characteristics and

Permeability Properties of Sago Starch Edible Film.

AGRITEKNO, Journal of Agricultural Technology

Online Version: http://ojs3.unpatti.ac.id/index.php/

0

5

10

Water Vapor

Transmission Rate (%)

Palmitic acid concentration

Pectin

concentration

10%

20%

30%

40%

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

176

agritekno Vol. 8, No. 2, 34-41, Th. 2019 DOI:

10.30598/jagritekno.2019.8.2.34 ISSN 2302-9218

McHugh TH, Krochta JM. 1994. Sorbitol vs Glycerol

plasticized whey protein edible films: integrated oxygen

permeability and tensile strength property evaluation.

Journal of Agricultural and Food Chemistry 42(4):841-

845.

Min Lai an Huey 1997. Properties of microstructure of

sheets plasticized with palmitic acid. J. Cereal

Chemiestry 42(2).

Park, D.P., Sung, J.H., Choi, H.J. and Jhon, M.S. (2004).

Electroresponsive characteristics of highly substituted

phosphate starch. Journal of Material Science 39:

60836086.

Park JW, Testin, RF, Vergano DJ, Park KJ, Weller CL,

1996. Application of Laminated Edible Film to Potato

Chip Packaging. Journal of Food Science 61(4): 66-76

Rangana S. 1977. Manual of Analysis of Fruit and

Vegetable Product. Tat MC. Grow Hill Publishing

Company Limited New Delhi.

Renata C., dos Reis., I. A. Devilla, G. H. H. Oliveira, P. C.

Corrêa, D. P. R. Ascheri, A. B. M. Souzay and A. C. O.

Servulo. 2014. Mechanical Properties, Permeability

and Solubility Of Films Composed of Yam Starch and

Glycerol. INVERCIENCIA, 39: 410415.

Ruan RR, Xu L, Chen PL. 1998. Water Vapor Permeability

and Tensile Strength of Cellulose-Based Composite

Edible Film Applied Engineering In Agriculture

14(4):411-413.

Setiani, W., T. Sudiarti, L. Rahmidar. 2013. Preparation

and characteristics of edible films from polyglend

breadfruit starch-chitosan. Valensi, 3(2): 100-10.

Sinaga L.L., Melisa S. R .S, Mersi S. S. 2013.

Characteristics of Edible Film From Soybean Extract

With The Addition Of Tapioca Flour And Glycerol As

Food Packaging Materials USU's Chemical

Engineering Journal, Vol. 2, No. 4 (2013)

Slade and Levine, 1991. Beyond water activity: Recent

advances on an alternative approach to the assessment

of food quality and safety. Food Sec. 61(1): 192-194.

Towle, G.G. and Chistinsen, O. 1973. Pectin, in

R.L.Wister Industrial GUM. Academic press New

York.

Villagomez-Zavala, D. L., C. Gomez-Corona, E. S.

M.Matinez and J. P. P. Orozco. 2008. Comparative

study the mechanical properties of edible films made

from single and blended hydrophilic biopolymer

matrices. Revista Mexicana de Ingenieria Quimica,

7(3): 263-273.

Characterization of Edible Film Made of Pectin from Nutmeg and Palmitic Acid

177