Characterization on Surface Morphology of GaN Layer

Deposited on 2D MoS

2

Developed by CVD System

Iwan Susanto

1,2

, Ing-Song Yu

1

, Chi-Yu Tsai

1

, Yen-Ten Ho

3

, Ping-Yu Tsai

4

, Dianta Mustofa Kamal

2

,

Belyamin

2

, Sulaksana Permana

5

1

Department of Materials Science and Engineering, National Dong Hwa University, Hualien 97401, Taiwan ROC

2

Department of Mechanical Engineering, Politeknik Negeri Jakarta, Depok 16424, Indonesia

3

International College of Semiconductor Technology, National Chiao Tung University, Hsinchu 300, Taiwan ROC

4

Department of Electronic Systems Research Division, Chung-Shan Institute of Science & Technology,

Tao-Yan 325, Taiwan ROC

5

Center of Mineral Processing and Corrosion Research, Department of Metallurgy and Materials Engineering,

Universitas Indonesia, Depok 16424, Indonesia

Keywords: Characterization, Gallium Nitride, Molybdenum Disulfide, Chemical Vapor Deposition, Molecular Beam

Epitaxy

Abstract: A few layers of GaN was deposited epitaxial on the MoS

2

layers by PA-MBE technique. A smooth surface

with mixed like-flakes of MoS

2

is provided by the development of CVD system. It is grown on the c-sapphire

substrate with a few layers. Further, surface morphology both of MoS

2

substrate and GaN layer was

investigated in detail by the AFM and FE-SEM characterization. The results demonstrated that the surface

morphology of the constructing GaN layer was smoother than MoS

2

layer. The surface texture was obtained

throughout the decreasing of area roughness up to 1.44 nm and root mean square (RMS) of 2.40 nm. However,

thin GaN layers covering the MoS

2

surface was in the less content of atomic with a weight Ga element. It

takes longer growth time and more flux to obtain a flat morphological surface with high smoothness.

1 INTRODUCTION

GaN included on the group III-IV semiconductor

materials has excellent properties such as high

conductivity, high electrons mobility, very hard

material, chemically and mechanically stable

(Kawashima et al., 1997; Hanada, 2009). In

accordance with those properties, GaN is used

extensively for application in optoelectronic,

electronic components, high-power and high-

frequency devices (Chen et al., 2017; Su, Chen and

Rajan, 2013; Würtele et al., 2011; Joshin et al., 2014).

However, since a high-cost of the GaN bulk (Liu and

Edgar, 2002), GaN layers are developed to be grown

on other materials substrate. Several materials are

attempted for providing GaN layers as a substrate

(Kukushkin et al., 2008). Unfortunately, distinguish

thermal expansion coefficient and the lattice-

mismatched might build the residual strain initiated

the defect as decreasing the temperature from

manufacturing (Trampert, 2002; Poust et al., 2003).

The beginning of the damage raised from the

interface and then spread it toward the surface of layer

(Trampert, 2002; Fachruddin et al., 2020), which

degrade the quality structure and reduction for long-

term application.

Recently, several studies have been devoted for

increasing the GaN quality by growing it near lattice

matched (Susanto et al., 2019; Gupta et al., 2016; and

Mánuel et al., 2010). 2D MoS

2

layers was a hot topic

when they were grown on GaN material as

semiconductor material for optoelectronic application

(Wan et al., 2018; Zhang et al., 2018). Moreover,

MoS

2

has a lattice-matched with GaN which promises

for the high-quality growing of GaN layers. As thick

layers of GaN films were grown up to it's thick of 1.8

µm (Kimura et al., 2005), the defects are not attended

on the film's surface. Besides, an investigation of the

surface morphology of the GaN layer near the

substrate has not been studied in detail. It could be an

exciting part to observe it.

In this report, the morphology of GaN films will

be characterized to get a deep understanding of the

contour and texture of surface condition. A few

Susanto, I., Yu, I., Tsai, C., Ho, Y., Tsai, P., Kamal, D., Belyamin, . and Permana, S.

Characterization on Surface Morphology of GaN Layer Deposited on 2D MoS2 Developed by CVD System.

DOI: 10.5220/0010537900003153

In Proceedings of the 9th Annual Southeast Asian International Seminar (ASAIS 2020), pages 93-96

ISBN: 978-989-758-518-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

93

epitaxial growth parameters will be used to deposit

the impinging Ga and N atom on the 2D MoS

2

layer.

The characterization results will be presented and

analyzed based on both of 2-dimensional (2D) images

and quantitative data observation of AFM and SEM

technique.

2 EXPERIMENTAL METHOD

The growing GaN films on 2D MoS

2

layers are

prepared by MBE technique. The growth GaN was

controlled at 600 ℃ for 20 minutes. The thermal

cleaning is given for 40 minutes and free-nitridation

of 10 minutes before the epitaxial growth. The

imaging atom of Ga flux is provided by K-cell at 800

℃, while Radiofrequency of Nitrogen Gun supplied

N flux at 500 W. The flow rate was provided in sccm

of 0.8 for N6 gas. Furthermore, the background

pressure was built at 8 x 10-6 Torr. The 2D MoS

2

layer substrate was exploited by the CVD method,

deposited on the single crystal of c-sapphire. Finally,

the ex-situ characterization was employed using

AFM and FE-SEM machine for investigating the

surface morphology.

3 RESULT AND DISCUSSION

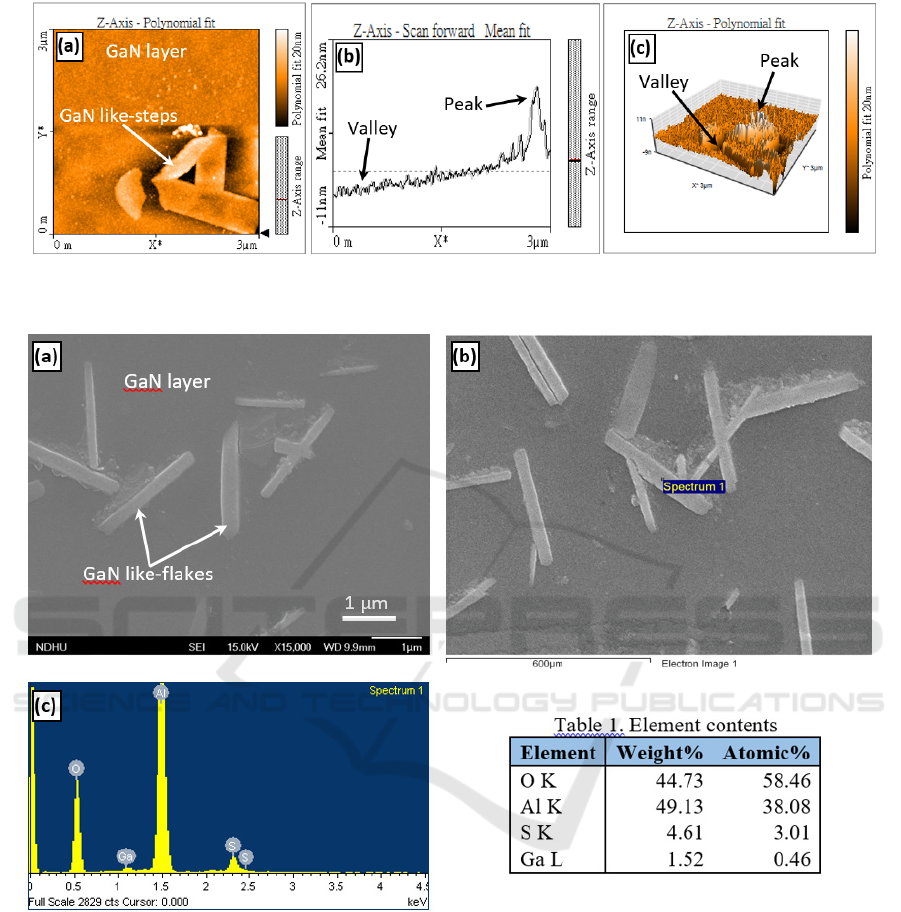

Figure 1. AFM image of 2D MoS

2

layer deposited on the

sapphire substrate

Fig 1 displays the surface morphology of MoS

2

layer

grown on the sapphire. The surface texture 2D MoS

2

layer was observed with 3 x 3 µm of scan area. The

bright color was related to peak of MoS

2

on the

surface, while the dark color was associate with the

valley of the surface. The difference both of the colors

elucidate the surface condition formed on the MoS

2

layer. The MoS

2

like-steps with the bright color, and

the dark area formed was associated with the surface

contour of the MoS

2

layer during the deposition

process using the CVD system. The area roughness of

MoS

2

surface is achieved to be 2.17 nm and the root

mean square is obtained about 4.19 nm. The high

peak value and the deep valley are 25.14 nm, and

31.99 nm, serially. Based on the characterization

using the AFM method, the texture of the MoS

2

layer

is established with smoother of surface condition.

Since the growth epitaxial, the morphology of

GaN layers on 2D MoS

2

has entirely demonstrated in

Fig 2. The surface texture GaN layer was observed

with a scan area of 3x3 µm in Fig 2(a). The bright

color was related to peak of GaN on the surface, while

the dark color was associate with the valley of the

surface in Fig 2(b). The surface texture was more

apparent as they were demonstrated using the 3-

dimension profile shown in Fig 2(c). The distinct

colors seem with a low degradation value, suggesting

the smooth surface formed on the GaN layer.

However, attending the protrusions, GaN like-steps

on the surface in Fig 2(a) could be increasing the

surface roughness on GaN layer. The GaN like-steps

formed was initiated with the surface contour of the

MoS

2

layer exhibited on Fig 1. As the impinging Ga

and N atoms on the MoS

2

layer, the GaN layer grew

epitaxial following the substrate's texture. So, in the

short growth time, the GaN layer formed based on the

substrate surface pattern (Susanto et al., 2019).

Furthermore, the area roughness on the surface GaN

has reached up to 1.44 nm and the root mean square

is 2.40 nm. The highest peak value is up to 21.07 nm

and the deep valley is until 15.01 nm. According to

the AFM images, the surface GaN layer constructed

with smoother than the MoS

2

surface. The smoother

of surface morphology as indicated by decreasing the

area roughness and root mean square up to 33.6 % and

44.7 %, respectively.

Fig 3 exhibit the FE-SEM images and EDS

observation of the surface morphology and element

composition on the GaN layer. By the magnitude of

15,000 displayed in Fig 3(a), the surface GaN layer's

condition looks smooth, indicating that it has grown

on the MoS

2

layer. However, the GaN like-flakes

were still visible on the surface, which is in tune to

the AFM images in Fig 2. Observation using the spot

scans in spectrum one on Fig 3(b) was carried out to

identify the GaN layer. Fig 3 show Ga element

detected in spectrum 1 with less content, suggesting

that the few GaN layers have grown on the MoS

2

flakes. All elements related to substrate layers were

tabulated more detail in Table 1. GaN layers have

successfully covered all of surface MoS

2

layer even

in the less content of percentage atomic with a

percentage weight Ga element.

Valley

Peaks

ASAIS 2020 - Annual Southeast Asian International Seminar

94

Figure 2. AFM images of surface GaN layer observed; (a) Scan area profile of 3x3 µm, (b) line-profile through of 3 µm, and

(c) 3-dimension profile with a deep of 20 nm

Figure 3. SEM images of surface morphology GaN layers (a, b), and (c) EDS of scan-spot on the surface GaN like-flakes

4 CONCLUSIONS

The characterization of surface morphology on the

GaN layer deposited on 2D MoS

2

layer by PA-MBE

system was successfully done using AFM and FE-

SEM technique. The surface texture of MoS

2

layers

was observed in detail for initial surface condition of

the substrate. Besides part for MoS

2

plat-layers,

attending MoS

2

like-flakes leads to establishing the

texture of GaN layers epitaxial. A less content of

atomic and weight Ga also covered the surface of

MoS

2

plat-layers. Even though the epitaxial was

employed in the short growth time, the decreasing of

the area roughness and root mean square attained the

smoother surface of the GaN layer. Thicker GaN

films should be employed by providing a higher Ga

and N fluxes with longer growth time.

Characterization on Surface Morphology of GaN Layer Deposited on 2D MoS2 Developed by CVD System

95

ACKNOWLEDGMENTS

The authors would like to thank Ministry of Science

and Technology, Taiwan for financially supporting

this study (MOST 107-2221-E-259- 001-MY2 and

107-3017-F-009-002), and a giving thanks to Pusat

Penelitian dan Pengabdian Masyarakat, Politeknik

Negeri Jakarta (PPPM PNJ nomor B.142 /PL3.18

/PN.00.03 /2020) and also for the Ministry of

Research and Technology, Research Council, and the

National Innovation Republic of Indonesia

REFERENCES

Chen, K. J. et al. (2017) ‘GaN-on-Si power technology:

Devices and applications’, IEEE Transactions on

Electron Devices. doi: 10.1109/TED.2017.2657579.

Fachruddin, et al. (2020) ‘Surface Modification of

Magnetic TiO

2

Core-Shell with Doped Cerium for

Enhancement of Photocatalytic Performance’, Eastern-

European Journal of Enterprise Technologies. doi:

10.15587/1729-4061.2020.203186

Gupta, P. et al. (2016) ‘Layered transition metal

dichalcogenides: promising near-lattice-matched

substrates for GaN growth’, Scientific Reports. doi:

10.1038/srep23708.

Hanada, T. (2009) ‘Basic Properties of ZnO, GaN, and

Related Materials’, in. doi: 10.1007/978-3-540-88847-

5_1.

Joshin, K. et al. (2014) ‘Outlook for GaN HEMT

technology’, Fujitsu Scientific and Technical Journal.

Kawashima, T. et al. (1997) ‘Optical properties of

hexagonal GaN’, Journal of Applied Physics. doi:

10.1063/1.365671.

Kimura, R. et al. (2005) ‘Thick cubic GaN film growth

using ultra-thin low-temperature buffer layer by RF-

MBE’, Journal of Crystal Growth, 278(1–4), pp. 411–

414. doi: 10.1016/j.jcrysgro.2005.01.058.

Kukushkin, S. A. et al. (2008) ‘Substrates for epitaxy of

gallium nitride: New materials and techniques’,

Reviews on Advanced Materials Science.

Liu, L. and Edgar, J. H. (2002) ‘Substrates for gallium

nitride epitaxy’, 37, pp. 61–127.

Mánuel, J. M. et al. (2010) ‘Structural and compositional

homogeneity of InAlN epitaxial layers nearly lattice-

matched to GaN’, Acta Materialia. doi:

10.1016/j.actamat.2010.04.001.

Poust, B. D. et al. (2003) ‘SiC substrate defects and III-N

heteroepitaxy’, Journal of Physics D: Applied Physics.

doi: 10.1088/0022-3727/36/10A/321.

Su, M., Chen, C. and Rajan, S. (2013) ‘Prospects for the

application of GaN power devices in hybrid electric

vehicle drive systems’, Semiconductor Science and

Technology. doi: 10.1088/0268-1242/28/7/074012.

Susanto, I., Tsai, C., et al. (2019) ‘Morphology and surface

stability of GaN thin film grown on the short growth

time by Plasma Assisted Molecular Beam Epitaxy’, J.

Phs : Conference Seriese, 1364(012067). doi:

10.1088/1742-6596/1364/1/012067.

Susanto, I., Tsai, C.-Y., et al. (2019) ‘The influence of 2D

MoS

2

layers on the growth of GaN films by plasma-

assisted molecular beam epitaxy’, Applied Surface

Science, 496(July), p. 143616. doi:

10.1016/j.apsusc.2019.143616.

Trampert, A. (2002) ‘Heteroepitaxy of dissimilar materials:

Effect of interface structure on strain and defect

formation’, in Physica E: Low-Dimensional Systems

and Nanostructures. doi: 10.1016/S1386-

9477(02)00317-X.

Wan, Y. et al. (2018) ‘Epitaxial Single-Layer MoS

2

on GaN

with Enhanced Valley Helicity’, Advanced Materials.

doi: 10.1002/adma.201703888.

Würtele, M. A. et al. (2011) ‘Application of GaN-based

ultraviolet-C light emitting diodes - UV LEDs - for

water disinfection’, Water Research. doi:

10.1016/j.watres.2010.11.015.

Zhang, Z. et al. (2018) ‘Interface Engineering of Monolayer

MoS

2

/GaN Hybrid Heterostructure: Modified Band

Alignment for Photocatalytic Water Splitting

Application by Nitridation Treatment’, ACS Applied

Materials and Interfaces. doi: 10.1021/acsami.8b01286.

ASAIS 2020 - Annual Southeast Asian International Seminar

96