Deterioration Analysis of Rigid Pavement

using Roadroid based on PCI

Eva Azhra Latifa

1

, Christina Aprilia Heryes

1

, Nuzul Barkah Prihutomo

1

1

Civil Engineering Department, Politeknik Negeri Jakarta, Depok 16424, Indonesia

Keywords: International Roughness Index (IRI), Pavement Condition Index (PCI), Roadroid, Road Deterioration

Abstract: The Indonesian government’s limited funds mandate efficient budget planning based on accurate data.

However, the Central Government (General Directorate of Highways) has no measurable, accurate data on

district roads, which can be used as the basis of evaluating proposals from provincial, regent, and city

administrations. The purpose of this research is to analyze the value of rigid pavement conditions based on

the International Roughness Index (IRI) which was carried out using the Roadroid application. The type of

deterioration is determined based on the Pavement Condition Index (PCI). Data were collected from Jalan

Raya Babelan for 2 km. Assessment of rigid pavement conditions throughout Jalan Raya Babelan using the

IRI and conducted with the Roadroid application produced an IRI value between 6.31 (medium) and 33.81

(heavy deterioration). Road deterioration survey conducted using Pavement Condition Index (PCI) shows

several types of road deterioration, such as broken corners, split slabs, damaged joint mantles, sloping

roadsides, linear cracking, slippery aggregate, pop-outs, punch-outs, bent corners, and bent joints.

Circumstantial assessment utilizing the Pavement Condition Index (PCI) method produces PCI values in the

range of 0 (failed) to 22 (severe). Both methods demonstrate that Jalan Raya Babelan needs to be included

minor reconstruction program. Deteriorations need to be repaired by renewing the pavement layer. Actions

taken to repair deteriorations include sealing cracks, partial as well as full-scale depth patching, reconstructing

or replacing slabs, resealing joints, smoothing flows, and reinforcing layers.

1 INTRODUCTION

Road maintenance is a series of strategic, technical

and operational decisions (Langevin,2016). Road

maintenance requires high costs, but it must still be

done by paying attention to relevant department

maintenance policies, material resources, competent

and experienced human resources, and appropriate

technology (Purboyo, H et al, 2017, Hadjidemetrieou,

2019, Siswanto et al., 2019). Road maintenance is

also a fulfillment of road user comfort requirements

(Yasuda, et al, 2018). The assessment of road

pavement conditions is an important aspect of

determining maintenance activities for road

improvement. In assessing pavement conditions the

first is to determine the type of deterioration, density

and severity (Setianingsih et al., 2017). Road

geometry, uneven surfaces, driving behavior, vehicle

characteristics, weather, also affect (Stachova, 2017,

Vignisdottir, et al, 2018, 2019, Yin, et al, 2020, Shi,

2018). Road maintenance management is needed that

takes all of these (Jokanovic, 2019, Thankgod, 2019).

The Ministry of PUPR's 2020-2024 Strategic Plan

data shows that there are 47,000 km of national roads

in active maintenance; 3,200 km with increased

capacity; and 3,800 km of new roads under

construction. The construction and maintenance of

national roads as of the end of 2019 increased stability

to 92.81% and accessibility to 87%. National roads

cost around 40 trillion rupiahs to operate. However,

only 22 km of regional roads are handled with a

budget of 10 billion rupiahs.

Indonesian government’s limited funds issue

requires optimization of budgeting based on accurate

data. On the other hand, the Central Government

(General Directorate of Highways) does not have

measurable and accurate data about the regency

roads, which can be used as the basis of evaluating

the Province/ Regency /City Governments’ proposal

(Rudjito et al., 2017).

Based on the background, this study was

conducted to analyze the rigid pavement condition of

Jalan Raya Babelan located in Bekasi Regency. The

analysis is based on International Roughness Index

Latifa, E., Heryes, C. and Prihutomo, N.

Deterioration Analysis of Rigid Pavement using Roadroid based on PCI.

DOI: 10.5220/0010510100003153

In Proceedings of the 9th Annual Southeast Asian International Seminar (ASAIS 2020), pages 31-36

ISBN: 978-989-758-518-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

31

(IRI) using Roadroid application. Types of

deterioration were analyzed based on the Pavement

Condition Index (PCI). Rigid pavement condition

value and the type of deterioration will later be used

as a reference to determine the appropriate response

to the existing type of deterioration.

1.1 Prior Research

This study refers to previous research that discussed

the assessment and identification of factors that cause

road deterioration, as well as solutions for road

deterioration (Agustyawan and Hartantyo 2016). The

assessment of the functional condition of roads used

the International Roughness Index (IRI) method with

the application of Roadroid, Surface Distress Index

(SDI) and Pavement Condition Index (Tho’atin, dkk

2016). Assessment of road conditions and network

surveys in regions/cities on Java using Roadroid

(Widjajanto, 2017).

Subsequent research to determine the

performance of the road based on the function

obtained from the comparison of IRI values with the

level of road service (V/C ratio) and the physical

condition of the road obtained from the SDI survey

results and then used as a consideration in

determining priorities for handling road rehabilitation

(Achmadi, F, 2017). Evaluates the surface condition

that is deteriorated using the Pavement Condition

Index (PCI) method as well as local factors that

influence the deterioration (Mulyadi and Saleh,

2018).

1.2 Causes of Rigid Pavement Road

Deterioration

Rigid pavement is a construction with aggregate raw

materials and use of cement as a binding material

(Suryawan 2009). Rigid pavement consists of

Portland cement concrete slab which is laid directly

above the subgrade, or land base (Hardiyatmo, 2015).

Deterioration to rigid pavement construction can be

resulted from traffic, which can include increased

load (vehicle axis) that exceeds the design load, and

load repititions (vehicle volumes) that exceeds the

volume of the plan so that the age of the road plan is

not reached (Sukirman, 1999; Direktorat Jendral Bina

Marga 2017). Besides, the poor road drainage system

are predicted to cause water to get into the pavement

structure through cracks, joints, and the road sides,

will damp the soil base and reduce pavement strength,

resulting in rapid deterioration of pavement

(Hardiyatmo, 2015).

The nature of the pavement construction materials

or poor material processing system can also be the

caused this deterioration. Temperatures and

precipitation are generally high, unstable subgrade

conditions, poor soil properties, also, the bending of

the rod straightness or incorrect use of the dowel and

stressing caused by the expansion and shrinkage,

rupture of the corner of the slab, deterioration to

connections, and others conditions caused by reduced

quality due to the strength of the concrete pavement

(Hardiyatmo, 2007)

1.3 International Roughness Index (Iri)

International Roughness Index (IRI) is a parameter

used by the world banks in the process of assessment

of the pavement condition in 1980 (UMTRI. 1998).

Pavement roughness is measured by the longitudinal

profile which is a representation of the comfort of

driving on highways. The roughness quantitative

values are expressed in International Roughness

Index (IRI), which is the cumulative length of the

surface per unit length expressed in meters per

kilometers (Suherman, 2008)

1.4 PAvement Condition Index (PCI)

The PCI value is determined by calculating and

iterating the area and severity of the deterioration.

According to Shahin (1994), there are 17 distress

types to the rigid pavement, among others: blow-

up/buckling, corner breaks/corner cracks, divided

slab, durability "D" cracking, settlement or faulting,

seal joint damage, lane/shoulder drop-off, linear

cracking: longitudinal, transverse, and diagonal

crack, patching and utility cuts, polished aggregate,

popouts, pumping, punch-out, railroad crossing,

scaling, map cracking, crazing, shrinkage cracks, and

spalling. The damage level is expressed as light,

medium and heavy. After that, determine the density,

then determine the deduct value, reduce it, then

correct the deduct value. All of these calculation steps

use different formulas at each stage. PCI value is 100

- correction deduct value.

2 METHOD

2.1 Research Design

The primary data were obtained by site survey, a

survey carried out with a car equipped with Roadroid

application to identify the type of deterioration by

walking along the research site. After collecting the

ASAIS 2020 - Annual Southeast Asian International Seminar

32

primary data, the data were analyzed. Road

deterioration data were analyzed using International

Roughness Index (IRI) method to obtain the value of

rigid pavement conditions and using Pavement

Condition Index (PCI) method to obtain the type of

deterioration.

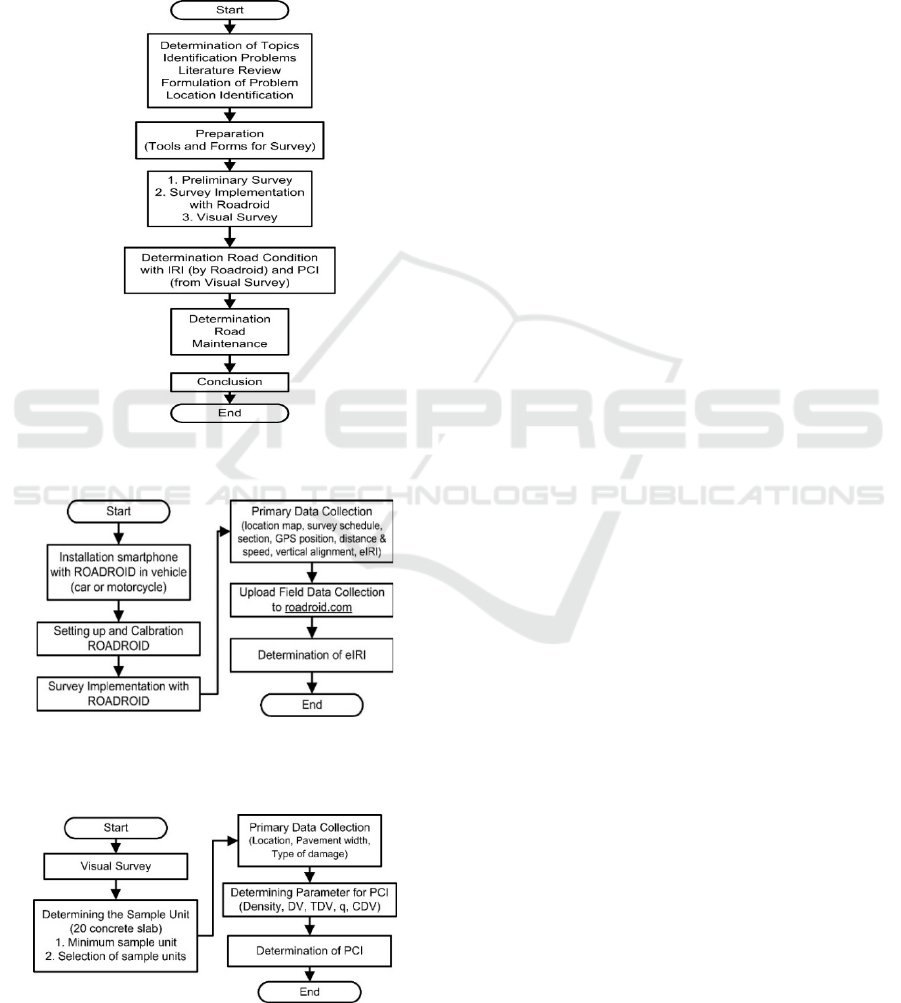

2.2 Research Stage

Figure 1. Flowchart of Survey Implementation with

Roadroid Application

Figure 2. Flowchart of Visual Preliminary Survey

Implementation according to Sample Selection Analysis

Results

Figure 3. Flowchart of Research

2.3 Maintenance Program Type

Determination

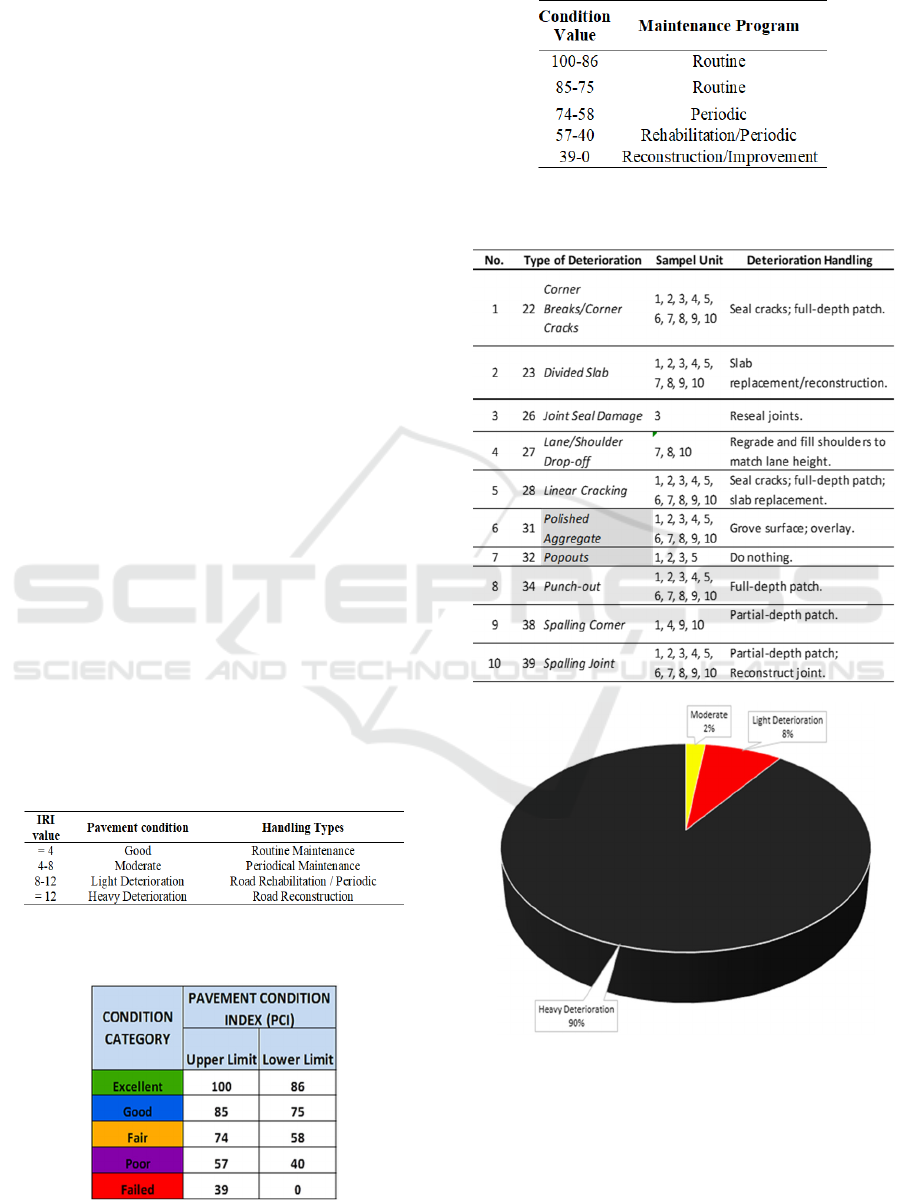

IRI value and maintenance program show in table 1

in appendix, table show PCI value with rigid

pavement condition, and table 3 show the corelation

of PCI value with maintenance program.

3 RESULT AND DISCUSSION

Rigid Pavement Condition Determination and

Maintenance Program

3.1 Using International Roughness

Index (IRI) Method

The results of rigid pavement condition assessment

obtained from the rigid pavement condition survey

results using Roadroid application show below. The

percentage using International Roughness Index (IRI)

method can be seen in Figure 4 appendix.

The data analyzed using IRI method indicated that

values obtained ranged from 6.31 (moderate) to 33.81

(heavy deterioration). At STA 1+500 - 1+520, the

largest IRI value (33.81) indicated the heaviest road

deterioration condition. This stated that most of the

Jalan Raya Babelan requires a minor reconstruction

program, by repairing the deterioration that occurred

in the form of the pavement overlay. Figure 5 and 6

in appendix shows IRI value at STA 1=500-1+520

3.2 Using Pavement Condition Index

(PCI) Method

Based on the analysis of road deterioration, the results

of the rigid pavement conditions value of the

Pavement Condition Index (PCI) method from

sample units 1 to 10 is gathered (see Figure 6). From

the data analyzed using PCI method, obtained

between 0 (failed) - 22 (serious. Sample unit 8 (STA

1+400 - 1+600) has the smallest PCI value of 0, which

stated that the sample unit 8 is on the heaviest

deterioration level. ) This stated that Jalan Raya

Babelan needs to be included in the minor

reconstruction program, by repairing the deterioration

that occurred in the form of the pavement overlay.

The correlation of PCI value and maintenance

program shows in fig.7 in appendix.

According to the two methods applied to the Jalan

Raya Babelan, a comprehensive maintenance

program can be recommended by re-coating the

pavement, commonly referred to as an overlay.

Deterioration Analysis of Rigid Pavement using Roadroid based on PCI

33

3.3 Deterioration Handling

From the research results, detailed deterioration

handling in the road segment can be seen in table 4 in

appendix. However, as described above, for

economical and efficiency, an overlay is a right step.

4 CONCLUSIONS

The results of condition assessment of Jalan Raya

Babelan based on the International Roughness Index

(IRI) and Pavement Condition Index (PCI) using

Roadroid application shown that the value of IRI

obtained between 6.31 (moderate) - 33.81 (heavy

deterioration) which is 90% heavy deterioration

condition.

According to the survey on Jalan Raya Babelan

Sta 0+000 to 2+000 using Pavement Conditions

Index (PCI), there are some types of deterioration

such as (corner breaks/corner cracks), divided slab,

seal joint damage, lane/shoulder drop-off, linear

cracking, polished aggregate, popouts, punch-out,

corner spalling, and joint spalling with high severity.

The deterioration handling that should be done to

the Jalan Raya Babelan are cracks seal, full-depth

patch, slab replacement/reconstruction, reseal joints,

grove surface, overlay and partial-depth patch

corresponding segments.

However, for economical and efficiency most of

the Jalan Raya Babelan needs to be included in the

minor reconstruction program, by repairing the

deterioration that occurred in the form of the

pavement overlay.

REFERENCES

Achmadi, F. (2017). Prioritas Rehabilitasi Jalan di

Kabupaten Karanganyar berdasarkan Metode Penilaian

Kinerja. Tesis Magister Teknik Sipil. Universitas

Sebelas Maret.

Agustyawan, P.E., Hartantyo, S.D. (2016). Identifikasi

Kerusakan Jalan Beton ditinjau dari Jenis

Kerusakannya. Jurnal Civilla. Vol. 1, No. 2, hlm. 1-11.

Departemen Pekerjaan Umum Direktorat Jendral Bina

Marga. (2017). Manual Desain Perkerasan Jalan, No.

02/M/BM/2017. Jakarta

Direktorat Jenderal Bina Marga, (2011). Perbaikan Standar

untuk Pemeliharaan Rutin Jalan, Kementerian Pekerjaan

Umum

Direktorat Jenderal Bina Marga, (2020). Kebijakan &

Implementasi Dukungan Aksesibilitas Pada Simpul-

SimpulTransportasi Darat (Terminal & Pelabuhan

Penyeberangan).

Hadjidemetriou GM, Tsangaris M, Christodoulou S, (2019).

Pavement Condition and traffic Indices for Prioritizing

Road Maintenance, European Conference on

Computing in Construction, Crete, Greece

Hardiyatmo, Hary Christady. (2007). Pemeliharaan Jalan

Raya. Yogyakarta: UGM Press.

Hardiyatmo, Hary Christady. (2015). Perencanaan

Perkerasan Jalan & Penyelidikan Tanah.

http://dpw.lacounty.gov/Pavement Management System)

Jokanovic, Igor, Zeljic, Dana, (2019). Emergency Response

Readiness of Road Maintenance Companies, DOI:

10.31075/PIS.65.02.02

Kementrian Pekerjaan Umum. (2011). Peraturan Menteri

Pekerjaan Umum Nomor 13/PRT/M/2011 (2011)

Tentang Tata Cara Pemeliharaan dan Penilikan Jalan.

Jakarta.

Langevin, Andre, (2016). Quantitative Approaches for Road

Maintenance, Prosiding Conference: the Seventh

Symposium DOI:10.1145/3011077.3011080

Mulyadi, Isya M., Saleh S. M. (2018). Studi Kerusakan Jalan

ditinjau dari Faktor Setempat (Studi Kasus Ruas Jalan

Blangkejeren-Lawe Aunan). Jurnal Teknik Sipil. Vol. 1,

No. 3, hlm. 667-678. Universitas Syiah Kuala.

Peraturan Menteri PUPR no 23 tahun 2020. Rencana

Strategis 2020-2024, Kementerian PUPR.

Purboyo, H, Putro, H, Utami, NLP, (2017). Local Road

Maintenance Prioritization Literature

Review, International Journal of System Modelling and

Simulation 2(4):21, DOI:10.24178/ijsms.2017.2.4.21

Rudjito, D., Gunawan, D., Putra, H. C. (2017). Pemanfaatan

Teknologi Murah untuk Survey Kondisi Jalan Daerah.

Buletin Infrastruktur Daerah edisi 2/tahun I/2016.

Jakarta. Kementerian Pekerjaan Umum dan Perumahan

Rakyat.

Shahin, M. Y. (1994). Pavement Management for Airport,

Road and Parking Lots. New York. Champan & Hall.

Shi, Xianming, Fu, Liping, (2018). Introduction to

Sustainable Winter Road Maintenance,

https://www.researchgate.net/publication/324550130,

DOI 0.1002/9781119185161.chi

Setianingsih, AI, et al, (2017). Road Maintenance and

Rehabilitation Program Using Functional and Structural

Assessment, International Conference on Advanced

Materials for Better Future 2016 IOP Publishing IOP

Conf. Series: Materials Science and Engineering 176

(2017) 012030 doi:10.1088/1757-899X/176/1/012030

Stachova, Darina, (2017). Trajectory of a Road Vehicle

During Road Maintenance, MATEC Web of

Conferences 107, 00029, DOI:

10.1051/matecconf/2017107000

Siswanto, Henri, et,al, (2019). District Road Maintenance

Priority using Analythical Hierarchy Process, AIP

Proceeding Conference,

https://doi.org/10.1063/1.5112490

Suherman. (2008). Studi Persamaan Korelasi antara

Ketidakrataan Permukaan Jalan dengan Indeks Kondisi

Jalan. Jurnal Teknik Sipil Volume 8 No. 3 (206-214)

Sukirman, Silvia. (1999). Perkerasan Lentur Jalan Raya.

Bandung. Nova.

ASAIS 2020 - Annual Southeast Asian International Seminar

34

Suryawan, A. (2009). Perkerasan Jalan Beton Semen

Portland (Rigid Pavement)-Perencanaan Metode

AASHTO 1993, Spesifikasi, Parameter Desain, Contoh

Perhitungan. Beta Offset. Yogyakarta. Yogyakarta: UGM

Press.Iskandar, H. 2005.

UMTRI. (1998). Roughness. University of Michigan Tran

Thankgod, Ezrim Kelechi, 2019, Evaluation of Road

Maintenance Culture in Nigeria; Tools ad Techniques,

https://www.researchgate.net/publication/333394295

Tho’atin, U., Setyawan A., Suprapto M. (2016). Penggunaan

Metode International Roughness Index (IRI), Surface

Distress Index (SDI) dan Pavement Condition Index

(PCI) Untuk Penilaian Kondisi Jalan Di Kabupaten

Wonogiri. Jurnal Teknik Sipil. Universitas

Muhammadiyah Jakarta.

Vignisdóttir, Hrefna Run, et al, (2019). Life cycle

assessment of winter road maintenance, J, The

International Journal of Life Cycle Assessment DOI:

10.1007/s11367-019-01682-y

Vignisdóttir, Hrefna Run, et al, (2019). A review of

environmental impacts of winter road maintenance,

Cold Regions

Widjajanto, A., Gunawan, D., Utomo, A. R. (2017).

Penerapan Teknologi Murah untuk Survey Kondisi

Jalan. Buletin Infrastruktur Daerah edisi 2/tahun I/2017.

Jakarta: Kementerian Pekerjaan Umum dan Perumahan

Rakyat.

Yasuda, Keiichi, et al., (2018). Matrix Evaluation of

Comfort on Road Maintenance and Management DOI:

10.5057/jjske.TJSKE-D-18-00030

Yin, Yana, Wen, Huiying, Hou, Wei., (2020). The Influence

of Road Geometry on Vehicle Rollover and Skidding,

International Journal of Environmental Research and

Public Health 17(5):1648 DOI: 10.3390/ijerph17051648

APPENDIX

Table 1: IRI Maintenance Program

(Source: General Directorate of Highways, 2011)

Table 2. PCI value

(Source:http://dpw.lacounty.gov/Pavement Management System)

Table 3 PCI Maintenance Program

(Source:http://dpw.lacounty.gov/Pavement Management System)

Table 4. Jalan Raya Babelan Deterioration

Figure 4. Rigid Pavement Condition Percentage Using IRI

Method

Deterioration Analysis of Rigid Pavement using Roadroid based on PCI

35

Figure 5. IRI Value at STA 1+500-1+520

Figure 6. IRI Value at STA 1+500-1+520

ASAIS 2020 - Annual Southeast Asian International Seminar

36