The Effect of Fermented White Corn Flour and Wheat Flour

Formulation on the Quality of Cookies

Jessica Selvira

1

, Rahmawati Rahmawati

1

, Rijanti Rahaju Maulani

2

, Dase Hunaefi

3

and Dede Saputra

4

1

Study Program of Food Technology, Faculty of Food Techonology and Health, Sahid University, Jakarta, Indonesia

2

Study Program of Post-Harvest Technology, School of Life Science Technology, Institut Teknologi Bandung, Indonesia

3

Departement of Science and Food Technology, Faculty of Agricultural Technology, IPB University, Bogor, Indonesia

4

Departement Food Technology, Bina Nusantara University, Jakarta, Indonesia

Keywords: Fermented White Corn Flour, Wheat Flour, Cookies.

Abstract: Cookies are a type of cookie that is small, crispy, has a sweet taste and can be eaten by all ages. The thing to

consider in cookie processing is crispness. Fermented white corn flour as a result of the Response Surface

Method (RSM) optimization has a setback viscosity value close to wheat flour, so that when used as a raw

material to make cookies, it will increase its crispness. This research aims to study the effect of fermented

white corn flour and wheat flour formulation in cookie making. The formulations ratio of fermented white

corn flour and wheat flour tested were: 0:100; 20:80; 40:60; 60:40; and 80:20. The results showed that the

higher of the formulation of fermented white corn flour, the lower the hardness of cookies, ash content, and

protein content, because the moisture content tends to increase. Based on physical, chemical and organoleptic

tests, the formulation of fermented corn flour and wheat flour (20:80) is a formulation that can be produce

quality cookies. The quality characteristics of the cookie produced are 3462.42 gF texture, 1.47% moisture

content, 2.43% ash content, 7.29% protein content, 24.74% fat content, 64.08% carbohydrate content, and

1.34% crude fiber.

1 INTRODUCTION

Cookies are a type of cookie that is small, crispy, has

a sweet taste, is a popular food product that can be

consume by various consumer segments. According

to National Standardization Agency of Indonesia

(2011), cookies are a type of biscuit made from a soft

dough, crispy and when broken, the texture looks less

dense. Generally cookies are made from wheat flour,

sugar and egg. Cookies can be made by other types of

flour besides wheat flour. The research by Kausar et

al. (2018) showed that cookies with carrot pomace

powder 12% has sensory evaluation of 8,2 crispness

value and 8,4 overall acceptability, it means like very

much by panelists. The research by Alflen et al.

(2016) showed that cookies with taro flour 30% has a

preference level of 6,9 it means like moderately by

panelists. Singh et al. (2008) conducted a study on

sweet potato flour cookies, the best results with sweet

potato flour 40% has crispness value of 3,7 it means

fragile (breaks easily when consumed) and an overall

acceptability of 3,6 which is acceptable to the

panelists.

Another study conducted by Suarni (2005),

substitution wheat flour with 80% corn flour has

crispness value of 2,95 it means rather like by

panelists. The advantage of cookies made from 80%

corn flour has a higher fiber content (3,59%)

compared to cookies made from 100% corn flour

(0,98%) (Suarni, 2009). The research by Purnamasari

(2019) showed that fermented white corn flour as a

result of optimization of the Response Surface

Method (RSM) has the lowest setback viscosity value

among other fermentation treatments, that is 1039,00

cP. The low setback viscosity will increase its

crispness and texture of product not as hard as other

fermentation treatments, so that fermented corn flour

is suitable for use in making cookies. Therefore, the

thing that must be considered when processing

cookies is crispness (Widiantara et al., 2018).

Based on the description above, this research was

carried out on the effect of fermented white corn flour

as a result of optimization of the RSM and wheat flour

formulation in making cookies. The formulation

using fermented white corn flour as a result of

38

Selvira, J., Rahmawati, R., Maulani, R., Hunaefi, D. and Saputra, D.

The Effect of Fermented White Corn Flour and Wheat Flour Formulation on the Quality of Cookies.

DOI: 10.5220/0010513800003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 38-46

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

optimization of the RSM was chosen because it has a

low setback viscosity value.

2 MATERIALS AND METHODS

2.1 Materials

The ingredient used in making of cookies are

fermented white corn flour as a result of the

optimization RSM (Purnamasari, 2019), Kunci Biru

brand flour (8-9% protein content), Blueband

margarine, chicken egg, Dancow brand full cream

milk, sugar, baking soda (NaHCO

3

), and vanilla.

The chemicals used for protein content analysis

include concentrated sulfuric acid (H

2

SO

4

), mercury

oxide (HgO), potassium sulfate solution (K

2

SO

4

),

sodium hydroxide solution (NaOH), sodium

thiosulfate solution (Na

2

SO

3

), saturated boric acid

solution (H

3

BO

3

), hydrochloric acid solution (HCl).

The chemicals used for fat content analysis is hexane.

The chemicals used for crude fiber content analysis is

concentrated sulfuric acid (H

2

SO

4

), etc. The

chemicals used are materials that are in the Chemical

Laboratory of Bogor Agricultural Institute.

2.2 Methods

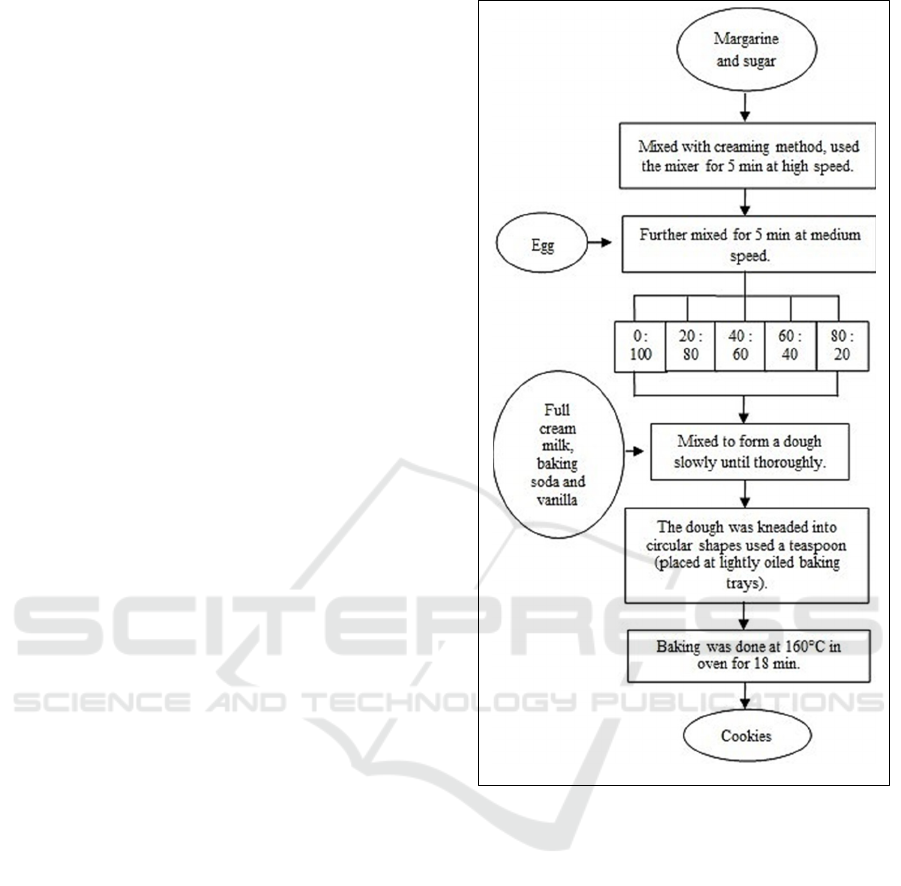

The process of making fermented white corn flour

cookies consists of 3 stages: mixing, molding, and

baking. The flowchart of the process making

fermented white corn flour cookies can be seen in

Figure 1.

2.2.1 Mixing

The first mixing are margarine and sugar, used the

mixer at high speed for 5 minutes until homogeneous

and creamy. After that, the second mixing with

addition of 1 egg and mixed at medium speed for 5

minutes.

The third stage of mixing is the addition of

fermented white corn flour and wheat flour

(formulation 0:100; 20:80; 40:60; 60:40; and 80:20),

full cream milk, baking soda, and vanilla, mixed to

form a dough slowly until thoroughly and can be

molded. The quantity of materials used can be seen in

Table 1.

Figure 1: Flowchart of making fermented white corn flour

cookies (modified) (Okpala & Ofoedu, 2018).

2.2.2 Molding

Molding was done by used the drop cookies method,

the dough was kneaded into circular shapes used a

teaspoon and then placed at lightly oiled baking trays.

2.2.3 Baking

The main purpose of the baking process is to improve

the quality of food (quality eating) of the raw

materials, as well as to add variety to foods. Cookies

that have been molded and placed at lightly oiled

baking trays are baked in the oven at 160°C for 18

minutes.

The Effect of Fermented White Corn Flour and Wheat Flour Formulation on the Quality of Cookies

39

Table 1: Composition of raw materials in the production of

fermented white corn flour cookies.

Raw Materials Quantit

y

(g) %

J : T 130,00 40,37

Suga

r

70,00 21,74

Mar

g

arine 63,00 19,57

Full cream

p

owdered mil

k

13,00 4,04

Baking soda 4,00 1,24

Vanilla 2,00 0,62

E

gg

40,00 12,42

Total 322,00 100,00

Note: J = Fermented white corn flour; T : Wheat flour

2.2.4 Testing Techniques

Quality testing of cookies was done through physical

quality (hardness) used a Texture Analyzer XT21

Stable Micro System, quality chemical include

moisture content with oven method (AOAC, 2006),

ash content with furnace method (AOAC, 2006),

protein content with Kjedahl method (AOAC, 2006),

fat content with soxhlet method (AOAC, 2006),

carbohydrate content (by difference) and crude fiber

content (SNI 01-2891-1992); organoleptic quality

(hedonic quality for color, aroma, taste and crispness;

and test ranking based on the overall level of

preference) (Permadi, et al., 2018 and

Ebookpangan.com, 2006).

3 RESULT AND DISCUSSION

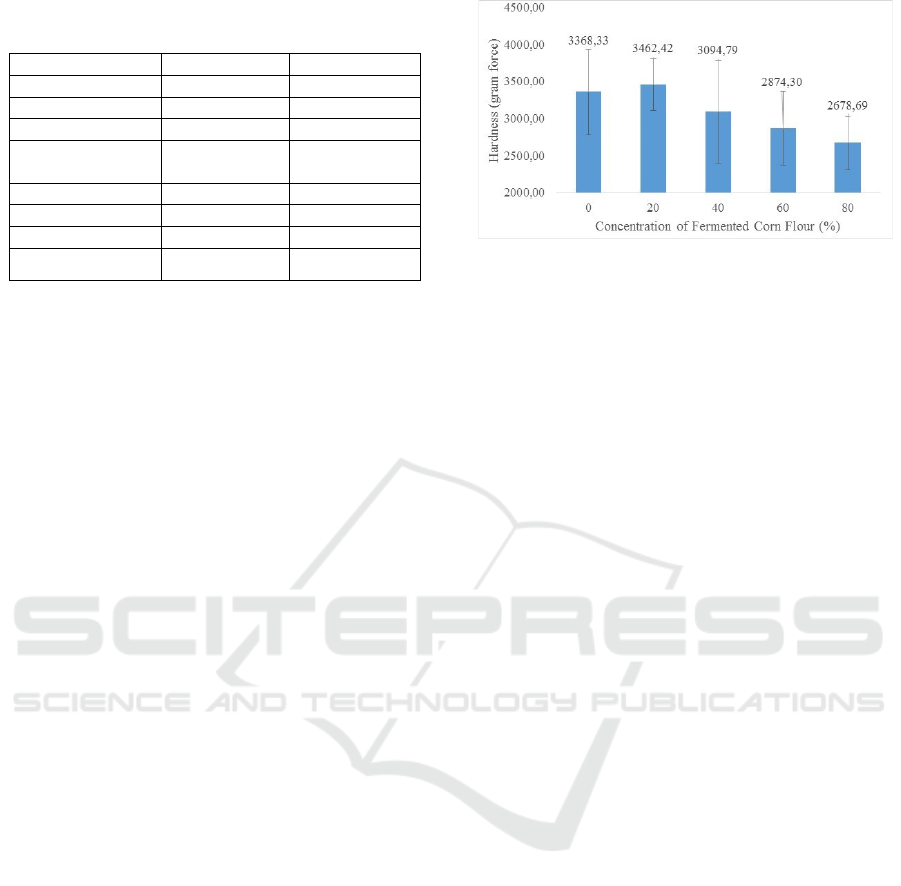

3.1 Texture Physical Quality

(Hardness)

Hardness of cookies were tested used a Texture

Analyzer XT21 Stable Micro System. Hardness value

of cookies (gF) decrease along with the increase in

the substitution concentration of fermented corn

flour. The results of the analysis of variance showed

that the different formulations of fermented corn flour

and wheat flour did not significantly affect the

hardness value of cookies. The graph of average

hardness of cookies is presented in Figure 2.

Figure 2: The graph of average hardness (gf) cookies.

The smaller the value obtained, the softer the

texture of the cookies. The greater the value obtained,

the greater the hardness, meaning the texture of the

cookie is getting drier and crispy. Hardness value of

cookies with fermented corn flour substitution

highest in the treatment with a concentration of 20%

i.e 3462,42 gF and the lowest in the treatment with

fermented corn flour concentration of 80% i.e

2678,69 gF. This shows that the smaller the

composition of fermented corn flour to 20% can

increase the crispness of the cookies. According to

Wulandari et al. (2016), the moisture content, fat

content, carbohydrate, protein and all the ingredients

used can determine the texture of the cookies.

3.2 Chemical Quality

3.2.1 Moisture Content

The moisture content in a food item affects the

freshness and durability of food. Moisture content

also affects physical properties such as hardness. The

higher moisture content causes the cookies to be less

crispy (Widiantara et al., 2018). The moisture content

of cookies with fermented corn flour substitution is

highest in treatment with a concentration of 40% i.e

2,13% and the lowest in treatment with a

concentration of 20% i.e 1,47%. The moisture content

of cookies in this research fulfills the SNI 2973:2011

requirements, i.e maksimum of 5%. The graph of

average moistue content of cookies can be seen in

Figure 3.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

40

Figure 3: The graph of average moisture content of cookies.

Based on the graph, it can be seen that the

moisture content of cookies with fermented corn flour

concentration of 40, 60 and 80% tend higher than

cookies without fermented corn flour, although there

is no significant difference. The lowest the moisture

content, the higher of the hardness of cookies, it

makes the texture becomes crispy.

This is in accordance with the treatment with a

concentration of fermented corn flour of 20% which

indicates the lowest moisture content has the highest

hardness value. Cookies absorb water from the

surrounding air due to the hygroscopic nature of

wheat flour (Kausar et al., 2018).

3.2.2 Ash Content

The amount of minerals in the ingredients used in

making cookies will affect of the ash content value

(Wulandari et al., 2016)

.

The higher the mineral

content, the higher of the ash content value obtained.

The ash content of cookies with fermented corn flour

substitution is highest in treatment with a

concentration of 20% i.e 2,43% and the lowest in

treatment with a concentration of 80% i.e 2,25%. The

graph of average ash content of cookies can be seen

in Figure 4.

Figure 4: The graph of average ash content of cookies.

Based on the graph, it can be seen that the ash

content of cookies decrease with the increase in the

substitution concentration of fermented corn flour.

However, the results of the analysis of variance

showed that the different formulations of fermented

corn flour and wheat flour did not significantly affect

the ash content of cookies.

3.2.3 Protein Content

The protein in cookies is influenced by the

composition of the constituent ingredients, especially

the flour used because in this research the

composition of the flour used is different. Wheat flour

used is a type of low protein flour (8-9%) and the

fermented corn flour used has a protein content of

6,90%. So that by increasing the concentration of

fermented corn flour substitution will reduce the

protein content of cookies.

Protein content of cookies with fermented corn

flour substitution is highest in treatment with a

concentration of 0% and 20% i.e 7,29% and the

lowest in treatment with a concentration of 80% i.e

6,30%. Protein content of cookies in this research

fulfills the SNI 2973:2011 requirements, i.e minimum

of 5%. Graph of average protein content (%) cookies

can be seen in Figure 5.

Based on the graph, it can be seen that the higher

the concentration of fermented corn flour, the lower

the protein content, although the results of the

analysis of variance showed that the different

formulations of fermented corn flour and wheat flour

did not significantly affect the value of the protein

content of cookies. From the results of his research,

(Suarni, 2005) reported that the higher the

concentration of corn flour, the lower the portein

content in cookies.

Figure 5: The graph of average protein content of cookies.

3.2.4 Fat Content

Fat can improve the physical structure of cookies,

such as development, tenderness, texture, and aroma.

The Effect of Fermented White Corn Flour and Wheat Flour Formulation on the Quality of Cookies

41

Based on the results of analysis of variance, the

different formulations of fermented corn flour and

wheat flour did not significantly affect the fat content

of cookies. The graph of average fat content of

cookies can be seen in Figure 6.

Figure 6: The graph of average fat content of cookies.

Based on the graph, it can be seen that the fat

content of cookies tends to fluctuate. Even so, the fat

content of cookies with the substitution of fermented

corn flour with a concentration of 60% tends to show

the highest value i.e 25,24% and the lowest at a

concnetration of 40% i.e 22,54%. According to

Wulandari et al. (2016), the fat content of cookies is

influenced by the addition of margarine and egg.

Margarine contains lipids that are bound as

lipoprotein and cause cookies to have a high fat

content when added with margarine. The results of

research Suarni (2005) showed that the fat content of

cookies was higher along with the increasing

concentration of corn flour substitution.

3.2.5 Carbohydrate Content

Carbohydrate can determining the characteristic of

food ingredients such as color, because carbohydrate

contain reducing sugars which when reacting to the

amino groups of the protein cause a non-enzymatic

browning reaction (Wulandari et al., 2016).

Carbohydrate are also a major source of calories. The

results of analysis of variance showed that the

different formulations of fermented corn flour and

wheat flour did not significantly affect the

carbohydrate content of cookies. The graph of

average carbohydrate content of cookies can be seen

in Figure 7.

Figure 7: The graph of average carbohydrate content of

cookies.

Based on the graph, it can be seen that the

carbohydrate content of cookies tends to fluctuate.

The carbohydrate content of cookies with fermented

corn flour substitution tends to have the highest value

in the treatment with a concentration of 40% i.e

65,88% and the lowest at a concentration of 60% i.e

63,61%.

The results of this research indicate that cookies

with the highest carbohydrate content (65,88%) at

40% fermented corn flour concentration has the

lowest fat content (22,54%) and cookies with the

lowest carbohydrate content (63,61%) at 60%

fermented corn flour concentration has the highest fat

content (25,24%). The carbohydrate content is

calculated by difference and is influenced by the

water, ash, protein and fat content . Wulandari et al.

(2016) states that the higher component of other

nutrients (water, ash, protein and fat) then

carbohydrates content decreases.

3.2.6 Crude Fiber Content

Crude fiber is needed by the body because it is good

for digestion. Crude fiber can prevent constipation

(difficulty defecating), so cookies with high crude

fiber contentare good for the body (Wulandari et al.,

2016). The results of analysis of variance showed that

the different formulations of fermented corn flour and

wheat flour did not significantly affect the crude fiber

content of cookies. The graph of average crude fiber

content of cookies can be seen in Figure 8.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

42

Figure 8: The graph of average crude fiber content of

cookies.

Based on the graph, it can be seen that the value

of crude fiber of cookies with fermented corn flour

substitution of 20%, 40%, 60% and 80% tends to be

higher than cookies without fermented corn flour.

Crude fiber of cookies with fermented corn flour

substitution is highest in a treatment with a

concentration of 40% i.e 1,63% and the lowest at a

concentration of 0% i.e 1,02%. A similar trend was

observed by Suarni (2005) which states that corn

flour based cookies has a higher crude fiber than

cookies made from 100% wheat flour.

3.3 Organoleptic Quality

The organoleptic quality of cookies was determined

based on the hedonic quality test assesment and

ranking test with 25 semi-trained panelists. In the

hedonic quality test, the panelists expressed an

impression of good or bad about the product. In the

ranking test, panelists were asked to measure the

preference level of overall product. The parameters

used were color, aroma, taste and crispness. The

results of analysis of variance showed that the

different formulations of fermented corn flour and

wheat flour did not significantly affect the

organoleptic quality of cookies. The results of the

organoleptic quality analysis are shown in Table 2.

3.3.1 Color

The color produced by cookies is influenced by a non-

enzimatic browning reaction (Maillard reaction)

which is caused by a reaction between sugars and

amino groups of protein during the baking process

(Wulandari et al., 2016). The results of the hedonic

quality test of color parameters (Table 2), the

different formulations of fermented corn flour and

wheat flour showed a color scale ranged from 2,84 –

4,68 (light brown – brownish yellow).

There is a tendency that the higher the

concentration of fermented corn flour substitution,

the higher the assessment of the cookies color scale,

it means that the cookies produced has a yellowish

brown color. The color hedonic quality test of cookies

with fermented corn flour substitution is highest in

treatment with a concentration of 20% i.e 4,21

(yellowish brown) and the lowest in treatment

without fermented corn flour i.e 3,28 (light brown).

3.3.2 Aroma

The aroma parameter tested is the strength of the corn

aroma that still smells on the cookies produced. The

hedonic quality test of cookies aroma ranged from

3,08 – 3,64 (strong slightly – not strong) (Table 2).

The aroma of the cookies was determined by the

ingredients used in the cookies.

According to Suarni (2009), the aroma of the

cookies is influenced by the components of the

ingredients used and their comparisons, such as

margarine, egg, additives, and types of flour. So that

the different formulations of fermented corn flour and

wheat flour will affect the aroma of the cookies

produced.

This is confirmed by Sitohang et al. (2015) which

states that mixing margarine and egg can cause a

distinctive smell of dough and the baking process also

affect the aroma of cookies. The results of aroma

hedonic quality test showed a tendency that the higher

Table 2: Panelist preferences value for color, aroma, taste and crispness of cookies with different formulation of fermented

corn flour and wheat flour.

Formulation of fermented

corn flour and wheat flour

Hedonic Quality Scale

Color Aroma Taste Crispness

0 : 100 3,28±0,6 3,40±0,1 3,45±0,2 4,12±0,5

20 : 80 4,21±0,4 3,40±0,2 3,45±0,1 3,85±0,7

40 : 60 4,20±0,1 3,35±0,3 3,24±0,2 2,75±0,4

60 : 80 3,89±0,6 3,31±0,1 3,25±0,4 3,43±0,2

80 : 20 4,12±0,4 3,23±0,2 2,91±0,2 2,76±0,8

Notes:

Color Scale: 1 = blackish brown, 2 = brown, 3 = light brown, 4 = yellowish brown, 5 = brownish yellow.

Aroma and Taste Scale: 1 = very strong, 2 = strong, 3 = strong slightly, 4 = not strong, 5 = very not strong.

Crispness Scale: 1 = very not crispy, 2 = not crispy, 3 = crispy slightly, 4 = crispy, 5 = very crispy.

The Effect of Fermented White Corn Flour and Wheat Flour Formulation on the Quality of Cookies

43

substitution concentration of fermented flour, the less

aroma of cookies, it means that the cookies produced

has a strong slightly corn aroma.

The aroma hedonic quality test of cookies with

fermented corn flour substitution is highest in

treatment with a concentration of 0% and 20% i.e

3,40 and the lowest in treatment with a concentration

of 80% i.e 3,23 has the same aroma, that is strong

slightly. This is because the strong aroma of

fermented corn flour has been mixed with other

ingredients used, so the aroma of corn in the cookies

produced is not too strong.

3.3.3 Taste

The taste parameter tested on the panelists is the

strength of the taste corn on the cookies produced.

The taste hedonic quality test of cookies ranged from

2,80 – 3,64 (strong slightly – not strong) (Table 2).

The result of research by Suarni (2005) showed that

the higher substitution concentration of fermented

corn flour, the taste of the cookies produced was like

slightly by the panelists. This is because the taste of

the corn in the cookies can still be felt by the panelists.

The results of taste hedonic quality test showed a

tendency that the higher the substitution

concentration of fermented corn flour, the taste of

cookies will decrease, it means that the cookies

produced has a strong slightly corn taste. The taste

hedonic quality test of cookies with fermented corn

flour substitution is highest in treatment with a

concentration of 0% and 20% i.e 3,45 and the lowest

in treatment with a concentration of 80% i.e 2,91 has

the same taste, that is strong slightly.

3.3.4 Crispness

The crispness hedonic quality test of cookies ranged

from 2,12 – 4,56 (not crispy – crispy). The crispness

of the cookies is influenced by the wheat flour and

fermented corn flour use. Both of the flours contain

low protein. The lower the protein value, the

crispness will decrease. A similar tren was observed

by Wulandari et al. (2016) which states that the

crispness of substitution 30% breadfruit flour to

cookies is not crispy because breadfruit flour contains

a small amount of protein.

The results of crispness hedonic quality test

showed a tendency that at concentration of fermented

corn flour of 0% and 20% cookies are crispy at

concentration of 40%, 60% and 80% cookies are

crispy slightly. Moisture content also affects the

crispness of cookies.

The test results showed that the higher the

substitution concentration of fermented corn flour,

the hardness value of cookies decreases, the moisture

content tends to increase and the crispness hedonic

quality decreases (not crispy). This is in line with the

results of physical tests (texture) and chemical test

(moisture content) that have been conducted.

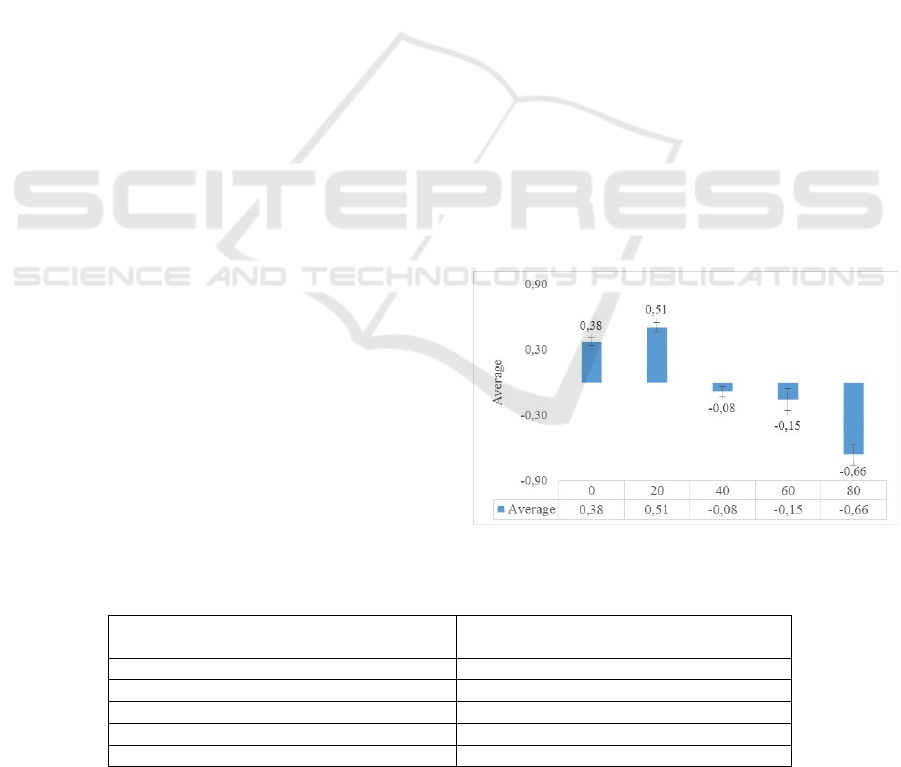

3.3.5 Ranking Test

The ranking test are performed based on overall

liking level. Panelists evaluate the sample from

number 1 the most preferred to number 5 the most

dislike. From the result, the sequence is converted

into Fischer and Yates table scores. The results of the

cookies ranking test in the treatment with fermented

corn flour concentrations of 0% and 20% obtained

positive values, while the concentrations of 40%,

60% and 80% obtained negative values. The results

of the ranking test are shown in Figure 9.

Figure 9: The graph of average of ranking test.

Table 3: Significance of the overall preference of fermented corn flour cookies.

Formulation of fermented corn flour and

wheat flou

r

Score of Average Ranking Test (*)

0 : 100 0,3800±0,0

b

20 : 80 0,5100±0,0

a

40 : 60 -0,0800±0,0

c

60 : 40 -0,1533±0,1

c

80 : 20 -0,6567±0,1

d

Note: *) Mean numbers followed by different letters indicate significant difference according

to the DMRT test at α = 0,05.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

44

Based on the graph, it can be seen that the higher

the substitution concentration of fermented corn

flour, the lower the level of panelists preference for

overall cookies. The results of analysis of variance

showed that the different formulations of fermented

corn flour and wheat flour have a significantly affect

on the panelist assessment of the overall cookie

produced. The significance of differences is shown in

Table 3.

The data in Table 3 showed that the substitution

concentration of 80% fermented corn flour (80:20)

resulted in a lower panelists assessment and were

significantly different from other treatments. This is

because the higher the substitution concentration of

fermented corn flour, the physical test value of the

texture hardness of cookies decreases (the cookies is

softer) in line with the organoleptic quality of

crispness hedonic decreases (not crispy).

Thus, the panelists evaluated the overall dislike

along with the increased concentration of fermented

corn flour substitution. The result of ranking test

showed that the panelists liked the cookies with the

formulation of fermented corn flour and wheat flour

20:80).

4 CONCLUSION

From the results of the research it can be concluded

that different formualtions of fermented corn flour

and wheat flour did not significantly affect on the

parameters of physical quality of texture (hardness),

chemical quality (moisture, ash, protein, fat,

carbohydrate, and crude fiber content) and hedonic

quality (color, aroma, taste and crispness), but

significantly affect in the overall liking level

parameter.

Based on physical, chemical and oragnoleptic

tests, the formulation of fermented corn flour and

wheat flour (20:80) is a formulation that can be

produce quality cookies with the charachteristics:

hardness value 3462,42 gF; moisture content 1,47%;

ash content 2,43%; protein content 7,29%; fat content

24,74%; carbohydrate content 64,08%; crude fiber

content 1,34%. Based on the organoleptic tests, the

color is yeloowish brown, the aroma and taste of corn

is strong slightly and the texture is crispy.

ACKNOWLEDGEMENT

The authors are thankful to Ministry of Research and

Technology and Higher Education Republic of

Indonesia for research funding through the Primary

Reseacrh of Higher Education Program in 2019.

REFERENCES

Alflen, T. A., Quast, E., Bertan, L. C., and Bainy, E. M.

2016. Partial Substitution of Wheat Flour with Taro

(Colocasia esculenta) Flour on Cookie Quality. Revista

Ciencias Exatas e Naturais, 18(2): 202-212.

Association of Official Analytical Chemist. 2006. Official

Methods of Analysis of The Association of Analytical

Chemist. Washington DC: AOAC Inc.

Ebookpangan.com. 2006. Organoleptic Testing in the Food

Industry. Food Technology, Muhammadiyah

University, Semarang. http://tekpan.unimus.ac.id/wp-

content/uploads/2013/07/Pengujian-Organoleptik-

dalam-Industri-Pangan.pdf Accessed 28/6/20.

Kausar, H., Parveen, S., Aziz, M. M., and Saeed, S. 2018.

Production of Carrot Pomace Powder and Its

Utilization in Development of Wheat Flour Cookies.

Journal of Agricultural Research, 56(1): 49-56.

National Standardization Agency of Indonesia. 1992. Food

and Beverages Test. SNI 01-2891-1992.

National Standardization Agency of Indonesia. 2011.

Biscuits. SNI 2973:2011.

Okpala, L. C., and Ofoedu, P. I. 2018. Quality

Characteristics of Cookies Produced From Sweet

Potato and Wheat Flour Blend Fortified with Brewer’s

Spent Grain Flour. Current Research in Nutrition and

Food Science, 6(1): 113-119.

Permadi, M., Oktafa, H. and Agustianto, K. 2018. Design

of Food Sensorical Test System with Testing Preference

Test (Hedonic and Hedonic Quality), Bread Case Study

Tawar, Using Function Network Basis Radial

Algorithm. Mikrotik Journal, 8(1): 29-42.

Purnamasari, W. 2019. Effect of Fermentation Duration

and Amilolytic Culture Addition to Corn Flour Quality.

[Skripsi]. Sahid University, Jakarta.

Singh, S., Riar, C. S., and Saxena, D. C. 2008. Effect of

Incorporating Sweetpotato Flour to Wheat Flour on the

Quality Characteristics of Cookies. African Journal of

Food Science, 2: 65-72.

Sitohang, K. A. K., Lubis, Z., and Lubis, L. M. 2015. The

Effect of Comparison of Total Wheat Flour and

Breadfruit Flour with Stabilizer Types on the Quality of

Breadfruit Cookies. Journal of Food Engineering and

Agriculture, 3(3): 308-315.

Suarni. 2005. Development of Corn Flour Based Pastry

Products in the Framework of Supporting

Agroindustries. Proceedings of the National Seminar of

the Indonesian Agricultural Engineering Association,

Faculty of Agricultural Technology, Padjadjaran

University, LIPI, Bandung.

Suarni. 2009. Prospects of Using Corn Flour for Cookies.

Journal of Agricultural Research, 28(2): 63-71.

Widiantara, T., Arief, D. Z. and Yuniar E. 2018.

Comparative Study of Koro Sword Bean Flour

(Canavalia ensiformis) with Tapioca Flour and Egg

The Effect of Fermented White Corn Flour and Wheat Flour Formulation on the Quality of Cookies

45

Yolk Concentration on Characteristics of Koro

Cookies. Pasundan Food Technology Journal, 5(2):

146-153.

Wulandari, F., Setiani, B. E. and Susanti, S. 2016. Analysis

of Nutritional Content, Energy Value, and

Organoleptic Test of Rice Flour Cookies with

Breadfruit Flour Substitution. Journal of Food

Technology Applications, 5(3): 107-112.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

46