Ethnobotany Production of Coconut Oil using Wet and Dry Methods

Handayani Nurma

1a

, Nurhayati Nurhayati

2b,

*, Yuli Wibowo

2

and Dedy Eko Rahmanto

3c

1

Graduate School of Master Agro-industrial Technology, Faculty of Agricultural Technology, University of Jember,

Jember 68121, Indonesia

2

Department of Agricultural Products Technology, Faculty of Agricultural Technology, University of Jember,

Jember 68121, Indonesia

3

Department of Renewable Energy Engineering, Jember Polytechnic 68101, Indonesia

Keywords: Blondo, Coconut Oil, Density, Medium Chain Fatty Acid.

Abstract: Ethnobotany mentioned that coconut oil have been a part of traditional medicine from ancient times and was

used as oilment in all kinds of illness. Athletes, body builders and dieting person used coconut oil. That is

because coconut oil contains less calories than other oils, and is easily converted in to energy and no lead to

accumulation of fat in the heart and arteries. Beside that, coconut oil can be boost energy and endurance to

enhances the performance of athletes. The material for making oil is mature coconut fruit was obtained from

the Agropolitan market at Senduro Lumajang Regency. This study determined the ethnobotany production of

coconut oil use wet and dry method. Wet method was conducted by extraction of coconut milk then cooking

the milk to evaporate the water so the oil was extracted from coconut protein cake (was called “blondo”). Dry

method was conducted by drying the grated coconut until less than 5% (3.37%) of water content, then pressure

dried coconut using hydraulic press (39-427 bar). The results showed that ripe mature coconut produced the

higher oil yield. Producing coconut oil used wet method have to use stainless steel or cast iron frying pan.

Characteristics of coconut oil were i.eclear colour, typical coconut aroma. Producing of coconut oil used wet

method can result 15.77%w/w of yield, 11.67% w/w of protein cake (blondo), 0.06% of water content and

0.9195g/cm

3

of oil density. While producing of coconut oil used dry method can result 21.56% w/w of oil

yield, 33.24% w/w of bagasse cake, 0.04% of water content and 0.9191 g/cm

3

of oil density.

1 INTRODUCTION

Ethnobotany studies show that coconut oil has many

uses. Coconut oil not only as vegetable oil, but also

for the world of medicine such as massage oil, hair

fertility oil, oil consumed to smooth the birth process,

skin moisturizing oil etc. Coconut oil is composed of

medium chain fatty acids (MCFA). The medium

chain in coconut oil is good for the body's health for

the digestive system.

Ethnobotany study of the coconut oil production

process of the ancestors also used two methods,

namely the wet method and the dry method. The wet

method of coconut oil production is the manufacture

of coconut oil from the extraction of the coconut milk,

while the dry method if the oil is extracted from dry

coconut is good without the process of refining,

bleaching and deodorizing.

Coconut oil production business claims without

the use of RBD (Refined Bleached Deodorized) are

advantages that must be communicated and

introduced properly. Conventionally, coconut oil

production is done by drying the coconut meat and

pressing it using thick, strong and sturdy wooden

blocks.

Ketaren (2012) explains that the oil production

process can be done using the wet or dry method. The

wet method of making coconut oil is done by

extracting coconut milk and heating it until the water

evaporates and the oil and “blondo” cake remain. The

method of making dry coconut oil is done by drying

the coconut flesh in the sun and pressing it

mechanically.

a

https://orcid.org/0000-0001-5125-9598

b

https://orcid.org/0000-0002-2398-9996

c

https://orcid.org/0000-0003-3982-7462

Nurma, H., Nurhayati, N., Wibowo, Y. and Rahmanto, D.

Ethnobotany Production of Coconut Oil using Wet and Dry Methods.

DOI: 10.5220/0010529400003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 75-78

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

75

Rumah Kelapa NHP is a household unit that

produces coconut oil. The business unit is located in

Lumajang Regency, East Java Province, which

produces coconut oil using wet and dry methods. This

study aims to determined ethnobotany of coconut oil

production using wet and dry methods to contribute

to the proper processing of coconut oil for the NHP

home industry.

2 METHOD

2.1 Materials

The tools used to produce coconut oil include a

coconut peeler, a coconut grater, a coconut milk press

(spinner), a drying rack, a heating pan, a pressing

device (WIPRO), and microfiber filters. The tools for

analysis include a 10 ml pycnometer (IWAKI), an

analytic digital scale (Ohaus), and a caliper. The main

ingredient for this research is coconut fruit obtained

from the Agropolitan market "Seroja", Lumajang

Regency. Old coconut trees are harvested at the age

of 13 months from the flowering period (Muis, 2016).

Complementary /auxiliary materials, namely clean

water.

2.2 Research Stages

2.2.1 Raw Material Preparation

The coconut fruit is peeled and grated and stirred until

evenly distributed. Grated coconut is divided into two

parts, one part for the wet extraction process and one

part for the dry extraction process and setting the

stove for the wet method. The dry method of

extraction process conditions is carried out using a

hydraulic press with a pressure of 39-427 bar.

2.2.2 Coconut Oil Extraction by Wet

Method

Wet coconut oil extraction is carried out by adding

water in a ratio of 1: 3, technically 1 part grated

coconut is extracted with 1 part water then filtered

and repeated three times. The filtering process

produces coconut milk and coconut dregs. Coconut

milk was heated using the optimum stove fire until

the water evaporates and oil and “blondo” cake are

formed.

2.2.3 Dry Coconut Oil Extraction

The production of coconut oil using the dry method is

carried out by shredding fresh old coconut, then

reducing the size by grating it and then drying it in the

sun until it is dry (about 5% moisture content).

Furthermore, pressing is carried out using a hydraulic

press at a pressure of 39-427 bar with each press using

200g of dry grated coconut. The results of the dry

extraction method are coconut oil and coconut dregs

cake.

2.2.4 Experimental Design

This study used a one-factor completely randomized

design (CRD) method, namely the extraction method

(wet and dry). Data were analyzed using descriptive

methods presented with an error bar.

2.2.5 Parameter Analysis

Analysis of physical properties parameters include

yield, moisture content and specific gravity (Ketaren,

2012).

3 RESULT AND DISCUSSION

3.1 Ethnobotany Coconut Oil

Extraction Process by Wet and Dry

Method

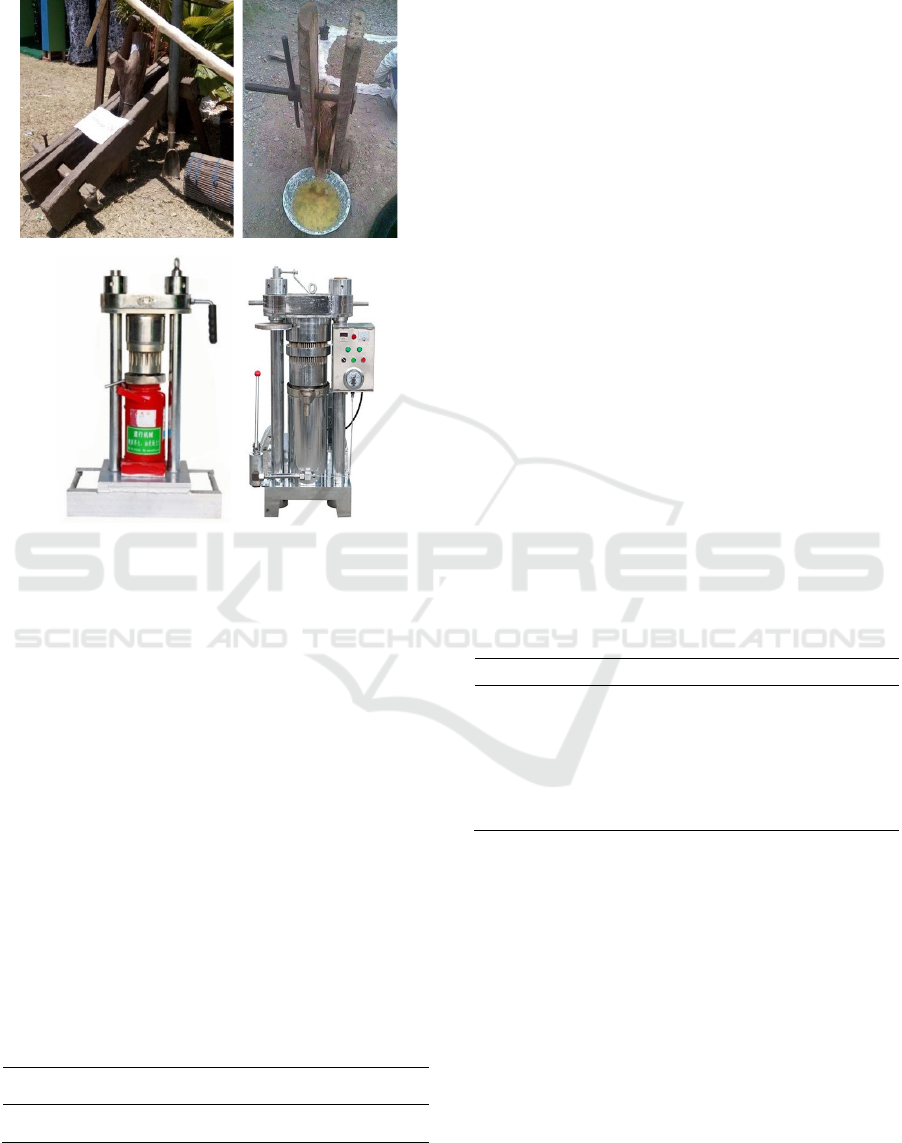

Ethnobotany study reported that coconut oil

extraction process used wet and dry methods. Wet

coconut oil extraction (Figure 1) requires heating that

can use a “tomang”, a gas stove or an electric stove.

Wet-dry coconut oil extraction requires both

traditional and semi-modern conventional presses

(Figure 2).

Figure 1: Processing of coconut oil wet with heating

“tomang” (Narasilia.com, 2020).

The extraction of ethnobotany coconut oil by

wet method was carried out by squeezing the

coconut milk. Then it is heated with optimal stove

flame, which takes about 45-55 minutes).

Ethnobotany coconut oil extraction by dry method

was carried out by shredding the coconut meat then

drying it using sunlight. If the grated coconut is dry

then it is continued by pressing it using both

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

76

traditional tools (wood press) and semi-modern

conventional ones (hydraulic press).

a b

c d

Figure 2: Ethnobotany coconut oil press (peuneurah pliek u

in Acehnese regional language) (a, b) and pressurized

hydraulic press (c, d) (id.aliexpress.com, 2020).

Processing of coconut oil with the wet heating

method produces blondo, while the processing of

coconut oil using the dry method by pressing

produces cake / dry pulp.

3.2 The Yield of Coconut Oil

The calculation of the yield of coconut oil from the

extraction using the dry method and the wet method

is based on the ratio of the amount of oil obtained

divided by the weight of fresh raw materials (grated

old coconut meat). Rahadian (2013) reported that the

oil content in old coconut meat was 35%.

The yield of coconut oil and cake produced from

these two methods can be seen in Table 1.

Table 1: The yield of coconut oil and cake produced using

wet and dry methods.

Coconut oil

Y

ield of oil (% w/w)

Weight of cake “blondo” /

“bungkil”

W

et method 15.77 ± 0.59 11.58 ± 0.47

D

ry method 21.56 ± 0.39 33.24± 0.02

The yield of coconut oil using the wet heating

method was 15.77% and from Blondo 11.58%. The

dry method produces more oil yields than the wet

method. The dry extraction process depends on the

tool used, such as the amount of pressure and the use

of the tool. The amount of pressure on the hydraulic

press used is 39-427 bar with coconut oil starting to

come out at a pressure of 70 bar.

Karauw & Santoso (2014) reported that the dry

method extraction process is more effective than the

wet method. The level of effectiveness can reach

70%. This study resulted in a higher level of

effectiveness that was 73%. The extraction of coconut

oil using the wet heating method resulted in lower

yields than the dry method. This is presumably

because in the wet method the critical point occurs in

pressing the coconut milk. If coconut milk is not

optimally squeezed, it can reduce the yield. In

addition, the critical point is also the oil involved in

the “blondo” cake. Therefore it is necessary to

separate the oil from "blondo" using a spinner.

3.3 Coconut Oil Water Content

Water content is an important parameter of oil quality

in order to minimize the risk of rancidity. The water

content of the coconut oil obtained was compared

with the moisture content of commercial coconut oil

(Table 2).

Table 2: Water content of ethnobotany coconut oil and

commercial coconut oil.

Coconut oil

W

ater content (%) Specific Gravity

Commercial “Barco” 0.05 ± 0.03 0.9214 ± 0.0005

Commercial “Dorang” 0.03 ± 0.02 0.9187 ± 0.0006

VCO (virgin coconut

oi

l

)

0.09 ± 0.04 0.9196 ± 0.0001

Wet method 0.11 ± 0.02 0.9191 ± 0.0001

Dry method 0.04 ± 0.01 0.9195 ± 0.0002

The water content of the wet method is higher than

the dry method. The water content of coconut oil can

be reduced by heating the oil longer when heating the

stove. However, you have to be careful because it can

cause further damage to the oil due to excess heat

(burning). The coconut oil quality standard states that

the water content of coconut oil ranges from 0.1-

0.5%.

3.4 Specific Gravity

The specific gravity of the oil was determined using a

10 ml pycnometer which was converted to the

specific gravity of pure water at 20

o

C. The principle

of this method is based on determining the mass of

Ethnobotany Production of Coconut Oil using Wet and Dry Methods

77

the liquid and determining the space occupied by this

liquid with a volume measured container

(pycnometer) (Ahmad et. Al, 2014). The density of

ethnobotany coconut oil with the wet extraction

method was higher (0.9195) than the ethnobotany

coconut oil with the dry extraction method. (0.9191).

According to SNI 3741-1995, the maximum density

for coconut oil is 0.921.

Herlina et al., (2017) reported that the specific

gravity of coconut oil that has been used for frying

RBC (banana chip ripe) is 0.9193. Sani et al. (2010)

reported that the density of materials is affected by

viscosity, mass of substances and dissolved solids.

Density is related (directly proportional) to viscosity.

The greater the viscosity of a substance, the greater

its density. Coconut oil which has high dissolved

solids can affect specific gravity. This results in

higher friction between particles so that the viscosity

is also higher (Sani et al., 2010).

4 CONCLUSIONS

The production of coconut oil using the dry method

produces more yields. The wet method yielded a yield

of 15.77% w / w, cake "blondo" of 11.67%, a

moisture content of 0.06%, and an oil specific gravity

of 0.9195. The dry method with hydraulic pressing

works at a pressure of 39-427 bar with an oil yield of

21.56% w / w, cake "coconut dregs cake of 33.24% w

/ w, water content of 0.04% and a specific gravity of

0.9191.

ACKNOWLEDGMENTS

Thanks to the University of Jember for supporting

this research through the Innovation-Based Startup

Enterprise Grant Programme 2018/2019.

REFERENCES

Ahmad D, Sari PN, Purwa GR. Uji Kualitas Minyak Kelapa

Dengan Uji Coba Penggorengan. [Skripsi] Program

Studi Teknologi Agroindustri Fakultas Pendidikan

Teknik dan Kejuruan Universitas Pedidikan Indonesia,

Bandung (Indonesian).

BPS. 2018. Produksi Perkebunan Kelapa Menurut

Kabupten/Kota di Jawa Timur Tahun 2006-2017

(Ton).https://jatim.bps.go.id/statictable/2018/11/12/13

88/produksi-perkebunan-kelapa-menurut-kabupaten

-kota-di-jawa-Timur-ton-2006-2017.Html [Diakses tgl

14-09-2020, 01.22 AM] (Indonesian).

Herlina, Astriyaningsih

E., Windarti S.W and Nurhayati.

2017. Tingkat Kerusakan Minyak Kelapa Selama

Penggorengan Vakum Berulang Pada Pembuatan Ripe

Banana Chips (RBC). Jurnal Agroteknologi Vol.11 No.

02. (Indonesian)

Id.aliexpress.com. 2020. Mesin press minyak kelapa

kopra.https://www.google.com/search?q=pengepress+

hidrolik&tbm (Indonesian)

Karouw, S., & Santosa, B. (2014). Minyak kelapa sebagai

sumber asam lemak rantai medium. Prosiding

Konferensi Nasional Kelapa VIII. Jambi, 21-22.

(Indonesian)

Ketaren, 2012. Minyak dan Lemak Pangan. UI Press,

Jakarta. (Indonesian)

Manik TR, Dimas WA, dan Aris S. 2013. Kajian

Pengembangan Kawasan Agropolitan Seroja

Kabupaten Lumajang. Jurnal Tata Kota dan Daerah:

Vol 5, No 1. (Indonesian)

Muis A. 2016. Pengaruh Metode Pengolahan dan Umur

Panen Kelapa Terhadap Kualitas dan Kandungan

Senyawa Fenolik Virgin Coconut Oil (VCO). Jurnal

Penelitian Teknologi Industri Vol. 8 No. 2 Desember

2016: 97-106 (Indonesian)

Narasilia.com, 2020. Pembuatan minyak kelapa secara

tradisional. (Indonesian)

Sani A, Masyhuri, Machfudz. 2010. Metodologi Riset

Manajemen Sumber Daya Manusia. Cetakan Pertama.

Maliki Press, UIN-Malang. (Indonesian)

Sulistiawati E. dan Imam S. 2015. Efisiensi Proses basah

dan Kering Pada Pembuatan Minyak dan Tepung

Kelapa dari Buah Kelapa Segar. Jurnal Simposium

Nasional Teknologi Terapan: (SNTT)3. (Indonesian)

Syafii M, Siti S. dan Ratna NH. 2017. Diversifikasi Produk

Minuman Non STMJ Terhadap Penjualan Minuman

STMJ. Universitas Islam Malang: Jurusan Administrasi

Niaga, Fakultas Ilmu Admiministrasi. (Indonesian)

Tien, R. Muchtadi dan Sugiyono. 1992. Petunjuk

Laboratorium Ilmu Pengetahuan Bahan Pangan. Bogor:

IPB-Press. (Indonesian)

Wilfred M., Oyagi B., Gongera E.G. 2014. An analysis of

concentric diversification strategy on Organization

compete-tiveness: Case of sugar firms in Kenya.

European Journal of Business and Management: Vol.6,

No.19.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

78