Preventing Vitamin C Photooxidation in Beverage Model System by

Virgin Coconut Oil-Rice Bran Oil Nanoemulsion

Yuli Perwita Sari, Sri Raharjo*, Umar Santoso and Supriyadi

Department of Food and Agricultural Product Technology, Faculty of Agricultural Technology, Universitas Gadjah Mada,

Bulaksumur, Yogyakarta 55281, Indonesia

Keywords: Vitamin C, Photooxidation, Nanoemulsion, Model Beverage.

Abstract: Vitamin C (L-ascorbic acid) is a water-soluble vitamin and frequently added in a beverage. This research

aimed to investigate the effect of virgin coconut oil-rice bran oil (VCO-RBO) nanoemulsion on vitamin C

photooxidation in beverage model system. The oil phase was VCO: RBO (3:7, v/v), surfactant (Tween 80) to

oil ratio was 2.5:1 and distilled water was used as the aqueous phase by emulsion phase inversion method.

One and 5% (v/v) of VCO-RBO nanoemulsion were added to a system containing vitamin C (450 and 1800

ppm), erythrosine (0-120 ppm) and citric acid (to adjust pH 2.3 and 3.2) in distilled water. The presence of

light and erythrosine can degrade vitamin C in beverage model system at 1 ppm vitamin C/min, effectively.

The increase in erythrosine concentration increased the vitamin C degradation in a dose-dependent manner.

By using VCO-RBO nanoemulsion (1 and 5% v/v), the degradation of vitamin C in beverage model system

can be inhibited. At pH 2.3, the addition of 5% (v/v) of VCO-RBO nanoemulsion in the beverage model

system was more effective in preventing vitamin C photooxidation than that at pH 3.2. It suggests that VCO-

RBO nanoemulsion can be added in beverage model system to protect the vitamin C photooxidation.

1 INTRODUCTION

Vitamin C or L-ascorbic acid is one of the water-

soluble vitamins. It is commonly added in beverage,

especially in isotonic water, for its health benefit and

to meet the consumer demand. Vitamin C is known

as a potent antioxidant. However, it can easily be

degraded under high pH, high temperature and by

photooxidation (Huang et al., 2004; Jeney-nagymate

and Fodor, 2008; Yang and Min, 2009; Sheraz et al.,

2015). Photooxidation is one of the main problems in

food and beverage. It was induced by the presence of

sensitizer such as food colorant (FD&C Red number

3) or erythrosine, riboflavin, chlorophyll, etc. (Lee et

al., 1997; Yettela and Min, 2008; Yang and Min,

2009). These compounds naturally present or

deliberately added to improve the appearance and

functional value of products. The reaction rate of

photooxidation is a lot faster than autooxidation. It

can produce oxidation products that contribute to off-

flavor or degradation of beneficial components like

vitamin C, vitamin D, amino acid, etc.

Photooxidation can be prevented by singlet oxygen

quencher or antioxidant. Unfortunately, many

antioxidants are lipid-soluble like β-carotene, α-

tocopherol, γ-oryzanol etc. It is very challenging to

use it in beverage product.

Solid lipid nanoparticle, nanostructured lipid

carrier and nanoemulsion are nano-lipid based

delivery systems. Some studies reported that

nanoemulsion can be incorporated into beverages to

increase the value of products. Zhang et al. (2020)

used docosahexaenoic acid (DHA) and

eicosapentaenoic acid (EPA) nanoemulsion in apple

juice. This nanoemulsion didn’t affect basic

properties such as pH, soluble solids, titratable acid

and reducing sugar of apple juice. Even though it

influenced the transparency of product, the addition

of DHA/EPA nanoemulsion in apple juice was still

acceptable by sensory test (Zhang et al., 2020). Buriti

(Mauritia flexuosa L.) oil nanoemulsion was also

potential as natural colorant replacer in isotonic sport

drink (Bovi et al., 2017). Fish oil and rice bran oil was

also used to be part of oil-in-water nanoemulsion

before incorporating with yoghurt as reported by

Zhong et al. (2018). This nanoemulsion gave some

significant impacts on reduction in acidity, syneresis

and peroxide value with maximum retention of EPA

and DHA.

Sari, Y., Raharjo, S., Santoso, U. and Supriyadi, .

Preventing Vitamin C Photooxidation in Beverage Model System by Virgin Coconut Oil-Rice Bran Oil Nanoemulsion.

DOI: 10.5220/0010541900003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 113-121

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

113

Rice bran oil is rich in a specific antioxidant

named γ-oryzanol up to 2. 6g/100 g of oil (Pokkanta

et al., 2019). These compounds have been attractive

because it was only found in rice bran products,

especially in rice bran oil. Virgin coconut oil is

known as oil which rich in lauric acid. The medium-

chain fatty acid is the main ingredient to produce

nanoemulsion by a low-energy method.

In this research, we used a combination of virgin

coconut oil and rice bran oil, which were incorporated

with Tween 80 and distilled water to make an oil-in-

water nanoemulsion. This study aimed to investigate

the effect of virgin coconut oil-rice bran oil (VCO-

RBO) nanoemulsion on photooxidation of vitamin C

in a beverage model system.

2 MATERIALS AND METHODS

2.1 Materials

Vitamin C or L-ascorbic acid for analytical grade (J.T.

Baker); Tween 80, potassium iodide and iodine were

obtained from Merck (Germany). Virgin coconut oil,

rice bran oil, sucrose, erythrosine and citric acid were

food grade that obtained from local market.

2.2 Methods

2.2.1 Preparation of Virgin Coconut

Oil-Rice Bran Oil (VCO-RBO)

Nanoemulsion

The VCO-RBO nanoemulsion formula were VCO:

RBO (3:7, v/v), surfactant (Tween 80) to oil ratio was

2.5:1 and distilled water was used as the aqueous

phase. This nanoemulsion was produced by emulsion

phase inversion according to Sari et al. (2020).

2.2.2 Preparation of Beverage Model

Systems

The beverage model systems was prepared according

to (Ariviani et al., 2011) with slight modification. The

beverage model system containing vitamin C (450-

1800 ppm, w/v), erythrosine (0-120 ppm, w/v), citric

acid (to adjust pH 2.3 and 3.2) in distilled water.

VCO-RBO nanoemulsion (0, 1 and 5%, v/v) were

added into the systems. A 10 mL of the beverages

model systems was prepared into 30-mL vial with

rubber cap and sealed with parafilm. The samples

were illuminated at + 3200 lux or stored in the dark

up to 2 hours. Vitamin C content were analyzed in

every 30 minutes.

2.2.3 Physicochemical Analysis

Vitamin C in each samples were analyzed by iodine

titrimetric according to Sudarmadji et al. (1997)

method. pH of samples were measured by Hanna

Instrument. The color of samples were determined

using a Konica Minolta Colorimeter with L*, a* and

b* parameters. The erythrosine concentration were

analyzed using spectrophotometer by (Yang and Min,

2009) with some modifications. Curva calibrations

were constructed in each sample formula. The

wavelength detection analysis according to each

maximum wavelength absorption by scanning

method (200-700 nm). Turbidity of samples were

determined at 600 nm (Zhong et al., 2017; Sari et al.,

2020).

2.2.4 Statistical Analysis

The experiment were done in duplicate. The samples

were analyzed at least duplicate in each experiment.

Data were analyzed by regression analysis with

Microsoft Excel 2013 and IBM SPSS Statistic 24.

3 RESULTS AND DISCUSSION

3.1 Characterization of VCO-RBO

Nanoemulsion

In this study, VCO:RBO (3:7, w/w) were used as the

oil phase. The surfactant (Tween 80) to oil ratio was

2.5:1. Distilled water as the aqueous phase in 80%

(v/v) of the total system. Based on the previous study,

this formula was selected because it gave the smallest

particle size of nanoemulsion (65.64 nm) with zeta-

potential was -12.16 mV (Sari et al., 2020). This

formula had slight transparency, therefore only

slightly affected the beverage model system’s

appearance.

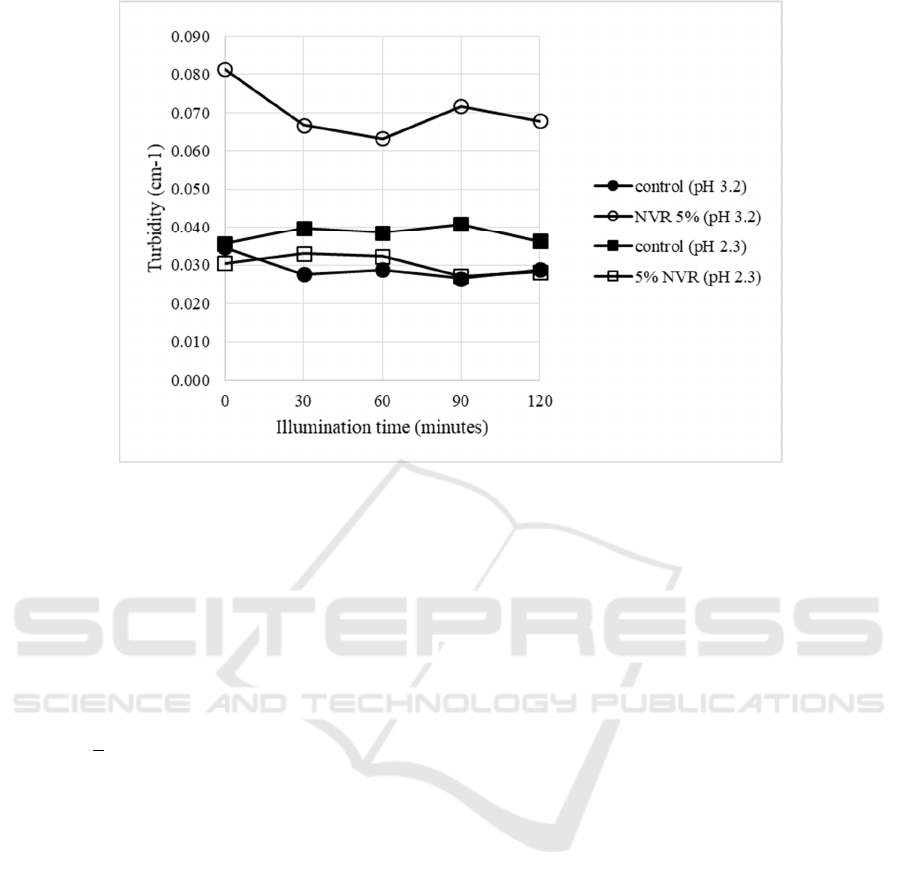

The visual sample product can be seen in Fig 1.

Samples containing 5% nanoemulsion in 450 ppm

vitamin C were more slightly pink than models with

1800 ppm vitamin C at the same concentration of

VCO-RBO nanoemulsion and pH system (2.3).

VCO-RBO nanoemulsion up to 5% (v/v) in beverage

model systems didn’t make samples to be turbid. The

turbidities of all samples containing 1800 ppm

vitamin C were relatively small (<0.1 cm

-1

) It might

be due to small size of nanoemulsion and a small

portion of it to be incorporated in beverage model

systems (Fig.2).

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

114

(a)

(b)

(c)

(d)

Figure 1: Visual apperarance of beverage model systems containing 450 ppm vitamin C with 0 and 5% of VCO-RBO

nanoemulsion (a) and (b), respectively; 1800 ppm vitamin C with 0 and 5% of VCO-RBO nanoemulsion (c) and (d),

respectively. All pH systems were 2.3.

0

30’

90’

60

’

120’

0

30’

90’

60’

120

’

Preventing Vitamin C Photooxidation in Beverage Model System by Virgin Coconut Oil-Rice Bran Oil Nanoemulsion

115

Figure 2: The changes of turbidity in photooxidation of beverage model systems (vitamin C 1800 ppm) (NVR=VCO-RBO

Nanoemulsion).

3.2 The Effect of Light and Sensitizer

on Vitamin C

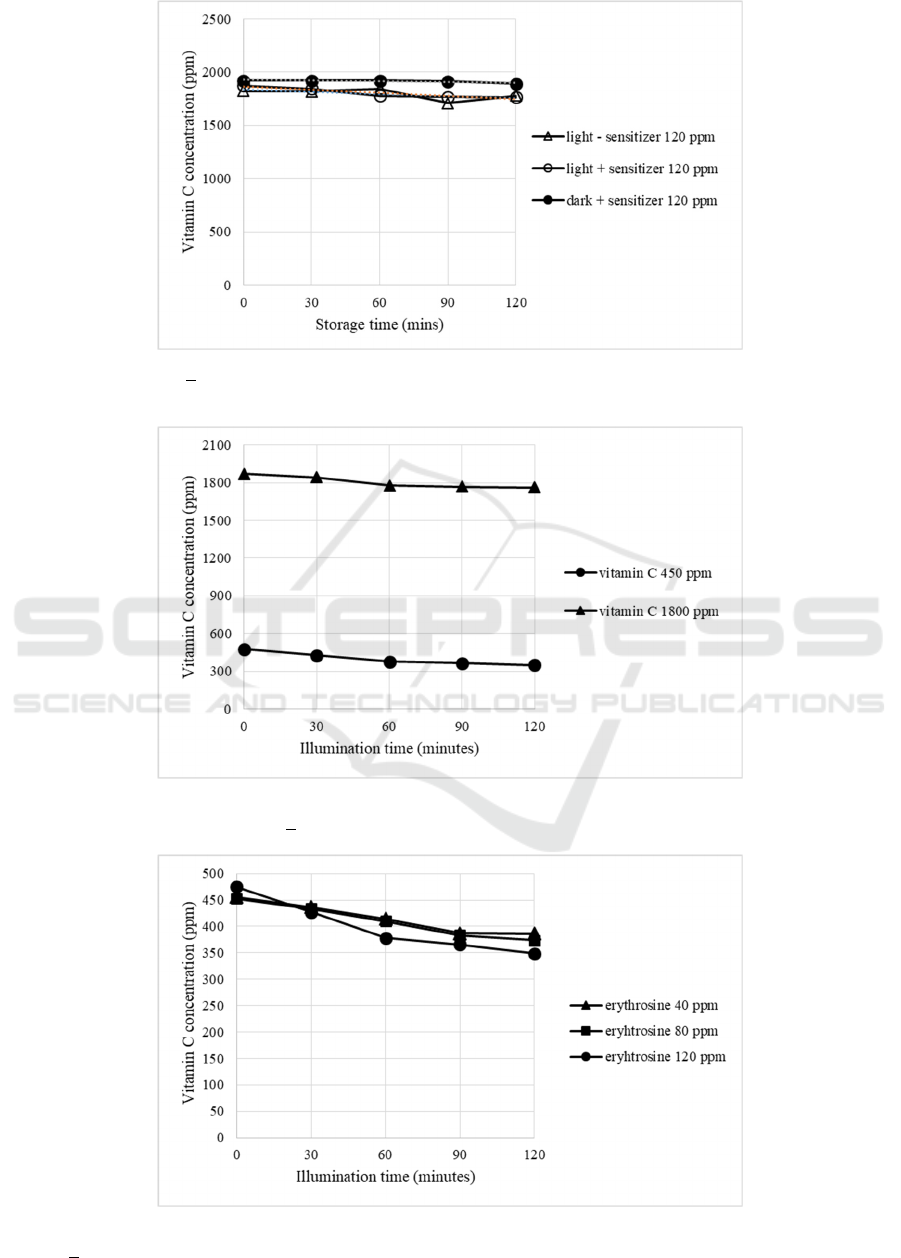

To investigate the cause of vitamin C degradation, we

used some sets of samples that were illuminated or

stored in the dark, with and without of erythrosine as

a sensitizer. According to Fig 3, the samples

containing 120 ppm or erythrosine and held in a

lightbox at + 3200 lux up to 2 hours gave a vitamin C

degradation almost 1 ppm of vitamin C/min (y = -

0.9724x + 1863.1; R

2

= 0.8732; p<0.05). Meanwhile,

the relatively stable vitamin C content was performed

by samples stored in the dark (y = -0.2182x + 1926.9;

R

2

= 0.6749; p>0.05) or without sensitizer and stored

under light (y = -0.6682x + 1833.4; R

2

= 0.3489;

p>0.05). By hypothesis null analysis in regression

statistic, these two latter slopes were almost 0. It

means that photooxidation can only occur by a

combination of sensitizer and light. This study was

similar to previous studies. At pH 4, 5.6 and 7, the 50

and 100 ppm of ascorbic acid were declined in the

photooxidation in the presence of food colorant red nr

3. Meanwhile, ascorbic acid content was relatively

stable under dark for one hour (Yang and Min, 2009).

The degradation of riboflavin was also faster under

the light than in the dark (Huang et al., 2004). It

suggests that singlet oxygen was involved in these has

sensitizer, light and triplet oxygen can produce singlet

oxygen that can degrade vitamin C. The reaction

between ascorbic acid with singlet oxygen produces

unstable hydroperoxide of ascorbic acid (Choe and

Min, 2005).

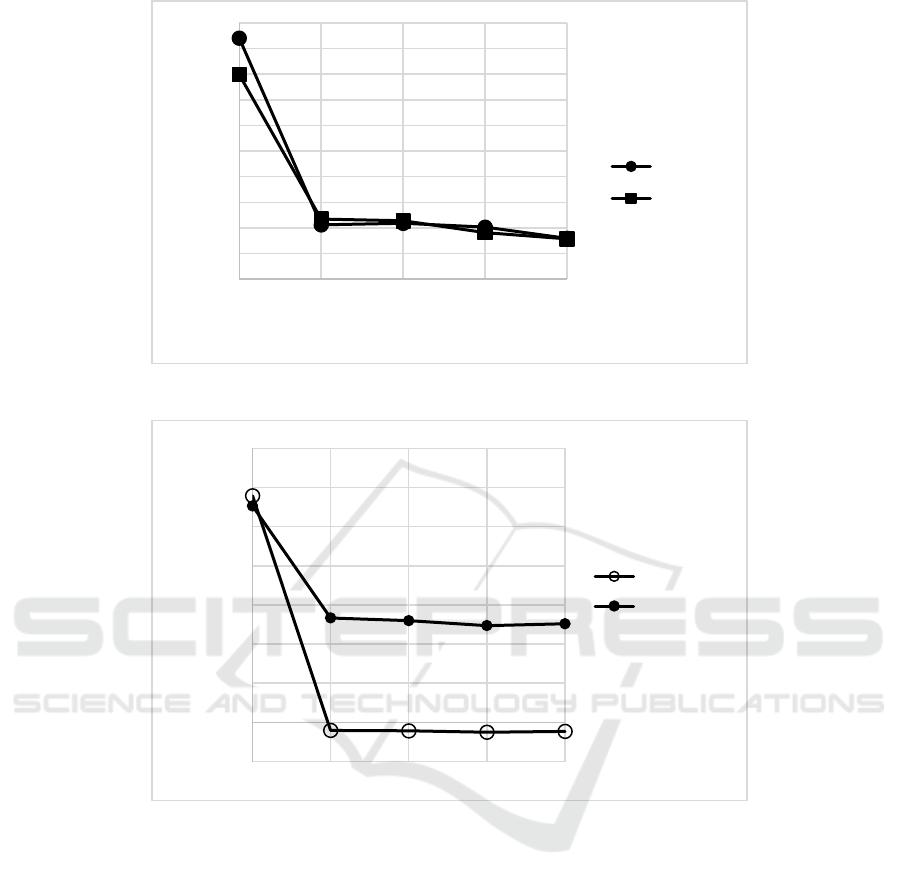

The effect of the initial concentration of vitamin

C before photooxidation was also studied. From Fig.4

showed that the 450 and 1800 ppm of ascorbic acid

content gives a relatively same of vitamin C

degradation rate for about 1 ppm/min (p>0.05). At

different pH (2.3 and 3.2), the degradation rate of

vitamin C with 1800 ppm as initial content was also

relatively same (0.97 and 1.02 ppm vitamin C/min,

respectively, p>0.05).

Comparatively, the increasing of erythrosine

concentration gave a significant effect on decreasing

of vitamin C in a dose-dependent manner (Fig.5). At

40 and 80 ppm, the degradation rate of vitamin C

were 0.62 and 0.69 ppm/min, respectively.

Meanwhile, by using 120 ppm in the reaction system,

the degradation rate of vitamin C up to 1.04 ppm/min.

From these results, it was concluded that the

difference of initial concentration or pH (2.3 and 3.2)

didn’t give any significant difference in the declining

rate of vitamin C. Erythrosine concentration gave

significant effect on the degradation rate of vitamin C

in photooxidation system. The higher erythrosine

concentration induced more singlet oxygen.

Therefore, vitamin C will be degraded more

frequently.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

116

Figure 3: Effect of light (+ 3200 lux) and sensitizer (120 ppm erythrosine) on vitamin C changes in beverage model system

up to 120 minutes stored.

Figure 4: Effect of initial vitamin C concentration (450 and 1800 ppm) on degradation of vitamin C in photooxidation of

beverage model system (light intensity + 3200 lux at room temperature).

Figure 5: Effect of erythrosine concentration degradation of vitamin C in photooxidation of beverage model system (light

intensity + 3200 lux at room temperature).

Preventing Vitamin C Photooxidation in Beverage Model System by Virgin Coconut Oil-Rice Bran Oil Nanoemulsion

117

3.3 Effect of VCO-RBO Nanoemulsion

on Photooxidation of Vitamin C in

Beverage Model Systems

Containing Various Erythrosine

Concentration

In this study, we added VCO-RBO nanoemulsion at

1 and 5% (v/v) in beverage model system. The 450

ppm vitamin C was relatively stable in beverage

model systems containing various erythrosine

concentration (40-120 ppm) and 5% of VCO-RBO

nanoemulsion (Table 1). It might be due to the

capability of nanoemulsion to maintain erythrosine in

photooxidation. By using 5% VCO-RBO

nanoemulsion, the color of the beverage model

system was more slightly pink than the control (Fig.

1). It was concluded that nanoemulsion could

maintain the stability of erythrosine; therefore, less

singlet oxygen was produced and 450 ppm vitamin C

was relatively constant for photooxidation reaction

time (Table 1). Adding 1% of VCO-RBO

nanoemulsion could avoid vitamin C degradation

almost 33 and 60% at pH system was 3.2 and 2.3,

respectively. By using regression statistical analysis,

5% of VCO-RBO nanoemulsion could protect

vitamin C degradation (slope ≈ 0) at 1800 ppm of

vitamin C as an initial concentration in pH 2.3 and

3.2. The natural antioxidant in oil phase such as α-

tocopherol was suspected responsible to protect

vitamin C avoid photooxidation. Some researchers

found that rice bran oil contained 13.2-29.95 mg α-

tocopherol /100 g oil (Pestana et al., 2008;

Dhavamani et al., 2014; Yang et al., 2018). It was also

known as effective singlet oxygen quencher with the

singlet oxygen quenching rate was 4.9 x 10

7

up to

3.54 x 10

8

/M/s (Nishida et al., 2007; Kim et al.,

2009; Ouchi et al., 2010).

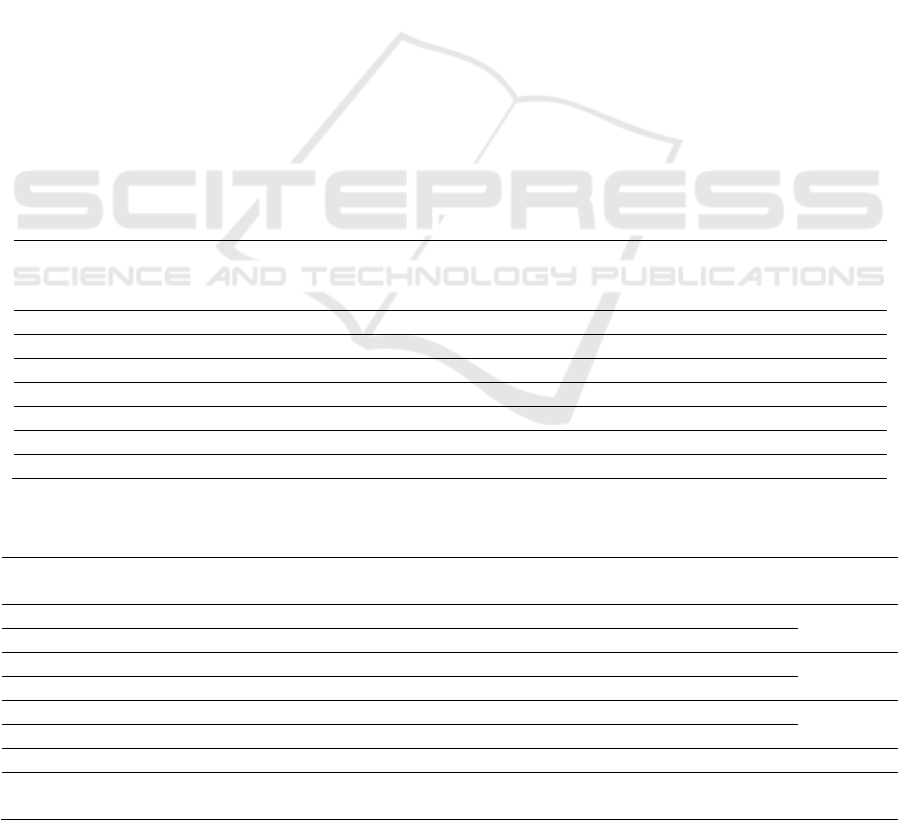

Comparatively with photooxidation in vitamin C

450 ppm, the preventing mechanism by VCO-RBO

nanoemulsion in beverage model systems containing

1800 ppm of vitamin C at pH 2.3 and 3.2 is not still

clearly understood. Although 1 and 5% of VCO-RBO

nanoemulsion can protect vitamin C degradation by

photooxidation (Table 2), the a* values samples

containing 5% VCO-RBO nanoemulsion at pH 2.3

and 3.2 were lower than the control (Fig. 6). This

value was positively correlated with erythrosine

concentration (Fig. 7). Therefore, VCO-RBO

nanoemulsion couldn’t maintain erythrosine in high

concentration of vitamin C beverage model systems.

Table 1: The regression equations of beverage model systems containing VCO-RBO nanoemulsion (0 and 5% v/v) and

various erythrosine concentration (40-120 ppm) in photooxidation reaction system.

Erythrosine

conc. (ppm)

VCO-RBO

nanoemulsion

% (v/v)

Regression equation R

2

Degradation rate

(ppm vitamin C/min)

p-value*

40 0 Y = - 0.6234x + 453.24 0.9524 0.6234 0.004

40 5 Y = - 0.2875x + 504.44 0.5852 0.2875 ≈ 0 0.132

80 0 Y = - 0.69x + 452.02 0.9851 0.69 0.001

80 5 Y = - 0.0146x + 499.5 0.0021 0.0148 ≈ 0 0.941

120 0 Y = - 1.0451x + 461.37 0.9263 1.0451 0.009

120 5 Y = - 0.1651x + 453.55 0.678 0.1651 ≈ 0 0.087

*p-value<0.05 means the slope was si

g

nificantl

y

different from 0.

Table 2: The regression equations of beverage model systems containing VCO-RBO nanoemulsion (0-5% v/v) at pH 2.3 and

3.2 in photooxidation reaction system.

pH VCO-RBO nano-

emulsion % (v/v)

Regression equation R

2

Degradation rate

(

p

p

m

vitamin C/min)

p-value* p-value**

2.3 0 Y = -0.9724x + 1863.1 0.8138 0.9724 0.02 0.885

3.2 0 Y = -1.0258x + 1933.8 0.8732 1.0258 0.036

2.3 1 Y = -0.401x + 1895 0.8072 0.401 0.038 0.110

3.2 1 Y = -0.6696x + 1883.3 0.9507 0.6696 0.005

2.3 5 Y = -0.1303x + 1818.9 0.0358 0.1303 ≈ 0 0.761 1

3.2 5 Y = -0.3796x + 1821 0.5096 0.3796 ≈ 0 0.176

* p-value<0.05 means the slope was si

g

nificantl

y

different from 0

** p-value>0.05 means the two slopes were not significantly different at different pH and same amount of

VCO-RBO nanoemulsion

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

118

It seems like there is a behind mechanism by this

nanoemulsion to prevent photooxidation of 1800 ppm

vitamin C in beverage model systems. In another

studies, vitamin C fortification (40-80 mg/100mL)

can degrade anthocyanin and color loss in cranberry

juice because the high concentration of vitamin C

could increase oxidation products of vitamin C that

degrade anthocyanin (Li et al., 2014; Roidoung et al.,

2016, 2017). Meanwhile, in this study, samples

containing 450 and 1800 ppm of vitamin C and 120

ppm of sensitizer without nanoemulsion gave the

same trend of a* values during photooxidation (Fig.

8). Only samples containing 1800 ppm of vitamin C

with VCO-RBO nanoemulsion that had transparent

appearance and lower a* than the 450 ppm of vitamin

C (Fig. 9).

Figure 6: The changes of a* (redness) in photooxidation of beverage model systems (vitamin C 1800 ppm). (NVR=VCO-

RBO Nanoemulsion).

Figure 7: The changes of erythrosine concentration in photooxidation of beverage model system (vitamin C 1800 ppm).

(NVR=VCO-RBO Nanoemulsion).

Preventing Vitamin C Photooxidation in Beverage Model System by Virgin Coconut Oil-Rice Bran Oil Nanoemulsion

119

Figure 8: The changes of a* values of beverage model systems (vitamin C 450 and 1800 ppm) without nanoemulsion.

Figure 9: The changes of a* values of beverage model systems (vitamin C 450 and 1800 ppm) with 5% of VCO-RBO

nanoemulsion during illumination.

4 CONCLUSIONS

The presence of light and erythrosine can degrade

vitamin C in beverage model system at 1 ppm vitamin

C/min, effectively. The increasing of erythrosine

concentration affected on decreasing of vitamin C in

a dose-dependent manner. By using VCO-RBO

nanoemulsion (1 and 5% v/v), the degradation of

vitamin C in beverage model system can be

prevented. In pH 2.3, the 5% (v/v) of VCO-RBO

nanoemulsion in beverage model system was more

useful to avoid vitamin C photooxidation than in pH

3.2. It suggests that VCO-RBO nanoemulsion can be

added in beverage model system to avoid the

photooxidation of vitamin C.

ACKNOWLEDGEMENTS

The authors thank to Ministry of Research and

Technology / National Agency for Research and

Innovation, Republic of Indonesia for financial

support.

REFERENCES

Ariviani, S., Raharjo, S., and Hastuti, P. 2011. Potensi

Mikroemulsi β -Karoten dalam Menghambat

Fotooksidasi Vitamin C Sistem Aqueous. Jurnal

Teknologi dan Industri Pangan XXII (1): 33–39.

0

1

2

3

4

5

6

7

8

9

10

0 30 60 90 120

a*

Illumination time (min)

1800 ppm

450 ppm

-2

0

2

4

6

8

10

12

14

0 306090120

a*

Illumination time (min)

1800 ppm

450 ppm

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

120

Bovi, G. G., Petrus, R. R., and Pinho, S. C. 2017. Feasibility

of incorporating buriti (Mauritia flexuosa L.) oil

nanoemulsions in isotonic sports drink. Internatioal

Journal of Food Science and Technology 1–9.

Choe, E., and Min, D. B. 2005. Chemistry and Reactions of

Reactive Oxygen Species in Foods. Journal of Food

Science 70 (9): 142–159.

Dhavamani, S., Poorna, Y., Rao, C., and Lokesh, B. R.

2014. Total antioxidant activity of selected vegetable

oils and their influence on total antioxidant values in

vivo: A photochemiluminescence based analysis. Food

Chemistry 164: 551–555.

Huang, R., Choe, E., and Min, D.B. 2004. Kinetics for

Singlet Oxygen Formation by Riboflavin

Photosensitization and the Reaction between

Riboflavin and Singlet Oxygen. Journal of Food

Science 69 (9): C726–C732.

Jeney-nagymate, E., and Fodor, P. 2008. The stability of

vitamin C in different beverages. British Food Journal

110 (3): 296–309.

Kim, J. I., Lee, J. H., Choi, D. S., Won, B. M., Jung, M. Y.,

and Park, J. 2009. Kinetic study of the quenching

reaction of singlet oxygen by common synthetic

antioxidants (tert-Butylhydroxyanisol, tert-di-

Butylhydroxytoluene, and tert-Butylhydroquinone) as

compared with α-Tocopherol. Journal of Food Science

74 (5): 362-369.

Lee, K. H., Jung, M. Y., and Kim, S. Y. 1997. Quenching

Mechanism and Kinetics of Ascorbyl Palmitate for the

Reduction of the Photosensitized Oxidation of Oils. 74

(9): 1053–1057.

Li, J., Song, H., Dong, N., and Zhao, G. 2014. Degradation

Kinetics of Anthocyanins from Purple Sweet Potato (

Ipomoea batatas L .) as Affected by Ascorbic Acid.

Food Science and Biotechnology 23 (1): 89–96.

Nishida, Y., Yamashita, E., and Miki, W. 2007. Quenching

Activities of Common Hydrophilic and Lipophilic

Antioxidants against Singlet Oxygen Using

Chemiluminescence Detection System. Carotenoid

Science 11: 16–20.

Ouchi, A., Aizawa, K., Iwasaki, Y., Inakuma, T., Terao, J.,

Nagaoka, S.I., and Mukai, K. 2010. Kinetic study of the

quenching reaction of singlet oxygen by carotenoids

and food extracts in solution. development of a singlet

oxygen absorption capacity (SOAC) assay method.

Journal of Agricultural and Food Chemistry 58 (18):

9967–9978.

Pestana, V. R., Zambiazi, R. C., Mendonça, C.R.B.,

Bruscatto, M. H., Lerma-García, M. J., and Ramis-

ramos, G. 2008. Quality Changes and Tocopherols and

γ-Orizanol Concentrations in Rice Bran Oil During the

Refining Process. Journal of American Oil Chemistry

Society 85: 1013–1019.

Roidoung, S., Dolan, K. D., and Siddiq, M., 2016. Gallic

acid as a protective antioxidant against anthocyanin

degradation and color loss in vitamin-C fortified

cranberry juice. Food Chemistry 210: 422–427.

Roidoung, S., Dolan, K. D., and Siddiq, M., 2017.

Estimation of kinetic parameters of anthocyanins and

color degradation in vitamin C fortified cranberry juice

during storage. Food Research International 94: 29–35.

Pokkanta, P., Sookwong, P., Tanang, M., and Setchaiyan,

S. 2019. Simultaneous determination of tocols, -

oryzanols, phytosterols, squalene, cholecalciferol and

phylloquinone in rice bran and vegetable oil samples.

Food Chemistry 271 (June 2018): 630–638.

Sari, Y.P., Raharjo, S., Santoso, U., and Supriyadi. 2020.

Formulation, characterization and stability of o/w

nanoemulsion containing rce bran oil prepared by

emulsion phase inversion. Food Research 4 (August):

1024–1029.

Sheraz, M. A. L. I., Khan, M. F., Ahmed, S., Kazi, S. H.,

and Ahmad, I. 2015. Stability and Stabilization of

Ascorbic Acid. Household and Personal Care Today

10 (3): 22–25.

Sudarmadi, S., Haryono, B., and Suhardi. 1997. Prosedur

Analisa untuk Bahan Makanan dan Pertanian.

Yogyakarta: Liberty.

Yang, T.S., and Min, D.B. 2009. Quenching mechanism

and kinetics of ascorbic acid on the photosensitizing

effects of synthetic food colorant FD & C Red Nr 3.

Journal of Food Science 74 (9): 718–722.

Yang, R., Zhang, L., Li, P., Yu, L., Mao, J., and Wang, X.

2018. A review of chemical composition and nutritional

properties of minor vegetable oils in China. Trends in

Food Science & Technology 74 (May 2017): 26–32.

Yettela, R. R., and Min, D. B. 2008. Quenching

mechanisms and kinetics of trolox and ascorbic acid on

the riboflavin-photosensitized oxidation of tryptophan

and tyrosine. Journal of Agricultural and Food

Chemistry 56: 10887–10892.

Zhang, L., Han, C., Liu, M., Yang, H., Zhang, F., Liu, B.,

and Meng, X. 2020. The formation, stability of DHA /

EPA nanoemulsion prepared by emulsion phase

inversion method and its application in apple juice.

Food Research International 133 (February): 109–132.

Zhong, J., Yang, R., Cao, X., Liu, X., and Qin, X. 2018.

Improved Physicochemical Properties of Yogurt

Fortified with Fish Oil/γ-Oryzanol by Nanoemulsion

Technology. molecules 23: 1–11.

Preventing Vitamin C Photooxidation in Beverage Model System by Virgin Coconut Oil-Rice Bran Oil Nanoemulsion

121