Quality Deterioration and Shelf Life Determination of Purwaceng

Coffee based on Packaging Variation using Accelerated Shelf Life

Testing (ASLT)

Alan S. U.

1

, Endy S.

2

, Wagiman

3

and Jumeri M. W.

1

1

Lab. of Bioindustry, Department of Agroindustrial Technology, Gadjah Mada University, Indonesia

2

Lab. of System Analysis, Department of Agroindustrial Technology, Gadjah Mada University, Indonesia

3

Lab. of Waste and Byproduct Engineering, Department of Agroindustrial Technology,

Gadjah Mada University, Indonesia

Keywords: Packaging, Purwaceng Coffee, Shelf Life.

Abstract: Purwaceng coffee is a varian of coffee products that has benefits for human health. The quality of purwaceng

coffee has significantly related with their shelf life. However, many purwaceng coffee producer still predicts

the shelf life manually without scientific method, which has relatively low accuration. Therefore, many

studies have been conducted to overcome that poblem in order to extend their shelf life. Packaging-based

prediction used since that method could detemine the shelf life of the poduct adequately. The aim of this study

is to analysis quality deterioration of purwaceng coffee and determine their shelf life based packaging

variation. The packaging used were PAP 0.11, AF 0.05, PP 0.05, PP 0.03, and PE 0.03. The quality

deterioration of purwaceng coffee was measured by 6 parameters, namely water content, water activity (Aw),

weight, pH, colour, and antioxidant activity. Water content was determined by thermogravimetry method,

colour by chromameter, and determination of antioxidant activity was carried out by DPPH method.

Futhermore, the product shelf life test was performed using the critical moisture content method. The longest

shelf life of coffee product was reached by AF 0.05 which has shelf life of 322 days and permeability value

of 0.27 g H

2

O/mmHg.m

2

.day.

1 INTRODUCTION

Coffee is an agricultural commodities which has the

most reliability in Indonesia. Coffee is not a native

plant of Indonesia, but originated from the African

Continent (Anonym, 1988). Purwaceng plant is an

endemic species that grows in the altitude mountains

of 1,800 - 3,500 m above sea level in West Java

(Mount of Pangrango), Central Java (Dieng plateau)

and East Java. Purwaceng seeds are expensive

commodities which has high demand as the herbal

medicine or functional food industry (Anonym, 2000,

Rostiana, 2006). Purwaceng coffee is the product

which containing a combination between coffee and

purwaceng powder, as well as other additives with a

percentage based on a determined formula.

The deviations in product quality from the

beginning of their quality are called deterioration

(Arpah, 2001). The deterioration process is caused by

a reaction that starts from contacting the product with

air, oxygen, water vapor, light, or due to changes in

temperature. This reaction can also be preceded by

physical treatments such as vibration, compression,

and also abrasion.

Packaging is one determinant of product shelf life.

Packaging permeability was the important factor in

relation to quality deterioration and shelf life

determination of product in a packaging through its

critical water content. Some of common quality

attributes which affected the product self life were

water content, water activity, pH, weight and colour

change (Brown et al., 2011). Each packaging has

specific caracteristics that will affect their capacity to

maintain product inside toward harsh environmental.

There were two methods for determine the shelf

life of a food item, namely Extended Storage Studies

(ESS) and Accelerated Shelf Life Test (ASLT)

(Floros and Gnanasekharan, 1993). Extended Storage

Studies is the conventional method of determining

expiration by storing a product under normal

conditions, then observing changes in their quality

U., A., S., E., Wagiman, . and W., J.

Quality Deterioration and Shelf Life Determination of Purwaceng Coffee based on Packaging Variation using Accelerated Shelf Life Testing (ASLT).

DOI: 10.5220/0010546800003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 137-144

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

137

and shelf life. This method requires the same amount

of time as the quality change, therefore, if the quality

change was long, the time used for research using this

model will also be long. The ESS method usually

used for food products that have a shelf life less than

3 months, whereas the ASLT methods was more

suitable to predict the food products that have a shelf

life more than 3 months.

There are two kind of approaches for determining

the shelf life with the ASLT method namely the

Arrhenius approach and the critical moisture content

approach. The Arrhenius approach is used for food

products that are damaged due to chemical reactions

which are influenced by temperature factors. The

critical moisture content approach is used for food

products caused by adsorption of mositure content,

usually it used in dried food products (Anandito et al,

2017). Objectives of the research were to analyze the

isothermic sorption curve of purwaceng coffee

products, to predict the self life of purwaceng coffee

in various types of packaging, and to analyze the

effect of packaging on the decline in quality of

purwaceng coffee

2 EXPERIMENTAL METHOD

2.1 Material

Robusta coffee roasted powder from a farmer in

Gunung Kelir, Semarang. The coffee which used is

robusta medium roasted. These coffee was packaged

in PP 0.05 mm of thickness. Purwaceng powder was

originated and produced by purwaceng farmer group

at Dieng, Wonosobo. This powder also packaged in

PP 0.05 of thickness. Addictive ingredient in this

product is non diary creamer and sugar. The materials

was sealed for further experiment. The materials were

keept on room temperature in the laboratory of

bioindustry, Gadjah Mada University before using.

In this study, purwaceng coffee was packaged

using 5 types of packaging. There were alumunium

foil (AF) (thickness of 0.05 mm), combination of

poliethylene - alumunium foil - paper foil (PAP)

(thickness of 0.11 mm), polipropylene (PP)

((thickness of 0.05 mm), polipropylene (PP)

((thickness of 0.03 mm), and poliethylene (PE)

(thickness of 0.03 mm).

2.2 Purwaceng Coffee Production

Purwaceng coffee production process generally

consists of 3 stages of production, namely the

manufacture of Robusta coffee powder, manufacture

of Purwaceng powder, and the mixing of ingredients.

Making robusta coffee powder using a roaster and

grinder with type roasting medium and fine grinding.

Purwaceng powder produce by drying purwaceng

plants, cleaned, and mashed using grinder to become

smooth. The following step is blend and homogenize

of robusta coffee powder, non dairy creamer,

purwaceng powder, and sugar. The mixtures were

then packaged using 5 type of packaging and kept in

room temperature for further experiment.

2.3 Quality Deterioration Testing

Quality deterioration of purwaceng coffee was tested

by 6 parameters. Those parameters were water

content, water activity (Aw), weight, pH, colour, and

DPPH antioxidant activity. Water content was

determined by thermogravimetry method, Aw was

measured by Aqualab Series 3 (USA), weight by

analitycal balance (ACIS 600i), pH by pH meter 009

(I) A (USA), colour by cromameter (Konica Minolta

FR 400), and antioxidant activity was measured by

DPPH method.

The samples were stored in incubator (Memmert

GmbH) at 30

o

C for 90

days. This assay was carried

out periodically every 15 days. Statistical test using

IBM SPSS Statistic 24 was performed for the

comprehensive test result from all of the assay. The

statistical tests used include data normality tests,

homogenity tests, and ANNOVA tests, and Kruskall

Wallis test. Statistical test was used to determine the

effect of packaging variations on the quality changes

of product packaged. A general quality deterioration

test was also used to confirm the estimated shelf life

that has been determined previously.

2.4 Determination of Purwaceng

Coffee Shelf Life

2.4.1 Initial Water Content (Mo)

Measurement

Initial water content was determined by

thermogravimetric method to evaporate the water

inside product. This experimental procedure refers to

the procedure of the Association of Official

Analytical Chemists/AOAC (Anonym, 1995). Two

grams of sample was evaporated using oven dyer at

105°C for about 6 hours, and then placed it in a

dessicator vacuum for 15 minutes before weighing

the dried samples using analytical balance. The assay

was carried out in triplicate.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

138

2.4.2 Isothermic Sorption Curves

Measurement

Determination of moisture isothermic sorption in this

study was conducted using the static

thermogravimetric method, Principle of this method

is to evaporate the water content when the sample in

an equilibrium state. Based on Anandito et al (2017,

data unpublished), the isothermic sorption curve was

determined at constant temperature (30

o

C). In this

study, different relative humidity (RH) was achieved

by using several saturated salt of NaBr, NaNO

2

,

NaCl, KCl, and BaCl

2

, which gave a relative humidity

value of 56%, 64%, 75%, 84% and 90%, respectively.

2.4.3 Packaging Permeability Test

The packaging permeability test for water vapor in

this study used the ASTM E-96 procedure by using a

device in the form of a WVTR (Water Vapor

Transmission Rate) cup filled with 15 grams of dry

silica gell and the sample of the package was placed

on a WVTR dish. After that, the weight of the WVTR

cup is weighed once a day for 7 days. According to

the ASTM E-96 (American Method) procedure, the

temperature and RH required for data collection are

30

o

C ± 2

o

C and RH 50-60%. The temperature and

relative humidity was controlled in an incubator.

2.4.4 Determination of Shelf Life

Determination of purwaceng coffee shelf life was

carried out using the equation as follow (Labuza,

1984):

t =

(1)

Components used for determine the shelf life were

initial water content (M

o

), critical water content (M

c

),

and equilibrium mositure content (M

e

). These three

parameters were expressed in units of g H

2

O / 100 g

solid. Material permeability (k/x) was expressed in gr

H

2

O/mmHg.m

2

.day. The surface area of the

packaging (A) is 0.00945 m

2

, and the weight of the

product/package was 21 grams. Saturated vapor

pressure was denoted by P

o

and the slope of the

isothermic sorption curve was denoted by b.

2.4.5 Statistical Analysis

All assay were carried out in at least triplicates.

Analysis of Varian (Annova) was used to analyze the

significance differences of parametric data of the

packaging with least significance difference (LSD) at

p < 0.05 as a level of significance. Meanwhile,

Kruskall Wallis was used to analyze the significance

differences of non parametric data.

3 RESULT AND DISCUSSION

3.1 Quality Deterioration

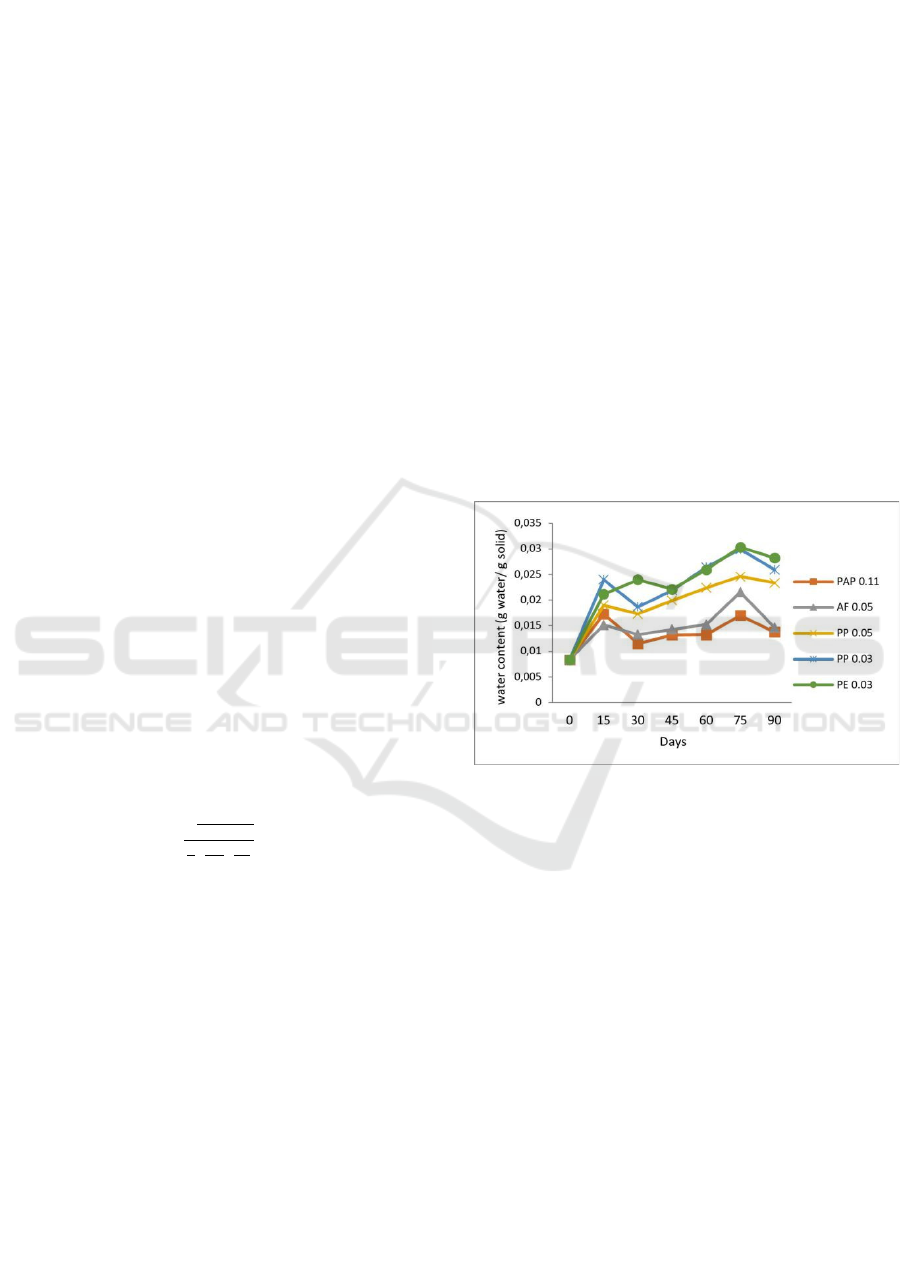

3.1.1 Water Content Assay

Water content is one of quality parameters which has

significant effect on agriculture product deterioration.

The result showed that all samples has a stagnant

increase of water content in general, eventhough at

90th day there was a decrease in water content in all

packaging. Increase in water content among 5

packaging showed different values. The result of

water content deterioration test was depicted in

Figure 1.

Figure 1: Quality deterioration graph based on water

content parameter.

The smallest increase in water content occurred in

the PAP 0.11 and AF 0.05 packaging, while the

largest increase of water content occurred in the PE

0.03 packaging. This differences of water content

increase may caused by the differences of the

packaging nature, especially in terms of packaging

permeability. Permeability of packaging materials

indicate the ability of packaging materials to protect

the products inside from the transpiration rate of

water vapor coming from the environment. The

smaller the permeability value, the better the

packaging's ability to protect the product from

transpiration of water vapor.

According to the water content as shown in Figure

1, AF 0.05 packaging has the lowest permeability

value, following by PAP 0.11, PP 0.05, PP 0.03, and

packaging PE 0.03 with highest permeability value.

Rahayu and Eny (2007) state that aluminum foil (AF)

Quality Deterioration and Shelf Life Determination of Purwaceng Coffee based on Packaging Variation using Accelerated Shelf Life Testing

(ASLT)

139

packaging was better than Polyethylene as well as

hand paper when used to maintain the moisture

content. That was the reason that the permeability

value of the aluminum foil packaging was smaller

than the other two packaging. Products which

packaged using aluminum foil also showed lower

water content. The smaller the increment of water that

enters the material, the better the packaging to use.

Based on the ANNOVA analysis, the significance

value of 0.009 (<0.05) was obtained, means that the

population tested was significantly different.

Therefore, it can be concluded that based on water

content parameters, the type of packaging

significantly influences the quality deterioration of

purwaceng coffee.

From the results of the Post Hoc Test by water

content parameter, data groups that have different

significantly was occurred in 2 pairs. Those data

were the decrease in water content in PAP 0.11 - PP

0.03 and PAP 0.11 - PE 0.03 packaging. Another

pairs data groups was not different significantly at all.

This means that the reduction in water content in the

packaging of PAP 0.11 and PP 0.03 was significantly

different.

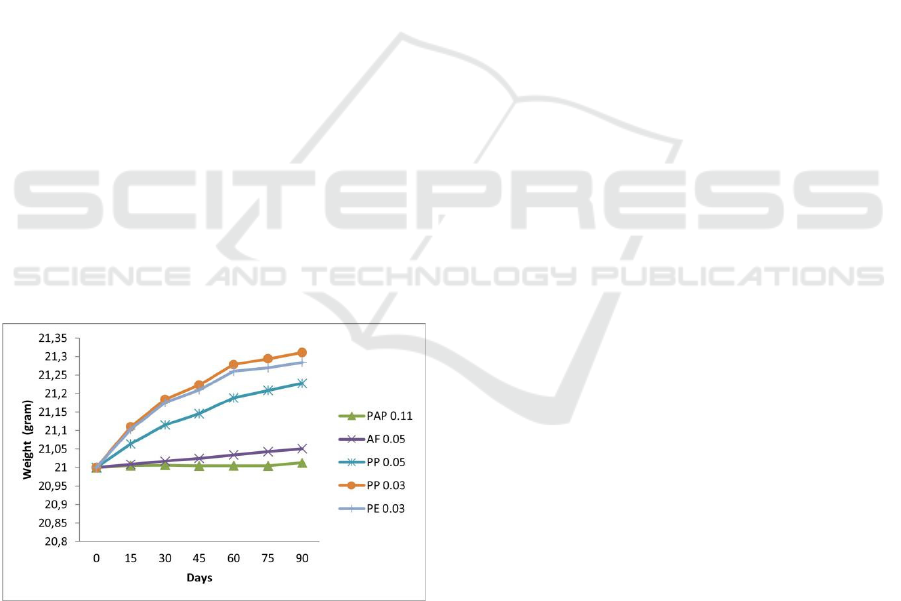

3.1.2 Weight Assay

The weight of purwaceng coffee stored in five

packaging showed that all have an increased stagnant

of water content in general. The product weights on 5

packaging have different values. The result of weight

deterioration test was depicted in Figure 2.

Figure 2: Quality deterioration graph based on weight

parameter.

According to Figure 2, the smallest weight

occurred in the PAP 0.11 and AF 0.05 packaging,

while the largest weight occurred in the 0.03 PE

packaging weight testing carried out for 90 days. This

difference in weight value occurs may caused by the

differences in the nature of the packaging, especially

in terms of packaging permeability. It also shows the

similarity between the results of water content and the

weighting assay of purwaceng coffee.

Kruskal Wallis test was performed in this assay

because the data classified into non-parametric data.

Kruskal Wallis test results obtained a significance

value of 0.005 (<0.05), indicated that the population

data was different significantly. The results showed

that the use of packaging variations has significant

influences to quality deterioration of purwaceng

coffee based on weight parameter.

The average weight of samples with PAP 0.11

packaging had the smallest weight changes,

meanwhile samples with PP 0.03 packagimg had the

highest average weight changes among 5 packaging.

Based on post hoc test, it can conclude that different

weights between populations occur in PAP 0.11

packaging against PP 0.05, PP 0.03, PE 0.03 and vice

versa. AF 0.05 packaging was also has different

significantly from PP 0.05 packaging, PP 0.03, PE

0.03 and vice versa. Population data which were not

significantly different occurred in PP 0.05 packaging

against PP 0.03, PE 0.03. In addition, PP 0.03 and PE

0.03 packaging also have not significant weight

differences.

3.1.3 Water Activity (Aw) Assay

The existence of microorganism growth in

purwaceng coffee was proven by the results of water

actuvity test. The assay results showed that

purwaceng coffee stored at 86% RH (Aw value of

0.86) and 90% RH (Aw value of 0.9) for 43 days has

been overgrown by microorganisms (mold)

As the results of water activity assay using

aqualab within a span of 90 days, the value of water

activity in purwaceng coffee was under 0.4, its mean

that storage of purwaceng coffee until the 90 days was

not affect their quality and suitable for consumption.

If purwaceng coffee consumed more than the

specified shelf life limit, it can endanger consumers

because the microorganisms have begun to grow. The

result of water activity deterioration assay was

depicted in Figure 3.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

140

Figure 3: Quality deterioration graph based on water

activity parameter.

In addition, the water activity assay was also used

as a parameter for determine the effect of packaging

variations on the quality deterioration. The value of

Aw tends to rise, even though on the 45

th

day until the

90

th

day has decreased. In general, the greatest

increase of Aw occurred in PP 0.03 packaging, while

the smallest increases in PAP 0.11 and AL 0.05

packaging.

The significance value of the five packaging has a

value > 0.05, its mean that the weight change data has

a normal distribution. Using homogeneity test with a

significance value of 0.928, the data was considered

to have homogenity. Based on the ANNOVA test, a

significance value of 0.000 was obtained, indicate

that based on the parameters of water activity, the

type of packaging significantly affected the quality

deterioration of purwaceng coffee products.

Based on post hoc test, 6 pairs of data groups have

significant difference. The pairs of data groups were

PAP 0.11 and PP 0.05, PAP 0.11 and PP 0.03, PAP

0.11 and PE 0.03, AF 0.05 and PP 0.03, and AF 0.05

and PE 0.03.

3.1.4 pH Assay

The degree of acidity (pH) is very influential on the

taste and aroma of coffee. According to Kustiyah

(1985), at a pH interval between 4.9-5.2 will give a

preferred coffee beverage aroma in general. The pH

will increase to greater than 6.0 if the roasting

imperfectly (lightly roasted). The optimum pH of

robusta coffee is between 5.0-5.8, while the pH of

ground coffee produced in the United States in

between 4.7-5.2 (Sivetz, 1972)

According to Winarno (2004), some

microorganisms such as mold and yeast can break

down acids so that they will increase pH. Mold will

isolate the acid and produce a final product that is

alkaline due to the proteolysis reaction. In addition,

the increase in pH occurs due to the formation of

compounds from protein decomposition by

microorganisms that are basic as ammonia. Ihwani

(2008) also states that, increasing or decreasing the

pH value is strongly influenced by the results of the

degradation formed and the ionic balance of the

protein solution. The result of water activity

deterioration test was depicted in Figure 4.

Figure 4: Quality deterioration graph based on pH

parameter.

Changes that occur in this pH test, do not

experience stagnation or a constant decrease. In

general, the change in pH of the two packages is only

at intervals 6.1 to 6.4. The pH value at the beginning

of the storage period was 6.2, then changed until the

last day (90th day), obtained information that the PAF

0.11 and PP 0.05 packages were able to maintain the

most stable pH value and close to the initial pH

quality value of 6.23. The 0.05 aluminum foil

packaging has decreased pH to 6.16, while the PP

0.03 and PE 0.03 packages have increased to 6.26 and

6.3, respectively.

Statistical analysis showed that the pH change of

the five packaging has a significance > 0.05 mean that

the pH change was to be normal data. Furthermore,

the homogeneity test obtained a significance value of

>0.05 indicate that the data was homogeneous and to

be further analyzed by ANNOVA. ANNOVA

statistical analysis showed a significance value of

>0.05, indicate that the type of packaging used was

not significantly affect the pH change of purwaceng

coffee.

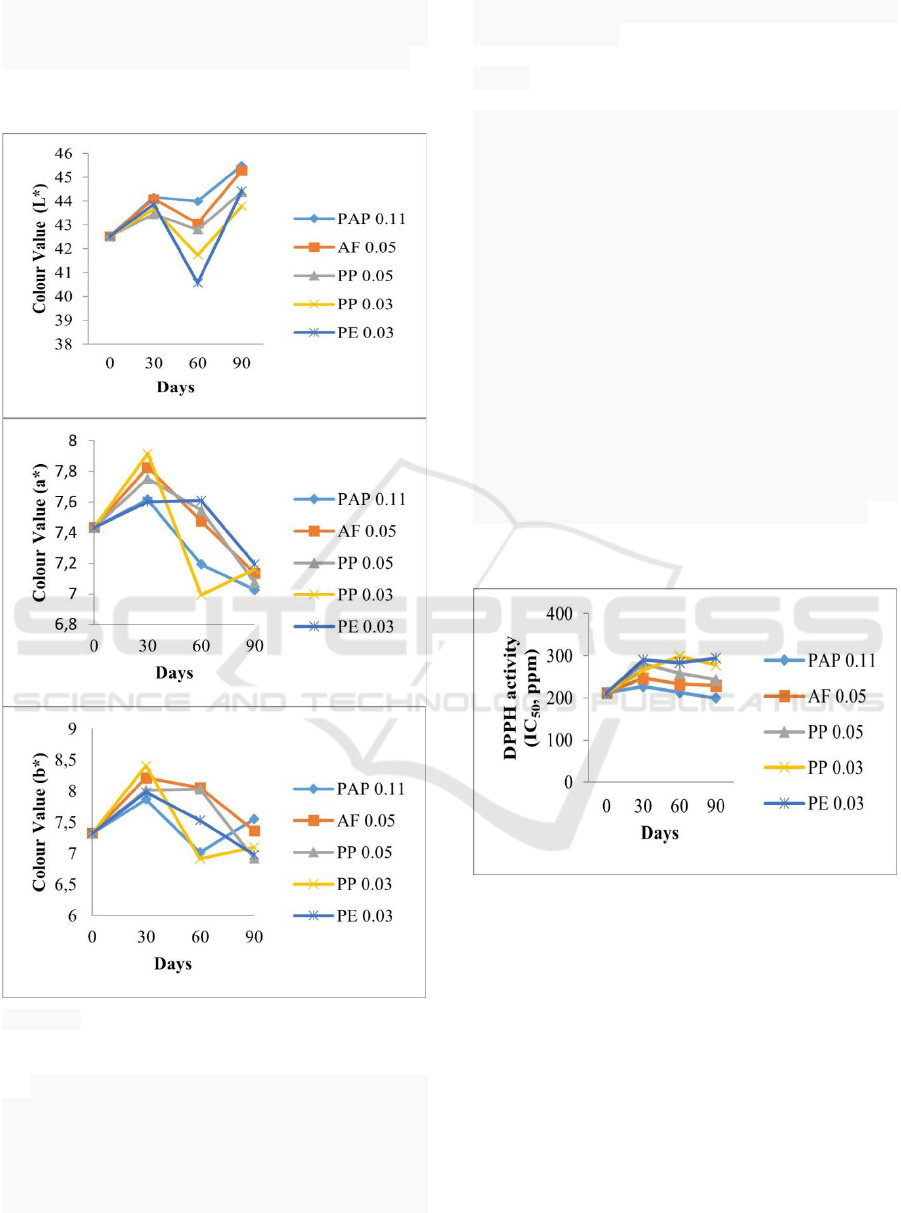

3.1.5 Lightness

According to Bicho et al (2012), brightness /lightness

(L*) decreases significantly with increasing roasting

intensity, and this process affects the browning level

of the product or is generally easier to understand

with longer and higher roasting temperatures the

product the resulting coffee is darker in color. This

Quality Deterioration and Shelf Life Determination of Purwaceng Coffee based on Packaging Variation using Accelerated Shelf Life Testing

(ASLT)

141

brownish level will also greatly affect the coordinates

of a* and b*. In this research, robusta coffee produced

by medium roasting was assayed their color and the

result of colour deterioration test (L*, a*, and b*) was

depicted in Figure 5.

Figure 5: Colour deterioration test (L*, a*, and b*) of

purwaceng coffee samples.

Results of the study found that the value of L* was

in the interval 41-46 in five packaging. This indicates

that purwaceng coffee has an L* value that almost

same as the L* results in the study of roasted medium

robusta coffee. The value of a * obtained was in the

range of number 8, it has similarities to the previous

studies. However, the value of b* was lower than the

previous research.

3.1.6 Antioxidant Activity

DPPH (2.2-diphenyl-1-picrylhydrazyl) scavenging

activity test was conducted by comparing the pure

antioxidant/strong antioxidant. The parameter of the

DPPH method is the 50% inhibition concentration

(IC

50

value) or the concentration that can reduce free

radical activity by 50% (Widyasanti et al,, 2016). A

compound classified into very strong antioxidant

activity if the IC

50

value is less than 50 ppm, those

belong to strong group have the IC

50

value in between

50-100 ppm, and those belong to moderate group

have the IC

50

value in beetwen 101-150 ppm, the

group is weak if the IC

50

value is between 150-200

ppm, and the group antioxidants are very weak if the

IC

50

value >200 ppm (Molyneux, 2004). Vitamin C

used as the comparative antioxidant (positive control)

which has an DPPH antioxidant IC

50

value of 6.0674

ppm. Its mean that DPPH scavenging activity of all

samples were much lower than vitamin C. The

antioxidant activity (IC

50

value) of purwaceng coffee

in five type of packaging was shown in Figure 6.

Figure 6: DPPH scavenging activity (IC

50

value) of

purwaceng coffee samples.

The changes in the value of the greatest

antioxidant levels occur in PE 0.03 packaging, then in

PP 0.03 packaging, and PP 0.05 packaging. On PAP

0.11 and AF 0.05 packages, the change in antioxidant

activity was smaller than the previous three packages.

The relationship between IC

50

concentration values

and the ability of packaging to maintain product

quality is the higher the IC

50

concentration value, the

worse the packaging is in maintaining product

quality. This study shows the antioxidant value of

purwaceng cream coffee >200 ppm. This can be

interpreted that the antioxidant value of purwaceng

coffee is classified as very weak.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

142

3.2 Determination of Purwaceng

Coffee Shelf Life

3.2.1 Permeability of Packagings

Five packages were tested their permeability values.

As shown in Table 1, each packaging have different

permeability values. The packaging that has the

lowest / smallest permeability in this study is AF 0.05

with a permeability value of 0.249 g / mmHg.m

2

.day,

while the packaging that has the highest permeability

is the PE 0.03 packaging with a permeability value of

0.465 g / mmHg.m2.day. In general, the order of 5

packages from the smallest permeability to the largest

permeability were AL 0.05, PAF 0.11, PP 0.05, PP

0.03, and PE 0.03, respectively.

Table 1: Packaging permeability value.

Packaging

Type

Area (m

2

) Slope Permeability

(g/mmHg.m

2

.day)

PAP 0,11 0,001555 0,0092 0,268211858

AF 0,05 0,001555 0,0082 0,249188856

PP 0,05 0,001555 0,0128 0,373164324

PP 0,03 0,001555 0,0144 0,437599942

PE 0,03 0,001555 0,0153 0,464949938

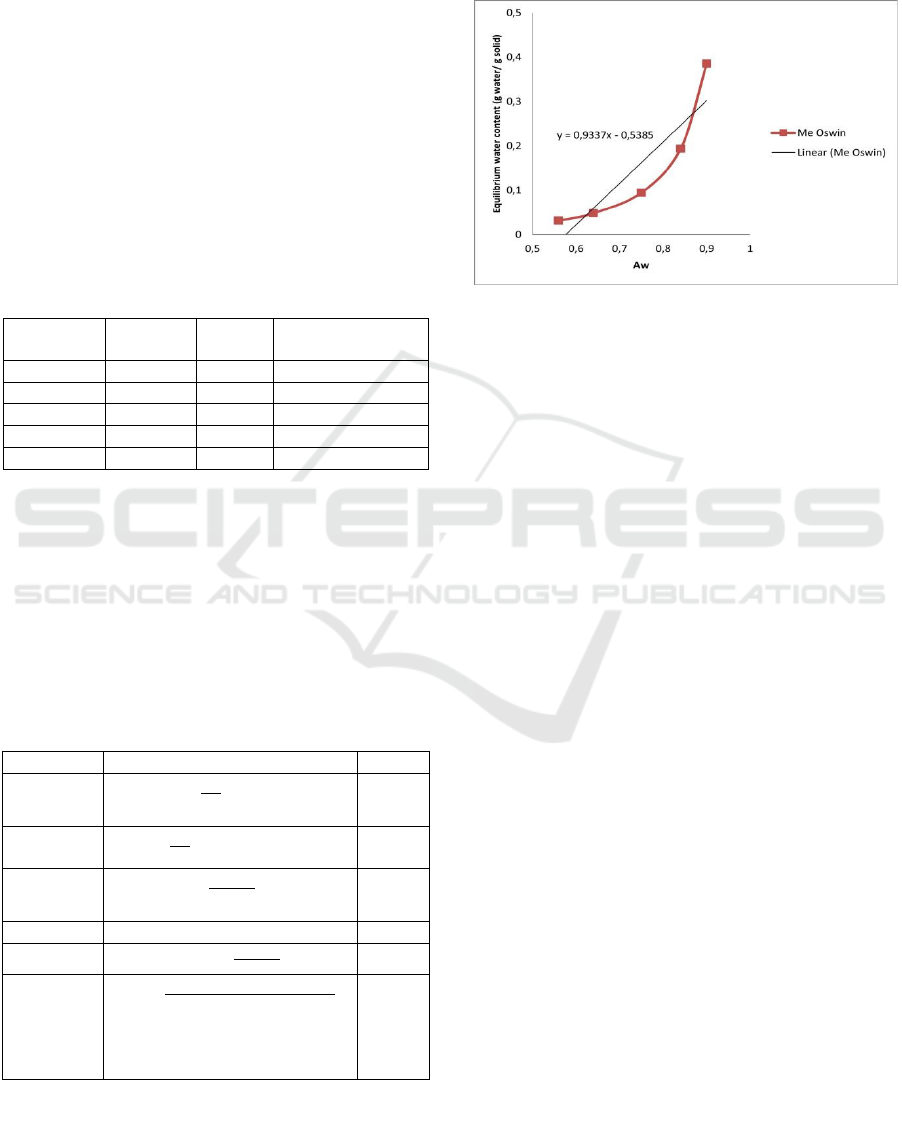

3.2.2 Isothermic Sorption Curve

The models used to determine the shape of the

isothermic sorption curve are very diverse. The model

to be selected is the one with the smallest Mean

Relative Determination (MRD) value. The Oswin

model was used to create an isothermic absorption

curve because it has the smallest MRD value

compared to the other 5 models, as shown in Table 2.

Table 2: Mean relative determination.

Model E

q

uation MRD

Hasley

logln

1

𝑎𝑤

1,241 0,672log𝑀𝑒

8,568

Chen –

Clayton

lnln

1

𝑎𝑤

0,594 4,814𝑀𝑒

41,636

Henderson

𝑙𝑜𝑔 ln

1

1𝑎𝑤

0,542 0,406log𝑀𝑒

10,170

Caurie

ln𝑀𝑒 7,610 7,205𝑎𝑤

13,522

Oswin

ln𝑀𝑒 1,279ln

𝑎𝑤

1𝑎𝑤

3,765

8,360

Guggenhe

im-

Anderson-

de Boer

(

GAB

)

𝑀𝑒

0,0198 𝑎𝑤

1 1,0481 1,068𝑎𝑤

55,357

Furthermore, Oswin model is used to determine

the equilibrium water content at A

w

of 0.6. Based on

the substitution results above, the equilibrium water

content value was 0.0389 gam water/gram solids. The

isothermic absorption curve of the Oswin model was

depicted in Figure 7.

Figure 7: The isothermic absorption curve of the Oswin

model.

According to Labuza (1984), the value of the

slope on the sorption curve is determined in the linear

region. The slope of the isothermal sorption curve is

the value of the straight-line slope of the linear region

which passes the water content at different relative

equilibrium values. The slope value of the isothermal

sorption curve in this study was 0.9337.

3.2.3 Estimation of Purwaceng Coffee Shelf

Life

By using equation 1, the self life of purwaceng coffee

in five types of packaging could be determined. The

shelf life of purwaceng coffee resulted from those

equation was depicted in Figure 8. The longest shelf

life was reached by purwaceng coffee packaged using

AF 0.05, with the self life estimation of 322 days.

Conversely, purwaceng coffee packaged using PE

0.03 has the shortest self life estimation. Purwaceng

coffee packaged using PAP 0.11 has a relatively

longer shelf life than those packaged using PP 0.05,

PP 0.03, and PE 0.03 as well.

Comparing with the other research of shelf life in

similar product, durian flavored coffee products has a

shelf life of 199 days (Nirmala, 2017) and brand

instant coffee XYZ has a shelf life of 21 months or

632 days (Wijaya, 2007) . The shelf life of purwaceng

coffee packaged by AF 0.05 was longer than those of

durian flavored coffee and shorter than those of XYZ

instant coffee. This may caused by many factors, one

of which was the packaging used. XYZ brand instant

coffee packaging in the form of metalized film was

much better in maintaining the quality of coffee

products, therefore their shelf life was longer.

Quality Deterioration and Shelf Life Determination of Purwaceng Coffee based on Packaging Variation using Accelerated Shelf Life Testing

(ASLT)

143

Figure 8: Shelf life estimation of purwaceng coffee using

five type of packaging.

4 CONCLUSIONS

Purwaceng coffee packaged by AF 0.05 has the

longest shelf life estimation (about 322 days),

compared to the other four packaging. By using water

content, water activity, and weight parameters

showed that the type of packaging used has a

significant effect on quality deterioration of

purwaceng coffee.

ACKNOWLEDGEMENTS

This funding research was fully supported by

Ministry of Research Technology and Higher

Education Through Gadjah Mada University with

Contract number: 2577/UN1. DITLIT/ DIT-LIT/ LT

2019.

REFERENCES

Anonym, 1988. Budidaya tanaman kopi. Aksi Agraris

Kanisius, Yogyakarta.

Anonim, 1995. AOAC official methods of analysis.

Association of Official Analytical Chemists,

Washington

Anonym, 2000. Penggalian pemanfaatan dan karakterisasi

mutu tumbuhan obat potensial dan langka. Laporan

Penelitian Ballitro, Bogor.

Anandito, R.B.K., Siswanti, L.P., Hangga S., 2017. Shelf

determination of fish koya using critical moisture

content approach. Proceedings of the Pakistan

Academy of Sciences No. 54 (3): 201 – 206.

Arpah, 2001. Buku monograf penentuan kadaluarsa

produk. Program Studi Ilmu Pangan. Bogor, Institut

Pertanian Bogor.

Bicho, N. C., António E. L., José C. R.,Fernando C. L.,

2012. Use of colour parameters for roasted coffee

assessment. Ciênc. Tecnol. Aliment. Campinas Journal

32(3): 436-442

Brown, H., James W., Mark K., 2011. Food and beverages

technology: packaged product quality and shelf life. 2

nd

Edition, Blackwell Publishing. New York.

Sivetz, M., 1972. How acidity affects coffee flavour. Inside

Clifford and Willson, 1985. Botany, Biochemistry and

Production of Beans and Beverage. The AVI

Publishing Company, Inc., Westport, Connecticut.

Floros, J.D., V. Gnanaskharan. 1993. Shelf life prediction

of packages food : chemical, biological, physical, and

nutritional aspects. Elsevier Publishing, London.

Ihwani, N. 2008. Pengaruh kemasan terhadap daya simpan

tahu segar pada suhu dingin. Skripsi. Fakultas

Teknologi Pertanian, Institut Pertanian Bogor, Bogor.

Kustiyah, 1985. Mempelajari beberapa karakteristik kopi

bubuk dari berbagai jenis cacat biji kopi. Skripsi S1,

Fakultas Teknologi Pertanian, Institut Pertanian Bogor,

Bogor.

Labuza, T.P., 1984. Moisture sorption : practical aspect of

isotherm measurement and use. American Association

of Cereal Chemists. St Paul Minnesota.

Molyneux, P. 2004. The use of the stable free radical

dyhenylpicrylhydrazil (DPPH) for estimating

antioxidant activity. Journals Science and Technology

26:211-219.

Nirmala, A. 2017. Pendugaan umur simpan kopi krimer

rasa durian. Skripsi Fakultas Teknologi Pertanian

UGM, Yogyakarta.

Rahayu, E. and Eny W. 2007. Pengaruh kemasan, kondisi

ruang simpan dan periode simpan terhadap vabilitas

benih caisin (Brassica chinensis L.). Jurnal Buletin

Agroindustri 35 (3): 191-196

Rostiana, O. D., 2006. Karakteristik nomor-nomor koleksi

purwoceng (Pimpinella pruatjan Molk.) di gunung

putri. Prosiding Seminar Nasional dan Pameran

Tumbuhan Obat Indonesia XXVIII: 55-61

Wijaya, C. H. 2007. Pendugaan umur simpan produk kopi

instan formula merek Z dengan pendekatan arrhenius.

Skripsi, Institut Pertanian Bogor, Bogor

Winarno, F.G., 2004. Kimia pangan dan gizi. Gramedia

Pustaka Utama, Jakarta.

Widyasanti, A., Dadan R., Novriana E., 2016. Aktivitas

antioksidan ekstrak teh putih (Camellia Sinensis)

dengan metode DPPH (2,2 Difenil -1- Pikrilhidrazil).

Jurnal Fortech 1 (1): 1-9

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

144