Characterization of Insoluble Fiber in Cassava Peel and Its

Hydrolyzate Potential as a Prebiotic for Lactobacillus Plantarum

Ilham Marvie

1,2

, Azis Boing Sitanggang

2

and Slamet Budijanto

2

1

Food Technology Study Program, Institute Technology of Sumatera, South Lampung, Indonesia

2

Department of Food Science and Technology, IPB University, West Java, Indonesia

Keywords: Cassava Peel, Cellobiose, Cellulase, Cellulose, Prebiotic.

Abstract: The cassava peel is an uncommon material for consumption as food for Indonesians because its use is widely

used in non-food industries. Exploration of the use of cassava peel in the food industry in this case as a

functional food ingredient such as prebiotics has the potential to be carried out. This study aims to determine

the characteristics of the insoluble fiber content of the cassava peel and testing its hydrolysate potential as a

prebiotic in growing Lactobacillus plantarum. The varieties of the cassava plant used in this study were Ratim

(RTM 22) and Ulujami (UJ 17). The method used in this study is the characterization of insoluble fiber. As

well as testing the prebiotic potency by determining the prebiotic activity score by doing Lactobacillus

plantarum. The results of this study indicate that the characteristics of insoluble fiber in the cassava peel are

hemicellulose content is more dominant than cellulose and lignin in the cassava peel. The hydrolysate of

cellulose from cassava peel showed its potential as a prebiotic in growing Lactobacillus plantarum. RTM 22

varieties had a higher prebiotic activity score than UJ 17. The prebiotic activity scores of RTM 22 and UJ 17

were 1.70 and 1.48, respectively.

1 INTRODUCTION

The Cassava peel is an uncommon material for

consumption as food for Indonesian people, its use is

more widely used as industrial raw material (Aripin

et al., 2013), animal feed (Oluwanike and Adeneye,

2014), and biodegradable packaging (Widiarto et al.,

2017). The use of the cortex of cassava peel as a

traditional Sumedang food ingredient called

kadedemes has inspired the development of cassava

peel as a food ingredient. Meanwhile, the cassava

peel has a dry weight that reaches 13% of the total

weight of cassava peel (Aripin et al., 2013). The

availability of raw material for cassava is also

predicted to continue to increase in line with the

increase in the national consumption of cassava

reaching 12.7 million tons in 2020 (BPS, 2013).

Therefore, exploration of utilization in the food

industry in this case as functional food ingredients

such as prebiotics has the potential to be carried out.

Cassava peel has a crude fiber content of up to

12.2% (Idugboe, Nwokoro and Imasuen, 2017).

Insoluble fiber is a part of crude fiber (Idris et al.,

2020). Cellulose under natural conditions is coated by

a matrix of hemicellulose and lignin (Elechi et al.

2016). The presence of lignin and hemicellulose

content is thought to affect the hydrolysis of cellulose

(Surendran et al., 2018). Therefore, it is necessary to

characterize the content and insoluble in the skin of

the cassava peel. The process to reduce the

hemicellulose and lignin content is also needed to

obtain the dominant cellulose content. Cellulose is

composed of D-anhydro glucopyranose in β-1,4-

glycoside or β-glucose bonds (Elechi et al., 2016).

The hydrolysate from the hydrolysis of cellulose with

cellulase enzymes can produce cellobiose as an

intermediate product (Razie et al., 2011).

Previous research has been carried out by

knowing the ability of cellobiose as a stimulus in the

growth of Lactobacillus acidophilus NCFM (van

Zanten et al., 2012). In-vivo test results have also

been carried out and do not give unwanted side effects

to humans (Van Zanten et al., 2014). Testing the

ability to grow other Lactobacillus strains such as

Lactobacillus plantarum also needs to be carried out

on products from the hydrolysis of cassava peel to add

information on the ability of cellobiose as a prebiotic.

This study aims to determine the characteristics of the

insoluble fiber content of the skin of cassava peel. and

testing its hydrolysate potential as a prebiotic in

Marvie, I., Sitanggang, A. and Budijanto, S.

Characterization of Insoluble Fiber in Cassava Peel and Its Hydrolyzate Potential as a Prebiotic for Lactobacillus Plantarum.

DOI: 10.5220/0010507300003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 31-37

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

31

growing Lactobacillus plantarum. This research is

expected to expand the exploitation of cassava peel as

raw material for functional food as a prebiotic and

increase its added value in the food industry.

2 METHOD

2.1 Material

The main material used in this study were cassava

peel (Manihot utilissima Sp) varieties of Ratim (RTM

22) and Ulujami (UJ 17) from the experimental garden

of the Department of Agronomy and Horticulture,

Bogor Agricultural University, Cigombong, Sukabumi

Regency, West Java. The enzymes used were complex

cellulase enzymes (Wathringthon, Murni). The

bacteria used were Lactobacillus plantarum and

Escherichia coli obtained from SEAFAST IPB.

Nylon-66 membrane pore size 0.20 µm and 0.45 µm

with a diameter of 25mm (Himedia). The media used

for bacterial growth are de Man Rogosa Sharpe

(Merck) and M9 (Merck).

2.2 Preparation of Cassava Peel

Material

The process of preparing the cassava peel raw

material consists of sorting, washing, reducing the

size, and peeling the tuber skin. Samples were dried

using a cabinet drier at 50

o

C for 24 hours and crushed

using a disc mill to form flour with a size of 40 mesh.

The raw material is again dried in the cabinet drier for

24 hours until the moisture content is <10% (Tasaso,

2015). The cooking of the cassava peel is done by

heating 50 g of cassava root flour in 1 L of water and

10% NaOH using an autoclave at a temperature of

130

o

C, a pressure of 190 kPa for 60 minutes.

Separation of the extraction results between the solid

residue and the black concentrated solution using a

filter cloth and washed with distilled water until the

solid residue reaches a pH of 7.0. The residue was

dried at 70

o

C for 24 hours. Bleaching process by

adding 30% H

2

O

2

at 70

o

C for 3 hours. Cassava peel

is separated again to get the residue and rinsed using

distilled water. The bleaching residue is dried again

at a temperature of 70

o

C (Tasaso, 2015).

2.3 Characterization of the Insoluble

Fiber Content

Characterization of cassava peel flour was carried out

using fiber content analysis consisting of Acid

Detergent Fiber (ADF), Neutral Detergent Fiber

(NDF), cellulose, lignin, and hemicellulose levels

(van Soest, 1963). All tests were carried out in two

duplicate replications.

2.3.1 Neutral Detergent Fiber (NDF)

NDF solution consisted of distilled water 1 L, Sodium

Sulfate 30 g, EDTA 18.81 g; Sodium Borate 10 H

2

O

6.81 g, 4.5 g anhydrous di-Na-HPO4 and 10 ml pure

2-ethoxy ethanol. a sample of 0.5 g (A) was put into

a 250 mL beaker. The sample was then added with

NDF solution and filtered with the help of a vacuum

pump, rinsed alternately with hot water and acetone.

The filter results were dried in an oven at 105

o

C until

stable, after that they were put in a desiccator for one

hour, then weighed (B). The measurement results are

reduced by the weight of the dry glass filter before

use (C)

NDF Content= ((B-C))/A ) x 100% (1)

2.3.2 Acid Detergent Fiber (ADF)

A sample of 1 g (A) was put into a beaker and ml of

ADF solution was added. The ADF solution consisted

of 1 L of 1 N H

2

SO

4

and 20 g of CTAB (cethyle

trimethyl ammonium bromide). The sample to which

the solution was added was heated for one hour on the

back cooler. Filtering is done with the help of a

vacuum pump using a glass filter. Washing is carried

out alternately with acetone and hot water. The filter

results were dried in an oven at 105°C until stable,

after that they were put in a desiccator for one hour,

then weighed (D). The measurement results are

reduced by the weight of the dry glass filter before

use (C)

ADF Content= ((D-C)/A) x 100% (2)

2.3.3 Cellulose, Hemicellulose, and Lignin

Content

ADF residue (E) which is in the glass filter is placed

on a tray of water about 1 cm high. Then added H

2

SO

4

as high as ¾ part of the glass filter and left for 3 hours

while stirring. Filtering with a glass filter is assisted

by a vacuum pump. Washing is done with acetone

and hot water. Do the drying and put the filter results

into the oven. After that, it is put back into the

desiccator to cool down and weigh (F). Furthermore,

the glass filter is in the furnace at 450

o

C for 3-4 hours,

then put again into the desiccator to cool down and

weigh (G)

𝐶𝑒𝑙𝑙𝑢𝑙𝑜𝑠𝑒 𝐶𝑜𝑛𝑡𝑒𝑛𝑡 = ((𝐹 − 𝐺)/𝐸) 𝑥 100% (3)

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

32

To find out the hemicellulose and lignin content,

you can use the equation below using the results of

the ADF and NDF tests.

𝐻𝑒𝑚𝑖𝑐𝑒𝑙𝑙𝑢𝑙𝑜𝑠𝑒 𝐶𝑜𝑛𝑡𝑒𝑛𝑡 = 𝑁𝐷𝐹 𝐶𝑜𝑛𝑡𝑒𝑛𝑡 − 𝐴𝐷𝐹 𝐶𝑜𝑛𝑡𝑒𝑛𝑡

(4)

𝐿𝑖𝑔𝑛𝑖𝑛 𝐶𝑜𝑛𝑡𝑒𝑛𝑡 = 𝐴𝐷𝐹 𝐶𝑜𝑛𝑡𝑒𝑛𝑡 − 𝐶𝑒𝑙𝑙𝑢𝑙𝑜𝑠𝑒 𝐶𝑜𝑛𝑡𝑒𝑛𝑡

(5)

2.4 Probiotic Growth Testing on

Cassava Peel Hydrolysates

The lactic acid bacteria used as probiotics are

Lactobacillus plantarum. Before use, Lactobacillus

plantarum was refreshed on MRS Broth for 24 hours

at 30

o

C. Growth was carried out on MRS Base media

with the addition of cellobiose as a substitute for

glucose for carbohydrate sources. The composition

for making MRS Base is peptone 10 g/L, meat extract

8 g/L, yeast extract 4 g/L, sodium acetate 5 g/L,

magnesium sulphate 0.2 g/L, manganese sulphate

0.05 g / l , dipotassium sulphate 0.05 g/L, polysorbate

80 1 g/L and prepared with a pH of 6.2±0.2 at 25

o

C

(De Man, Ragosa and Sharpe, 1960). Inoculation of

0.1 mL of Lactobacillus plantarum on MRS added

0.1 mL of cellobiose. Lactobacillus plantarum was

also grown on MRS with 0.1 glucose added at a

concentration of 250 mg/mL to compare with the

growth on MRS with cellobiose. The cellobiose to be

added to the MRS must first be filtered on a

membrane with a sterile 0.25 µm pore size to avoid

bacterial contamination. The growth of Lactobacillus

plantarum can be observed by growing it on MRS

agar. Measurements were carried out on

Lactobacillus plantarum which had been incubated

for 0, 24 and 48 hours at 30

o

C (Herawati et al., 2019).

as much as 1 mL of Lactobacillus plantarum was

inoculated on MRS agar and incubated for 48 hours.

The growth of Lactobacillus plantarum is indicated

by the presence of white colonies.

The prebiotic activity score is a comparison

between the ability of prebiotics to grow probiotics

and inhibit the growth of Escherichia coli against

growth in glucose during 24 hours of incubation.

Lactobacillus plantarum was grown on MRS media

added by prebiotics and Escherichia coli was growth

on M9 media added by prebiotics (Moongngarm,

Trachoo and Sirigungwan, 2011). The prebiotic

activity score can be found using the equation below.

𝑃𝑟𝑒𝑏𝑖𝑜𝑡𝑖𝑐 𝐴𝑐𝑡𝑖𝑣𝑖𝑡𝑦 𝑆𝑐𝑜𝑟𝑒

=

log

𝑐𝑓𝑢

𝑚𝑙

𝑝𝑟𝑜𝑏𝑖𝑜𝑡𝑖𝑐 & 𝑝𝑟𝑒𝑏𝑖𝑜𝑡𝑖𝑐 24 ℎ𝑜𝑢𝑟𝑠 − log

𝑐𝑓𝑢

𝑚𝑙

𝑝𝑟𝑜𝑏𝑖𝑜𝑡𝑖𝑐 & 𝑝𝑟𝑒𝑏𝑖𝑜𝑡𝑖𝑐 0 ℎ𝑜𝑢𝑟𝑠

log

cfu

mL

𝑝𝑟𝑜𝑏𝑖𝑜𝑡𝑖𝑐 & 𝑔𝑙𝑢𝑐𝑜𝑠𝑒 24 ℎ𝑜𝑢𝑟𝑠 − log

𝑐𝑓𝑢

𝑚𝑙

𝑝𝑟𝑜𝑏𝑖𝑜𝑡𝑖𝑐 & 𝑔𝑙𝑢𝑐𝑜𝑠𝑒 0 ℎ𝑜𝑢𝑟𝑠

−

log

𝑐𝑓𝑢

𝑚𝑙

𝐸 𝑐𝑜𝑙𝑖 & 𝑝𝑟𝑒𝑏𝑖𝑜𝑡𝑖𝑐 24 ℎ𝑜𝑢𝑟𝑠 − log

𝑐𝑓𝑢

𝑚𝑙

𝐸 𝑐𝑜𝑙𝑖 & 𝑝𝑟𝑒𝑏𝑖𝑜𝑡𝑖𝑐 0 ℎ𝑜𝑢𝑟

log

𝑐𝑓𝑢

𝑚𝑙

𝐸 𝑐𝑜𝑙𝑖 & 𝑔𝑙𝑢𝑐𝑜𝑠𝑒 24 ℎ𝑜𝑢𝑟𝑠 − log

𝑐𝑓𝑢

𝑚𝑙

𝐸 𝑐𝑜𝑙𝑖 & 𝑔𝑙𝑢𝑐𝑜𝑠𝑒 0 ℎ𝑜𝑢𝑟

In this test, the composition of the addition of

cellobiose and glucose to M9 media followed the

concentration on MRS. Before using Escherichia

coli, its condition can be freshened by growing it on

Triptic Soy Broth (TSB) / Brain Heart Infusion Broth

(BHIB) and M9 media for 24 consecutive hours

respectively. Escherichia coli grown on M9 was

focused on Triptic Soy Agar (TSA) to count the

number of colonies that grew during 24 hours of

incubation at 35oC. The number of colonies that grew

on TSA and MRS agar media was converted to log

cfu/mL and then entered in equation (1)

2.5 Data Analysis

Data presentation was carried out using the Microsoft

Excel 2016 program and the Minitab 18 program.

Analysis of variance (ANOVA) between samples was

carried out using Tukey's honest real difference

(HSD) test at the 5% level (p <0.05).

3 RESULT AND DISCUSSION

3.1 Characterization of Cassava Peel

The skin of the Ratim variety of cassava peel (RTM

22) has physical characteristics in the form of red

colour on the inner peel (cortex) and has a bland taste.

While the Ulujami variety (UJ 17) has white peel with

a bitter taste. Based on its structure, the cassava peel

consists of two layers, namely the periderm and

cortex (Mohd-asharuddin et al., 2017). The cortex

layer used as the raw material in this study has a

slippery texture, is flexible, is lighter in colour than

the periderm. According to Idris et al., (2020) the

cortex layer has a higher crude fiber content than the

tuber content (flesh), while the cyanide compound

content is not significantly different at 0.01 mg/Kg

dry basis. The raw material preparation process can

be carried out to clean cassava peels from soil

impurities and reduce the cyanide acid content found

in cassava peels (Falade and Akingbala, 2010).

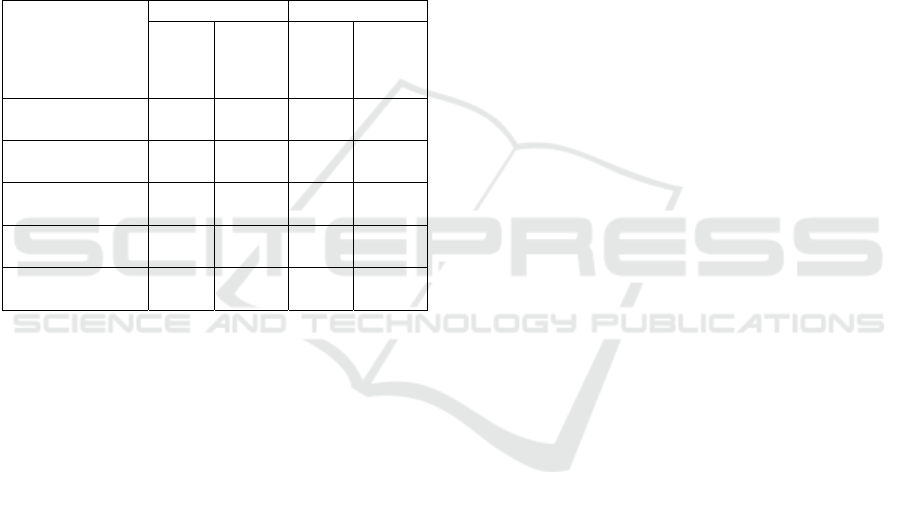

Based on Table 1, the NDF content of cassava

peel of UJ 17 variety was 13.35% and RTM 22

variety was 48.64%. Meanwhile, the ADF content of

the cassava peel of UJ 17 variety was 6.36% and

RTM 22 variety was 7.63%. Neutral Detergent Fiber

(NDF) is an insoluble fiber content in neutral

detergents consisting of cellulose and lignin, while

Acid Detergent Fiber (ADF) is an insoluble fiber

content in acidic detergents consisting of lignin,

cellulose, and hemicellulose. The difference between

ADF and NDF indicates the amount of hemicellulose

Characterization of Insoluble Fiber in Cassava Peel and Its Hydrolyzate Potential as a Prebiotic for Lactobacillus Plantarum

33

content (Oluwanike and Adeneye, 2014). The total

content of cellulose, hemicellulose, and lignin which

does not reach 100% both before cooking and after

blanching indicates other compounds that do not

include insoluble fiber such as starch, protein, fat, and

so on. The NDF and ADF content of the two varieties

of cassava bark had a significant difference. After

cooking with NaOH and blanching with H

2

O

2

, the

NDF and ADF content were not significantly

different. The NDF content of cassava peel of UJ 17

variety increased to 68.51% and RTM 22 variety to

67.60%, while the ADF content of cassava peel of UJ

17 variety increased to 60.83% while RTM 22 variety

increased to 60.27%.

Table 1: The cassava peel insoluble fiber content.

Insoluble Fiber

Before Cooking Afte

r

Bleaching

UJ17 RTM 22 UJ17 RTM 22

NDF (%)

13,35

±0,55

b

48,64

±0,09

a

68,51

±0,07

a

67,60

±0,64

a

ADF (%)

6,36

±0,10

b

7,63

±0,07

a

60,83

±1,21

a

60,27

±0,45

a

Cellulose (%)

4,99

±0,09

a

5,74

±0,05

a

55,50

±2,20

a

55,79

±0,44

a

Hemicellulose (%)

6,97

±0,45

b

41,02

±0,02

a

7,68

±1,14

a

7,32

±0,19

a

Lignin (%)

1,39

±0,01

a

1,88

±0,02

a

5,34

±0,99

a

4,49

±0,01

a

Note: Dry base with 8.98% moisture content. Tests were carried

out in 2 replications. a / b: Tukey's real difference test (ANOVA)

and honest real difference test (HSD) at the 5% level

Hemicellulose content in cassava peel flour of

varieties UJ 17 and RT 22 was 6.97% and 41.02%,

respectively. This significant difference shows that

different varieties can indicate different

characteristics of crude fiber. The lignin content of

varieties UJ 17 and RTM 22 were 1.39% and 1.88%,

respectively. A study by Barati, Latif and Müller,

(2019) states that cassava contains 30.4%

hemicellulose. The lignin content in cassava skin

reaches 7.50% (Aripin et al., 2013). After the cooking

and bleaching process, the hemicellulose content

changed to 7.32%, while the lignin content became

4.49%. Changes in hemicellulose and lignin content

are caused by dissolving insoluble non-fiber

compounds during the cooking process with NaOH

and bleaching with H

2

O

2

. The process of dissolving

lignin and hemicellulose also occurs during cooking

with NaOH at high temperatures. The reaction

between NaOH and lignin in hot conditions results in

the formation of a thick black and sticky solution that

can be separated from the solvent. The bleaching

process carried out after extraction through the

addition of H

2

O

2

aims to remove the remaining lignin

by oxidizing the chromophore molecules in the lignin

so that it becomes polar and water-soluble. This

process is important because naturally lignin is water-

insoluble and binds to hemicellulose and lignin (Allen

et al., 2016).

The cellulose content of the RTM 22 variety of

cassava peel after cooking with NaOH and blanching

with H

2

O

2

showed an increase from 5.74% to

55.70%. The increase in cellulose content in the

cassava peel varieties UJ 17 from 4.99% to 55.50%

The increase in cellulose content is due to the nature

of cellulose which has good resistance to alkaline and

heat compounds up to 280

o

C used in the extraction

process (Suryanto, 2015). Meanwhile, according to

Widiarto et al., (2017) the use of acids in extraction

makes cellulose hydrolysed into a simpler form. In

addition to the extraction method used in this study,

the alternative use of 4% NaOH and 4% NaOCl in

extraction resulted in 40.5% cellulose, 11.7% lignin,

and 21.4% hemicellulose (Widiarto et al., 2019).

Therefore, the extraction method using 11% NaOH

and 30% H

2

O

2

has a better result to increase the

percentage of cellulose. In this bleaching process, it

is also possible to decrease cellulose in the

amorphous form and increase the percentage of

cellulose in the crystalline form (Leite, Zanon and

Menegalli, 2017).

3.2 Probiotic Growth Testing on

Cassava Peel Hydrolysates

The hydrolysate of the cassava peel was obtained

based on the results of the hydrolysis of the cassava

peel flour which had been cooked with NaOH and

blanched with H2O2. Hydrolysis was carried out

using cellulase enzymes with a concentration of 4.03

U/mL on UJ 17 and RTM 22 varieties. The enzyme

concentration was obtained from the results of

preliminary research using a concentration of 18.91

U/mL and 22.06 U/mL with the results of the first 1

hour of hydrolysis. has reached the degree of

polymerization 1,00. Hydrolysis using a substrate of

200 mg, 0.1 mL, 200 mL of citrate buffer pH 4.8, and

10% sodium azide as antimicrobial. The cellulase

enzyme activity used was 115 U/mL (Worthington,

2020). Hydrolysis was performed using a shaker

incubator at 37

o

C with an agitation speed of 150 rpm

for 24 hours (Selig, Weiss and Ji, 2008). Hydrolysate

is obtained when the hydrolysis process has been

going on for 12 hours. The results of hydrolysis of

cassava peels for 12 hours were used as a

carbohydrate source substitute in MRS media to

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

34

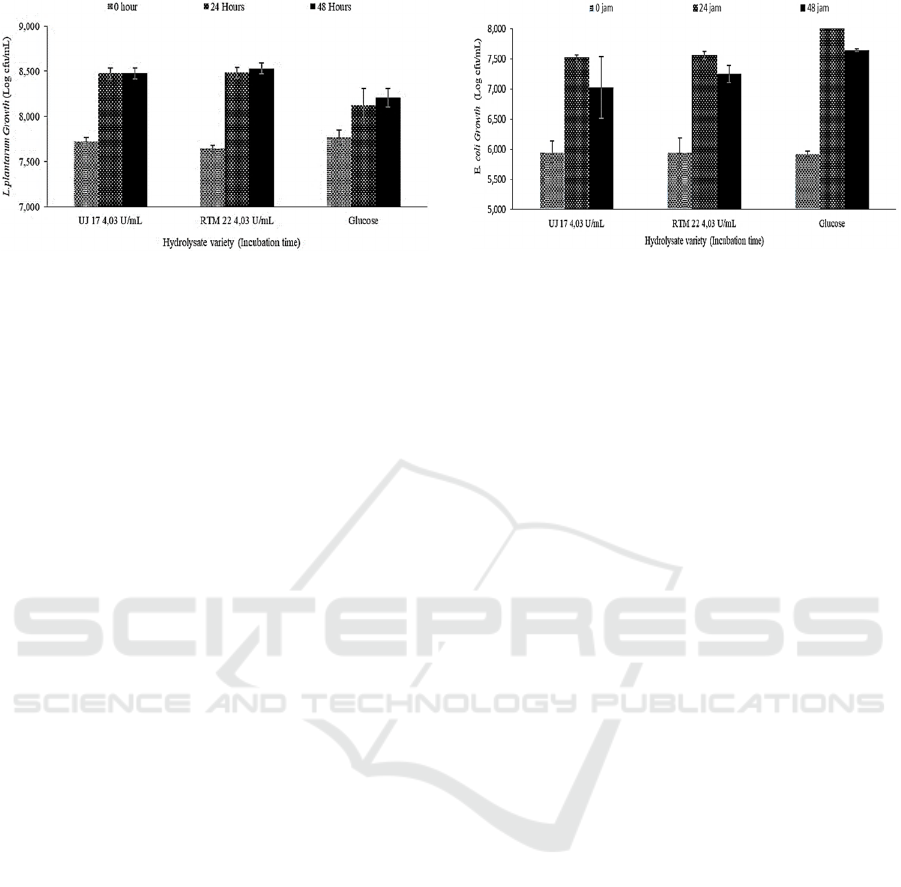

Figure 1: Lactobacillus plantarum growth on cassava peel

hydrolysate and MRS.

growth Lactobacillus plantarum and as a

carbohydrate source substitute in M9 medium to grow

Escherichia coli. Based on the preliminary research

that has been carried out, the hydrolysate has a degree

of polymerization below 2.00 which indicates that the

content of cellobiose and cello-oligosaccharide has

been dominant.

The growth of Lactobacillus plantarum growth

with UJ 17 hydrolysate at 0 hour was 7,719 log

cfu/mL and increased significantly at 24 hours of

growth with 8,475 cfu/mL, but after 48 hours there

was no significant difference, namely 8,479 cfu/mL.

The growth of Lactobacillus plantarum on RTM 22

variety hydrolysate was at 7,643 log cfu/mL at 0

hours and increased significantly to 8,482 log cfu/mL.

Growth at 24 hours and 48 hours had no significant

difference with 8,535 log cfu/mL. In the two varieties

of cassava peel at 24 and 48 hours, the growth was

not significantly different. This shows that the

microbes have been in a stationary phase because

they are still in the same log colony number with

growth at 24 hours. (Karnaouri, Matsakas, Bühler, et

al., 2019) reported that the growth of Lactobacillus

plantarum in media added with cellobiose also

showed a stationary phase at the incubation time of

48 hours to 72 hours. The amount of cellobiose

consumed would correlate with the increase in the

amount of lactic acid, acetic acid, and propionic acid

formed. The growth of Lactobacillus plantarum is

suspected not because there are still peptides from the

inactivation of the cellulase enzyme by heating at

85oC for five minutes. Apart from the percentage use

of the enzyme which is 1% of the total hydrolysis

volume, the stratified filtration process with a

membrane measuring 0.45µm and 0.20µm is

expected to minimize the contamination of

macronutrients and microorganisms that bias the

growth of Lactobacillus plantarum.

The growth of Escherichia coli on M9 medium

grown on the hydrolysate of cassava peels of UJ 17

Figure 2: Escherichia coli growth on cassava peel

hydrolysate and M9.

variety in 0 hours was 5.953 log cfu/mL and increased

significantly to 7.524 log cfu/mL at 24 hours of

growth. While the growth of Escherichia coli on M9

media added to the hydrolysate of cassava varieties

RTM 22 in 0 hours was 5.952 log cfu / mL. The

increase occurred in growth within 24 hours to 7.566

log cfu / ml. The growth of Escherichia coli at 48

hours experienced a decrease in both the hydrolysates

of UJ 17 and RTM 22 varieties, respectively 7,026 log

cfu / mL and 7,253 log cfu / mL. The growth of

Escherichia coli on M9 media with added glucose

had a higher growth than in M9 media which was

added by hydrolysis of cassava peel. The growth of

Escherichia coli by two logs shows that the products

of cellulose hydrolysis of the three varieties still

contain β glucose which is easily digested by

Escherichia coli, but after 24 hours the incubation of

β glucose contained in M9 is reduced and the growth

of Escherichia coli is lower because cannot digest

cellobiose and cello-oligosaccharides found in M9.

Growth conditions in the hydrolysate that are

expected to occur in cellobiose as a prebiotic in

providing the ability to grow Lactobacillus plantarum

as a probiotic and not a source of carbohydrates for

Escherichia coli in the human digestive tract.

Cellobiose which is thought to be dominant in the

product of cellulase enzyme hydrolysis has the ability

to grow Lactobacillus plantarum which is better with

an optical density (OD) value of 600 more than 5

compared to other Lactobacillus strains and

Bifidobacterial strains as probiotics, Lactobacillus

plantarum has low growth. on media with added

glucose for 24 hours (Karnaouri, Matsakas,

Krikigianni, et al., 2019).

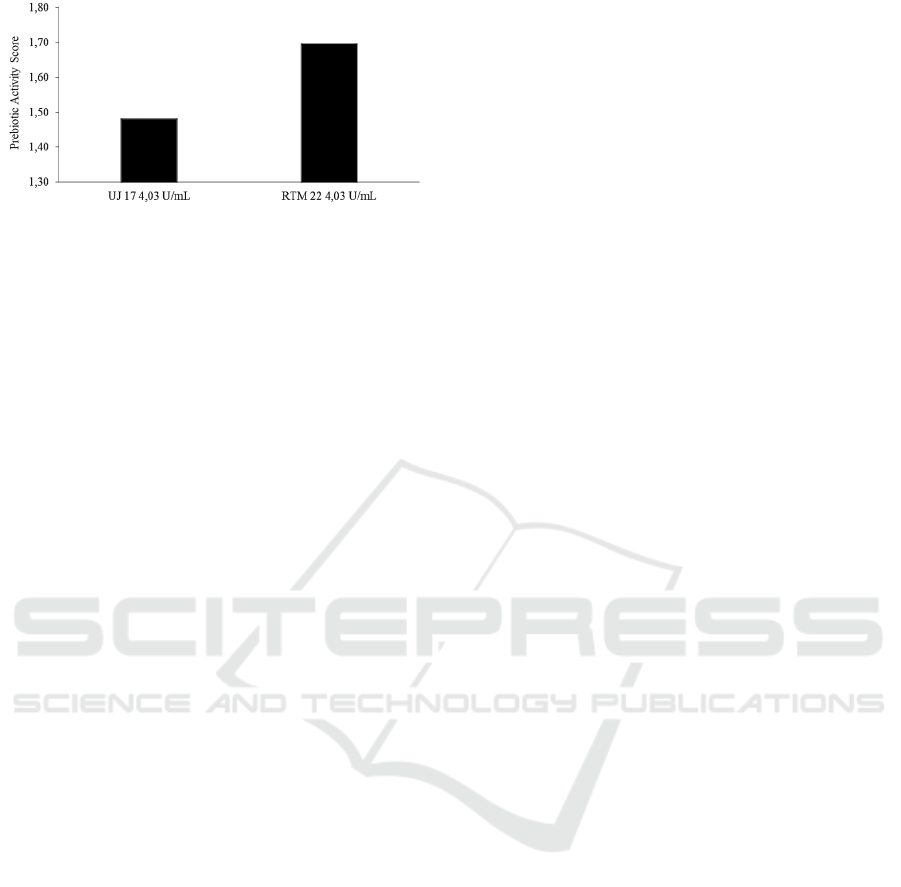

The ability of hydrolysis products needs to be

measured as a prebiotic potency using prebiotic

activity score analysis. The hydrolysate of RTM 22

cassava peel with 2.88 U / mL cellulase had a higher

prebiotic activity score than the UJ 17 variety. The

difference in prebiotic activity scores between

Characterization of Insoluble Fiber in Cassava Peel and Its Hydrolyzate Potential as a Prebiotic for Lactobacillus Plantarum

35

Figure 3: Prebiotic Activity Score on cassava peel

hydrolysate.

cassava varieties was thought to be due to differences

in the amount of cellobiose and β glucose found in

hydrolysis products. The high percentage of

cellobiose content will increase the growth of

Lactobacillus plantarum, while the higher percentage

of β glucose content will increase the growth of

Escherichia coli. The percentage of growth of the two

bacteria affects the prebiotic activity score. The

difference in the content of cellulose, lignin, and

hemicellulose contained in the substrate was thought

to affect, however, the cellulose extraction process

made the composition of the lignocellulose

compounds not significantly different between

cassava varieties. The prebiotic activity scores of the

two-cassava peel hydrolysates of UJ 17 and RTM 22

varieties were 1.48 and 1.70, respectively. The

prebiotic activity score was higher than the score on

inulin from the hydrolysis of red fruit grown on

Lactobacillus casei of 0.88 (Murtiningrum et al.,

2019). The prebiotic activity score was also higher

than the prebiotic activity score of

gallactooligosaccharide (GOS) grown on

Lactobacillus plantarum 12006 (Huebner, Wehling

and Hutkins, 2007). The prebiotic activity score on

the RTM 22 hydrolysate was also higher than the

growth of Lactobacillus acidophilus on

fructooligosaccharides (FOS), but lower than the

growth of Lactobacillus acidophilus on inulin

(Moongngarm, Trachoo and Sirigungwan, 2011).

4 CONCLUSION

The characteristics of insoluble fiber in the cassava

peel consist of cellulose, hemicellulose, and lignin.

Hemicellulose content is more dominant than

cellulose and lignin in the cassava peel. The

hemicellulose content of UJ 17 and RTM 22 varieties

had a significant difference. After cooking with

NaOH and blanching with H

2

O

2

, cellulose content

became dominant compared to hemicellulose and

lignin. This process causes changes in the

characteristics of insoluble fiber, such as the

dissolution of non-soluble fiber compounds and

hemicellulose and lignin. The cassava peel varieties

UJ 17 and RTM 22 contained no significant

difference in cellulose. The hydrolysate of cellulose

from the cassava peel showed its potential as a

prebiotic in growing Lactobacillus plantarum. The

hydrolysates from cassava peels of RTM 22 varieties

had a higher prebiotic activity score than UJ 17. The

prebiotic activity scores of the cassava peel

hydrolysates of RTM 22 and UJ 17 varieties were

1.70 and 1.48, respectively.

ACKNOWLEDGEMENTS

Thank you to the Directorate of Higher Education,

Ministry of Education and Culture of the Republic of

Indonesia for funding this research through the

master's thesis research scheme. Thanks to Prof. Dr.

Ir. Lilis Nuraida, M.Sc. who has allowed the use of

lactobacillus plantarum 026 culture that is owned and

thanks to Dr. Ir. Nurul Khumaida, M.Sc. which has

permitted the use of cassava peel of a Ratim variety

(RTM 22) dan Ulujami variety (UJ 17) that were

owned for this study.

REFERENCES

Allen, S. A. et al. (2016) ‘Lignocelluloses : An Economical

and Ecological Resource for Bio-Ethanol Production –

A Review’, International Journal of Natural Resource

Ecology and Management, 1(3), pp. 128–144. doi:

10.11648/j.ijnrem.20160103.18.

Aripin, M. et al. (2013) ‘Cassava Peels for Alternative Fibre

in Pulp and Paper Industry : Chemical Properties and

Morphology Characterization’, International Journal

of Integrated engineering, 5(1), pp. 30–33.

Barati, Z., Latif, S. and Müller, J. (2019) ‘Enzymatic

hydrolysis of cassava peels as potential pre-treatment

for peeling of cassava tubers’, Biocatalysis and

Agricultural Biotechnology. Elsevier Ltd, 20

(December 2018), p. 101247. doi: 10.1016/j.bcab.20

19.101247.

BPS, B. P. S. (2013) Pengeluaran dan Konsumsi Penduduk

Indonesia, Survey Sosial Ekonomi Nasional.

Elechi, O. O. et al. (2016) ‘Acid Hydrolysis Of Cassava

Peel’, International Journal of Scientific & Technology

Research, 5(01), pp. 184–187.

Falade, K. O. and Akingbala, J. O. (2010) ‘Utilization of

Cassava for Food’, Food Review International,

9129(27), pp. 51–83. doi: 10.1080/87559129.2010.518

296.

Herawati, E. R. N. et al. (2019) ‘Oligosaccharides Profile

and Prebiotic Potential of Gembolo Tuber ( Dioscorea

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

36

bulbifera ) Oligosaccharides Profile’, in IOP Conf.

Series: Earth and Enviromental Science. IOP

Publishing. doi: 10.1088/1755-1315/251/1/012048.

Huebner, J., Wehling, R. L. and Hutkins, R. W. (2007)

‘Functional activity of commercial prebiotics’,

International Dairy Journal, 17(7), pp. 770–775.

doi: 10.1016/j.idairyj.2006.10.006.

Idris, S. et al. (2020) ‘Physicochemical composition of

different parts of cassava (Manihot esculenta crantz)

plant’, Food Research, 4, pp. 78–84. doi:

10.26656/fr.2017.4(S1).S33.

Idugboe, Nwokoro, O. and Imasuen, S. (2017) ‘Chemical

Composition of Cassava Peels Collected from Four

Locations (Koko , Warri , Okada and Benin City),

Brewers` Spent Yeast and Three Grades of

“Caspeyeast”, International Journal of Science and

Research, 6(4), pp. 2015–2018. doi: 10.21275/ART

20172389.

Karnaouri, A., Matsakas, L., Bühler, S., et al. (2019)

‘catalysts Tailoring Celluclast ® Cocktail ’ s

Performance towards the Production of Prebiotic Cello-

Oligosaccharides from Waste Forest Biomass’,

Catalysts, 9, p. 897.

Karnaouri, A., Matsakas, L., Krikigianni, E., et al. (2019)

‘Valorization of waste forest biomass toward the

production of cello-oligosaccharides with potential

prebiotic activity by utilizing customized enzyme

cocktails’, Biotechnology for Biofuels. BioMed Central,

12(1), pp. 1–19. doi: 10.1186/s13068-019-1628-z.

Leite, A. L. M. P., Zanon, C. D. and Menegalli, F. C. (2017)

‘Isolation and characterization of cellulose nanofibers

from cassava root bagasse and peelings’, Carbohydrate

Polymers. Elsevier Ltd., 157, pp. 962–970. doi:

10.1016/j.carbpol.2016.10.048.

De Man, J. ., Ragosa, M. and Sharpe, M. E. (1960) ‘A

Medium For Cultivation of Lactobacilli’, J Appl Bact,

1, pp. 130–135.

Mohd-asharuddin, S. et al. (2017) ‘A Chemical and

Morphological Study of Cassava Peel : A Potential

Waste as Coagulant Aid’, in MATEC Web of

Conferences. EDP Sciences, pp. 1–8. doi: 10.1051/

matecconf/201710306012.

Moongngarm, A., Trachoo, N. and Sirigungwan, N. (2011)

‘Low Molecular Weight Carbohydrates, prebiotic

content, and prebiotic activity of selected food plants in

Thailand’, Advance Journal of Food Science and

Technology, 3(4), pp. 269–274.

Murtiningrum et al. (2019) ‘Identification of Inulin Profile

From Red Fruit (Pandanus Conoideus L) Pedicel

Extract Using LC-MS And Its In Vitro Prebiotic

Activity Test’, International Journal of Advance

Reasearch, 7(11), pp. 344–351. doi: 10.21474/IJAR01/

10014.

Oluwanike, A. and Adeneye, M. A. (2014) ‘Evaluation of

chemical composition and nutritive potential of oil

palm slurry fermented with cassava peel as feed for

livestock’, African Journal of Agricultural Research,

9(26), pp. 2062–2067. doi: 10.5897/AJAR2013.7565.

Razie, F. et al. (2011) ‘Aktivitas Enzim Selulase Mikroba

Yang Diisolasi Dari Jerami Padi Di Persawahan Pasang

Surut di Kalimantan Selatan’, J. Tanah Linkungan,

13(2), pp. 43–48.

Selig, M., Weiss, N. and Ji, Y. (2008) Enzymatic

Saccharification of Lignocellulosic Biomass

Laboratory Analytical Procedure. Colorado.

van Soest, P. J. (1963) ‘Use of Detergents in the Analysis

of Fibrous Feeds. II. A Rapid Method for the

Determination of Fiber and Lignin’, Journal of AOAC,

46, pp. 829–835.

Surendran, A. et al. (2018) ‘Inhibition and Kinetic Studies

of Cellulosa and Hemicellulose Degrading Enzymes of

Ganoderma Boniense by NaturallyOccurring Phenolic

Compounds’, Journal of Applied Microbiology, 124(6),

pp. 1544–1555. doi: 10.1111/jam.13717.

Suryanto, H. (2015) ‘Thermal degradation of mendong

fiber’, in The 6th Green Techonlogy. Malang.

Tasaso, P. (2015) ‘ptimiz tio of Re ctio o ditio s for Sy thesis

of rboxymethy e u ose from i P m Fro ds’, International

Journal of Chemical Engineering and Applications,

6(2), pp. 3–6. doi: 10.7763/IJCEA.2015.V6.460.

Widiarto, S. et al. (2017) ‘Preparation and Characterization

of Cellulose and Nanocellulose from Agro-industrial

Waste - Cassava Peel’, in IOP Conference Series:

Materials Science and engineering. IOP Publishing, p.

176. doi: 10.1088/1742-6596/755/1/011001.

Widiarto, S. et al. (2019) ‘Cellulose Nanofibers Preparation

from Cassava Peelsvia Mechanical Disruption’, Fibers,

7(44), pp. 1–11. doi: 10.3390/fib7050044.

Worthington (2020) Worthington Enzyme Manual

Cellulase, Worthington Biochemical Corporation.

Available at: http://www.worthington-biochem.com/

CEL/default.html.

van Zanten, G. C. et al. (2012) ‘The Effect of Selected

Synbiotics on Microbial Composition and Short-Chain

Fatty Acid Production in a Model System of the Human

Colon’, PloS ONE, 7(10). doi: 10.1371/journal.pone.0

047212.

Van Zanten, G. et al. (2014) ‘Synbiotic Lactobacillus

acidophilus NCFM and cellobiose does nt affect humat

gut bacterial diversity but increases abudance f

lactobacili, bifidobacteria and branched-chain fatty

acids: a randomizes, double-blinded cross-over trial.’

doi: 10.1111/1574-6941.12397.

Characterization of Insoluble Fiber in Cassava Peel and Its Hydrolyzate Potential as a Prebiotic for Lactobacillus Plantarum

37