Investigation and Comparison of Physicochemical Characteristics of

Non-aged and 4-month Aged Mulberry Wine Prepared from

Three Different Wine Making Techniques

Resha Shrestha

1

, Siriwan Panprivech

2

, Kamolnate Kitsawad

1

and Viyada Kunathigan

1,*

1

Department of Food Biotechnology, Faculty of Biotechnology, Assumption University, Bangkok, Thailand

2

Department of Agro-Industry, Faculty of Biotechnology, Assumption University, Bangkok, Thailand

Keywords: Mulberry, Cold Pressed, Physicochemical Analysis, Antioxidant, Anthocyanin.

Abstract: Winemaking techniques and the aging process of wine are important to the quality of wine. This study was

investigated and compared the effect of different winemaking practices on physicochemical characteristics

among non-aged and 4-month aged of Morus alba Linn (cv. Chiang Mai 60) wines. Hand press juice (HPJ),

hand press juice with pulp (HPP) and cold press juice (CPJ) were prepared from fresh mulberry fruit which

were fermented using Saccharomyces cerevisiae (Premier rouge) and then bottled and aged for 4 months in

the cold room (12±2˚C). The pH, total titratable acidity (TTA), alcohol content, reducing sugar, color

measurements, total phenolic content (TPC), total flavonoid content (TFC), antioxidant capacity and total

anthocyanin content (TAC) were observed. The results showed significant differences on the chemical

parameters (TTA, alcohol content, reducing sugar, TPC, TFC and TAC) among three treatments of mulberry

wines without aging. Among all wine making techniques used, HPP and CJP method produced wine that

have similar level of TFC, and color intensity which was higher than the wine prepared by HPJ method. The

HPJ method resulted in the wine that have significantly lower level of TPC, TAC, and TFC than the other two

techniques. In addition, after aged the mulberry wines for 4 months, the wine made with different technique

had significantly lower level of TPC, antioxidant capacity, TAC, TFC and color hue than the non-aged

mulberry wine made from the same technique.

1 INTRODUCTION

Mulberry has unique flavour, texture, and color.

(Vijayan et al., 2011) considered that mulberry fruits

have well balanced sweetness and tartness. It is highly

perishable therefore it is used in manufacturing

different types of food for example sauce, fruit tea,

ice-creams, supplements, syrup, vinegar and also

alcoholic beverages (Juan et al., 2012). Mulberry is a

potential plant due to the presence of bioactive

ingredients (Ercisli and Orhan, 2007). Moreover,

Yang and Tsai (1994) found nutritional components

such as sugars, organic acids, free amino acids,

vitamins and micronutrients in mulberry. Thus, it has

significant importance inhuman health. Moreover,

Nomura et al. (1976) found that the parts of mulberry

such as twigs, leaves, fruits and root bark contain

phenolic compounds which can be used to treat

various diseases. The mulberry contains functional

components such as phenolic, flavonoids and

ascorbic acid (Bae and Suh, 2007) which add both

interest and value to it. It also contains anthocyanin.

According to Kim and Lee (2020) major anthocyanin

component found in mulberry are cyanidin-3-O-

glucoside and cyanidin-3-O-rutinoside. Due to the

presence of the ascorbic acid, flavonoids and

anthocyanin, mulberry possess antioxidant

characteristics. Besides, anti-microbial, anti-

inflammatory and anti-cancer (Butt et al., 2008) and

antiradical (Suh et al., 2004) properties are also found

in mulberry fruit extract. In addition, Mattivi et al.

(2006) and Mcdougall et al. (2005) reviewed anti-

atherosclerotic, anti-carcinogenic, and anti-

inflammatory properties in mulberry. These

significant therapeutic qualities in mulberry may be

one of the reasons for its consumption in various

possible forms of food and beverages.

The raw materials, environment, temperature,

yeasts, different processing techniques, fermentation

and aging have significant impact on the physical,

chemical and organoleptic properties in wine. Iland et

Shrestha, R., Panprivech, S., Kitsawad, K. and Kunathigan, V.

Investigation and Comparison of Physicochemical Characteristics of Non-aged and 4-month Aged Mulberry Wine Prepared from Three Different Wine Making Techniques.

DOI: 10.5220/0010529500003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 79-87

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

79

al. (2000) considered pre- fermentation, fermentation

and post fermentation as vital processes in wine

making. For example, Wang et al. (2020) experiment

on apple juice extracted by three different mechanical

juice extraction methods such as squeezed juice,

spiral juicer and broken juice have greater impact on

the quality of apple juice. The quality of juice

depends upon parameters such as pressing time, flow

rate, pressure and heat. Moreover, the processes such

as crushing, pressing and filtration can affect the

yield, texture and quality of juice. The proper

mashing and filtration results in less viscous juice.

One of the challenging part in making mulberry wine

is high viscosity of juice. The fruits contain fibre of

11.75 ± 1 g/100 g fresh weight (Imran et al., 2010)

making juice thicker and syrupy resulting in

prolonged filtration time. The quality, time and cost

due to extraction may add or reduce the value to

winemaking. Chen et al. (2015) suggested that there

are lesser information on influence on the quality of

fruit and vegetable juice due to processing

technologies. Thus, there may be a debate on the

quality of fruit juice extracted from different

methods. Perez-Cacho and Rouseff (2008) stated that

juice processing methods can affect the juice flavour.

According to Nadulski et al. (2017) depending on raw

material and operation type, different juice extraction

techniques are applied. Hydraulic, basket, belt and

screw press are popular in food industry for pressing

(Jaeger et al., 2012). Cautela et al. (2010) stated that

the juice processing method can affect the

phytochemical content. However, less information

about various wine making techniques and their

comparative study in terms of mulberry wine can be

found till date

In one of the recent study done by Chang (2020)

on cold pressed mulberry wine, the temperature for

fermentation of wine has significant impact on

physiochemical properties. The same study showed

that the alcohol production is faster in room

temperature (30±2°C) whereas the higher amount of

phenolic (2319.44±2.94 mg/L cyanidin-3-glucoside)

was obtained in lower temperature (12±2˚C).

Therefore, temperature can also play an important

role affecting the phenolics. The cold pressed

mulberry wine can have high phenolic contents.

Aging of wine can be another factor that has great

impact on its chemical composition. Balga et al.

(2015) specified that the phenolic compounds

undergo various chemical reactions during aging. The

alteration in phenolic affects the quality of wine.

Somers (1971) expressed that the phenolic play an

important role in the taste and color of wine during

maturation, aging and storage. Maturation and aging

of wine can change the taste, aroma, texture and

flavour of a wine due to the chemical reactions among

sugar, phenolic and acids. The wine become smoother

creating the complex aroma and taste.

The objective of this study is to analyse and

compare the non-aged and 4-month aged mulberry

wines which were prepared from three different wine

making techniques.

2 MATERIALS AND METHODS

2.1 Wine Preparation

The fresh and ripe mulberry (Morus alba Linn.cv.

Chiang Mai 60) fruits were sorted and directly

proceed for hand pressed and cold pressed juice. The

juice was prepared using three different processing

techniques namely manual mashed mulberry juice

without pulp (HPJ), manual mashed mulberry Juice

with pulp (HPP) and cold-pressed mulberry juice

without pulp (CPJ). HPJ and HPP were hand mashed.

The difference between the two treatments was

filtration of pulp in HPJ whereas pulp was included

in HPP. However, CPJ was prepared using cold press

machine (Slow juicer Tefal model ZC150838). Each

treatment was then added with distilled water in the

ratio 4:1 (v/v) (juice: water). The pH was adjusted to

3.7 using acid blend (citric: malic = 1:1.5 w/w). The

˚Brix was adjusted to 22˚ with granulated cane sugar.

Then the pectinase enzyme (L.D. Carlson, OH, USA)

was added (0.67 g/L), followed by addition of

potassium meta-bisulphite (KMS) (150mg/L). After

10-12 hours, Saccharomyces cerevisiae (Premier

Rouge UCD#904) was added (7.5x10

6

cell/ml) along

with 2 g/L diammonium phosphate (DAP). After

complete fermentation (6 days), all treatments of

wines were filtered, bottled and aged for 4 months at

12±2 ˚C. All treatments were sampled after

completed fermentation and 4-month aged then

centrifuged (3000 rpm for 2 min) and transferred

supernatant into new tubes and subsequently frozen

at -20˚C until analysis.

2.2 Chemical Analysis

The chemical compositions of each sample were

analyzed in triplicate. The pH was analyzed using the

pH meter (pH 211 Microprocessor pH meter, China).

The alcohol content was measured using

Ebulliometer (160000-complete traditional

Ebulliometer, Laboratories Dujardin Salleron

TM

,

France). The official method of analysis (AOAC

926.12, 1990) was used to measure total titratable

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

80

acidity (TTA) and expressed percentage of citric acid.

The 3, 5-dinitrosalicylic acid (DNS) assay (Miller,

1959) was followed to measure the amount of

reducing sugar in all wine samples which was

expressed in g/L.

2.3 Total Phenolic Content (TPC)

TPC was quantified using Folin-Ciocalteu micro

method (Waterhouse, 2002). Wine sample (0.02 mL)

was added to 1.58 mL distilled water. To it, 0.1 mL

F-C reagent was added. After 5 min, 0.3 mL 20%

sodium carbonate (Na

2

CO

3

) was added, mixed well

then incubated for 1.5 hours at 30±2 ºC. The

absorbance was read at 765 nm in triplicate. TPC was

calculated from the calibration curve and expressed

as mg/L of gallic acid equivalent.

2.4 Total Flavonoids Content (TFC)

TFC was determined using aluminium chloride

colorimetric method (Ivanova et al., 2010, Zhishen et

al., 1999) in triplicate. Wine sample (1 mL) was

mixed with distilled water (4 mL) in a tube. Then 0.3

mL of 5% sodium nitrite (NaNO

2

) was added and

rested for 5 min at room temperature. Then 0.3 mL of

10% aluminium chloride (AlCl

3

) was added and

reacted for 5 min. Then 2 mL of 1M sodium

hydroxide (NaOH) was added and the total was made

up 10 mL with distilled water. The solution was

mixed well, and the absorbance was read at 510 nm

in triplicate. TFC was calculated from the calibration

curve and expressed as mg/L of Rutin equivalent.

2.5 Total Anthocyanin Content (TAC)

TAC was determined in triplicate by using the pH

differential method described by AOAC Official

method 2002.02. TAC was determined as mg/L of

cyanidin-3-glucoside equivalent according to the

following equation (1):

TAC = (A × MW × DF × 10

3

) / (ɛ × L)

(1)

Where A is absorbance [(A520nm – A700nm) pH

1.0 – (A520nm – A700nm) pH 4.5]; MW is the

molecular weight of cyanidin-3-glucoside (449.2

g/mol); DF is the dilution factor (100); L is the path

length in cm (1); and ε is the molar extinction

coefficient of cyanidin-3-glucoside (26900 L/mol

cm).

2.6 Antioxidant Content

Antioxidant was determined by using DPPH radical

scavenging method described by Šimić et al. (2017).

The DPPH radical scavenging activity is calculated in

terms of percentage inhibition of DPPH activity

according to the following equation (2);

% inhibition = [(AC - AA) / AC] x 100 (2)

Here AA and AC are the absorbance values of the

samples and the control, respectively. The percentage

inhibition of DPPH activity of Trolox solution was

also tested. The calibration curve was constructed

with the Trolox solution concentrations versus the

percent inhibition of DPPH activity. The antioxidant

capacity of the samples were quantified and

expressed as Trolox equivalents mg/L from the

calibration curve.

2.7 Color Measurement

The absorbance of the wine samples at 420, 520, and

620 nm was measured directly by use of a

spectrophotometer with an optical path length of 10

mm. The color intensity was calculated as the sum of

the absorbance at 420, 520, and 620 nm (A

420

+ A

520

+ A

620

). Hue was obtained as the ratio of absorbance

measured at 420 and 520 nm (A

420

/A

520

).

2.8 Statistical Analysis

All the physicochemical parameters of non-aged and

4-month aged wines were carried out in triplicates.

All the data were analysed using Statistical Analysis

System (SAS) program version 9.4 (SAS Institute,

Cary, NC and USA). The statistical difference

between the means was evaluated using least

significant difference (LSD) test. T-test was used to

compare the difference in the mean between each

parameter of non-aged and 4-month aged wines.

3 RESULTS AND DISCUSSION

3.1 Chemical Compositions

The chemical composition of mulberry wines

prepared by three different wine making techniques

(HPJ, HPP, and CPJ) was determined before and after

4 months aging period (Figure 1). The HPJ has given

significantly higher alcohol content in all three

treatments. HPJ and CPJ contained only juice making

Investigation and Comparison of Physicochemical Characteristics of Non-aged and 4-month Aged Mulberry Wine Prepared from Three

Different Wine Making Techniques

81

them lesser viscous than HPP. In this study, the

alcohol content in HPJ with lesser viscous fluid is

higher. The amount of sugar was well utilized by

Saccharomyces cerevisiae in HPJ and CPJ resulting

in higher alcohol content in them. According to

Abdullah et al. (2007), the use of pectinase aid in the

hydrolysis of soluble polysaccharides (high viscosity)

to soluble sugars and short chain (low viscosity).

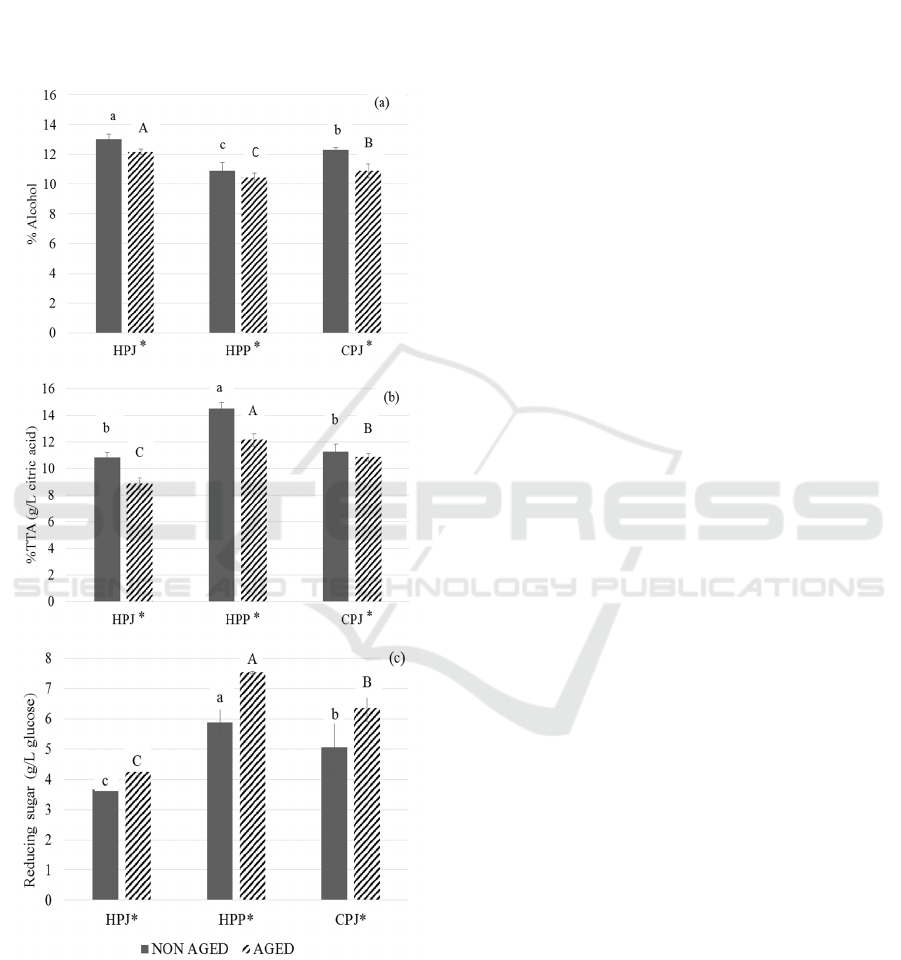

Figure 1: The changes in chemical composition of non-aged

and 4 months aged mulberry prepared from three different

wine making techniques (HPJ, HPP and CPJ).: (a) alcohol

content, (b) acidity (TTA) percentage, and (c) reducing

sugar. The data are expressed as mean ±SD (n=3). The

different letters indicate significant difference (p < 0.05).

‘*’ represents the significant difference.

However, the alcohol percentage significantly

decreased [Figure 1(a)] during 4 months aging in all

three treatments. During fermentation or aging of

wine, the ethyl esters formation such as ethyl esters

of lactic, malic and tartaric acid occurs developing

odor and taste of wine (Shinohara et al., 1979). These

might be the reason for decrease in the percentage of

alcohol in all three treatments after 4 months aging.

When the acidity of all three treatments were

observed [Figure 1(b)] in 4-month aged mulberry

wine, the result showed significantly reduction in the

acidity in all treatments. Shinohara et al. (1979) stated

that during aging, ethyl esters acid are formed rapidly.

The acid in wine reacts with alcohol to form esters.

Ancin-Azpiicueta et al. (2008) stated that during

aging the ethyl esters of organic acid increased

leading to decrease in acidity.

The reducing sugar content [Figure 1 (c)] of the

three treatments was compared. HPP had

significantly higher reducing sugar. Comparatively,

HPJ had the least reducing sugar content (3.66 g/L

glucose). This indicated that the most of the sugar was

well consumed by yeast and converted to alcohol in

HPJ. However, after 4-month of aging, the reducing

sugar content was increased in all the treatments. As

stated by Butt et al. (2008), mulberry fruit contains a

good amount of proteins, carbohydrates, fats, fiber

and vitamins. Carbohydrates from mulberry may

have been remained in the wine especially in the HPP

treatment. Chapman et al. (1991) stated that pectin in

fruits can be hydrolyzed into free sugars by a

pectinase enzyme. As the pectinase enzymes has been

added to the fermentation from the beginning,

remaining activity from the pectinase could have

slowly released these sugars into wine cause the

increase in reducing sugar during 4-months aging.

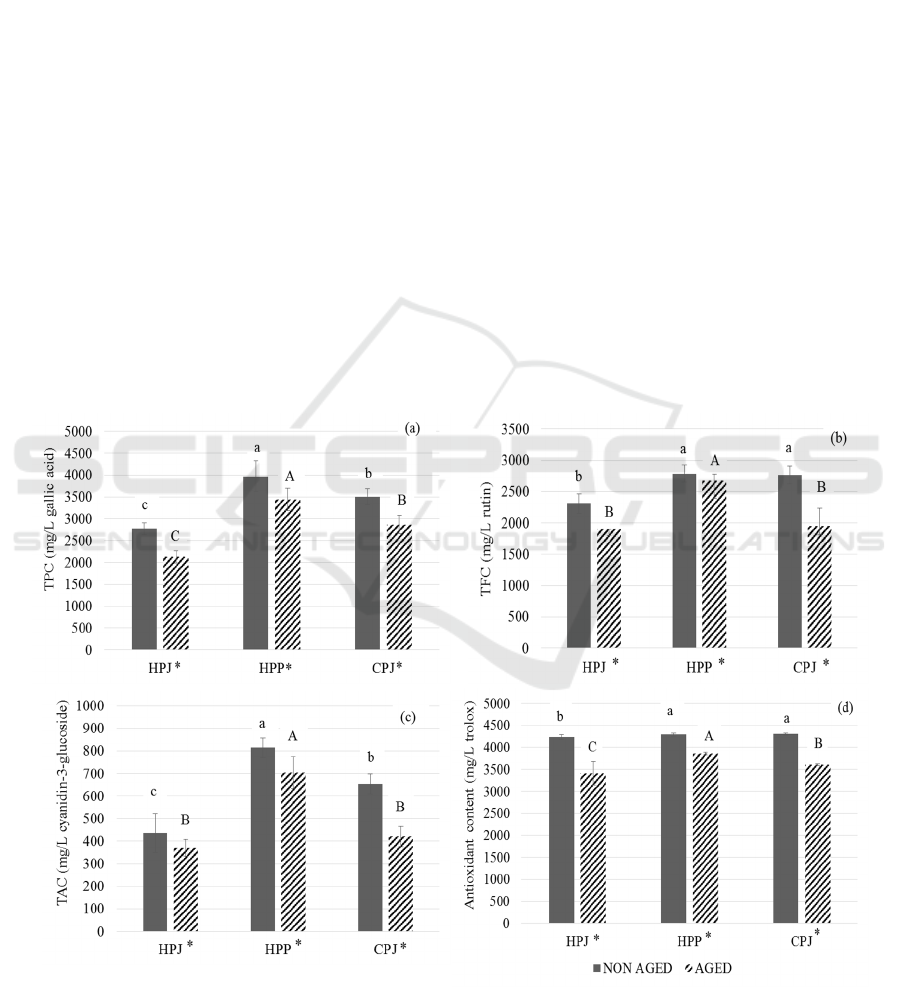

3.2 TPC

The TPC of all the treatments were analyzed [Figure

2 (a)]. The results showed that there was a significant

difference (p < 0.05) between all the treatments.

Mulberry contains phenolic and polysaccharides

(Chen et al., 2015) which might give higher phenolic

content in HPP. The wine with filtered juice (HPJ)

with absence of whole fruit had significantly lesser

phenolic in it. Martinez-Lapuente et al. (2017) stated

that winemaking step such as filtration causes

decrease in wine polysaccharide content which is why

HPJ had the lesser phenolic content. However, after

4-months aging, the decreased in TPC in all the

treatments was observed. Mulberry is rich in

phytochemicals such as phenolic compounds,

flavonoids, anthocyanin and ascorbic acid (Bae and

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

82

Suh, 2007). According to Ribereau-Gayon et al.

(2006), the chemical reactions such as thermal and

oxidative degradation of anthocyanin, interaction of

tannins with proteins and polysaccharides,

polymerization of procyanidin and copigments and

formations of anthocyanindins are the reasons for

changes in level of phenolic compounds. Whereas

Yıldırım et al. (2015) emphasized on the subsequent

transformation of wine phenolic in bottled (i.e.

anaerobic) condition where slow polymerization and

condensation reaction occurs. This process can cause

the decrease in TPC. Moreover, the similar reduction

of phenolic in mulberry juice was seen in a study done

by Zou et al. (2017). However, the reason for the

reduction in the same study was the formation of

sediments in mulberry juice during storage in which

was not a case in this study as the sediments was not

observed.

3.3 TFC

The TFC of the treatments were analyzed [Figure 2

(b)]. The HPP resulted in the higher flavonoid content

(2785.24 ± 136.53 mg/L rutin) before aging. The

fermentation with pulp in HPP may account for the

higher flavonoid content due to the increasing time

for extraction. The fruit of mulberry is rich in

phytochemicals such as phenolic, flavonoids,

anthocyanin and ascorbic acid (Bae and Suh, 2007).

Thus, the addition of pulp in the juice may promote

the higher flavonoids in wine. After 4-month of

aging, the reduction in TFC was seen in all the three

treatments. This result may show the importance of

presence of pulp in the juice for the higher flavonoid

content in wine.

The flavonoids and non-flavonoids are polyphenolic

contents (Lachman et al., 2009) which get affected by

factors such as pH, temperature and aging. The total

flavonoid phenols tended to decrease with aging of

wine. Furthermore, the flavonol, a major class of

flavonoids in wine can react with sugar to form

flavonol glycosides (Hertog et al., 1993). During

wine aging the formation of flavonol glycosides

occurs which undergo self-hydroxylation (Somers,

1971). High antioxidant properties and free radical

scavenging characteristics are due to flavonoids

(Scherer and Godoy, 2009) thus the degradation in

TFC may affect the antioxidant content.

Figure 2: The changes in phenolic of non-aged and 4 month aged mulberry prepared from three different wine making

techniques (HPJ, HPP and CPJ).: (a) total phenolic content, (b) total flavonoids content, (c) total anthocyanin content, and (d)

antioxidant content. The data are expressed as mean ±SD (n=3). The different letter indicates significant difference (p < 0.05).

‘*’ represents the significant difference between non aged and 4 months aged mulberry wines.

Investigation and Comparison of Physicochemical Characteristics of Non-aged and 4-month Aged Mulberry Wine Prepared from Three

Different Wine Making Techniques

83

3.4 TAC

The comparative study of TAC in all the treatments

[Figure 2(c)] showed that HPP had the higher

anthocyanin content (813.79±44.73 mg of cyanidin-

3-glucoside per L) before aging whereas HPJ had the

lower TAC. According to Hunjaroen and

Tongchitpakee (2010), the young mulberry has total

anthocyanin content of 2.6-6.8 mg of cyanidin-3-

glucoside. Chen et al. (2006) states that anthocyanin

is an important constituent of mulberry fruit. Thus the

presence or absence of pulp in juice affects the TAC

in juice and wine. However, slight decrease in the

TPC was observed in three treatments after 4-months

aging. The TAC of non-aged wine showed significant

difference (p < 0.05) with that of 4-month aged wines.

The reduction may be due to the conversion of

anthocyanin into non-pigmented compounds. The

anthocyanin undergoes oxidative polymerization

resulting in oligomeric and polymeric pigments

which convert red wine color to brown (Somers,

1971). Wang et al. (2015) states that the anthocyanin

possesses low stability and factors such as pH,

temperature and oxygen can affect it. Anthocyanin

are more stable at low pH resulting in red pigment

(Wahyuningsih et al., 2017). In this study, the

reduction in acidity during aging may alter the

anthocyanin content as according to (Khoo et al.,

2017), the anthocyanin pigments decreases when

there is lower acidity. These can be the reason for

anthocyanin reduction after 4 months aging.

3.5 Antioxidant Content

The analysis of antioxidant content of all three

treatments was done [Figure 2(d)]. The antioxidant

content of all three treatments ranged from 4297.54 to

4306.09 mg of gallic acid/L. According to Rice-

Evans et al. (1996), polyphenolic components in

higher plants give antioxidant activity. The presence

of other functional bioactive components such as

ascorbic acid (Ercisli and Orhan, 2007) and niacin

(Imran et al., 2010) besides anthocyanins, phenolic

and flavonoids might be the reason for similar amount

of antioxidant content in all the treatments.

However, the decrease in all three treatments was

seen after 4 months of aging. The abundant bioactive

compounds in mulberry give it great antioxidant

properties (Castrejon et al., 2008). The antioxidant

capacity is due to phenolics (Wu et al., 2013) thus

change in phenolics can change the antioxidant

capacity. The decrease in antioxidant content is due to

the reduction of phenolic content, the similar result can

be previously seen in mulberry juice (Zou et al., 2017).

This lower antioxidant is corelated with the result

of TPC, TFC and TAC presented earlier. The wine

made with HPP demonstrated the highest amount of

TPC, TFC, TAC and also antioxidant content which

could be a contribution of longer pulp extraction time

during fermentation.

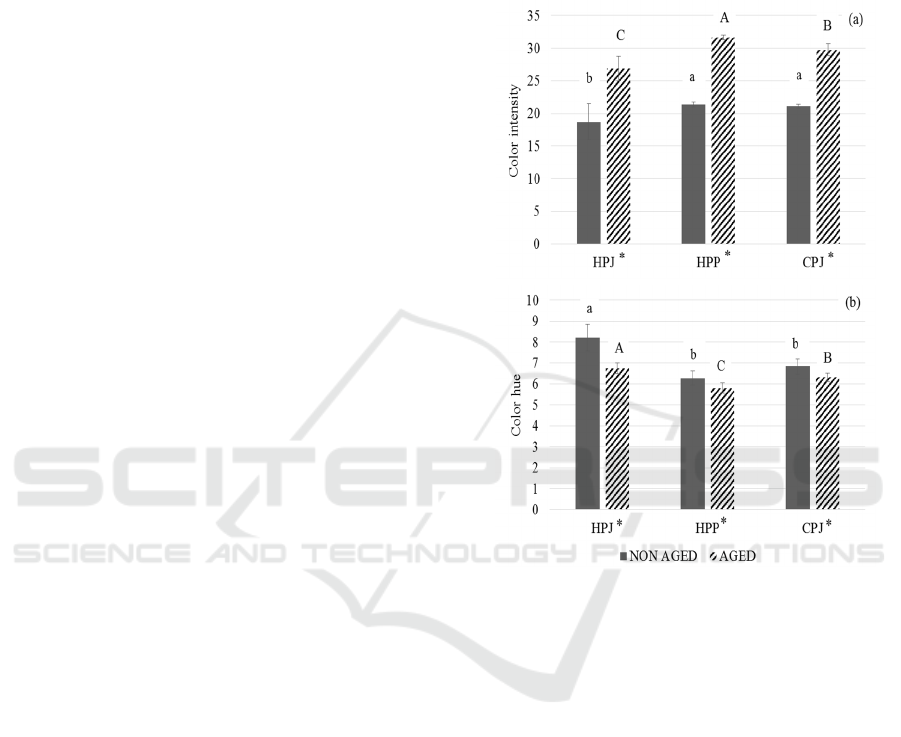

Figure 3: The changes in color measurement of non-aged

and 4 month aged mulberry prepared from three different

wine making techniques (HPJ, HPP and CPJ): (a) color

intensity, and (b) color hue. The data are expressed as mean

±SD (n=3). The different letter indicates significant

difference (p < 0.05). ‘*’ represents the significant

difference between non aged and 4 months aged mulberry.

3.6 Color Measurement

The change in the wine color measurement of three

treatments was analyzed (Figure 3). The wine color

intensity in HPJ, HPP and CPJ are found to be in

range of 18.69 to 21.34 and, the wine color hue of the

same treatments ranged from 6.28 to 8.23 before

aging. Khoo et al. (2017) suggested that the

anthocyanins are responsible for the colors of fruits,

flowers and vegetables. Mulberry is dark red fruit.

The wine color intensity and color hue measured after

4 months aging was found to be increased [Figure

3(a)] and decreased [Figure 3(b)] respectively. After

4 months aging, the color intensity of HPJ, HPP and

CPJ were increased after aging (26.90, 31.64, and

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

84

29.75, respectively). This study showed that HPP has

the highest color intensity before and after aging.

However, the color hue of HPJ, HPP and CPJ were

decreased after 4 months aging (6.75, 5.81, and 6.32,

respectively). In both wine color intensity and hue,

there found to be significant difference (p < 0.05)

between aged and non-aged mulberry wines. HPP has

the highest color intensity whereas HPJ has the

highest color hue. Color intensity shows how dark the

wine is whereas wine color hue measures the

appearance of yellow and red color present in wine.

Anthocyanin is less stable and easily degrade by

pH, storage temperature, light, oxygen,

concentration, enzyme’s presence, proteins and

flavonoids (Rein, 2005). The structure of anthocyanin

and pH has high effect on pigments of anthocyanin

(Torskangerpoll and Andersen, 2005). According to

Ummi et al. (2011), experiment on anthocyanin,

when the acidity decreases, the color changes to

purplish tones causing the decrease in color hue.

Boulton (2001) suggested that anthocyanins can react

with other molecules and convert into co-pigments

and polymerized pigments. In one of the study done

by Heras-Roger et al. (2016), the copigments

decreases hue but increases color intensity in wine

and the copigmentation increases A

520

more than in

A

420

. This condition resembles with current study

in

which A

520

had increased causing decrease in hue.

4 CONCLUSION

The comparison analysis of different treatments of

mulberry wine before aging showed that the different

wine making techniques affect the physicochemical

characteristics of wine. Among all wine making

techniques used, HPP and CJP method produced wine

that have similar level of TFC, and color intensity

which was higher than the wine prepared by HPJ

method. The 4 months aging of mulberry wine at

12±2˚C resulted in increasing level of reducing sugar,

and color intensity of wine. In contrast, the alcohol

content, acidity, phenolic, and color hue was

decreased after aged for 4 months. However, sensory

analysis of wines will be worthwhile to perform in the

future which will help to understand the sensory

characteristic along with consumer preference of

these wines from different wine making techniques.

REFERENCES

Abdullah, A. L., Sulaiman, N. M., Aroua, M. K., and Noor,

M. M. M., 2007. Response surface optimization of

conditions for clarification of carambola fruit juice

using a commercial enzyme. Journal of Food

Engineering, 81(1), pp.65-71.

Ancin-Azpilicueta, C., Gonzalez-Marco, A. and Jimenez-

Moreno, N., 2008. Current knowledge about the

presence of amines in wine. Critical reviews in food

science and nutrition, 48(3), pp.257-275.

AOAC (Association of Official Analytical Chemists).,

2002. Official methods of analysis, 15th ed. Arlington.

Bae, S.H. and Suh, H.J., 2007. Antioxidant activities of five

different mulberry cultivars in Korea. LWT-Food

Science and Technology, 40(6), pp.955-962.

Balga, I., Lesko, A., Ladanyi, M. and Kallay, M., 2015.

Influence of ageing on changes in polyphenolic

compounds in red wines. Czech Journal of Food

Sciences, 32(6), pp.563-569.

Boulton, R., 2001. The copigmentation of anthocyanin and

its role in the color of red wine: A critical review.

American Journal of Enology and Viticulture, 52(2),

pp.67-87.

Butt, M.S., Nazir, A., Sultan, M.T. and Schroën, K., 2008.

Morus alba L. nature's functional tonic. Trends in food

science & technology, 19(10), pp.505-512.

Castrejón, A.D.R., Eichholz, I., Rohn, S., Kroh, L.W. and

Huyskens-Keil, S., 2008. Phenolic profile and

antioxidant activity of high bush blueberry (Vaccinium

corymbosum L.) during fruit maturation and ripening.

Food Chemistry, 109(3), pp.564-572.

Cautela, D., Castaldo, D., Servillo, L., and Giovane, A.

(2010). Enzymes in citrus juice processing. In Enzymes

in Fruit and Vegetable Processing. pp. 211-228. CRC

Press.

Chang, P. H., 2020. Study the effect of fermentation

conditions on physiochemical of Mulberry wine.

Bachelor’s thesis, Faculty of Biotechnology.

Assumption University, Bangkok, Thailand.

Chapman Jr, G.W., Horvat, R. J., and Payne, J.A., 1991.

The non-volatile acid and sugar composition of

mayhaw fruits (Crataegusaestivalis, C. opaca, C.

rufula). Journal of food quality, 14(5), pp.435-439.

Chen, C., You, L. J., Abbasi, A. M., Fu, X., and Liu, R. H.,

2015. Optimization for ultrasound extraction of

polysaccharides from mulberry fruits with antioxidant

and hyperglycemic activity in vitro. Carbohydrate

Polymers, 130, pp.122-132.

Chen, P. N., Chu, S. C., Chiou, H. L., Kuo, W. H., Chiang,

C. L., and Hsieh, Y. S., 2006. Mulberry anthocyanin,

cyanidin3-rutinoside and cyanidin 3-glucoside,

exhibited an inhibitory effect on the migration and

invasion of a human lung cancer cell line. Cancer

letters, 235(2), pp.248-25.

Ercisli, S. and Orhan, E., 2007. Chemical composition of

white (Morus alba), red (Morus rubra) and black

(Morus nigra) mulberry fruits. Food Chemistry, 103(4),

pp.1380-1384.

Heras-Roger, J., Alonso-Alonso, O., Gallo-Montesdeoca,

A., Díaz-Romero, C. and Darias-Martín, J., 2016.

Influence of copigmentation and phenolic composition

on wine color. Journal of food science and technology,

53(6), pp.2540-2547.

Investigation and Comparison of Physicochemical Characteristics of Non-aged and 4-month Aged Mulberry Wine Prepared from Three

Different Wine Making Techniques

85

Hertog, M. G., Feskens, E. J., Kromhout, D., Hollman, P.

C. H., and Katan, M. B., 1993. Dietary antioxidant

flavonoids and risk of coronary heart disease: the

Zutphen Elderly Study. The lancet, 342(8878),

pp.1007-1011.

Hunjaroen, M., and Tongchitpakdee, S., 2010. Effects of

cultivar and maturation on anthocyanins of mulberry

fruit. Warasan Witthayasat Kaset, 41(1), pp.106-109.

Iland, P., 2000. Techniques for chemical analysis and

quality monitoring during winemaking. Patrick Iland

Wine Promotions.

Imran, M., Khan, H., Shah, M., Khan, R., and Khan, F.,

2010. Chemical composition and antioxidant activity of

certain Morus species. Journal of Zhejiang University

Science B, 11(12), pp.973-980.

Ivanova, V., Stefova, M. and Chinnici, F., 2010.

Determination of the polyphenol contents in

Macedonian grapes and wines by standardized

spectrophotometric methods. Journal of the Serbian

Chemical Society, 75(1), pp.45-59.

Jaeger, H., Schulz, M., Lu, P., and Knorr, D., 2012.

Adjustment of milling, mash electroporation and

pressing for the development of a PEF assisted juice

production in industrial scale. Innovative Food Science

and Emerging Technologies, 14, pp.46-60.

Juan, C., Jianquan, K., Junni, T., Zijian, C., & Ji, L., 2012.

The profile in polyphenols and volatile compounds in

alcoholic beverages from different cultivars of

mulberry. Journal of food science, 77(4), pp. C430-

C436.

Khoo, H. E., Azlan, A., Tang, S. T., & Lim, S. M., 2017.

Anthocyanidins and anthocyanins: colored pigments as

food, pharmaceutical ingredients, and the potential

health benefits. Food & nutrition research, 61(1),

1361779.

Kim, I. and Lee, J., 2020. Variations in Anthocyanin

Profiles and Antioxidant Activity of 12 Genotypes of

Mulberry (Morus spp.) Fruits and Their Changes during

Processing. Antioxidants, 9(3), pp.242.

Lachman, J., Šulc, M., Faitová, K. and Pivec, V., 2009.

Major factors influencing antioxidant contents and

antioxidant activity in grapes and wines. International

Journal of Wine Research, 1, pp.101-121.

Martínez-Lapuente L, Guadalupe Z, Ayestarán B., 2017.

Effect of egg albumin fining, progressive clarification

and cross-flow microfiltration on the polysaccharide

and proanthocyanidin composition of red varietal

wines. Food Research International. 96, pp.235-243.

Mattivi, F., Guzzon, R., Vrhovsek, U., Stefanini, M. and

Velasco, R., 2006. Metabolite profiling of grape:

flavonols and anthocyanins. Journal of agricultural and

food chemistry, 54(20), pp.7692-7702.

McDougall, G. J., Fyffe, S., Dobson, P. and Stewart, D.,

2005. Anthocyanins from red wine–their stability under

simulated gastrointestinal digestion. Phytochemistry,

66(21), pp.2540-2548.

Miller, G. L., 1959. Use of di-nitrosalicylic acid reagent for

determination of reducing sugar. Analytical chemistry,

31(3), pp.426-428.

Nadulski, R., Kobus, Z., Wilczyński, K., Guz, T., &

Ahmed, Z., 2017. Characterization of Selected Apple

Cultivars in the Aspect of Juice Production in the

Condition of a Farm.

Nomura, T., Fukai, T., Yamada, S. and Katayanagi, M.,

1976. Phenolic constituents of the cultivated mulberry

tree (Morus alba L.). Chemical and Pharmaceutical

Bulletin, 24(11), pp.2898-2900.

Perez-Cacho, P. R., and Rouseff, R., 2008. Processing and

storage effects on orange juice aroma: a review. Journal

of Agricultural and Food Chemistry, 56(21), pp.9785-

9796.

Rein, M., 2005. Co-pigmentation reactions and color

stability of berry anthocyanins. Dissertation. University

of Helsinki, Department of Applied Chemistry and

Microbiology. EKT series, 1331, 88, pp.10-14.

Ribéreau-Gayon, P., Glories, Y., Maujean, A., &

Dubourdieu, D., 2006. Handbook of Enology, Volume

2: The Chemistry of Wine-Stabilization and Treatments

(Vol. 2). John Wiley and Sons.

Rice-Evans, C. A., Miller, N. J., and Paganga, G., 1996.

Structure-antioxidant activity relationships of

flavonoids and phenolic acids. Free radical biology and

medicine, 20(7), pp.933-956.

Scherer, R. and Godoy, H.T., 2009. Antioxidant activity

index (AAI) by the 2, 2-diphenyl-1-picrylhydrazyl

method. Food chemistry, 112(3), pp.654-658.

Shinohara, T., Shimizu, J. I., &Shimazu, Y., 1979.

Esterification rates of main organic acids in wines.

Agricultural and Biological Chemistry, 43(11),

pp.2351-2358.

Šimić, G., Horvat, D., Dvojković, K., Abičić, I., Vuletić, M.

V., Tucak, M., & Lalić, A., 2017. Evaluation of total

phenolic content and antioxidant activity of malting and

hulless barley grain and malt extracts. Czech Journal of

Food Sciences, 35(1), pp.73-78.

Somers, T. C., 1971. The polymeric nature of wine

pigments. Phytochemistry, 10(9), pp.2175-2186.

Suh, H. J., Kim, J.M., Lee, H., Lee, S.W. and Choi, Y.M.,

2004. Thermal kinetics on antiradical capacity of

mulberry fruit extract. European Food Research and

Technology, 219(1), pp.80-83.

Torskangerpoll, K. and Andersen, Ø.M., 2005. Colour

stability of anthocyanins in aqueous solutions at various

pH values. Food Chemistry, 89(3), pp.427-440.

Ummi, K. I., Ida, I. M., and Ruzitah, M. S., 2011. The effect

of pH on color behavior of Brassica oleracea

anthocyanin. Journal of Applied Sciences, 11(13),

pp.2406-2410.

Vijayan, K., Tikader, A., Weiguo, Z., Nair, C. V., Ercisli,

S., and Tsou, C. H., 2011. Morus. In Wild Crop

Relatives: Genomic and Breeding Resources (pp. 75-

95). Springer, Berlin, Heidelberg.

Wahyuningsih, S., Wulandari, L., Wartono, M. W.,

Munawaroh, H., & Ramelan, A. H., 2017. The effect of

pH and color stability of anthocyanin on food colorant.

In IOP conference series: Materials science and

engineering. 193(1), pp.12047.

Wang, L., Sun, X., Li, F., Yu, D., Liu, X., Huang, W. and

Zhan, J., 2015. Dynamic changes in phenolic

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

86

compounds, colour and antioxidant activity of mulberry

wine during alcoholic fermentation. Journal of

Functional Foods, 18, pp.254-265.

Wang, Z., Cui, H., and Fan, S., 2020. Effect of mechanical

juice extraction method on the quality of fresh-

squeezed apple juice. In IOP Conference Series:

Materials Science and Engineering, 711(1), pp.

012051.

Waterhouse, A. L., 2002. Determination of total phenolics.

Current protocols in food analytical chemistry, 6 (1).

Wu, T., Tang, Q., Gao, Z., Yu, Z., Song, H., Zheng, X. and

Chen, W., 2013. Blueberry and mulberry juice prevent

obesity development in C57BL/6 mice. PLoS One,

8(10), p.e77585.

Yang, C. H., & Tsai, T. C., 1994. Anthocyanins in mulberry

fruit. Food Science, 21, pp.319-330.

Yıldırım, H. K., and Altındışli, A., 2015. Changes of

Phenolic Acids During Aging of Organic Wines.

International Journal of Food Properties, 18(5),

pp.1038-1045.

Zhishen, J., Mengcheng, T. and Jianming, W., 1999. The

determination of flavonoid contents in mulberry and

their scavenging effects on superoxide radicals. Food

chemistry, 64(4), pp.555-559.

Zou, B., Xu, Y. J., Wu, J. J., Yu, Y. S., and Xiao, G. S.,

2017. Phenolic compounds participating in mulberry

juice sediment formation during storage. Journal of

Zhejiang University-SCIENCE B, 18(10), pp.854-866.

Investigation and Comparison of Physicochemical Characteristics of Non-aged and 4-month Aged Mulberry Wine Prepared from Three

Different Wine Making Techniques

87