The Effect of Addition of Plastic Waste in Porous Asphalt

Concrete on Permeability and Properties Marshall

Eko Wiyono, Anni Susilowati, Pratikto

Department of Civil Engineering, Politeknik Negeri Jakarta, Jln. Prof. Dr. GA Siwabessy,

UI Depok 16425, New Campus, Depok, Indonesia

Keywords: Porous Asphalt Concrete, Plastic Waste, Permeability

Abstract: Porous asphalt mixture has low stability but high permeability due to the cavities in the mixture. For this

reason, it is necessary to add other materials in order to increase the stability of pavement mixture. The

purpose of this study was to obtain the Marshall property value of the porous asphalt concrete mixture. This

study is also analyze the effect of plastic waste in the porous asphalt concrete mixture on the permeability

and properties of Marshall. This research used is the experimental method in the laboratory. The Optimum

Asphalt Content (KAO) made with asphalt content 4.5%; 5%; 5.5%; 6%; and 6.5% without variation of

plastic waste. Furthermore, it is also made by KAO and the addition of plastic waste by 0%; 5%, 10%, 15%,

20% and 25% and tested with Marshall test and permeability. The results of the research with 5,5% KA0,

that the addition of plastic waste in the porous asphalt mixture can increase the value of stability, flow, and

marshall quotient. with an average value of 25% plastic waste content of 1296.71 kg; 3.62 mm and 353.19

kg / mm. However, the VIM and permeability values decreased, respectively, with an average value 20.65%

and 0.188 cm / s. The mixture of porous asphalt with plastic waste, for all parameters Marshall satisfied the

specifications required by the Australian Asphalt Pavement Association (2004) for moderate traffic

1 INTRODUCTION

One of the pavement types currently being

developed as a cover layer is porous asphalt

concrete. This mixture has low stability but high

permeability of cavities in the mixture. For this

reason, it is necessary to add other materials to

increase the stability value of the pavement mixture

(Arlia, Sofyan, Renni, 2018). The porous asphalt

mixture also contains a large percentage of coarse

aggregate, a small percentage of fine aggregate, thus

providing a large air cavity that can drain water

from the surface into the soil. The large cavity

makes porous asphalt has a low stability value. To

increase stability, added materials are needed

(Supriyadi, 2018 dan Ghulam, 2017). The high

cavity content results in a larger oxidized asphalt

surface which reduces the ability of the binder to

maintain the aggregate position, therefore an asphalt

with strong durable, and high viscosity binding

capacity is required. The porous asphalt mixture is a

mixture of hot asphalt between open-graded

aggregate and modified asphalt with a certain ratio

(Affan, 2006).

Plastic is a commodity that is often used in

everyday life. The most possible way to handle

plastic waste is to reuse plastic (reuse), reduce

plastic consumption (reduce), and recycle (Anonim,

2018). Recycling plastics can be used as a mixture

of asphalt concrete. Asphalt concrete plastic has

been developed in several areas such as Bekasi and

Bali. Asphalt Concrete plastics has several

advantages, namely having a high level of pavement

better, it is not easy to leave a trail of wheels when

wet asphalt is traversed vehicle, and its durability

also increases when compared to ordinary asphalt

(Sumadilaga, 2017). According to (Zulfiani,2012)

that plastic flakes can dissolve in 60/70 penetration

asphalt at a temperature of 1540C. The substitution

of plastic flakes for 60/70 penetration asphalt can

save the use of asphalt by 2.5% of the weight of

asphalt used in the mixture asphalt concrete AC-

WC. With the percentage of PE and HDPE as an

asphalt mixture of 0%, 2%, 4% and 6% of the

weight of the asphalt tends to increase the value of

stability, flow, and VFA but tends to decrease the

values of VIM, VMA, and MQ. The effect of adding

HDPE on the application of asphalt mixture

Wiyono, E., Susilowati, A. and Pratikto, .

The Effect of Addition of Plastic Waste in Porous Asphalt Concrete on Permeability and Properties Marshall.

DOI: 10.5220/0010560200003153

In Proceedings of the 9th Annual Southeast Asian International Seminar (ASAIS 2020), pages 127-132

ISBN: 978-989-758-518-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

127

Marshall characterization value is better than the

mixture of asphalt with PE (Rahmawati, 2015).

According to Veranita, 2016) with an optimum

asphalt content of 5.88%, a permeability of 0.28%

was obtained and the higher the retona blend content

of 55 in the porous asphalt mixture, the stability,

and durability values increased while the

permeability and cavity levels continued to

decrease. (Novrianto, 2016) that the use of LDPE

plastic values for density, stability, and Marshall

Quotient (QM) all meet the requirements (General

Specifications of Bina Marga 2018). According to

(Ismayalomi, 2019) the addition of PET plastic:

LGA can increase the stability value due to the same

PET properties as asphalt and the presence of

bitumen content in the LGA granules, an increase

also occurs in the value flow because the more PET:

LGA content can make the mixture more flexible.

HDPE plastic waste as bitumen binder provides

better resistance to permanent deformation due to its

high stability and high Marshall Quotient and

contributes to the recirculation of plastic waste for

environmental protection.

There are several advantages of porous asphalt,

according to Kraemer, (1997) in (Falderika, 2004);

Greater slip resistance; Rapid drainage of water

from the pavement surface which reduces wet time

from the surface; and Flexibility without fatigue or

rutting. Apart from these advantages, there are

several disadvantages of porous asphalt mixtures,

including (Falderika, 2004): Low stability; Requires

a high cost; Has low durability so that the service

life of the pavement ranges from 7 to 10 years.

(Hendrastianto, 2019) Plastic waste is a waste

material made of plastic that is no longer used and is

no longer useful for human life. Plastic waste can

become useful again after being recycled. As for PP

plastic (polypropylene) seeds, it is a seed plastic

made of propylene monomer which has rigid,

odorless, and properties resistant to chemical

solvents, acids, and alkalis.The process of recycling

plastic waste into plastic pellets (pellets).

(Veranita. 2016) The addition of 2% -4% UF

on KAO, shows that the permeability coefficient

value of the open-graded asphalt concrete mixture is

increasing, this indicates that the greater the addition

of UF, the greater the cavities produced by the

mixture and the faster the water flow time from the

surface to the bottom of the concrete asphalt. this

addition of UF will provide stiffness and reduce the

elasticity of the asphalt.

Typical mean values of

porous asphalt aggregate grading for a maximum

diameter of 10 mm, 14 mm and 20 mm are quoted

from AAPA (2004).One of the aggregates grading

for porous asphalt according to (Australian Asphalt

Pavement Association,2004) is as in Table 1 below.

Table 1. Aggregate Grading Limits for Porous Asphalt

Mixtures, (According to Australian Asphalt Pavement

Association, 2004)

Sieve

Size

(mm)

Filter Pass Specifications

(

%

)

Range Ideal

19,0 100 100

12,7 85

–

100 92,5

9,5 45

–

70 57,5

4,75 10

–

25 17,5

2,36 7

–

15 11

1.18 6

–

12 9

0.6 5

–

10 7,5

0.3 4

–

86

0.15 3

–

75

0.075 2

–

53,5

The specifications of porous asphalt concrete

mixture according to

(According to Australian

Asphalt Pavement Association, 2004) as shown in

Table 2

Table 2. Specifications of mix concrete asphalt Porus

,according to (According to Australian Asphalt Pavement

Association, 2004)

No

Planning

Criteria

Unit Value

1. Cantabro loss % Mak 20

2.

A

sphalt flow down % Mak 0,3

3. Stability Marshall Kg Min.

500

4. Flow Mm 2

–

6

5. Voids % 10

–

28

6. Marshall Quotient Kg/mm Maks.

400

7. Densit

y

g

r/cm3 Min. 2

8. Durabilit

y

% ≥75

9. Permeability cm/dt 0.187-

0.844

(Suhardi, 2013) The addition of variations of

PET (Polyethylene Terephthalate) to the AC-BC

(Asphalt Concrete-Binder Course) mixture affect on

Marshall characteristics, the higher the level of

addition of PET (Polyethylene) Terephthalate) then

the stability value will increase but for the value of

the cavity content in the mixture the higher the

percentage. Meanwhile, (Ali, 2013) a mixture of

porous asphalt based on asbuton using Japanese

grading has a permeability value of 0.143 cm / s,

and a marshall stability value of 952.92 kg. These

results indicate a sufficient of potential feasibility in

ASAIS 2020 - Annual Southeast Asian International Seminar

128

using Asbuton-based porous asphalt mixtures. The

purpose of this research was to obtain the properties

Marshall of porous asphalt concrete mixtures with

variations of plastic waste and to analyze the effects

of plastic bag waste on the properties Marshall of

asphalt concrete mixtures

2 RESEARCH METHOD

This research was carried out in the Laboratory of

Civil Engineering Material Testing, State

Polytechnic of Jakarta. The materials used in this

study were Esso asphalt, coarse-aggregate of

crushed stone, rock ash, and plastic waste. This

research was conducted at the Laboratory of Civil

Engineering Material Testing, State Polytechnic of

Jakarta. The materials used in this study were Esso

asphalt, coarse-aggregate of crushed stone, rock ash,

and plastic waste.

The main research method used is an

experimental method by making a specimen of

porous hot asphalt concrete mixture. To determine

the optimum asphalt content, a mixture of porous

asphalt and plastic waste tannin was made with an

asphalt content of 4.5; 5; 5.5; 6; and 6.5%. After

obtaining KAO, then making the test object by

adding variations of plastic waste of 0, 5, 10, 15, 20

and 25% to KAO. For each variation of asphalt

content and variations in plastic waste, 3 test objects

were made for each type of test. The total number of

specimens in need in this study was 105 pieces, as

shown in Table 3 as follows:

Table 3. Variation of plastic waste in Mixture Concrete

asphalt Porous

Number

of

Variation of plastic waste (%) Totta

l

Objec

t

Test

5 10 15 20 25

Marshall

Standart

3 3 3 3 3 15

Cantabr

o Loss

3 3 3 3 3 15

Asphalt

Flow

Down

3 3 3 3 3 15

Permeab

ilit

y

3

3

3 3 3 15

Total

12

12

12 12 12

60

60

3 RESULTS AND DISCUSSION

3.1 Aggregates and Test Results

Asphalt

From the test results of the physical properties of

aggregates, each of them fine aggregate and coarse

aggregate meet the specifications. The test results

with a specific gravity greater than 2.5 indicate that

the aggregate can be used for roads with high traffic

volume. The results of the examination physical

properties of aggregate and asphalt are presented in

Table 4.

Table 4. Results of Aggregate and Asphalt Inspection

Tests Unit

Results

of

Testing

Requirement

Bina Marga

2018

Min Max

FINE

AGGREGATE

-Bulk Specific

Gravit

y

2.57 2.5 -

-Apparent

Specific Gravit

y

2.68 2.5 -

Water Absor

p

tion % 1.59 - 3

COARSE

AGGREGATE

- Bulk Specific

Gravit

y

2.56 2.5 -

-Apparent

Specific Gravit

y

2.7 2.5 -

Water Absor

p

tion % 2.15 - 3

ASPHALT

Penetration m

m

65 60 79

Specific Gravit

y

1,02 0,92 1,06

Softenin

g

Point ⁰C 48,5 45 -

Ductilit

y

m

m

101 100 -

3.2 Test Marshall Asphalt Concrete

Mixtures

Results for Porous Marshall test results for porous

asphalt concrete mixtures without plastic waste

obtained KAO 5.5%. Furthermore, with KAO 5.5%,

and variations of plastic waste 0, 5, 10, 15, 20 and

25%, the recapitulation is presented in Figures 1 to

7.

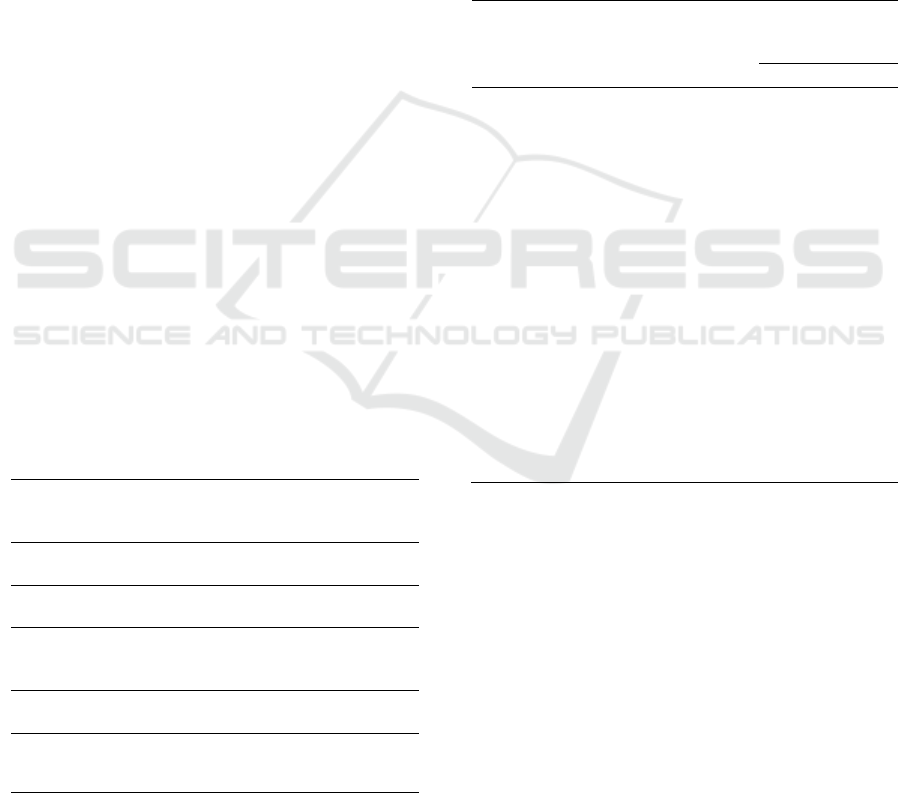

3.2.1 VMA

Based on the results of statistical tests, the

significance value is 0.002 <0.05, so it can be

concluded that the variation of plastic waste has a

significant effect on VMA and the value of R square

The Effect of Addition of Plastic Waste in Porous Asphalt Concrete on Permeability and Properties Marshall

129

is 0.930 which means that the variation of plastic

waste has an effect of 93.0% on VMA. The test

results also showed that the VMA value tended to

decrease with the increase in plastic waste, although

the decrease was small. (As in Figure 1).

Figure 1. VMA Graph

3.2.2 VFB

The significance value of the statistical result tests

was 0.0025 <0.050, so it can be concluded that the

variation of plastic waste has a significant effect on

VFB. The value of R square is 0.755 which means

that the variation of plastic waste has an effect of

75.5% on VFB. The test results also show that the

VFB value tends to increase with the addition of

variations in plastic waste(as in Figure 2).

Figure 2. VFB Graph

3.2.3 VIM

The significance value of the result test was 0.001

<0.05, so it can be concluded that the variation of

plastic waste has a significant effect on VIM. The

value of R square is 0.959%, which means that the

variation of plastic waste has an effect of 95.9% on

VIM. The relationship between plastic waste and

VIM shows a tendency for the cavity value to

continue to decrease according to the addition of

plastic waste because fills the mixed cavity. The

VIM value was suitable to the required in the 2004

AAPA specifications, namely 10 - 28% ( Figure 3)

Figure 3. VIM Graph

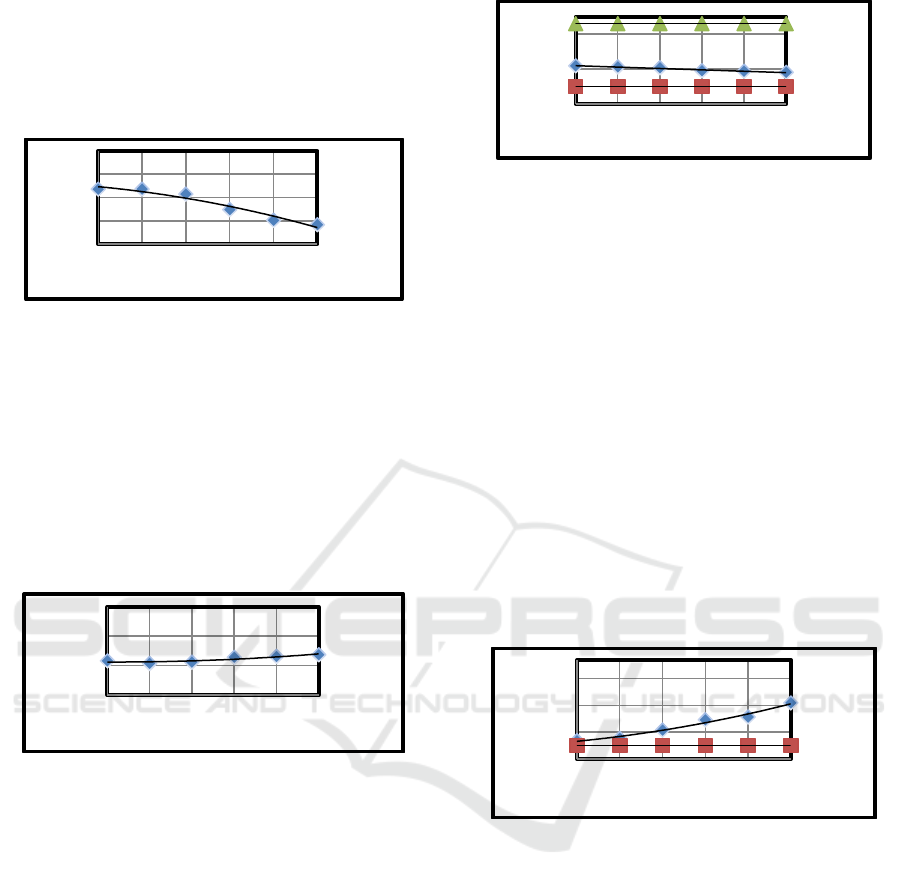

3.2.4 Stability

The significance value of the result test was

obtained a value of 0.001 <0.05, so it can be

concluded that the variation of plastic waste has a

significant effect on stability. This can be seen from

the R square value of 0.963 which means that the

variation of plastic waste has an effect of 96.3% on

stability. The value of the stability of the mixture is

higher along with the increasing variation of plastic

waste in the mixture. This is because plastic waste is

mixed with 60/70 penetration asphalt in the mixture,

where this mixing causes the adhesion of the asphalt

to be better so that the value of the stability of the

mixture increases. The value of stability value was

suitable to the required in the 2004 AAPA

specifications, which is a minimum of 500 kg (As in

Figure 4).

Figure 4. Stability Graph

3.2.5 Flow

The significance value of the result test, it is found

that a significance value of 0.004 <0.05, so it can be

concluded that the variation of plastic waste has a

significant effect on melting.. This can be seen

from the value of R square is 0.893, which means

that the variation of plastic waste has an effect of

89.3% on melting. Meltability continues to increase

with an increasing variety of plastic waste, as the

asphalt blanket increases. The melting value was

suitable to the required in the 2004 AAPA

specifications, namely 2 - 6 mm ( Figure 5).

24,00

25,00

26,00

27,00

28,00

0 5 10 15 20 25

VMA(%)

PLASTICWASTE(%)

30,00

40,00

50,00

60,00

0 5 10 15 20 25

VFB(%)

PLASTICWASTE(%)

5,00

15,00

25,00

0 5 10 15 20 25

VIM(%)

PLASTICWASTE(%)

250,00

750,00

1250,00

1750,00

0 5 10 15 20 25

Stability (Kg)

PLASTICWASTE(%)

ASAIS 2020 - Annual Southeast Asian International Seminar

130

Figure 5. Flow Graph

3.2.6 Marshall Quotient

The significance value of the result test was

obtained a value of 0.001 <0.05, so it can be

concluded that the variation of plastic waste has a

significant effect on the Marshall Quotient. This can

be seen from the R square value of 0.866, which

means that the variation of plastic waste has an

effect of 86.6% on the Marshall Quotient. More and

more plastic waste increases the Masrshall Quotient

(MQ). The MQ value was suitable to the required

in the 1997 AAPA specifications is a maximum of

400 kg / mm (as in Figure 6)

Figure 6. Marshall Quotient Graph

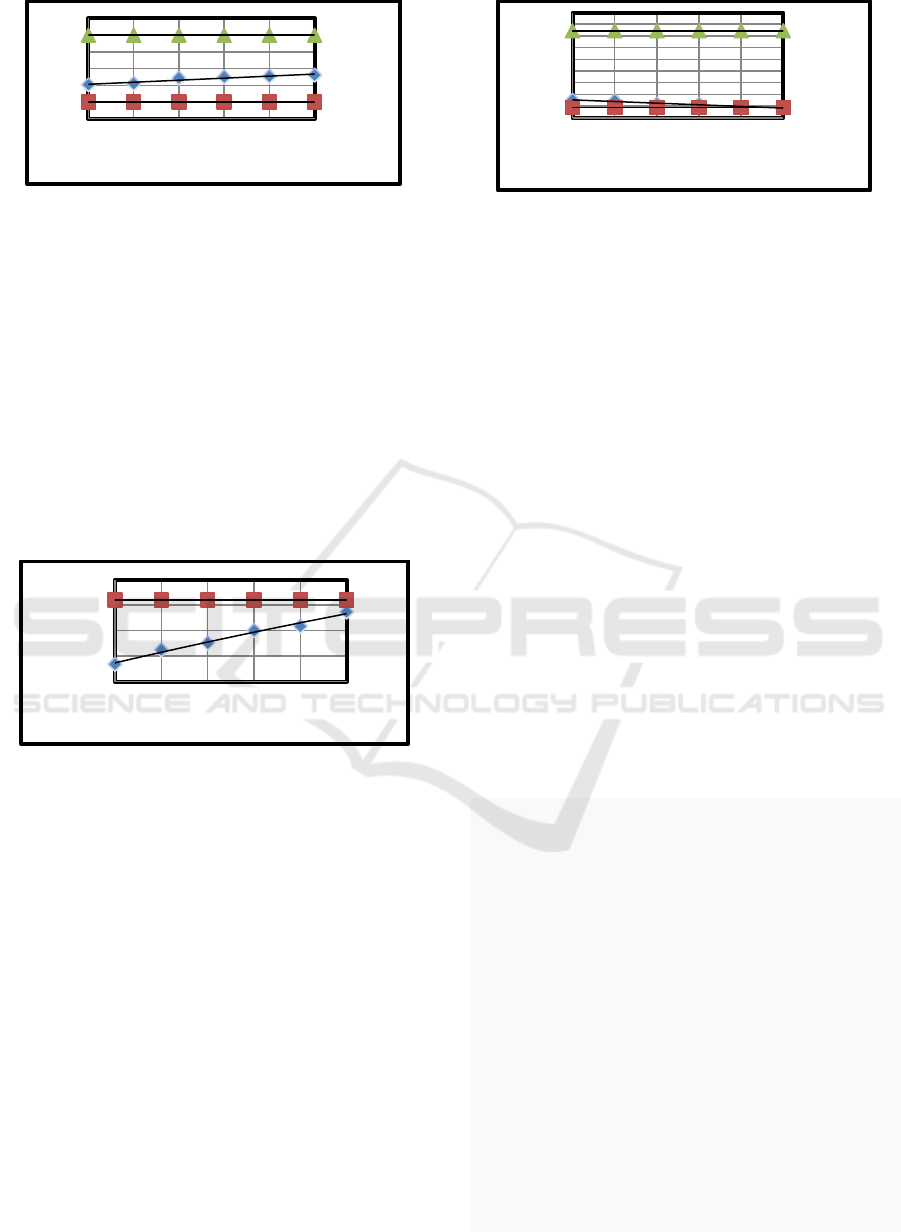

3.2.7 Permeability

The significance value of the result test was

obtained a value of 0.001 <0.05, so it can be

concluded that the variation of plastic waste has a

significant effect on permeability. This can be seen

from the R square value of 0.946, which means that

the variation of plastic waste has an effect of 94.6%

on permeability. The results test shows that the

relationship between plastic waste and the

permeability coefficient where the increase in

plastic waste, the permeability coefficient value of

the porous asphalt concrete object will decrease, this

is because the increase in plastic waste, the volume

of cavities inside the test object decreases due to the

closure of the cavity. by the asphalt film so that the

time to drain water from the surface will be longer.

(as in Figure 7)

Figure 7. Permeability Graph

4 CONCLUSION

The results of this research shows that: The

variation of plastic waste from 0 to 25% of the

optimal asphalt content has a significant effect to the

VIM, Stability, Meltness, and values Marshall

Quotient, and permeability but did not significantly

influence the VFB and VMA values because the

significance value> 0.05.

In addition, the addition of plastic waste

increases the% cavity filled with asphalt, stability,

Melt, Marshall Quotient and melt and lower%

cavity in the mixture, % voids between aggregates,

and permeability.

As for the addition of plastic waste up to 25% to

KAO for all parameters of Marshall has met the

specifications required by the Australian Asphalt

Pavement Association (2004) for moderate traffic

REFERENCES

AAPA. Australian Asphalt Pavement Association. 2004.

Open Graded Asphalt Design Guide, Australian

Affan.M, 2006, Study of the Role of Cavities on Stability

and Durability of Porous Asphalt Mixtures Due to

Addition of Mortar, Thesis, Masters in Civil

Engineering, Undergraduate Program, Syiah Kuala

University, Banda Aceh

Ali, Nur., Halidin Arfan, J. Patanduk, Muralia Hustim.

2013 Study of Permeability Mixed Buton Asphalt

based on Buton Asphalt (Asbuton), 3rd National

Seminar on Civil Engineering 2013 Muhammadiyah

University of Surakarta

Anonim. 2018. Impact of Plastic on the Environment

https://bulelengkab.go.id/detail/artikel/dampak-plastik-

terhadap-lingkungan-88. 8 mei2020

Arlia, L., Sofyan M. S, & Renni A. 2018. Characteristics

of Porus Asphalt Mixture with Gondorukem

Substitution in Asphalt Penetration 60/70 Journal of

Civil Engineering, Syiah Kuala University ISSN 2088-

9321 Syiah Kuala University ISSN e-2502-5295.

Thing. 657 - 666.5 May 2020

1,00

2,00

3,00

4,00

5,00

6,00

7,00

0 5 10 15 20 25

FLOW (mm)

PLASTICWASTE(%)

80,00

180,00

280,00

380,00

480,00

0 5 10 15 20 25

MQ(Kg/mm)

PLASTICWASTE(%)

0,100

0,200

0,300

0,400

0,500

0,600

0,700

0,800

0,900

1,000

0 5 10 15 20 25

Permeability (cm/dt)

PLASTICWASTE(%)

The Effect of Addition of Plastic Waste in Porous Asphalt Concrete on Permeability and Properties Marshall

131

Circular Number:… / SE / Db / 2018. General

Specifications of Bina Marga 2018 for Road and

Bridge Works. Directorate General of Highways

Falderika.2004. Evaluation of Resilient Modulus and

Permanent Deformation of Porous Asphalt Mixtures

with Buton Natural Asphalt (BNA) Addition.

Unpublished thesis. Asphalt Masters Program in

Highway Systems and Engineering, ITB.

reponsitory.unikom.ac.id. p / VII21-VII26. 10 MAY

2020.

Ghulam, Mirza R., Wahyu Nariswari, Enes Ariyanto S.,

Tri Gunawan. (2017). Nilai Stabilitas Porous Asphalt

Menggunakan Material Lokal

Hendrastianto, Z. A. 2019. Plastic Waste Treatment Process

Using Extrusion Machine

https://foresteract.com/author/zulkarnain-ali/

Ismayalomi, S. Boedi R. Pranoto. 2019. Experimental

Study of Addition of Pet Plastic (Polyethylene

Terephthalate) and Asbuton LGA (Lawele Granular

Asphalt) to Porus Asphalt Mixture. Journal of

Buildings, Vol. 24, No.1, March 2019: 1-14. 5 May

2020. Journal2.um.ac.id

Novrianto, Ignatius B. A. 2016. Effect of Addition of

Plastic Waste as Addition to Ac-Wc Asphalt Concrete

With Gypsum Filler.

http://ejournal.uajy.ac.id/id/eprint/9188. May 5, 2020.

Rahmawati, A. 2015. The Effect of Polyethylene (Pe) and

High Density Polyethylene (Hdpe) Plastics in the

Lataston-Wc Mixture on Marshall Characteristics.

Semesta Teknika Scientific Journal Vol. 18, No.2,

147-159.

https://journal.umy.ac.id/index.php/st/article/viewFile/181

6/1820 10mei2020

Sumadilaga, D. H. 2017. Ministry of PUPR Trials

Mixture of Asphalt-Waste Plastics.

Https://www.suara.com/bisnis/2017/12/15/1030/

Suhardi., Priyo Pratomo., Hadi Ali. 2016. Study of

Marshall Characteristics on Asphalt Mixture with

Addition of Plastic Bottle Waste. JRSDD, June 2016

Edition, Vol. 4, No. 2, Page: 284-293 (ISSN: 2303-

0011)

Supriyadi, I. R. D. Boedi Rahardjo. Pranoto (2018).

Kajian Eksperimental Campuran Aspal Porus Den-

Gan Bahan Tambahan Plastik Hdpe (High Density

Poly Ethylene) Jurnal Bangunan, Vol. 23, No.2,

Oktober 2018: 19-28

Veranita. 2016. Determination of the Optimum Asphalt

Content for Porus Asphalt Mixtures Using the Retona

Blend 55 with the Australian Method. Journal of Civil

Engineering, Faculty of Engineering. Vol. 2 No.1

April 2016. Pages 80 - 90. May 2010

Zulfiani, A. S. A. Adisasmita , S. Rauf , 2012. Study of

the Characteristics of Asphalt Concrete Mixture (AC-

WC) on the Effect of Plastic as Asphalt Substitution

Material. Journal of Final Project Univ. Hasannuddin.

2012 pp. 1-16. 7mei2020

ASAIS 2020 - Annual Southeast Asian International Seminar

132