Performance of Self Compacting Concrete (SCC) with Precious Slag

Ball as Fine Aggregate Substitute

Amalia

1

and Muhtarom Riyadi

1

1

Department of Civil Engineering, State Polytechnic of Jakarta, Jalan Prof. Dr. G. A. Siwabessy, Kampus Baru UI, Depok,

Indonesia

Keywords: Self Compacting Concrete, PS Ball, Compressive Strength.

Abstract: Precisious slag ball (PS Ball) is a waste of residual steel processing which was originally liquid and then

recycled using Slag Atomizing Technology (SAT) technology into small, compact granules. . PS ball has a

grain size of 0.1-4.5 mm with a higher specific gravity and hardness than sand. The PS ball's granular structure

is very powerful, weather resistant, and not easy to wear, so it can be used in SCC concrete as a replacement

for fine aggregate. The purpose of this study was to examine the performance of SCC concrete with a PS ball

as a substitute for some of the fine aggregate. The concrete performance of SCC studied consisted of fresh

concrete performance and concrete mechanical performance. Concrete performance includes filling ability

and passing ability, while concrete mechanical performance consists of compressive strength and concrete

tensile strength. The specimens of 4 variations were obtained in PS Ball quantity, namely 0%, 10%, 20%, and

30% of the fine aggregate weight. The findings showed that the use of the PS ball as a fine aggregate would

enhance SCC concrete's filling and passing abilities. The use of the PS ball as a replacement for fine aggregate

will improve concrete's compressive strength and tensile strength by up to 20%.

1 INTRODUCTION

Precisious slag ball (PS Ball) is a steel processing

residual waste which is originally liquid is then

recycled to thetechnology slag atomizingTechnology

(SAT) into small granules are solid. PS ball has a

grain size of 0.1-4.5 mm with a higher specific gravity

and hardness than sand. The PS ball grain structure is

very strong, weather resistant, and not easy to wear.

The chemical composition of this waste consists of:

Fe (20.83%), SiO2 (12.69%), CaO (40.30%) and

other elements up to 100% (PT. Purna Baja Harsco,

2020). The amount of this waste is approximately 150

million tonnes / year worldwide. The amount of PS

Ball waste at Krakatau Steel that is processed by a

subsidiary of PT Purna Baja Harsco is 5000 tons per

month. With this large amount of waste, it is

necessary to handle it so that the waste can be used

optimally. Judging from the physical and chemical

properties, PS Ball waste can replace sand in high

performance concrete.

The results of research using PS Ball up to 40% in

normal concrete can increase compressive strength

and make concrete more durable (e.g. S. Sharath,

BC., Gayana, Krishna, R., Reddy & K. Ram Chandar

Chia, Lau, & Tan, 2019). Similar research conducted

by Avinash. H. Talkeri and AU Ravi Shankar (2019)

led to a rise in concrete compressive strength and

resistance to fatigue using PS Ball as a fine aggregate

in normal concrete compared to concrete using sand.

In both of these studies, the concrete studied is

conventional concrete which still uses a vibrating

device to compact it, which causes noise, is difficult

to implement on dense reinforced concrete, has the

potential to disrupt the location of the reinforcement

during compaction which can result in lowering the

strength of the structure. Furthermore, the two studies

have not examined concrete performance, especially

the concrete tensile strength, flexural strength. and its

ductility, so that the resulting concrete tends to be

brittle and suddenly collapses. It can be seen that PS

Ball has the ability to replace sand in concrete as a

fine aggregate. The problems discussed in this paper

are the performance of SCC concrete using PS Ball as

a partial substitution material for SCC concrete.

Concrete performance discussed includes the

performance of fresh concrete consisting of filling

ability and passing ability, while hard concrete work

consists of compressive strength and tensile strength

of concrete.

108

Amalia, . and Riyadi, M.

Performance of Self Compacting Concrete (SCC) with Precious Slag Ball as Fine Aggregate Substitute.

DOI: 10.5220/0010541200003153

In Proceedings of the 9th Annual Southeast Asian International Seminar (ASAIS 2020), pages 108-115

ISBN: 978-989-758-518-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 LITERATURE REVIEW

Precious Slag Ball (PS Ball) is a steel processing

waste which was originally liquid form processed by

Slag Atomizing Technology (technology SAT) into

granules of 0.1 mm - 4.5 mm in diameter. This waste

chemical composition is made up of Fe (20.83%),

SiO2 (12.69%), CaO (40.30%) and other elements up

to 100% (PT. Purna Baja Harsco, 2020). The granular

structure of the PS ball is very strong, weather

resistant, not easy to wear, with a specific gravity of

3.45 and a hardness of 739.8 HVC. The value of

specific gravity and hardness of PS Ball is higher than

natural sand. With its high density and hardness, PS

Ball can be used as fine aggregate in high

performance concrete.

Research on the performance of conventional

concrete using PS Ball as a fine aggregate substitution

of 20%, 40%, 60%, 80%, and 100%, findings of this

research suggest that the optimum composition of PS

Ball of 40% produces the maximim compressive

strength of 62.89 MPa at 28 days age. Judging from

the permeability of concrete, the use of a PS Ball of

40% and 100% results in a more durable

/concretedurable (Sharath, Gayana, Krishna and Ram

Chandar, 2019).

The use of GGBS as an added material and PS

Ball as an aggregate in conventional concrete applied

to rigid pavement roads showed that the PS Ball use

in concrete for rigid pavement may increase the

concrete compressive strength and 41-64 MPa is the

resulting concrete compressive strength. In addition,

the use of the PS Ball can also raise the concrete's

resistance to fatigue (Avinash and Ravi Shankar,

2019).

The use of PS Ball as fine aggregate with a GGBS

binder mixture of 443 kg / m3, Na2SiO3 / NaOH ratio

(1,1.5,2 and 2.5) resulted in a higher slump value of

25 mm versus slump cones conventional. The

compressive strength of concrete produced with these

materials is 24-58 MPa under conditions of exposure

to temperature. The use of PS Ball in concrete can

also increase the fatigue life (Avinash and Ravi

Shankar, 2018).

3 METHOD

The study was conducted by making SCC concrete

specimens with the percentage of PS Ball as a

substitute for fine aggregate of 0%, 10%, 20%, and

30% of the weight of fine aggregate and steel scrap

waste fibers of 1% of the weight of Portland cement

for all types test object. Fresh SCC concrete

performance studied consisted of flowability, Passing

Ability, Segregation Ressistance, and when tied

concrete. To test the properties Flowability tool

Slump flow T50cm is used, while to test the nature of

Passing Ability and Segregation Ressistance

usingtool L-Box. The method of testing the properties

of fresh SCC refers to the EFNARC standard in 2002.

The performance of the hard concrete consists of:

the concrete's weight, compressive strength and

tensile strength. A Ø15 cm concrete cylinder with 30

cm high is the test sample to test the compressive

strength and tensile strength. Each test was repeated

3 times. Tests were conducted at the ages of 3, 7, 14,

and 28 days to assess the growth of the compressive

strength of concrete. The tensile strength of the

concrete was tested at the age of 28 days. All

specimens were cured before measuring the

properties of hard SCC concrete by immersing them

in water at room temperature before the test was

performed.

4 RESULTS

4.1 Properties of the Constituent

Materials of Self Compacting

Concrete

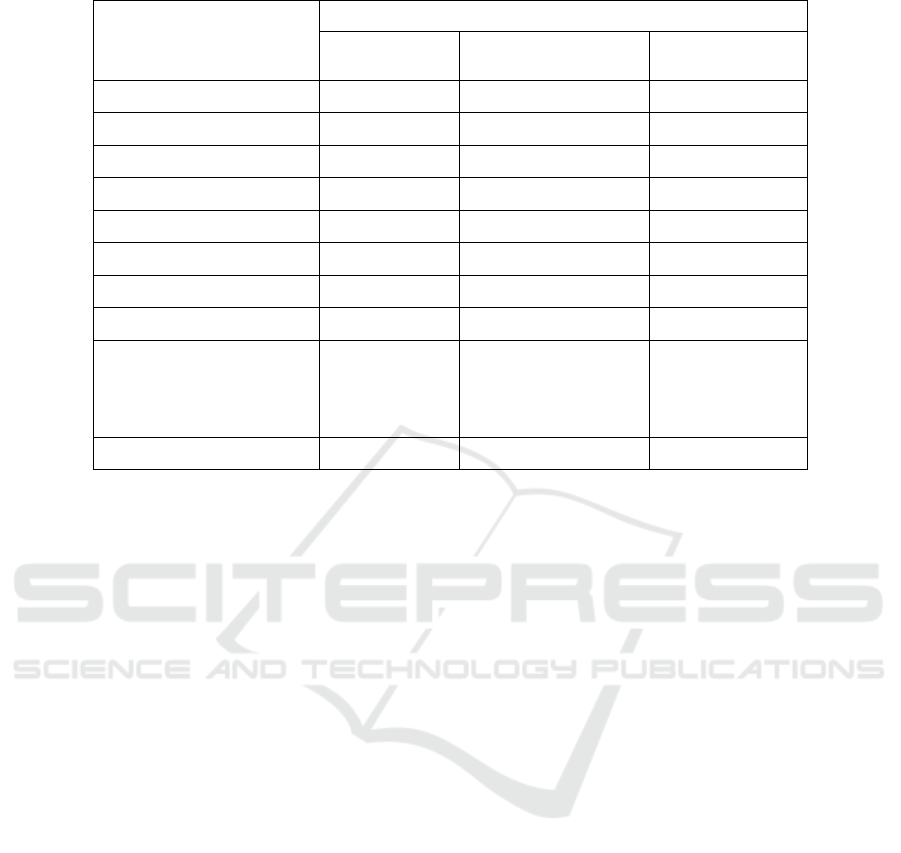

Table 1 presents the properties of the SCC concrete

constituent components. The results presented in

Table 1, the test results of SCC concrete constituent

materials, it can be seen that all materials used meet

the requirements for making SCC concrete.

Performance of Self Compacting Concrete (SCC) with Precious Slag Ball as Fine Aggregate Substitute

109

Table 1. SCC Constituent Materials Properties

Material Properties

Value

fine aggregates coarse aggregates

Precious Slag

Ball

Specific gravity 2.48 2.28 3.67

SSD Specific gravity 2.53 2.30 3.67

apparent Specific gravity 2.62 2.33 3.67

Loose Unit Weight (kg/m3) 1565.10 1337.82 2481.33

Solid Unit Weight (kg/m3) 1702.55 1482.11 2557.98

water absorption (%) 2.19 0.92 0.05

Water content (%) 0.06 0.01 0.27

Fine Modulus 0.03 6.25 2.35

sieve analysis Zona 2

maximum aggregate

diameter 10 mm

Zona 2 (BS)

Sludge content (%) 1.10 0.17 0.15

4.2 Properties Fresh SCC Concrete

Workability

Workability is the property of fresh concrete to

demonstrate the ease with which concrete is stirred,

poured, molded, and compacted. The fatigue, water

retention and plasticity of the fresh concrete mix,

which is inseparable from the material's properties

and the fineness of the aggregates, affect this

property. The fresh SCC concrete mixture must have

the following characteristics: filling capacity, passing

capacity, and segregation resistance or segregation

resistance. In this study, the filling ability of the SCC

concrete was tested by means of thetested using the

T50cm Slump Flow Test, while the properties of the

Passing Ability were tool L-Box. Results of SCC

concrete PS Ball filling and passing abilities, shown

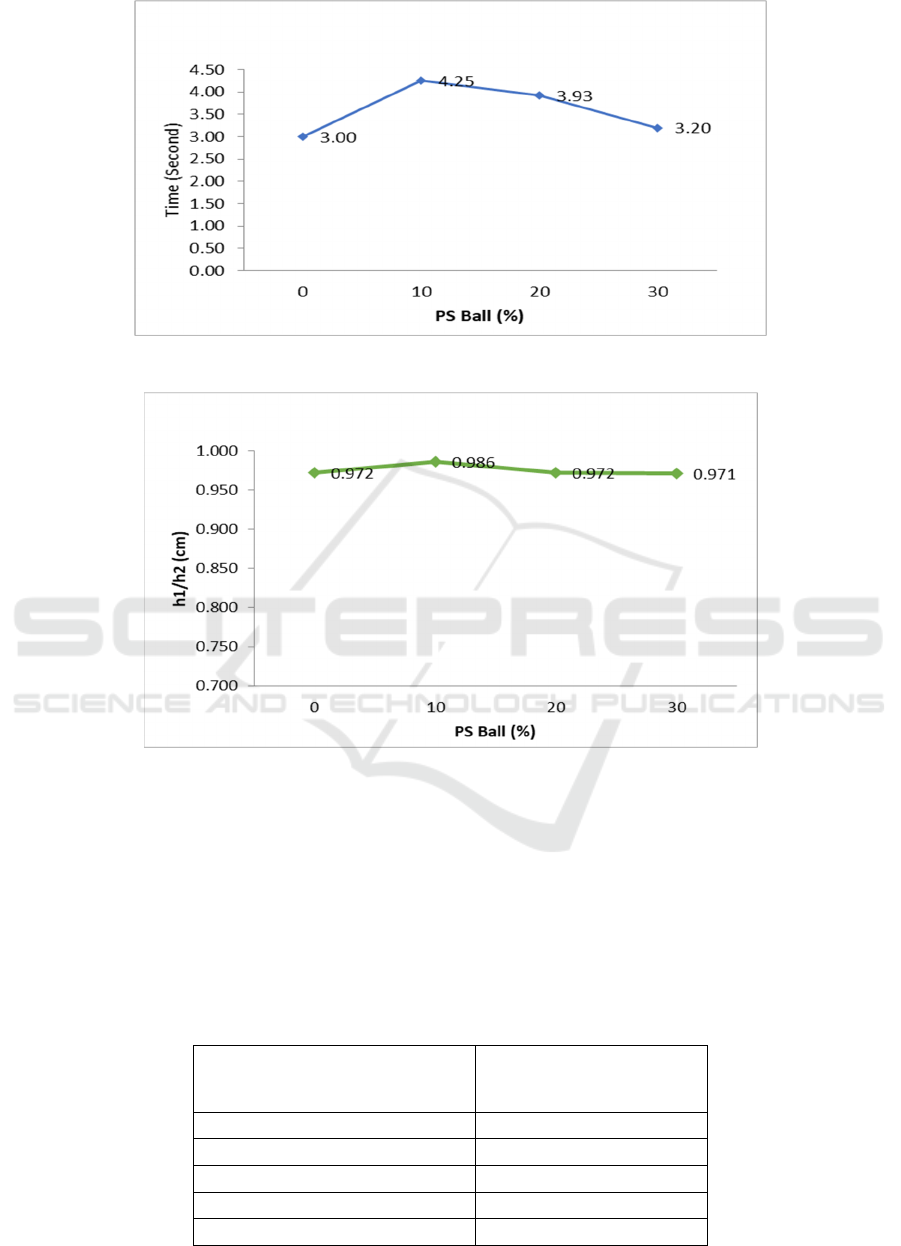

in Figures 1 and 2.

Filling ability is the ability of fresh concrete

mixers to fill spaces or voids. From Figure 1, it can

be shown that the use of PS Ball in SCC concrete as

a replacement for fine aggregate causes the SCC

concrete to decrease fluidity. This can be seen from

the longer it takes for the concrete flow to reach a

diameter of 50 cm. However, using PS Ball up to

30%, the filling ability concrete still meets the

requirements set by EFNARC, which is 2-5 seconds.

The homogeneity of the concrete was also seen in the

T50cm Slump Flow test. In fresh concrete, the use of

the PS Ball on SCC concrete does not cause

segregation and bleeding. Stir can be evenly and

homogeneous.

Passing ability is the ability of the fresh concrete

mixture to pass through reinforcement. This property

is required when the concrete mix is used to create

structures with tight reinforcement spacing. SCC

concrete, which has good passing ability, can pass

through tight reinforcement gaps without segregation.

The results of the research on SCC concrete using PS

Ball as a substitute for fine aggregate by 10% resulted

in higher passing ability and segregation resistance

values compared to SCC concrete without PS Ball.

This condition can be seen from the h2 / h1 value of

the L-Box test results that have increased (Figure 2).

This means that the ability of SCC concrete with PS

Ball aggregate to pass through tight reinforcement

gaps is higher than that of concrete without PS ball.

The concrete mix for all variations meets the

requirements of concrete as SCC concrete as in the

EFNARC provisions which require an h2 / h1 value

of 0.8 - 1.0

ASAIS 2020 - Annual Southeast Asian International Seminar

110

Figure 1. Filling Ability (Slump Flow TestT50) Concrete SCC PS Ball

Figure 2. Passing Ability (L-Box) Concrete SCC PS Ball

4.3 Time of Initial Bonding of Concrete

Bonding time is the condition in which the concrete

begins to harden. The initial bonding time needs to be

known to determine how long it takes for the concrete

to harden from the plastic state. It is important to

know the initial bonding time in order to determine

how long the concrete can be worked. The initial

binding time of SCC PS Ball concrete with steel scrap

waste fibers is presented in Table 2. binding time.

It can be seen from Table 2 that the initial binding

time of concrete appears to be the same for all variants

of the specimen. This means that the use of PS Ball

on SCC concrete does not affect the initial bonding

time of the concrete.

Table 2. Time of Initial bonding of SCC PS Ball

Percentage of

Time (minutes)

Fiber Binding

0.00% 320

0.25% 320

0.50% 320

0.75% 310

1.00% 310

Performance of Self Compacting Concrete (SCC) with Precious Slag Ball as Fine Aggregate Substitute

111

4.4 Unit Weight of Hard Concrete

Unit weight is used to calculate the structure's own

weight. The greater the value of the weight, the larger

the weight of the structure itself. The results of this

study are shown in Figure 3.

Unit weight is a value that states the ratio between

the weight and volume of concrete in a hard state. The

weight of the concrete contents serves to calculate the

structure's own weight. The greater the weight value,

the larger the structure has its own weight. Concrete

load weight is closely related to the concrete density,

which will influence the concrete strength. It can be

seen from Figure 3 that the use of the PS Ball on

concrete can raise the concrete's weight. However, at

30% PS Ball content, the weight of the concrete

content decreased. This happens because the use of

the PS Ball is 30%, the concrete looks segregated and

bleeding, so that the density of the concrete also

decreases.

Figure 3. Unit Weight of SCC PS Ball Concrete Content

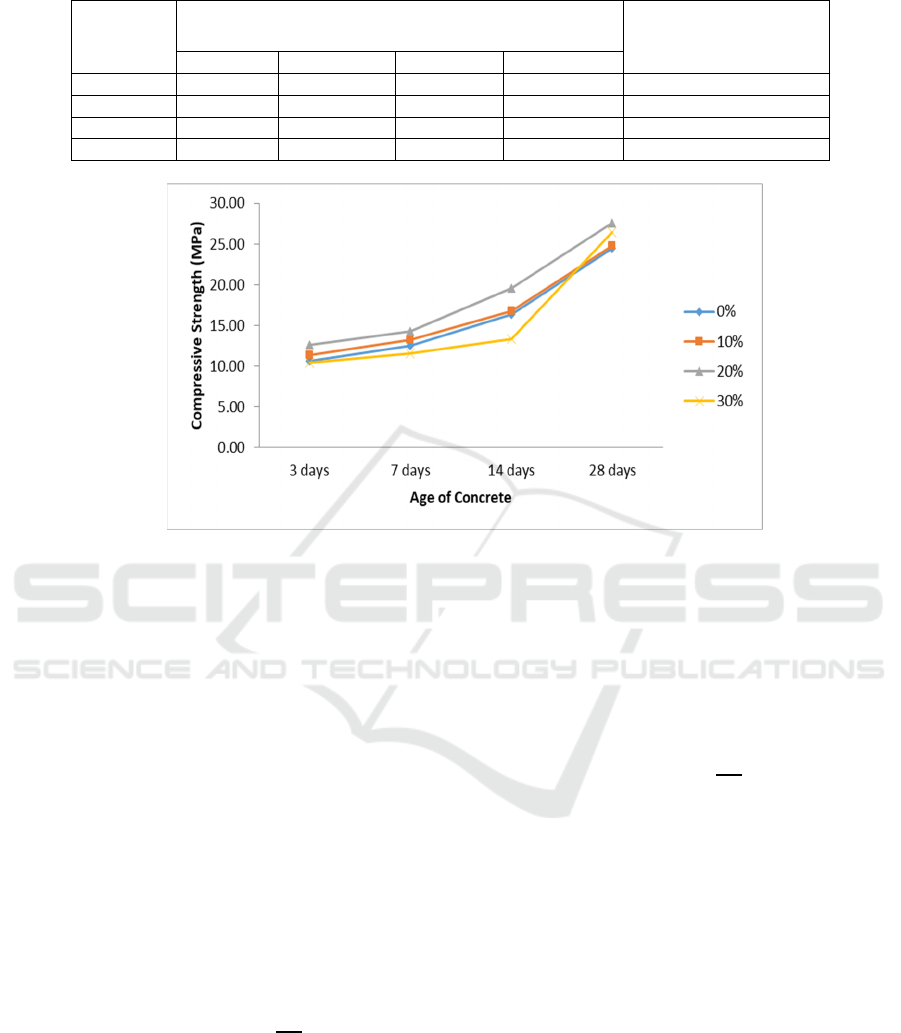

4.5 Compressive Strength of Concrete

Compressive strength was measured at the ages of 3,

7, 14, and 28 days to assess the development of

concrete strength. At this age, the purpose of the

compressive strength test is to assess the development

of the concrete strength, so that it can be determined

when the formwork/concrete mold can be opened, the

structure can be installed, or the load can be accepted

by the structure. Table 3 and Figure 4 summarizes the

findings of the study on the compressive strength of

PS Ball concrete.

Concrete compressive strength is the amount of

load per unit area that causes the concrete sample to

crumble when filled with a certain compressive force

that the compression testing machine generates. The

concrete compressive strength is the ability of

concrete to bear loads that act on the structure. In

comparison with other concrete properties, the

compressive strength of concrete is the most

significant and dominant feature of concrete.

Concrete compression strength is highly affected by

the quality of the aggregate, the quality of the

adhesive and the composition of the mixture, and the

level of density of the concrete.

It can be seen from table 3 that the use of PS Ball

as a fine aggregate at the age of 3,7,14, and 28 days

can increase the compressive strength of concrete. At

the age of 28 days, consecutively concrete with a 10%

PS Ball content had an increase in compressive

strength by 1.27%, a 20% PS Ball level compressive

strength increased by 13.22%, and a 30% PS Ball

content increased compressive strength by 8.11%.

The biggest increase in compressive strength

occurred in concrete with a content of 20% PS Ball.

SCC concrete's compressive strength is closely

linked to workability, where SCC concrete with high

slump flow value and high filling ability can easily

allow SCC concrete flow to fill the voids between the

reinforcement and solidify itself easily. In this study,

SCC concrete with fine aggregate PS Ball at 10% and

20% levels hasvalues which slump flow and filling

ability tend to be the same as SCC concrete without

PS Ball.

ASAIS 2020 - Annual Southeast Asian International Seminar

112

Table 3. Development of Compressive Strength SCC PS Ball

PS Ball

percentage

Average Compressive Strength (Mpa)

% increased strength at

28 days

3 days 7 days 14 days 28 days

0% 10.65 12.53 16.36 24.43

10% 11.35 13.19 16.76 24.74 1.27%

20% 12.6 14.23 19.53 27.61 13.02%

30% 10.44 11.57 13.33 26.41 8.11%

Figure 4. Development of Compressive Strength of SCC PS Ball

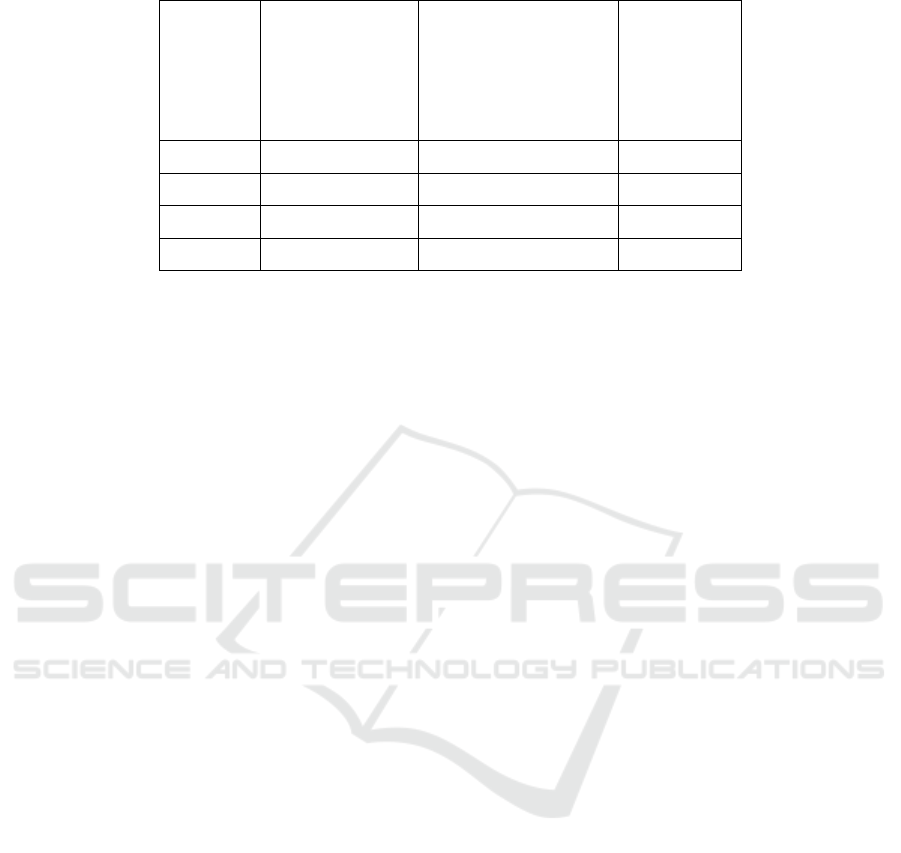

4.6 Tensile Strength of SCC PS Ball

Concrete

Table 4 shows the reliability test results of concrete

tensile strength. The concrete's tensile strength is the

ability of the concrete to withstand the concrete's

tensile stress. Concrete is a type of brittle material that

has high compressive strength but low tensile

strength. The tensile strength of concrete is usually

10%-15% of its compressive strength. The tensile

strength of this concrete is therefore neglected in the

design of reinforced concrete structures, in particular

in order to quantify the need for reinforcement, and

the concrete is deemed unable to withstand tensile

strength. Concrete only functions to hold pressure,

while the tensile area is held by reinforcement.

However, the concrete must have a minimum tensile

strength as required by SNI T 12 2005 article

4.4.1.1.2, which is equal to 0.33

𝑓′𝑐

.

The tensile strength of the concrete serves to

prevent cracks due to shrinkage, but it is not taken

into consideration. If there is shrinkage, concrete with

high tensile strength is not susceptible to cracking. It

can be seen from table 4 that the use of PS Ball as a

fine aggregate in SCC concrete causes the concrete's

tensile strength to raise at levels of 20%. In general,

however, the use of the PS Ball as a fine aggregate in

concrete causes the concrete to decrease its tensile

strength. Concrete tensile strength is not directly

proportional to its compressive strength, but concrete

tensile strength is directly proportional to the square

root of its compressive strength. The SCC concrete

tensile strength with a 20 percent PS Ball content is

greater than the tensile strength required by SNI 2847

2002, which is equal to 0.33

𝑓′𝑐

.

Performance of Self Compacting Concrete (SCC) with Precious Slag Ball as Fine Aggregate Substitute

113

Table 4. Tensile Strength of SCC PS Ball

Percentage

of PS Ball

Average Tensile

Strength (MPa)

Tensile Strength

Formula SNI =

0.33.Ѵfc '(MPa )

% increase in

Tensile

Strength

0% 1.69 1.63

10% 1.31 1.64 -22.70%

20% 2.29 1.73 34.96%

30% 1.48 1.7 -12.81%

5 CONCLUSIONS

Several conclusions can be reached as follows, based

on the findings of analysis and discussion, show that

(1) Up to 30 percent of SCC concrete with PS Ball as

a substitute for fine aggregate results in the filling and

passing abilities of SCC concrete that meets the

criteria of EFNARC standards for SCC concrete and

(2) The initial bonding time of the concrete with the

PS Ball was not much different from the initial

bonding time of the SCC concrete without the PS

Ball. Properties of hard concrete show that (1) The

weight of the concrete with the PS Ball substitution is

10% and 20% higher than the weight of the concrete

without the PS Ball and (2) Using up to 30% of PS

Ball as a replacement for fine aggregate can raise the

concrete's compressive strength. At 20% PS Ball

content, the highest increase in the compressive

strength of concrete and (3) The highest tensile

strength of concrete is produced by concrete with a

level of 20% PS Ball.

From the results of this study, it is suggested (1)

Further research on the use of the PS Ball for beam

and plate structural elements needs to be carried out

and (2)

Further research was carried out on other

concrete properties required for the design of

structural elements.

REFERENCES

Amit Rai, Dr. Y.P. Joshi. 2014. Applications and

Properties of Fiber Reinforced Concrete. Int. Journal of

Engineering Research and Applications ISSN: 2248-

9622, Vol. 4, Issue 5 (Version 1), May 2014, pp123-

131. www.ijera.com.

Avinash, H. Talkeri, AU Ravi Shankar, 2019. A study on

initial setting time and the mechanical properties of

AASC using the PS ball as fine aggregate. International

Journal of Pavement Research and Technology volume

12, 659-663.

Avinash, H. T, AU Ravi Shankar, 2018. Experimental

Study On Aasc Using Ps Ball As Fine Aggregate At The

Higher Concentration Of Sodium Silicate. IJRET:

International Journal of Research in Engineering and

Technology eISSN: 2319-1163 | pISSN: 2321-7308

Volume: 07 Special Issue: 01 pp. 20 - 24.

www.ijret.org.

Balvir Singh, Jaspal Singh, 2014. An Experimental Study

on Compressive Strength of Fiber Reinforced Concrete

With Fly Ash. Proceedings of ACI International

Conference on Recent Advances in Concrete

Technology, Warsaw Poland, 23–25 May, pp. 399-408.

Collepardi, M., 2007. Recent Developments of Special

Self-Compacting Concretes. Proceedings of Second

International Symposium on Concrete Tecnology for

Sustainable Proceedings of ACI International

Conference on Recent Advances in Concrete

Technology.

AM Shende, AM Pande, M. Gulfam Pathan, 2012.

Experimental Study on Steel Fiber Reinforced Concrete

for M-40 Grade. International Refereed Journal of

Engineering and Science (IRJES) ISSN (Online) 2319-

183X, (Print) 2319-1821 Volume 1, Issue 1 (September

2012), PP. 043-048. http://www.irjes.com/Papers/vol1-

issue1/G11043048.pdf.

Luca G. Sorelli, Alberto Meda, Giovanni A. Plizzari, 2006.

Steel Fiber Concrete Slabs on Ground: A Structural

Matter. ACI Structural Journal V. 103, No. 4, July-

August 2006. http: www. ACI Structural Journal.com.

L. Sai Indrasena Reddy, MM Vijayalakshmi,

Praveenkumar, T R., 2019. Behavior of GGBS and

ROBO Sand Replaced High Performance Concrete.

International Journal of Innovative Technology and

Exploring Engineering (IJITEE) ISSN: 2278-3075,

Volume-8 Issue-12. www.ijitee.org.

PT. Purna Baja Harsco, 2020. What is PS Ball

http://purnabajaharsco.blogspot.com/2012/10/apa-itu-

ps-ball_10.html.

Ravande Kishore, V., Bhikshma,P., Jeevana Prakash, 2011.

Study on Strength Characteristics of High Strength Rice

ASAIS 2020 - Annual Southeast Asian International Seminar

114

Husk Ash Concrete. Procedia Engineering 14 (2011)

2666–2672. http:www. Elsevier.com/locate/procedia.

S. Sharath, BC., Gayana, Krishna, R., Reddy and K. Ram

Chandar, 2019. Experimental investigations on

performance of concrete incorporating Precious Slag

Balls (PS Balls) as fine aggregates. Advances in

Concrete Construction Volume 8, Number 3,

November 2019, pages 239-246,

http://www.technopress.org/content/?page=article&jo

urnal=acc&volume=8&num=3&ordernum=8.

S.G. Jeurkar1, K.S., Upase, 2015. Behavior of Steel Fiber

Reinforced Concrete for M-25 Grade. IJETST- Vol. ||

02 || Issue || 02 || Pages 1842-1846 || February || ISSN

2348-9480. www.ijetst.in. (Accessed April 6, 2019).

Tan Lie Ing, Ronald Simatupang, and Deni Setiawan,

2015. Comprehensive Study of Effect Steel Waste Into

Mechanical Properties Of Concrete. Proceedings of the

International Conference on Engineering Technology

and Industrial Application. The 2nd ICETIA 2015.

https://publikasiilmiah.ums.ac.id/handle/11617/6564?s

how=full.

Performance of Self Compacting Concrete (SCC) with Precious Slag Ball as Fine Aggregate Substitute

115