Development of Alginate-based Antibacterial Edible Films by

Incoporating Green Betel Leaf Extract

Giyatmi Giyatmi

1

, Hari Eko Irianto

2

, Mohammad Sabariman

1

and Bintang Anggoro

1

1

Study Program of Food Technology, Sahid University, Jakarta University, Jakarta, Indonesia

2

Research and Development Center for Marine and Fisheries Product Processing and Biotechnology, Indonesia

Keywords: Antibacterial, Edible Film, Green Betel Leaf Extract, Staphylococcus aureus, Escherichia coli.

Abstract: The aim of this research was to develop an environmentally friendly packaging of alginate-based antibacterial

edible films. The antibacterial sources used was green betel leaf extract. Concentration levels of green betel

leaf extract which was studied were 0,5%, 1,0% and 1,5%. The edible film obtained was evaluated physically,

mechanically, chemically and microbiologically including parameters of Water Vapor Transmission Rate

(WVTR), water solubility, tensile strength, elongation, brightness, thickness, moisture content, and

antibacterial clear zone test. Experiment was conducted two replicates. The results showed that concentration

level of green betel leaf extract affected on the quality and antibacterial properties of alginate-based edible

films. Overall, the best alginate-based antibacterial edible film is produced by incorporating green betel leaf

extract at concentration level of 1,5%.

1 INTRODUCTION

Edible films are types of biodegradable plastic that

attract scientists around the world to explore. Edible

films have been employed to pack a variety of food

products, such as meat, sausages, fresh fruits and

vegetables. Edible films can maintain the quality of

packaged food because edible film can withstand

carbon dioxide, oxygen diffusion, water evaporation,

and flavor contamination with other products.

Another benefit of edible films is that it can extend

the shelf life and is environmentally friendly. Edible

films can be consumed together with the product.

(Junianto et al. 2012). The main components of

edible film can be grouped into three categories,

namely hydrocolloids, lipids, and composites.

Composites are a combination of hydrocolloids and

lipids. The hydrocolloids that can be used to make

edible films are proteins and carbohydrates.

Meanwhile, the lipids used are wax and fatty acids

(Donhowe and Fema, 2994). Alginate is one of

hydrocolloids polysaccharides which are available in

nature derived from seaweed and can be applied as

bio polymeric film. Film forming and binding ability

of alginate makes it suitable for the use of packaging

material (Parveen et al, 2019).

Production of edible films from alginate have

been explored by Murdinah et al. (2007), Khairunnisa

et al. (2018), Koushki et al. (2015) and others.

Alginate based edible films are found strong, but poor

water resistance due to hydrophilic nature. One way

to increase the performance of alginate based edible

film is by developing it as an active packaging. The

film can be used as a carrier of antioxidants, flavoring

and/or coloring agents and antimicrobials to improve

food safety and quality (Siracusa et al, 2018).

Incorporating antimicrobial into alginate film can

increase the resistance of the film to bacteria so that

the film has good mechanical quality and can inhibit

bacteria that potentially contaminate food.

One of the natural ingredients that contain

antimicrobials is green betel leaf. The active

antibacterial components found in green betel are

tannins, flavonoids and essential oils (Baskaran et al.,

2011). These compounds are able to inhibit the

growth of Escherichia coli and Staphylococcus

aureus. These bacteria produce enterotoxins which

can cause diarrhea. The antimicrobial activity of betel

leaf active compounds is by denaturing proteins and

damaging bacterial cell walls, as well as destructing

lipids in cell membranes by reducing the surface

tension of the cell membranes.

This study was aimed to develop an

environmentally friendly packaging of alginate-based

52

Giyatmi, G., Irianto, H., Sabariman, M. and Anggoro, B.

Development of Alginate-based Antibacterial Edible Films by Incoporating Green Betel Leaf Extract.

DOI: 10.5220/0010514000003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 52-58

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

antibacterial edible films by using green betel leaf

extract as antimicrobial agent. added during the

process. Meanwhile, physical, mechanical, chemical

and antibacterial properties of the edible film were

also observed.

2 MATERIALS AND METHODS

2.1 Material

Alginate flour used was extracted from Sargassum sp.

by employing an extraction method developed by

Yunizal (2000). The modified cassava (mocaf) flour

used was the “Ladang Lima” brand, while sorbitol

and beeswax were purchased from PT Geochem

Globalindo, Jakarta. Green betel leaves were obtained

from the Ciracas market, East Jakarta.

2.2 Method

2.2.1 Extraction of Antibacterial

Compounds from Green Betel Leaves

Antibacterial from green betel leaves were extracted

through modifying a method previously employed by

Sitorus (2018) for extracting antibacterial from betel

leaves as well. After washing, the betel leaves were

chopped so that they were exposed to more ethanol.

The mixing was carried out in a large and closed

container so that the maceration process of the

material run perfectly. During mixing, the mixture

was stirred periodically. After that, the soaking

process was conducted for 3 days with stirring every

24 hours. Then the mixture was filtered with a 100

mesh filter cloth and the obtained filtrate was

evaporated using a rotary vacuum evaporator until a

thick extract was obtained (Sitorus, 2018).

2.2.2 Preparation of Edible Film

Edible film was prepared according to the experiment

conducted by Murdinah et al (2007) with

modification. About 97 mL of distilled water in a

beaker glass was heated to 50

o

C, then 1,5 g of alginate

powder was gradually added while stirring with a

magnetic stirrer. After that, 0,3 g of mocaf starch was

added with stirring for 30 minutes. After mixing

completely, the antibacterial green betel leaf extract

was added into the solution according to the treatment

(0,5%; 1,0%; 1,5%) and stirred for 30 minutes until

evenly mixed at 75

o

C. Furthermore, the solution is

casted by pouring into a square acrylic plate, where

one edible film solution recipe can be casted on two

acrylic plates. After that the acrylic plate was left to

stand at room temperature for approximately 24 hours

and then the dried edible film was removed.

2.2.3 Experiment

Experiment was executed in two stages, i.e.

preliminary and main experiments. Preliminary

experiment was conducted to investigate antibacterial

activity of green betel leaf extract to S. aureus and E.

coli. The results of this preliminary experiment will

be used in the main experiment. The main research

was performed to determine the optimum addition

level of green betel leaf extract as antibacterial agent

on alginate-based edible film. The concentration level

of betel leaf extract tested consisted of 3 levels (0,5%,

1,0%, 1,5%) with 2 replications.

2.2.4 Analyses

Alginate based antibacterial edible films obtained

were assessed their performance in terms of physical,

mechanical, chemical and antibacterial properties

including thickness using digital micrometer

(Mitutoyo, Japan), tensile strength and elongation

using Texture Analyzer (TAXT Plus, Stable Micro

System, UK) (Balqis et al., 2017), water vapor

transmission rate (WVTR) based on ASTM E96

using PERME® W3 / 031 Water Vapor Transmission

Rate Tester (Labthink, China), brightness using

Hunter Lab, water solubility (Murni et al, 2013),

moisture content (Farhan and Hani, 2017), as well as

antibacterial activity for S. aureus and E.coli (da Silva

et al, 2013) and surface morphological analysis using

SEM (Scanning Electron Microscopy) JEOL JSM-

6360LA, Japan (Setiani et al, 2013).

3 RESULT AND DISCUSSION

3.1 Antibacterial Activity of Green

Betel Leaf Extract

Antibacterial compounds extracted from green betel

leaves using alcohol as the extracting solvent showed

antibacterial activity on S. aureus and E. coli as

shown in Table 1. The highest antibacterial activity

of green betel extract against S. aureus based on the

largest inhibition zone shown at the extract

concentration of 1% was 14 mm, and the lowest

activity exhibited by the extract concentration of

0,5% was 12,50 mm. While, the highest inhibition

zone of green betel leaf extract against E. coli

occurred at

a concentration of 1,0% extract was 14

Development of Alginate-based Antibacterial Edible Films by Incoporating Green Betel Leaf Extract

53

mm, and the lowest zone of inhibition shown at a

concentration of 0,5% extract was 12,50 mm.

Table 1: Antibacterial activity of green betel leaf extract

(Clear Zone, mm).

Microorganism

Concentration of Green Betel Leaf

Extract

0,5% 1,0% 1,5%

Staphylococcus

aureus

14,00 13,50 14,00

Escherichia

coli

12,50 14,00 13,00

The antibacterial activity of betel leaf extract is

suspected to be produced by the chemical compounds

of the betel leaves, namely saponins, flavonoids,

polyphenols, and essential oils. Saponin compounds

can work as antimicrobials by damaging the

cytoplasmic membrane and killing cells. Flavonoid

compounds are thought to denaturate bacterial cell

proteins and irreparably damage cell membranes.

Natural phenols contained in essential oils have

antiseptic properties 5 times stronger than ordinary

phenols (bactericides and fungicides) but are not

sporacid. The mechanism of phenol as an

antibacterial agent acts as a toxin in the protoplasm,

damages and penetrates the walls and precipitates

bacterial cell proteins (Carolia and Noventi, 2016).

The main components of essential oil are betel

phenol and some of its derivatives including eugenol

allypyrocatechin 26,8 – 42,5%, cineol 2,4 – 4,8%,

mehyl eugenol 4,2 – 15,8%, caryophyllen 3,0 -9,8 %,

kavikol hydroxy, kavikol 7,2-16,7%, kabivetol 2,7

6,2%, estragol, ilypryrocatekol 9,6%, carvacol 2,2 –

5,6%, alkaloids, flavonoids, triterpenoids or steroids,

saponins, terpenes, phenylpropane, terpinen, diastase

from 0,8 - 1,8%, and tannins 1,0 – 1,3% (Damayanti

and Mulyono, 2003). Phenol at a concentration of 0,1

– 1,0% is bacteriostatic, while it is as bactericidal at a

concentration of 1 - 2% (Fuadi, 2014),

3.2 Characteristics of Alginate-based

Antibacterial Edible Film

The moisture content of the edible film increased with

the increase in the concentration of antibacterial

extract of green betel leaves in the film (Table 2).

Suryaningrum et al (2005) noted that edible films

being biodegradable with high moisture content will

be easily grown by microorganisms, due to the

presence of nutritional components in the film such

as protein. On the otherhand, edible films with low

moisture content will be more resistant to

microbiological destruction.

WVTR value of alginate edible film with different

antibacterial concentration treatment resulted in

different WVTR values with a tendency to decrease

with increasing concentration. WVTR test results for

edible film made with various concentrations of betel

leaf extract yielded WVTR values ranging from

1640,65 to 1871,79 g/m

2

.24h. The lowest WVTR

value of edible film was obtained at the addition of

1,5% antibacterial extract of betel leaves. Irianto et al

(2006) reported that the lowest WVTR was resulted

from a combination of 2,0% carrageenan, 0,7%

tapioca and 0,3% beeswax, i.e. 746,2g/m

2

/day, which

was lower than the value from this study.

The WVTR value in this study showed that the

edible film with the addition of green betel leaf

extract had a WVTR value which increased in line

with the increase in the addition level of betel leaf

extract. The higher the WVTR value, the higher the

permeability of the edible film. When edible film is

made into packaging, it will cause more moisture to

come out and enter the package. A good edible film

must not be easily passed by moisture or have a low

WVTR. The compact edible film structure can inhibit

water vapor diffusion through the edible film. Betel

leaf extract contains oil and water. Oil components

have high protective properties against water vapor

which will reduce the hydrophilic properties of the

film. Guilbert & Biquet (1996) informed that the fatty

components such as wax, emulsifier and fatty acids in

composite edible films have an effect on reducing

WVTR because fat has low polarity and a dense

crystal structure.

Table 2: Physical and Chemical properties of alginate based

antibacterial edible film.

Parameter

Concentration of Green Betel Leaf Extract

0,5% 1,0% 1,5%

Moisture

Content (%)

11,09±0,40 11,53±0,04 12,42±0,10

WVTR

(g/m

2

.24h)

1871,79±68,19 1790,28±4,15 1640,65±57,05

Water

Solubility

(%)

57,98±10,22 70,59±1,68 84,95±11,90

Brightness

(%)

14,2±1,27 12,1±0,27 11,5±1,70

Thickness

(mm)

0,114±0,014 0,104±0,013 0,108±0,008

The water solubility value of alginate edible film

with the addition of antibacterial extract of betel

leaves at different concentrations resulted in film

solubility which increased with increasing

concentration of betel leaf extract. The more betel

leaf extract is added, the more easily the edible film

will dissolve. The lowest solubility value indicates

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

54

that the edible film is the best because it plays a very

important role when the film is used for edible

products. This is also in accordance with the opinion

of Stuchell and Krochta (1994) that if the application

of a film is expected as an edible packaging, high

solubility is desired. Likewise, if the application of

edible film on foods with high water content, a film

that is not water-soluble is used. Imeson (1999) adds

that water resistance is an important property for

films applied as food protection.

The addition level of green betel leaf extract

affected the brightness of alginate edible film, in

which increasing addition level of betel leaf extract

resulted in edible film with lower brightness

percentage values. Ningsih (2015) mentioned that the

basic material used will affect the color of the edible

film. Therefore, the edible film using different

antibacterial concentrations will bring about different

brightness of edible films.

The use of betel leaf extract with different

concentrations in the production of alginate edible

film did not significantly affect the thickness of the

edible film, in which the thickness of edible film

obtained in this study was in the range of 0,104 –

0,114 mm. Those values are thicker compared to

thickness values of edible film made of composite

consisting of carrageenan, tapioca flour and beeswax,

i.e. 0,050 – 0,074 mm (Irianto et al, 2006).

Meanwhile, Saputro et al (2017) produced edible

films with a thickness of 0,03 – 0,08 mm which was

carrageenan, tapioca flour and glycerol used as raw

materials. According to Wahyu (2009) that a good

edible film has a thickness of 0,15 – 0,20 mm which

can withstand external influences and reduce WVTR.

Thickness is an important parameter that needs to be

considered in the use of edible film as a packaging.

The thickness of the film will affect the gas

permeability. The thicker the edible film, the lower

the gas permeability, which can protect the product.

The tensile strength values of alginate edible film

were insignificantly influenced by the addition levels

of green betel leaf extract. The higher addition of the

betel leaf extract did not result in a pronounced

difference in tensile strength of the edible film. The

tensile strength of the edible film in this study was in

the range of 1,31±0,84 – 2,67±0,51 MPa (Table 3).

Those tensile strength values are not in the range of

ASTM polypropylene standard values, i.e. 24,7-302

MPa. In addition, the best tensile strength of edible

films is between 10 - 100 MPa while edible films with

a tensile strength range of 1 - 10 MPa are classified as

marginal (Han and Gennadios, 2005). The increase in

the forces of attraction between the molecules making

up the edible film induces an increase in the strength

of its structure. The greater the tensile value, the

stiffness of a material will increase or be inelastic.

Sara (2015) noted that tensile strength is a mechanical

property related to the strength of the edible film to

withstand physical damage when applied as food

packaging. Edible film with high tensile strength

value is highly expected in order to minimize

packaged product damage due to mechanical

interferences.

Table 3: Mechanical properties of alginate based

antibacterial edible film.

Parameter

Concentration of Green Betel Leaf

Extract

0,5% 1,0% 1,5%

Tensile

Strength

(Mpa)

2,52±0,75 2,67±0,51 1,31±0,84

Elongation

(

%

)

47,05±18,88 38,30±4,95 24,40±13,58

The elongation test results showed that the more

the betel leaf extract on the alginate edible film, the

lower the elongation value. The elongation

percentage of the film is categorized as poor if the

value is less than 10% and good if the elongation

percentage exceeds 50%. Elongation percentage of

alginate based edible film added with various

concentrations of betel leaf extract in this study was

in the range of 24,40±13,5 – 47,05±18,88 %. The

elongation value of the edible film from this study

was lower than the elongation value of edible film

made of bligon goat skin gelatin, namely 70,97 –

95,33% (Said et al., 2013). Edible films from whey

and agar have comparable elongation, i.e. 26,06 –

34,52% (Hakim, 2015). Elongation of edible films

made from avocado seed starch and agar is smaller,

i.e. 0,17 – 0,45% (Coniwanti et al, 2016).

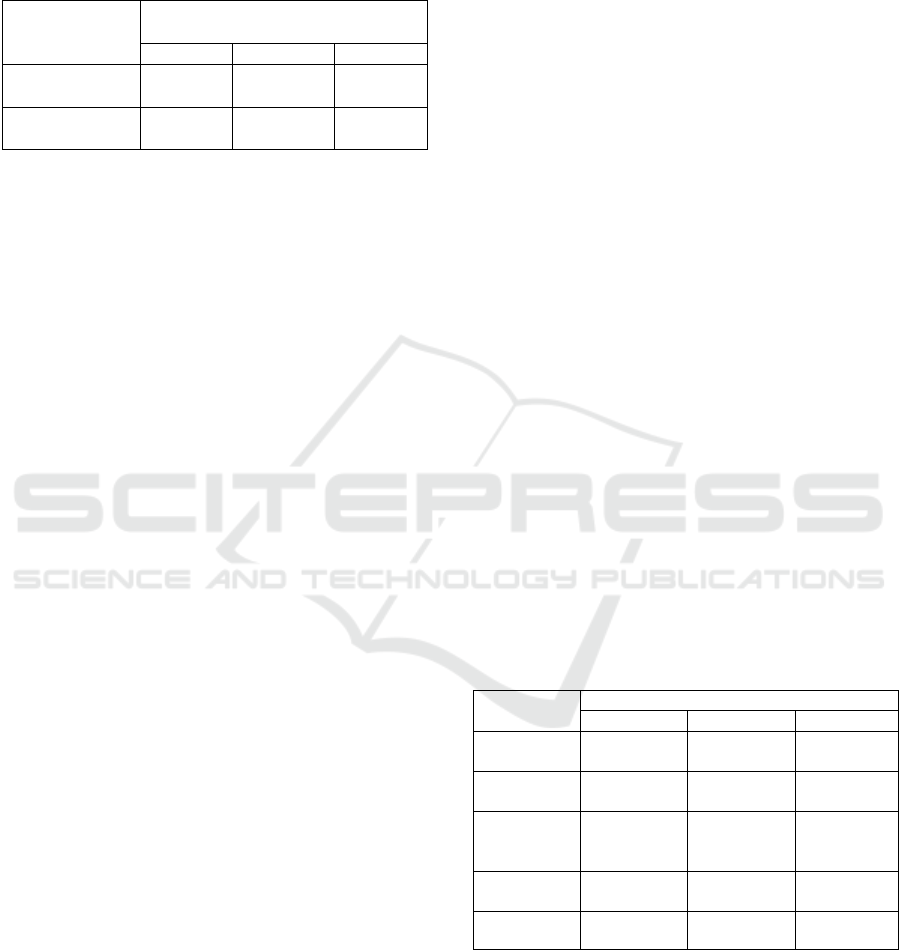

The antibacterial test showed that the alginate-

based edible film incorporated with green betel leaf

extract had antibacterial activity against S. aureus and

E. coli (Table 4) as indicated by the formation of a

clear zone on the test medium (Figure 1). The

antibacterial activity was getting more significant

with the higher concentration level of antibacterial

betel leaf extract, both for S. aureus and E. coli which

showed the same trend. Thus, if greater antibacterial

activity is expected, the addition level of betel leaf

extract must be increased. The development of

antibacterial edible films based on various types of

starch has also been carried out using several

antibacterial sources from the extracts of beluntas

leaves (Mulyadi et al, 2016), garlic (Anggraini et al,

2018), red galangal/Alpinia purpurata (Sholehah et

al, 2016) and areca nut (Ningsih, 2018).

Development of Alginate-based Antibacterial Edible Films by Incoporating Green Betel Leaf Extract

55

Table 4: Antibacterial properties (Clear Zone, mm) of

alginate based edible film added with green betel leaf

extract.

Parameter

Concentration of Green Betel Leaf

Extract

0,5% 1,0% 1,5%

Staphylococcus

aureus

14,25 17,85 18,15

Escherichia

coli

12,40 14,00 13,40

(1) Staphylococcus aureus (2) Escherichia coli

Figure 1: Clear zone as antibacterial effects of green betel

leaf extract of alginate based edible film on S. aureus and E

coli.

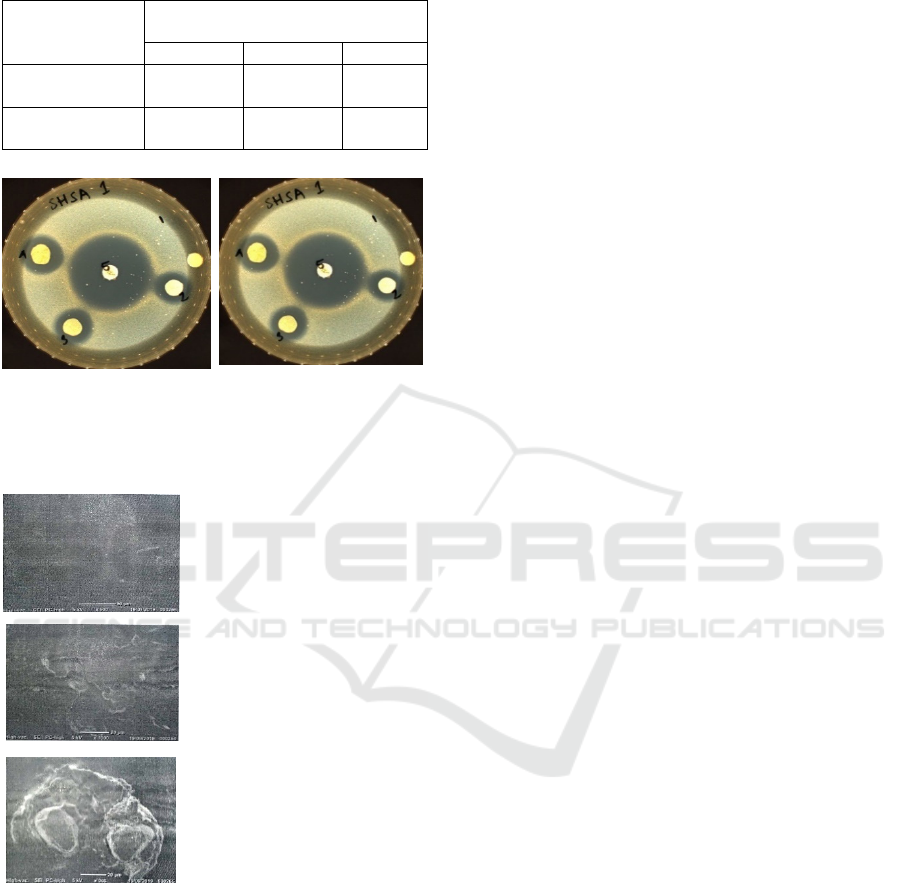

Figure 2: SEM images of alginate edible film added with

1.5% betel leaf extract with three times magnification.

Surface morphological analysis using SEM was

carried out on alginate based edible film added with

green betel leaf extract at a concentration of 1.5%

(Figure 2), generally showing the best physical,

mechanical and chemical properties. Analyses

revealed that the molecular structure surface of the

alginate edible film at 500 and 1000 times

magnification was dense. The higher the

magnification used, the more obvious the surface

morphology of the edible film, and it turned out that

it showed the lack of molecular density in the

resulting edible film. The less dense structure of these

molecules brought about more water to be absorbed.

The image also showed a less smooth and porous

surface. The non-smooth surface indicated that the

film was less homogeneous. This occurrence was

probably due to a too short stirring period, so that it

resulted in inhomogeneous edible film solution

inducing a non-dense molecular structure surface of

the alginate edible film. Therefore, further study to

explore this phenomenon are highly recommended.

4 CONCLUSION

1) Green betel leaf extract has antibacterial activity

against S. aureus and E. coli

2) Alginate-based edible film added with green betel

leaf extract has relatively good physical and

mechanical characteristics, especially in terms of

thickness, tensile strength, elongation and

WVTR.

3) Edible film added with betel leaf extract as

antibacterial showed antibacterial activity against

S. aureus and E, coli; so it can be called as an

antibacterial edible film

4)

Antibacterial edible film is recommended for

performance testing by being used as a packaging

for food products

ACKNOWLEDGEMENT

Authors would like to thank to the Ministry of

Research, Technology and Higher Education of the

Republic of Indonesia, who has provided funding for

executing this study through PTUPT program 2019

No: 45.3/USJ-11/H.54/2019.

AUTHORS’ CONTRIBUTIONS

Giyatmi Giyatmi and Hari Eko Irianto are the main

contributors in conducting experiment and preparing

the draft of manuscript, while Mohammad Sabariman

and Bintang Anggoro are as supporting contributors.

All authors read and approved the final manuscript.

The molecular structure

surface of the alginate

edible film is dense at 500

times magnification.

The molecular structure

surface of the alginate

edible film is dense at 1000

times magnification.

The molecular structure

surface of the alginate

edible film is not dense at

2000 times magnification

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

56

REFERENCES

Anggraini, T.N., Agustini, T.W. and Rianingsih, L. 2018.

Karakteristik Edible Film Karaginan Dengan

Penambahan Ekstrak Bawang Putih (Allium sativum)

Sebagai Antibakteri. Saintek Perikanan 14 (1) : 70-76

Baskaran, C., Rathabai, V., & Kanimozhi, D., 2011.

Screening for antimicrobial activity and phytochemical

analysis of various leaf extract of Murraya koenigii. Int

J. Res Ayurveda Pharm, 2, 1807-10

Balqis, A. I., Khaizura, M. N., Russly, A. R., and Hanani,

Z. N., 2017. Effects of plasticizers on the

physicochemical properties of kappa-carrageenan films

extracted from Eucheuma cottonii. International

Journal of Biological Macromolecules, 103, 721-732.

https://doi.org/ 10.1016/j.ijbiomac.2017.05.105

Carolia, N. and Noventi, W., 2016. Potensi Ekstrak Daun

Sirih Hijau (Piper betle L.) sebagai Alternatif Terapi

Acne vulgaris. Majority 5 (1): 140 – 145

Coniwanti, P., Sari, D.M., and Ferbriana, R., 2016.

Pengaruh Rasio Massa Pati Biji Alpukat dan Agar -

Agar Terhadap Pembuatan Edible Film. Jurnal Teknik

Kimia. 22(2) : 51-59

Damayanti R. and Mulyono, 2003. Khasiat & manfaat daun

sirih: obat mujarab dari masa ke masa. Agromedia

Pustaka. Jakarta.

da Silva, M., Lamanaka, B., Taniwaki, M. and Kieckbusch,

T. 2013. Evaluation of the Antimicrobial Potential of

Alginate and Alginate/ Chitosan Films Containing

Potassium Sorbate and Natamycin. Packaging

Technology and Science 26 (8): 479-492

Donhowe, G. and Fennema, O., 1994. Edible film and

coating: Characteristic, formation, definitions and

testing methods. In Krochta, J.M., Baldwin, E.A. and

Nisperos-Carriedo, M.O. (eds.). Edible Coating and

Film to Improve Food Quality. Technomic Publ. Co.

Inc. Lancaster, Pennsylvania. 378 pp

Farhan, A. & Hani, N. M., 2017. Characterization of edible

packaging films based on semi-refined kappa

carrageenan plasticized with glycerol and sorbitol.

Food Hydrocolloids, 64, 48-58. https://doi.org/

10.1016/j.foodhyd.2016.10.034

Fuadi S., 2014. Efektivitas ekstrak daun sirih hijau (Piper

betle L.) terhadap pertumbuhan bakteri Streptococcus

pyogenes in vitro. Skripsi. Universitas Islam Negeri

Syarif Hidayatullah. Jakarta.

Guilbert, S. and Biquet, B., 1990. Edible Films and

Coatings. In Food Packaging Technology Vol. 1. (Eds.

Bureau, G. and Multon, J.L.). VCH Publisher, Inc. New

York.

Hakim, M.Q., 2015. Karakteristik Edible Film dari Whey

Dangke yang Ditambahkan Level Agar yang Berbeda.

Skripsi. Fakultas Peternakan. Universitas Hasanuddin.

Makassar

Han, J.H. and Gennadios, A., 2005. Edible Film and

Coatings: A Review. Innovations in Food Packaging.

Academic Press.

Irianto, H. E., Darmawan, M. and Mindarwati, E., 2006.

Pembuatan Edible Film dari Komposit Karaginan,

Tepung Tapioka dan Lilin Lebah (Beeswax). J.

Pascapanen Dan Bioteknologi Kelautan Dan Perikanan

1 (2): 93-101.

Imeson, A., 1999. Thickening and Gelling Agents for Food.

Aspen Publishers Inc. Maryland.

Junianto., N., Kurniawati, O.S., Djunaidi, and Khan,

A.M.A., 2012. Physical and Mechanical Study on

Tilapia’s Skin Gelatine Edible Films with Addition of

Plasticizer Sorbitol. African Journal of Food Science

6(5):142-146.

Khairunnisa, S., Junianto, Zahidah, and Rostini, I., 2018.

The effect of glycerol concentration as a plasticizer on

edible films made from alginate towards its physical

characteristic. World Scientific News 112: 130-141

Koushki, M.R., Azizi, M.H., Azizkhani, M., and Koohy-

Kamaly, P., 2015. Effect of Different Formulations on

Mechanical and Physical Properties of Calcium

Alginate Edible Films. Journal of Food Quality and

Hazards Control 2: 45-50

Mulyadi, A.F., Maimunah Hindun Pulungan, M.H. and

Qayyum, N., 2016. Pembuatan Edible Film Maizena

dan Uji Aktifitas Antibakteri. Industria: Jurnal

Teknologi dan Manajemen Agroindustri 5(3): 149-158

Murdinah, Darmawan, M. and Fransiska, D., 2007.

Karakteristik Edible Film dari Komposit Alginat,

Gluten dan Lilin Lebah (

Beeswax). Jurnal Pascapanen

dan Bioteknologi Kelautan dan Perikanan 2(1): 19-25

Murni, S. W., Pawignyo, H., Widyawati, D., & Sari, N.,

2013. Pembuatan Edible Film dari Tepung Jagung (Zea

mays L.) dan Kitosan. Prosiding Seminar Nasional

Teknik Kimia Kejuangan (p. B17 1-9).

Ningsih, W., 2018. Formulasi Dan Uji Efektivitas

Antibakteri Edible Film Ekstrak Biji Pinang (Areca

catechu Linn). Jurnal Ilmu Farmasi dan Farmasi Klinik

(JIFFK) 15 (2): 71-76

Parveen, I., Maraz, K.M., Mahmud, M. and Khan, R.A.,

2019. Seaweed Based Bio Polymeric Film and Their

Application: A Review on Hydrocolloid

Polysaccharides. Scientific Review 5 (5): 93-102

Said, M.I., Triatmojo, S., Erwanto, Y., and Fudholi, A.,

2013. Evaluasi Karakteristik Fisik Edible Film dari

Gelatin Kulit Kambing Bligon yang Menggunakan

Gliserol Sebagai Plasticizer. Jurnal Ilmu dan Teknologi

Hasil Ternak. 8(2) : 32

Saputro, B.W., Eko Nurcahya Dewi, E.N. and Susanto, E.,

2017. Karakteristik Edible Film Dari Campuran

Tepung Semirefined Karaginan Dengan Penambahan

Tepung Tapioka Dan Gliserol. J. Peng. & Biotek. Hasil

Pi. 6 (2): 1-6

Sara, N.E.M., 2015. Karakteristik edible film berbahan

dasar whey dangke dan agar dengan penambahan

konsentrasi sorbitol. Skripsi. Universitas Hasanuddin.

Makassar

Setiani, W., Sudiarti, T. and Rahmidar, L. 2013. Preparasi

Dan Karakterisasi Edible Film Dari Poliblend Pati

Sukun-Kitosan. Valensi 3 (2): 100 - 109

Sholehah, M.M., rid Ma’ruf, W.F. and Romadhon., 2016.

Karakteristik Dan Aktivitas Antibakteri Edible Film

Dari Refined Carageenan Dengan Penambahan Minyak

Atsiri Lengkuas Merah (Alpinia purpurata). J. Peng. &

Biotek. Hasil Pi. 5 (3): 1-8

Development of Alginate-based Antibacterial Edible Films by Incoporating Green Betel Leaf Extract

57

Siracusa, V., Romani, S., Gigli, M., Mannozzi, C.,

Cecchini, J.P., Tylewicz, U. and Lotti, N., 2018.

Characterization of Active Edible Films based on Citral

Essential Oil, Alginate and Pectin. Materials 11(10):

1980

Sitorus, P. 2018., Uji Efek Kombinasi Amoksisilin Dengan

Ekstrak Etanol Daun Sirih (Piper betle L) Terhadap

Pertumbuhan Bakteri Escherichia Coli Dan

Staphylococcus Aureus. TM Conference Series 01:

313–319

Stuchell, Y. M. and J. M. Krochta., 1994. Enzymatic

treatments and thermal effects on edible soy protein

films. J. Food Sci. 59(6): 1332-1337.

Suryaningrum, Th. D., Basmal, J. and Nurrochmawati,

2005. Studi pembuatan Edibel Film dari Karagenan.

Jurnal Penelitian Perikanan Indonesia. Edisi Pasca

Panen. Badan Riset Perikanan dan Kelautan

Departemen Kelautan dan Perikanan 2(4): 1 – 13.

Wahyu, M. K., 2009. Pemanfaatan Pati Singkong sebagai

Bahan Baku Edibel film. Jurusan Teknologi Industri

Pangan, Fakultas Teknologi Industri Pertanian,

Universitas Padjajaran. Bandung

Yunizal, 2000. Penelitian Teknologi Ekstraksi Alginat dari

Rumput Laut Coklat (Phaeophyceae). Balai Penelitian

Perikanan Laut. Jakarta. 100 pp.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

58