Laboratory Study on Shear Strength of Soil using Woven and

Non-woven Geotextiles

Yelvi

1

, Aisyah Salimah

1

, Vatih Abdullah

1

1

Civil Engineering, Politeknik Negeri Jakarta, Depok 16424, Indonesia

Keywords: Geotextiles, Woven, Non-Woven, Shear Strength

Abstract: In constructing a construction, it is necessary to identify the type of soil as a place for the foundation and the

building to rest on it. The carrying capacity of the soil also varies, in sand that has a uniform gradation when

it is saturated, the shear strength will decrease. One way that can be done to increase the shear strength of the

soil is to provide reinforcement with the addition of geotextiles. The shear strength parameters used in the

planning of the bearing capacity of the soil reinforced by geotextiles are the internal friction angle and the

interaction coefficient between the geotextile and the sand. The sample of this study used liquefaction

potential sand Bangka using woven and non-woven geotextile reinforcement with a relative density variation

of 25%, 50%, 75%. For use geotextiles are installed vertically and horizontally. To get the parameter value of

shear strength, Direct Shear testing is carried out. Based on the test results, it is found that Bangka sand is

uniform sand with values of Cu <6 and Cc <1. The increase in shear strength in the samples reinforced by

geotextile vertically is greater than horizontally at a density of 25% and 50%, while at a density of 75% it

states otherwise.

1 INTRODUCTION

Geotextiles have been widely applied in civil

engineering projects with various functions. One of

its functions is for reinforcement. Some examples of

soil reinforcement with geotextiles are soil

embankments, slopes, and retaining walls. Soil

reinforcement with geotextiles requires knowledge of

the soil-geotextile interface behavior for structural

stability analysis (Day, 2000). In order to analyze the

interface shear strength parameters, several studies

have been conducted to understand the shear strength

behavior of geotextile-reinforced sand soils. An

significant factor in the design of geotextile structures

is the interface shear strength. (Omar AH et al. 2019;

Punetha et al. 2017; Wang et al. 2016; Brahim et al.

2016; Aldeeky et al. 2016; Hatami and Esmaili 2015;

Vieira et al. 2015; Anubhav and Wu. 2015; Dixon and

Jones 2005; Bergado et al. 2006). The results

generally reveal that the addition of fibers to sandy

soils as reinforcement can increase the shear strength

compared to unreinforced sand. To improve

performance in different soil conditions,

strengthening the soil is increasingly important. The

reinforcement mechanism is to withstand the soil's

tensile deformation, thus increasing the overall

resistance of the composite soil matrix through the

interface bond resistance limited by the tensile

strength of the geotextile. Jewell (1996) has examined

the interaction between reinforced soil and

geotextiles. There are two conditions in soil

interaction with reinforcement, namely direct shear

and pull-out conditions. The results showed that the

direct shear resistance is the ratio of the interface

friction angle to the friction angle in the soil. The

mobilization of the interface friction angle is one of

the important factors affecting the stability analysis.

Some researchers use the Direct Shear Test to

understand the shear strength of reinforced soil

behavior. The choice of direct shear test installation

depends on the interaction mechanism to be

reproduced. The reinforcement layer located parallel

to the shear plane of the shear box offers laboratory

test results in many literature studies. (Palmeira EM,

2008; Takasumi et al. 1991; Tan SA et al. 1998;

Cerato AB and Lutenegger AJ 2006; Abu-Farsakh

MY et al. 2007; Liu CN et al. 2009; Lopes ML,

Silvano R 2010; Hossain B et al. 2012; Anubhav

Basudhar PK 2013; Rifa'i, A., 2003; Tuna SC, Altun

S 2012; Vieira CS, Lopes ML 2013; Kim D, Ha S

2014; Vangla P, Latha GM 2015; Choudhary AQ, and

Krishna AM 2016. Other studies place the

58

Yelvi, ., Salimah, A. and Abdullah, V.

Laboratory Study on Shear Strength of Soil using Woven and Non-woven Geotextiles.

DOI: 10.5220/0010514700003153

In Proceedings of the 9th Annual Southeast Asian International Seminar (ASAIS 2020), pages 58-64

ISBN: 978-989-758-518-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

reinforcement layer perpendicular to the shear plane

Jewell RA, Wroth CP 1987; Athanasopoulos GA

1993; Bauer GE, Zhao Y 1994; Palmeira EM 1999;

Moayedi H et al. 2010; Saya˜o ASFJ, Sieira ACCF

2012; Jose D et al. 2016. The reinforcement layer was

positioned perpendicular to the shear plane in that

study to characterize the behavior of the composite

materials when the soil and reinforcement are shifted.

Based on previous research which has given some

evidence that the effect of geotextiles as

reinforcement on the soil can increase the interface

shear strength. However, not much research has been

done on the effect of geotextile placement on sandy

soil on the interface shear strength. Therefore, it is

necessary to do more research on the effect of

geotextile position on the soil on the interface shear

strength. So it is hoped that the results of this study

can add to the literature that can be used as a reference

in geotextile reinforcement analysis to obtain the right

design.

2 THEORY

Soil shears the resistance force exerted by soil grains

against pressure or pull (Hardiyatmo, 2002). Based on

this understanding, when the soil is exposed to

freight, it will be held back by soil cohesion which

depends on the type of soil and its density, but does

not depend on the normal stresses acting on the shear

plane and the friction between the grains of soil

whose magnitude is directly proportional to the

normal stress in the shear plane. Then the shear

strength equation can be formulated as follows.

(2.1)

(Note: c = 0 for sand and σ = σ ')

For the shear strength which is strengthened by

Geotextile, the determining parameters are the

Mobilization of the Angle of Friction of the interface

Sand-Geotextile (δ) and Adhesion (c

sg

).

(2.2)

Determination of shear strength can be carried out

Direct shear test utilizing controlled shear stress,

where the addition of shear forces is made constant

and regulated, or utilizing controlled stress in which

the shear stress is applied by adding dead load

sustainably, and with the same addition big every

time, until it collapses.

3 METHOD

3.1 Soil

The soil sample used in the study was a disturbed

sample by selecting Bangka sand which has a uniform

gradation. On the soil, the grain size analysis test is

conducted first to determine whether the soil is

included in the soil criteria that have the liquefaction

potential.

3.2 Geotextiles

Material as the interface consists of woven and non-

woven types. Woven type is GT 200 (GTX-N-2 High

strength polyester) and non-woven type GT 250 PET.

The characteristic of woven geotextile is a woven

sheet with a polyester base material which has a

uniform tensile strength. This type weights 200 gr /

m2. The tensile strength value for the long direction is

4.15 kN / m and the transverse direction is 6.38 kN /

m. Non-woven geotextile is a non-woven sheet that

functions as separation, filtration, protection, and

drainage. This type weights 250 gr / m2. The tensile

strength value for the long direction is 8.87 kN / m and

the transverse direction is 11.76 kN / m. The tensile

strength test of the two types of geotextiles refers to

the technical standard test ASTM D4595. Geotextile

used is woven and non-woven can be seen in Figure 1.

Figure 1 Woven and Non-Woven Geotextiles

3.3 Sample Preparation and Testing

Phase

3.3.1 Sample Preparation

The dry weight of sand is prepared for the relative

density of 25%, 50%, and 75%, respectively. For sand

Laboratory Study on Shear Strength of Soil using Woven and Non-woven Geotextiles

59

soil without geotextile reinforcement, the sand soil is

directly put into the shear box. Then it is saturated and

ready for the shear test. As for sand soil with

geotextile, a sand-geotextile soil sample is prepared

according to the position of the geotextile placement

in the shear box. If the position is parallel to the

sliding direction, then testing is carried out every one

layer, two layers, and three layers. Meanwhile, if the

direction is perpendicular to the sliding direction,

only one layer is sufficient for each woven and non-

woven. After the sand-geotextile soil has been put

into the shear box, it is saturated and ready for the

shear test, then it is put into the shear box.

3.3.2 Testing Procedure

The test is divided into two stages. The first is testing

to obtain the physical properties of the soil according

to the provisions of the 1989 Annual Book of ASTM

Standards and followed by testing the shear strength

under static loads with the direct shear test. As many

as 15 samples were made, namely sand without using

geotextiles, sand using Woven and Non-Woven

geotextiles which were installed horizontally and

vertically. Each treatment had a different density,

namely 25%, 50%, and 75%.

4 ANALYSIS AND DISCUSSION

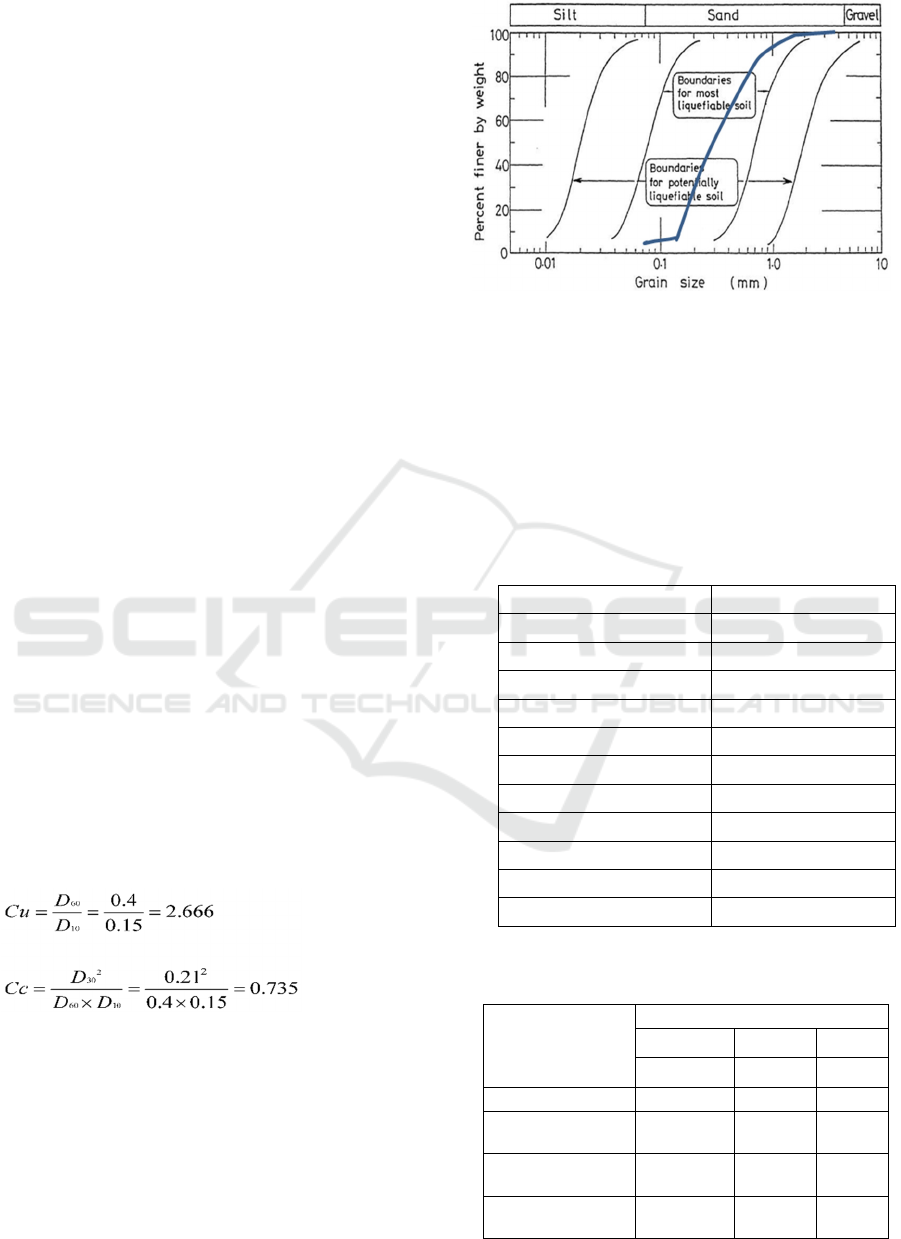

The result of the Analysis of shieve, it shows that the

sandy soil of Bangka

the entry into

an area that is

potentially liquefied and can be seen in Figure 4.1

The USCS classification system is used to see the

uniformity coefficient and curvature of grading. From

the graph, it can be seen that the values of

D

60

= 0.4, D

10

= 0.15, D

30

= 0.21

Figure 2 Grading boundary curve between soils that have

the potential for liquefaction (Tsuchida, 1970)

Well graded sand if Cu > 6 and 1 < Cc < 3, both

criteria must be fulfilled, otherwise it is classified as

poorly graded. From the Cu and Cc values obtained,

Bangka sand is considered to be poorly graded with

uniform gradations. The following is a summary of

the Bangka sand soil property index which is

presented in Table 1.

Table 1 Soil Property Index Soil

Properties Value

γd max 18.92 kN/m

3

γd min 14.69 kN/m

3

Gs 2.644

e

max

0.799

e

min

0.397

D50 0.32 mm

D10 0.15 mm

D60 0.4 mm

D30 0.21 mm

Cu 2.666

Cc 0.735

Table 2 Results of the interaction coefficient between sand

and geotextile (c

sg

)

Sample

Treatment

Relative Density (Dr%)

25% 50% 75%

c

sg

c

sg

c

sg

Woven Vertical 0.035 0.021 0.02

Horizontal

Woven

0.032 0.021 0.01

Vertical Non-

Woven

0.059 0.058 0.053

Horizontal Non-

Woven

0.008 0.005 0.004

ASAIS 2020 - Annual Southeast Asian International Seminar

60

Table 3 Results Comparison of shear angle values after and

before (δ and ∅) use of geotextiles

Sample

Treatment

Relative Density (Dr %)

25% 50% 75%

/ / /

Without

Geotextile

1 1 1

Vertical Woven

1.23 1.24 1.29

Horizontal

Woven

1.29 1.28 1.24

Vertical Non-

Woven

1.21 1.27 1.3

Horizontal Non-

Woven

1.49 1.44 1.37

Based on the results of the shear test, the shear

strength parameter is obtained, so that the equation

used to obtain the shear strength value (f =

tan

)

pure sand and = c

sg

+ tan ) for sand

reinforced

geotextile with the assumption of normal stress of 1

unit. Table 4 shows the results of the calculation of

shear strength.

Table 4 The sand shear strength with the assumption of

normal load 1 unit

Sample

Treatment

25% 50% 75%

τ (kg / cm

2

) τ (kg / cm

2

) τ (kg / cm

2

)

Without

geotextile

0669 0615 0589

Woven

vertical

0.681 0712 0.819

Woven

horizontal

0717 0743 0767

Non-

woven

vertical

0696 0770 0861

Non-

woven

horizontal

0846 0851 0877

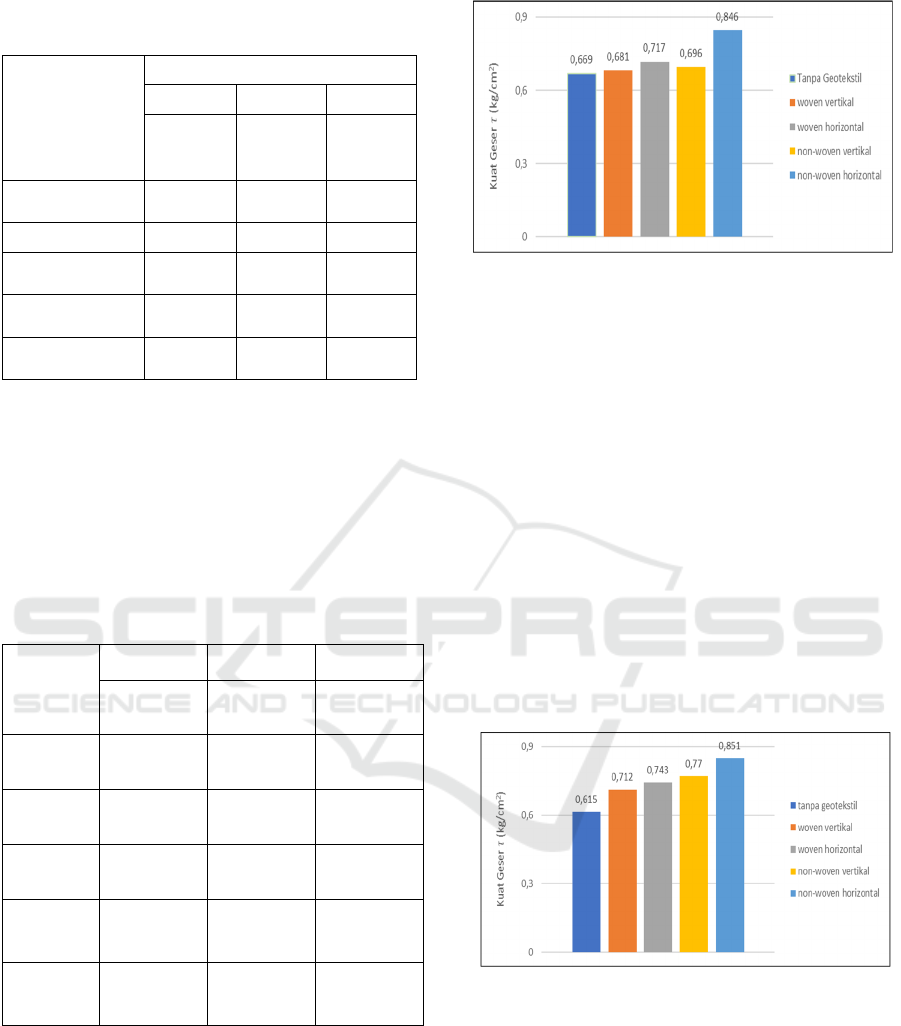

Figure 3 Graph relationship shear strength (kg / cm

2

) with

sample tests on the density of 25%

Shear strength sand after the addition of geotextile

on the density of a 25% increase, with strong

maximum shear on samples of sand by geotextile

non-woven horizontally by 0.846 kg/cm

2

and a

minimum in samples of sand by woven geotextile

vertically by 0.681 kg/cm

2

.

The increase in the pure shear strength with

vertical woven geotextile reinforced sand was 1.8%,

and the pure sand with horizontal woven geotextile

reinforced sand was 7.2%. Pure sand with sand

reinforced with non-woven geotextiles vertically by

4.1% and pure sand with sand reinforced by

horizontal non-woven geotextiles by 26%. The

horizontal use of geotextiles indicates a greater

increase than the use of vertical geotextiles based on

data on the increase in sand shear intensity at a density

of 25%.

Figure 4 Graph of the relationship of shear strength (kg /

cm

2

) with the Test Sample at a density of 50%.

The shear strength of sand after the addition of

geotextiles at a density of 50% has increased, with the

maximum shear strength in sand samples given

horizontal non-woven geotextiles of 0.851 kg /cm

2

and minimum sample was woven geotextile sand by

vertically by 0.712 kg / cm

2

.

The increase in pure shear strength with vertical

woven geotextile reinforced sand was 15.7%, pure

sand with horizontal woven geotextile reinforced

Laboratory Study on Shear Strength of Soil using Woven and Non-woven Geotextiles

61

sand was 20.8%. pure sand with vertical sand

reinforced by non-woven geotextiles by 25.2% and

pure sand with horizontal non-woven geotextile

reinforced sand by 38.3%. Based on the data on the

increase in the shear strength of sand at a density of

50%, the horizontal use of geotextiles shows a greater

increase than the use of vertical geotextiles.

Figure 5 Graph of the relationship of shear strength (kg /

cm

2

) with the Test Sample at a density of 75%

The Shear strength of sand after the addition of

geotextiles at a density of 75% has increased, with the

maximum shear strength in sand samples given

horizontal non-woven geotextiles of 0.877 kg/cm

2

and minimum sample by woven geotextile sand

horizontally by 0.767 kg / cm

2

.

The increase in pure shear strength with vertical

woven geotextile reinforced sand was 39%, and the

pure sand with horizontal woven geotextile

reinforced sand was 30.2%. Pure sand with vertical

sand reinforced by non-woven geotextiles amounting

to 46.2% and pure sand with horizontal non-woven

geotextile reinforced sand by 48.9%. Based on the

data on the increase in the shear strength of sand at a

density of 75%, the average increase in the use of

geotextiles vertically shows a greater increase than

the use of horizontal geotextiles, namely 42.6%

versus 39.6%.

5 CONCLUSION

Based on the actual results of this research, it can be

inferred as follows:

1. Shear strength of pure sand or without geotextile

reinforcement decreases with each increase in the

average relative density of 6.15%

2. Vertical has an increase with each addition of

relative density by an average of 9.75%.

3. The shear strength of sand that is reinforced with

woven geotextiles installed horizontally has an

increase with each addition of an average relative

density of 3.4%.

4. The shear strength of sand that is reinforced with

non-woven geotextiles installed vertically has an

increase with each addition of an average relative

density of 11%.

5. The shear strength of sand that is reinforced with

non-woven geotextiles installed horizontally

increases with each addition of an average relative

density of 1.8%.

6. The increase in shear strength in geotextile

reinforced samples vertically is greater than

horizontally at a density of 25% and 50%,

whereas at a density of 75% states the opposite.

ACKNOWLEDGMENTS

The authors would like to sincerely thank the Head of

UP2M Jakarta State Polytechnic for providing

support for this research through the PNJ DIPA

funding. The authors also honor the PNJ Department

of Civil Engineering's Head of Laboratory for

granting permission to use laboratory facilities..

The Geotextiles were provided by PT Mitra Hijau

Lestari, Indonesia. We highly appreciate this support.

REFERENCES

Abu-Farsakh MY, Coronel J, Tao M (2007) Effect of soil

moisture content and dry density on cohesive soil–

geosynthetic interactions using large direct shear tests.

J Mater Civ Eng 19(7):540–549

Aldeeky, H., O. Al Hattamleh, and B. A. Alfoul. 2016.

“Effect of Sand Placement Method on the Interface

Friction of Sand and Geotextile.” International Journal

of Civil Engineering 14 (2): 133–138.

doi:10.1007/s40999-016-0019-0.

Anubhav Basudhar PK (2013) Interface behaviour of

woven geotextile with rounded and angular particle

sand. J Mater Civ Eng ASCE 25(12):1970–1974

Anubhav, W. H. 2015. “Modelling of Non-linear Shear

Displacement Behaviour of Soil–Geotextile Interface.”

International Journal of Geosynthetics and Ground

Engineering 1: 19. doi:10.1007/s40891- 015-0021-7

Abu-Farsakh MY, Coronel J, Tao M (2007) Effect of soil

moisture content and dry density on cohesive soil–

geosynthetic interactions using large direct shear tests.

J Mater Civ Eng 19(7):540–549

Aldeeky, H., O. Al Hattamleh, and B. A. Alfoul. 2016.

“Effect of Sand Placement Method on the Interface

Friction of Sand and Geotextile.” International Journal

of Civil Engineering 14 (2): 133–138.

doi:10.1007/s40999-016-0019-0.

ASAIS 2020 - Annual Southeast Asian International Seminar

62

Anubhav Basudhar PK (2013) Interface behaviour of

woven geotextile with rounded and angular particle

sand. J Mater Civ Eng ASCE 25(12):1970–1974

Anubhav, W. H. 2015. “Modelling of Non-linear Shear

Displacement Behaviour of Soil–Geotextile Interface.”

International Journal of Geosynthetics and Ground

Engineering 1: 19. doi:10.1007/s40891- 015-0021-7

Athanasopoulos GA (1993) Effect of particle size on the

mechanical behaviour of sand-geotextile composites.

Geotext Geomembr 12(3):255–273

Bauer GE, Zhao Y (1994) A realistic stress transfer model

for geogrids in pullout. In: Proceedings of the 5th

International Conference on Geotextiles,

Geomembranes and Related Products, vol 1. Singapore,

pp 457–460

Bergado, D. T., G. V. Ramana, H. Sia, and I. Varun. 2006.

“Evaluation of Interface Shear Strength of Composite

Liner System and Stability Analysis for a Landfill

Lining System in Thailand.” Geotextiles and

Geomembranes 24 (6): 371–393.

doi:10.1016/j.geotexmem.2006.04.001

Brahim, A., A. Arab, M. Belkhatir, and I. Shahrour. 2016.

“Laboratory Study of Geotextiles Performance on

Reinforced Sandy Soil.” Journal of Earth Science 27:

1060. doi:10.1007/s12583-015-0621-0

Cerato AB, Lutenegger AJ (2006) Specimen size and scale

effects of direct shear box tests of sands. Geotech Test

J 29(6):1–10. doi:10.1520/GTJ100312

Choudhary AQ, Krishna AM (2016) Experimental

investigation of interface behaviour of different types

of granular soil/geosynthetics. Int J Geosynth Ground

Eng 2(1):1–11. doi:10. 1007/s40891-016-0044-8

Day, R.W., 2000, Geotechnical Engineer’s Portable

Handbook, Mc Graw Hill, New York

Dixon, N., and D. R. V. Jones. 2005. “Engineering

Properties of Municipal Solid Waste.” Geotextiles and

Geomembranes 23 (3): 205–233.

doi:10.1016/j.geotexmem.2004.11.002.

Hatami, K., and D. Esmaili. 2015. “Unsaturated Soil –

Woven Geotextile Interface Strength Properties from

Small-scale Pullout and Interface Tests.” Geosynthetics

International 22 (2): 161–172. doi:10.1680/

gein.15.00002.

Hossain B, Hossain Z, Sakai T (2012) Interaction properties

of geosynthetic with different backfill soils. Int J Geosci

3:1033–1039. doi:10.4236/ijg.2012.35104

Jewell RA, Wroth CP (1987) Direct shear tests and

reinforced sand. Ge´otech 37(1):53–68

Jewell, R.A., 1996, Soil Reinforcement with Geotextiles,

CIRIA, London

Jose D., Infante U., Martin GAM, Ariel P. Eberhardt M.,

(2016), Shear Strength Behavior of Different

Geosynthetic Reinforced Soil Structure from Direct

Shear Test, Int. J. of Geosynth. and Ground Eng. (2016)

2:17, Springer International Publishing Switzerland.

Kim D, Ha S (2014) Effects of particle size on the shear

behaviour of coarse grained soils reinforced with

geogrid. Mater 7:963–979. doi:10.3390/ma7020963

Liu CN, Ho YH, Huang JW (2009) Large scale direct shear

tests of soil/PET-yarn geogrid interfaces. Geotext

Geomembr 27:19–30

Lopes ML, Silvano R (2010) Soil/geotextile interface

behavior in direct shear and pullout movements.

Geotech Geol Eng 28:791–804

Moayedi H, Huat BBK, Kazemian S, Asadi A (2010)

Optimization of tension absorption of geosynthetics

through reinforced slope. Electron J Geotech Eng

15(2):93–104. Available at the website ejge.com at

http://www.ejge.com/2010/Ppr10.010/Ppr10.010.pdf

Omar AH, Samer R, Hussein dan Husam AQ. (2019).

Evaluating aqaba marine sand geotextile interface shear

strength, International Journal of Geotechnical

Engineering,

https://doi.org/10.1080/19386362.2019.1651985

Palmeira EM (1999) Execution and interpretation of

laboratory tests on geosynthetic material (in

Portuguese). In: Proceedings of the 1st south-American

symposium on geosynthetics, ABMSISSMGE, vol 1.

Rio de Janeiro, pp 87–108

Palmeira EM (2008) Soil-geosynthetic interaction:

modeling and analysis. Geotext Geomembr 27(5):368–

390

Punetha, P., P. Mohanty, and M. Samanta. 2017.

“Microstructural Investigation on Mechanical Behavior

of Soil-geosynthetic Interface in Direct Shear Test.”

Geotextiles and Geomembranes 45 (3): 197–210.

doi:10.1016/j.geotexmem.2017.02.001.

Rifa’i, A., (2003), Perilaku Interaksi Tanah-Geotekstil

Terhadap Parameter Kuat Geser, dinamika TEKNIK

SIPIL, Volume 9, Nomor 1, Januari 2009 : 92 – 100,

Yogyakarta.

Saya˜o ASFJ, Sieira ACCF (2012) Evaluation of direct

shear tests on geogrid reinforced soil. Soils Rocks

35(1):65–74

Takasumi DL, Green KR, Holtz R (1991) Soil–

geosynthetics interface strength characteristics: a

review of state-of the-art testing procedures. In:

proceedings of the geosynthetics’91 conference,

Atlanta 1:87–100

Tan SA, Chew SH, Wong WK (1998) Sand–geotextile

interface shear strength by torsional ring shear tests.

Geotext Geomembr 16(3):299–328

Tuna SC, Altun S (2012) Mechanical behaviour of sand–

geotextile interface. Sci Iran 19(4):1044–1051

Vangla P, Latha GM (2015) Influence of particle size on the

friction and interfacial shear strength of sands of similar

morphology. Int J Geosynth Ground Eng 1(6):1–12.

doi:10.1007/ s40891-014-0008-9

Vieira CS, Lopes ML (2013) Soil-geosynthetic interface

shear strength by simple and directshear tests. In:

Proceedings of the 18th international conference on soil

mechanics and geotechnical engineering, Paris 1:3497–

3500

Vieira, C. S., M. L. Lopes de, and L. Caldeira. 2015. “Sand-

nonwoven Geotextile Interfaces Shear Strength by

Direct Shear and Simple Shear Tests.” Geomechanics

and Engineering 9 (5): 601–618. doi:10.12989/

gae.2015.9.5.601.

Laboratory Study on Shear Strength of Soil using Woven and Non-woven Geotextiles

63

Wang, J., F. Y. Liu, P. Wang, and Y. Q. Cai. 2016. “Particle

Size Effects on Coarse Soil-geogrid Interface Response

in Cyclic and Post-cyclic Direct Shear Tests.”

Geotextiles and Geomembranes 44 (6): 854–861.

doi:10.1016/j.geotexmem.2016.06.011

ASAIS 2020 - Annual Southeast Asian International Seminar

64