Preparation of Double Emulsion of Vitamin C with Two Different

Emulsifiers in the Outer Aqueous Phase

Marcellina Indah Permatasari

1

, M. Yusuf Sulaeman

1

and Bambang Nurhadi

1,2

1

Food Technology Department, Faculty of Agric. Industrial Technology, Universitas Padjadjaran,

Jl. Raya Bandung Sumedang km. 21, Jatinangor Sumedang 45363, Indonesia

2

Study Centre of Agric. Technology Development, Faculty of Agric. Industrial Technology, Universitas Padjadjaran,

Jl. Raya Bandung Sumedang km. 21, Jatinangor Sumedang 45363, Indonesia

Keywords: Double Emulsion, Tween 80, Vitamin C, W/O/W, WPC-Pectin.

Abstract: Vitamin C is one of common bioactive compound widely known and used by many people, especially in

Indonesia. The weakness of vitamin C stablity are sensitive with extreme pH, temperature, oxygen and direct

light. Because of that, the encapsulation of itamin C with W

1

/O/W

2

emulsion can be the solution for

maintaining the stability of vitamin C. This study is aimed to emulsify Vitamin C in the inner aqueous phase

of water-in-oil-water (W

1

/O/W

2

) emulsions with soybean oil as the oil phase. Two type of emulsifier Tween

80 and WPC-Pectin in the outer aqueous phase used to compare their stability during storage. The result of

this research showed that emulsion with WPC-Pectin had bigger droplet size 1.34 μm than emulsion with

tween 80 0.91 μm. Tween 80 had a better stability with 14.41% of creming index compared to WPC-Pectin

with 23.06% of creaming index. Morphology of W

1

/O/W

2

emulsion with Tween 80 can be described as

W

1

/O/W

2

when emulsion with WPC Pectin cannot be described as W

1

/O/W

2

Emulsion. Tween 80 is a better

emulsifier than WPC-Pectin to stabilized the W

1

/O/W

2

emulsion in the outer aqueous phase.

1 INTRODUCTION

Vitamin C is a water-soluble vitamin which is widely

known and popularly used in Indonesia. This is

proven by the number of food products that contain

vitamin C in it. Vitamin C has the main function as a

compound that can maintain body endurance and can

increase skin moisture (Gregory, 2017). Vitamin C

consists of ascorbic acid compounds that have a low

pH and sour taste that is obtained from citrus fruits

such as oranges, lemons, lime and berries

(strawberries, blueberries and others). However the

stability of Vitamin C is very prone and it would

affect it functionality. Vitamin C is unstable to

extreme temperatures, extreme pH, high oxygen, and

light (Levine et al., 2004). Prolonged contact can

cause damage to vitamin C and ultimately can be bad

for health. Therefore, further efforts are needed so

that the vitamin C compound remains stable during

processing and storage.

Emulsification is one method of maintaining

vitamin C compounds in food products. Emulsion is

a dispersion system which consists of two solutions

which do not dissolve each other. There are two basic

types of emulsions, namely oil-in-water (O/W)

emulsion and water-in-oil (W/O) emulsion. This

emulsion is called as single emulsion. Another

emulsion system namely water-in-oil-in-water

(W

1

/O/W

2

) is a method for emulsifying hydrophilic

bioactive components. W

1

/O/W

2

consists of an

internal water phase (W

1

) which can be filled with

bioactive components such as vitamin c, intermediate

oil phase (O) and external water phase (W

2

). The use

of water as an outer phase of the emulsion system

aims to keep vitamin C soluble in water so that it is

easily applied in various processed food products.

The emulsion system W

1

/O/W

2

uses two

emulsifiers where the first emulsifier has high

hydrophobic properties while the second emulsifier

has high hydrophilic properties. The use of these two

types of emulsifiers play an important role in the

stability of the emulsions formed (Anton,

Vandamme, Ding, Yu, & Serra, 2018). The use of

emulsifiers to be studied are high molecular weight

emulsifiers such as bio complex proteins (whey

protein concentrate, and pectin) and low molecular

weights such as tween 80 in the outer phase of the

system. The effect of both type emulsifiers on the

Permatasari, M., Sulaeman, M. and Nurhadi, B.

Preparation of Double Emulsion of Vitamin C with Two Different Emulsifiers in the Outer Aqueous Phase.

DOI: 10.5220/0010513900003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 47-51

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

47

stability of the double emulsion during storage was

studied.

2 MATERIAL AND METHODS

2.1 Material

Vitamin C (Brataco, Indonesia), Aqua Deminerals

(Brataco, Indonesia), Commercial soybean oil (Salim

Ivomas, PT., Indonesia), Natrium Chloride (Brataco,

Indonesia), Propyl Paraben (Brataco, Indonesia),

Citric Acid (Weifang Ensign Industry Co. Ltd.,

China), Magnesium Sulfate (Brataco, Indonesia),

Tween 80 (Croda International, UK), Span 65 (Futura

Ingredients Pte, Ltd., Singapore), Pectin (CP Kelco,

U.S.) and Whey Protein Concentrate 80% (Avonlac,

Glanbia USA).

2.2 Methods

2.2.1 Preparation of the W₁ / O (Water in

Oil) Emulsion System

Aqueous phase in the form of a 10% vitamin C solution

was prepared by mixing 10 g (10% w / v) into 100 ml

aqua demineralized and adding 2 grams of MgSO₄.

The oil phase is made by adding 3.5 grams (5% w / v)

Span 65 to 70 ml of soybean oil at 70°C until it

dissolves at a speed of 500 rpm. W

1

/O emulsions were

prepared by adding 30 ml of the water phase to 70 ml

of the oil phase at room temperature (around 25 ℃) at

800 rpm, followed by the first stage emulsification at

4000 rpm for 2 minute using homogenizer.

2.2.2 Preparation of W

2

Biopolymer

Solution and Tween 80

Biopolymer solution was used as a second emulsifier

made from a mixture of 80% WPC (Whey Protein

Concentrate) and pectin. Biopolymer solution was

prepared by dissolving 3.1 g (3.5% w/v) WPC into

100 ml of aqua demineralized at 50˚C for 30 minutes

then adding 0.1 g of pectin, 0.7 g of citric acid, 3.9 g

of NaCl and 0.5 g of propyl parabens. After 30

minutes, the solution is lowered to room temperature

and stored for 24 hours at 4°C. Preparation of tween

80 solution refers to Gharehbeglou et al., (2019) with

a slight modification. Tween 80 of 3.6% (w/v) was

dissolved into aqua demineralized at room

temperature, also added 3.3% NaCl (w/v) to maintain

the osmotic pressure of the emulsion system that will

be formed. The solution is then stored at a chiller

temperature before use.

2.2.3 Preparation of W

1

/O/W

2

(Water in Oil

in Water) Emulsion Systems

Preparation of the W

1

/O/W

2

emulsion system was

firstly done by mixing 20 ml of W

1

/O emulsion into

80 ml of W₂ solution, then the mixture was

homogenized with Ultrasonic Homogenizer (Qsonica

Q500, US.) for 10 minutes with a pulse of 3 seconds

on 3 seconds off 70% amplitude. The homogeneity

process aims to homogenize the solution and reduce

the size of the droplet emulsion. The W

1

/O/W

2

emulsion formed is stored in a bottle at 25℃ for

stability testing for 14 days. The process of double

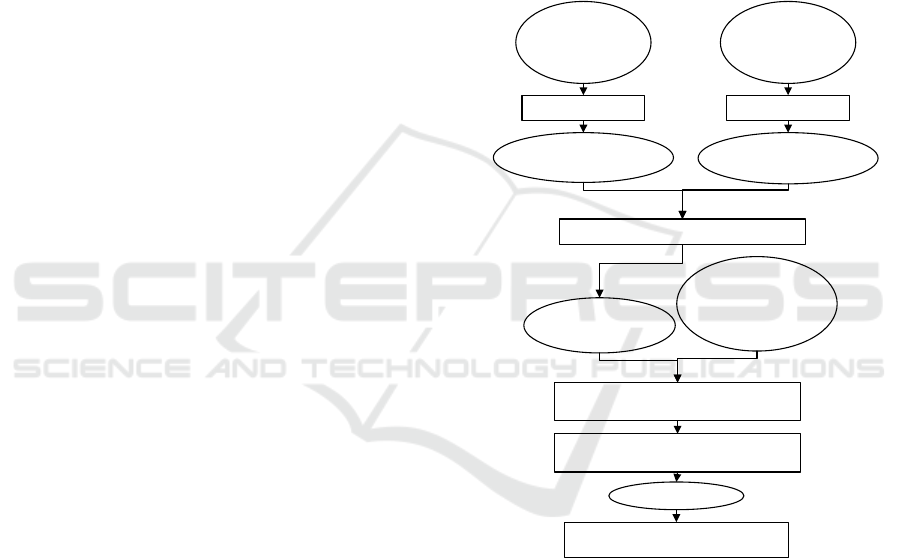

emulsion can be seen in Figure 1.

W₁/O Emulsion

Outer Aqueous

Phase (W₂)

• WPC-Pectin

• Tween 80

W₁/O/W₂

Storage T = 25° C t = 14 Days

80%20%

Homogenizer 2 minutes

Aqua Deminerals

Vitamin C

MgSO₄

Soybean Oil

Span 65

Homogenization

70%

30%

Mixing Mixing

Inner Aqueous

Phase (W₁)

Intermediate Oil

Phase (O)

Ultrasound 10 minutes

Figure 1: Preparation of Double Emulsion.

2.2.4 Particle Size Measurement

The particle size of droplet was analyzed with particle size

analyzer (Beckman Coulter LS 13 320, Beckman Coulter,

Inc. US). Particle size was measured for the fresh emulsion

immediately after preparation (H0), Days 7 (H7) and after

14 Days (H14) storage at 25℃.

2.2.5 Creaming Index Measurment

Measurement of the creaming index by calculating the

height of the cream formed divided by the height of the

sample. The creaming index measurement was carried out

every 4 days for 14 days at 25℃ then the creaming index

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

48

percentage was calculated using the formula:

𝐶𝐼 = (

ℎ

ℎ

) × 100%

CI = Creaming Index (%)

h

0

= Cream Height

h

1

= Sample Height

2.2.6 Morphology Particle of W

1

/O/W

2

Morphology particle of W/O/W emulsions were made by

Transmission Electronic Microscope (Jeol, Japan) after 14

days of storage.

3 RESULT AND DISCUSSION

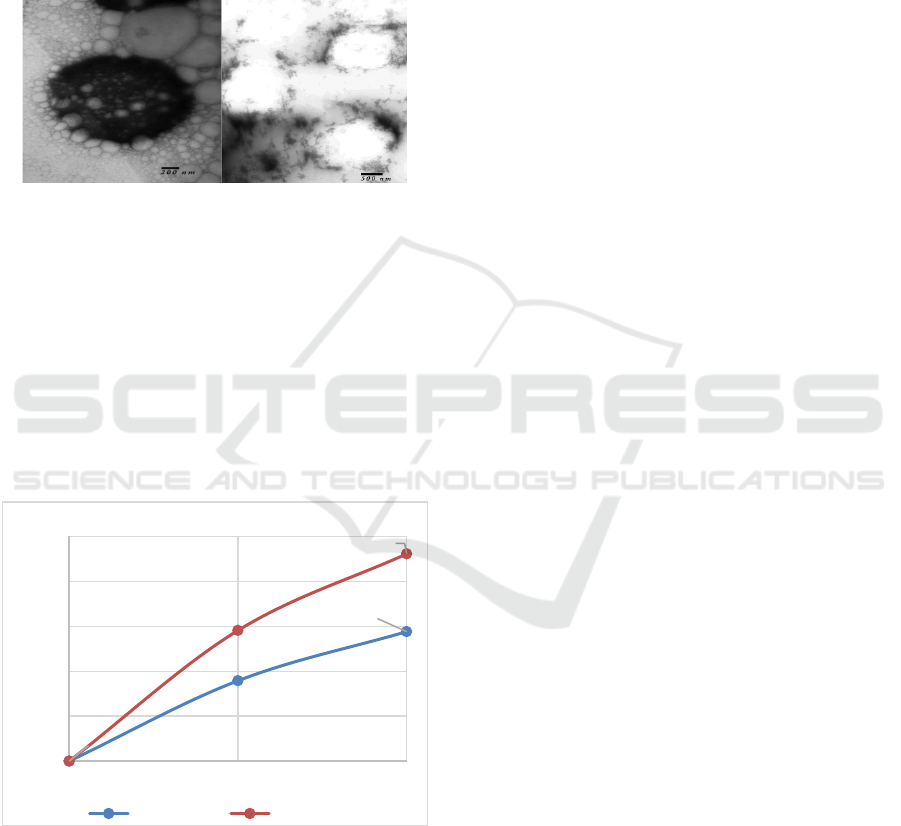

Particle size of the emulsion with tween 80 increased

after storage for 7 and 14 days. Emulsion with

biopolymer solution has a bigger droplet compare to

tween 80. Emulsion with biopolymer solution start

from 1.34 μm and tween 80 start from 0.91 μm.

According to Gharehbeglou et al., (2019) WPC and

Pectin have larger droplet sizes due to interactions

between the WPC and pectin forming a massive

complex and trapped the oil phased inside it.

Particle size was increased significantly in the

emulsion with WPC-Pectin than tween 80. Figure 2

shows droplet size of both emulsions increased on the

7th day, on the 14th day, only the droplet of emulsion

with tween 80 increased by 1.15 μm while the

emulsion with WPC Pectin decreased from 1.32 μm

to 0.87 μm. The decrease in droplet emulsion in

Figure 2 can occur due to the broken of the W

1

/O

emulsion in the W

1

/O/W

2

emulsion so it changes into

an O/W.

Figure 2: Particle Size of W

1

/O/W

2

Emulsion Vitamin C.

Increasing the size of the droplet emulsion causes

the emulsion system to become unstable. Research

from Mohammadi et al., (2016) states that the large

size of the emulsion droplet with the WPC Pectin

emulsifier because of the addition of WPC and Pectin

together causing the thickening of the biopolymer

compound around the W/O emulsion, thereby

increasing the size of the WPC and Pectin droplet

emulsion and reduce the stability of the emulsifier

proving by cream formed.

Another thing that enlarging the droplet size of the

emulsion and causes the W/OW emulsion system to

be unstable is the coalescence process of the W/O

emulsion during storage. According to Chung and

Mcclements (2018), coalescence causes the emulsion

droplet fuse into a larger droplet resulting the increase

of droplet size during storage. This is also supported

by Schuch et al., (2014) where the emulsifier

concentration also affects the stability of the emulsion

system formed. If the concentration of the emulsifier

are less, the emulsifier is not able to bind the water

completely, causing the water molecules to fuse and

coalescence occurs so the droplet enlarges. Other

studies that support coalescence as a cause of

increasing droplet size and as a sign of instability of

the emulsion system were carried out by (Vicente et

al., 2018). Coalescence occurs because the lack of

hydrocolloid compounds as a stabilizer for

emulsifiers can initiate the Brownian motion on the

droplet emulsion.

Brownian motion is random motion that occurs in

droplets. When the emulsion system is stable,

brownian motion will maintain the distribution of

dissolved phase droplets evenly throughout the

solvent phase (Dickinson, 2010). If the emulsion is

not stable, there will be a tendency for droplets to

separate from each other because they have different

densities so the brownian motion can no longer move

evenly. If the density of the droplet is small, the

brownian motion will make the droplet emulsion

move towards the solution whereas if the density of

the droplet is large, then the brownian motion will

make the droplet move downward (Zhang &

Mcclements, 2018).

Based on the results in figure 3, W

1

/O/W

2

Emulsion with Tween 80 as the outer phase

emulsifier are better than with WPC Pectin as the

outer phase emulsifier. Figure 3 (a) can be described

as W

1

/O/W

2

emulsion when the dark phase are oil and

bubble phases inside the dark one are the water phase

(W

1

) and the white phase around the dark are the W

2

.

This is supported by Mainz (2006) that the dark

particle are made from mass thickness contrast

method depends on mass weight of the particle that

0,91

1,07

1,15

1,34

1,32

0,87

0,80

0,90

1,00

1,10

1,20

1,30

1,40

0714

Droplet Emulsion size (µm)

Storage Day

Tween 80 WPC Pektin

Preparation of Double Emulsion of Vitamin C with Two Different Emulsifiers in the Outer Aqueous Phase

49

used. Figure 3 (b) cannot be described as W

1

/O/W

2

emulsion because there is no dark phase between the

light phase like figure 3 (a). it means that WPC-Pectin

cannot be outer phase emulsifier. This phenomena

happens because the amplitude from sonication

process doesn’t match with WPC-Pectin as a

emulsifier, if the amplitude is high, then proteins that

contained in WPC-Pectin are denaturized (Hubinger,

2018).

Figure 3: Morphology of Double Emulsio with Tween 80

(Left) and WPC-Pectin (Right).

Based on the experimental results, the WPC

Pectin emulsifier cannot be used as an emulsifier for

the W

1

/O/W

2

vitamin C emulsion system. The

increase in the creaming index value is more

significant in the WPC Pectin emulsifier compared to

the Tween 80 emulsifier based on the curves in Figure

4. The higher creaming index value indicates that the

emulsion system formed is increasingly unstable.

Tween 80 emulsifier has better stability than the

Pectin WPC emulsifier with the same concentration.

Figure 4: Creaming Index of W/O/W Vitamin C.

The high value of the creaming index on the WPC

Pectin emulsifier can be caused by flocculation of the

formed emulsion system compo

nents. This is supported

by Khalid, Kobayashi, Neves, Uemura, & Nakajima, (2013)

who stated that the speed of creaming is influenced

by the flocculation that occurs in the W

1

/O emulsion

system components. The occurrence of flocculation

can be due to the droplet aggregation process, thereby

accelerating the process of creaming (Schmidts, Dobler,

Nissing, & Runkel, 2009). According to Dickinson (2010),

the flocculation process is the process that most influences

the creaming of an emulsion system. Flocculation has a big

role because the droplets that have undergone flocculation

move faster than individual droplets in the emulsion

solution. This occurs because the emulsion droplets that

have undergone flocculation are much larger than the intact

emulsion droplets.

Research from Schuch, Helfenritter, Funck, &

Schuchmann, (2014) stated that the instability of the

W

1

/O/W

2

emulsion can be caused by differences in the

surface tension of the emulsifier used. In addition, the

active components that become surfactants in the Pectin

WPC emulsifier can also cause instability of the W

1

/O/W

2

emulsion system that has been formed. According to

Schuch et al., (2014), the instability of an emulsifier using

a protein which is a hydrophilic emulsifier can occur due to

the lack of a stabilizer concentration in the form of a

hydrocolloid compound. Hydrocolloid compounds that can

be used as stabilizers are gum arabic, CMC and pectin.

Pectin has been added to the WPC as a stabilizer but the

small pectin concentration (0.1%) is not able to maintain

the stability of the W

1

/O/W

2

emulsion system.

Based on the results of the experiments conducted, the

tween 80 emulsifier is more stable than the WPC Pectin

emulsifier for the W

1

/O/W

2

emulsion system so that the

tween 80 emulsifier is more suitable for use as a second

emulsifier for vitamin C emulsions.

4 CONCLUSIONS

Emulsion W

1

/O/W

2

Vitamin C with WPC-Pectin as

emulsifier in the outer aqueous phase bigger particle

size 1.34 μm compared with Tween 80 with 0.91 μm

after preparation. Tween 80 as emulsifier was more

stable during storage with little cream formed in the

surface. When the droplet size become bigger, the

stability of the emulsion have been decreased. TEM

Result also showed that the morphology of emulsion

with Tween 80 remained stable as a double emulsion

after storage for 14 days. tween 80 is the best

emulsion to maintain the stability of W

1

/O/W

2

emulsion containing vitamin C.

ACKNOWLEDGEMENTS

This work financially supported by the Directorate

General of Higher Education (Ristek Dikti) of the

Ministry of Education and Culture Republic of

Indonesia, under the grant of basic research program.

0

8,94

14,41

0

14,54

23,06

0

5

10

15

20

25

0714

Creaming Index (%)

Storage Days

Tween 80 WPC-Pectin

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

50

REFERENCES

Anton, N., Vandamme, T. F., Ding, S., Yu, W., & Serra, C.

A. (2018). Double emulsions prepared by two–step

emulsification: History, state-of-the-art and

perspective. Journal of Controlled Release, 295

(December 2018), 31–49. https://doi.org/10.1016/j.jcon

rel.2018.12.037

Chung, C., & Mcclements, D. J. (2018). Characterization

of Physicochemical Properties of Nanoemulsions :

Appearance , Stability , and Rheology. Nanoemulsions.

Elsevier Inc. https://doi.org/10.1016/B978-0-12-

811838-2.00017-5

Dickinson, E. (2010). Hydrocolloids and emulsion stability.

Handbook of hydrocolloids. Woodhead Publishing

Limited. https://doi.org/10.1533/9781845695873.23

Gharehbeglou, P., Mahdi, S., Hamishekar, H., &

Homayouni, A. (2019). Pectin-whey protein complexes

vs . small molecule surfactants for stabilization of

double nano-emulsions as novel bioactive delivery

systems. Journal of Food Engineering, 245(October

2018), 139–148. https://doi.org/10.1016/j.jfoodeng.20

18.10.016

Gregory, J. F. (2017). Vitamins. Fennema’s Food

Chemistry. Elsevier Inc. https://doi.org/10.1201/9781

315372914

Khalid, N., Kobayashi, I., Neves, M. A., Uemura, K., &

Nakajima, M. (2013). Preparation and Characterization

of Water-in-Oil-in-Water Emulsions Containing a High

Concentration of L-Ascorbic Acid. Bioscience,

Biotechnology and Biochemistry, 77(6), 1171–1178.

https://doi.org/10.1271/bbb.120870

Levine, M., Katz, A., Padayatty, S. J., Wang, Y., Eck, P.,

Kwon, O., Lee, J. H. (2004). Vitamin C. Encyclopedia

of Dietary Supplements, 745–755. https://doi.org/

10.1081/E-EDS-120022052

Mohammadi, A., Jafari, S. M., Esfanjani, A. F., &

Akhavan, S. (2016). Application of nano-encapsulated

olive leaf extract in controlling the oxidative stability of

soybean oil. FOOD CHEMISTRY, 190, 513–519.

https://doi.org/10.1016/j.foodchem.2015.05.115

Schmidts, T., Dobler, D., Nissing, C., & Runkel, F. (2009).

Journal of Colloid and Interface Science Influence of

hydrophilic surfactants on the properties of multiple W

/ O / W emulsions. Journal of Colloid And Interface

Science, 338(1), 184–192. https://doi.org/10.1016/

j.jcis.2009.06.033

Schuch, A., Helfenritter, C., Funck, M., & Schuchmann, H.

P. (2014). emulsions. Colloids and Surfaces A:

Physicochemical and Engineering Aspects.

https://doi.org/10.1016/j.colsurfa.2014.06.012

Vicente, J., José, L., Pereira, B., Pinto, L., Bastos, H.,

Carvalho, M. G. De, & Garcia-rojas, E. E. (2018).

Effect of xanthan gum or pectin addition on Sacha Inchi

oil-in-water emulsions stabilized by ovalbumin or

tween 80: Droplet size distribution, rheological

behavior and stability. International Journal of

Biological Macromolecules, #pagerange#.

https://doi.org/10.1016/j.ijbiomac.2018.08.041

Zhang, Z., & Mcclements, D. J. (2018).

Overview of

Nanoemulsion Properties : Stability , Rheology , and

Appearance. Nanoemulsions. Elsevier Inc.

https://doi.org/10.1016/B978-0-12-811838-2.00002-3

Preparation of Double Emulsion of Vitamin C with Two Different Emulsifiers in the Outer Aqueous Phase

51