Study the Characteristics of Rice Supplements Made by Formulating

the Composition of Skim Milk, Ferrous Fumarate, and Thiamine

Asep Dedy Sutrisno

Food Technology Departemen, Engineering Faculty, Pasundan University,

Jl. Setiabudi no 193, Bandung 40153, West Java, Indonesia

Keywords: Supplements, Skim Milk, Ferrous Fumarate, Thiamine.

Abstract: Rice is a staple food ingredient as a source of carbohydrates, but low in micronutrients such as iron and

calcium, as well as relatively low thiamine (vitamin B

1

) and riboflavin (vitamin B

2

) due to the rice milling

process. This study aims to explore the manufacture of rice supplements by formulating the composition of

skim milk, ferrous fumarate and thiamine. The experimental research design used a factorial pattern, the first

factor was the concentration of skim milk with a variation of 20%; 30%; and 40%, the second factor is the

concentration of ferrous fumarate with a variation of 200 ppm; 300 ppm; and 400 ppm, and the third factor is

thiamine concentration with a variation of 300 ppm; 400 ppm; and 500 ppm. The rice supplements were tested

for micronutrient stability and organoleptic tests by adding them to rice when cooked. The results showed that

rice supplements which were added or fortified at the time of cooking, the test results showed that the protein,

calcium, and iron content were stable, while thiamine showed an average decrease in response of 9-10%.

Based on the results of the organoleptic test on the color parameters, the response was not significantly

different, while the organoleptic test for the taste and aroma parameters showed a significantly different

response.

1 INTRODUCTION

Rice (Oryza sativa) is a high source of energy from

carbohydrates and contributes to the largest

percentage of calorie fulfillment, however rice

contains relatively low protein, vitamins and

minerals. Grains and their yields are relatively low in

protein, also protein in grains is incomplete, with one

of the amino acids being lysine. The lysine content in

rice is approximately 4%. Skim milk is a good source

of protein, skim milk protein contains essential amino

acids (Hardinsyah and Martianto, 1989), to increase

the nutritional value of protein in rice can be done by

adding skim milk. According to the International Rice

Research Institute in the Philippines, the nutritional

value of rice needs to be improved. So far, rice is

known as a food source of energy, not a source of

vitamins and minerals that are important for health.

As nutrients, vitamins and minerals are needed by the

body in small amounts, but in fact they have a very

important function for the body’s metabolism so that

efforts are needed to increase the iron and thiamine

content in rice. In this case, to increase the iron

content, ferrous fumarate compounds are used,

because these compounds are organoleptically

acceptable and have good absorption in the body,

while to increase vitamins, thiamine is used which is

not easily oxidized and functions as an important

coenzyme in the body’s metabolic system.

Based on the nutritional adequacy ratio (RDA),

the protein requirement in adults is 62-65 g per day,

13-26 mg iron per day and 1.4 mg thiamine per day.

To meet the needs of daily nutritional intake (daily

intake) a food-based approach can be carried out,

namely by improving food or food and food

fortification.

Fortification is a deliberate effort to add important

micronutrients, namely vitamins and minerals to food

so that it can improve the nutritional quality of the

food supply and benefit public health with minimal

risk to health.

Rice was chosen as food for fortification because

it is a staple food consumed by the population,

especially in Asia. In addition, rice is generally

cooked singly, without the addition of other

ingredients and seasonings. Therefore, rice has a great

opportunity to be fortified. The Indonesian

government also launched mandatory fortification for

Sutrisno, A.

Study the Characteristics of Rice Supplements Made by Formulating the Composition of Skim Milk, Ferrous Fumarate, and Thiamine.

DOI: 10.5220/0010507200003108

In Proceedings of the 6th Food Ingredient Asia Conference (6th FiAC 2020) - Food Science, Nutrition and Health, pages 25-30

ISBN: 978-989-758-540-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

25

rice products that must contain thiamine, folic acid,

iron, zinc and others.

The purpose of this study was to study the

characteristics of rice supplements containing sources

of protein, calcium, iron, and thiamine (vitamin B

1

)

by testing cooked rice. The results of this study are

expected to contribute to the fulfillment of

community nutrition through rice, which is a staple

food source, especially in the Asian region.

2 METHODOLOGY

2.1 Materials

The materials used in this study include the main raw

materials, namely maltodextrin, skim milk, ferro

fumarate, and thiamine, and IR-64 rice supporting

materials and chemicals for testing protein, calcium,

iron, and thiamine. The tools used consisted of a set

of rice supplement powder making tools, including a

tunnel dryer, mixer / blender, grinder. A set of rice

cookers and a set of analyzers / test kits for protein,

calcium, iron and thiamine.

2.2 Method

The research was conducted in three stages, namely

the first, second and third stages of research.

2.2.1 First Stage Research

The first phase of research was to conduct nutritional

analysis of protein, calcium, iron, and thiamine on IR

64 rice and analysis of skim milk on protein and

calcium content.

2.2.2 Second Stage Research

The second stage of research was the manufacture of

rice supplements with the amount (weight) according

to the research needs, namely by mixing maltodextrin

and skim milk with a composition variation of 4: 1

(s1); 7: 3 (s2); and 3: 2 (s3), the mixture of these

ingredients is then mixed with 30% (w / w) water,

stirring until homogeneous. Then in each of these

mixtures were added Ferrous Fumarate to reach a

concentration of 200 ppm (f1), 300 ppm (f2), and 400

ppm (f3), and thiamine was added to each mixture

until it reached a concentration of 300 ppm (t1), 400

ppm (t2) and 500 ppm (t3), while continuing to stir

until homogeneous. Furthermore, each drying

process was carried out at a temperature of 45

○

C. For

4 hours using a tunnel dryer, after the dry conditions

have been reached, it is milled and sieved with an 80

mesh sieve so that rice supplements are obtained in

the form of powder with varying nutritional

compositions, then testing the nutritional stability of

rice cooking. In this second phase of research,

analysis of rice supplements on protein, calcium, iron

and thiamine was also carried out. The second stage

experimental formulation can be described in the

following table:

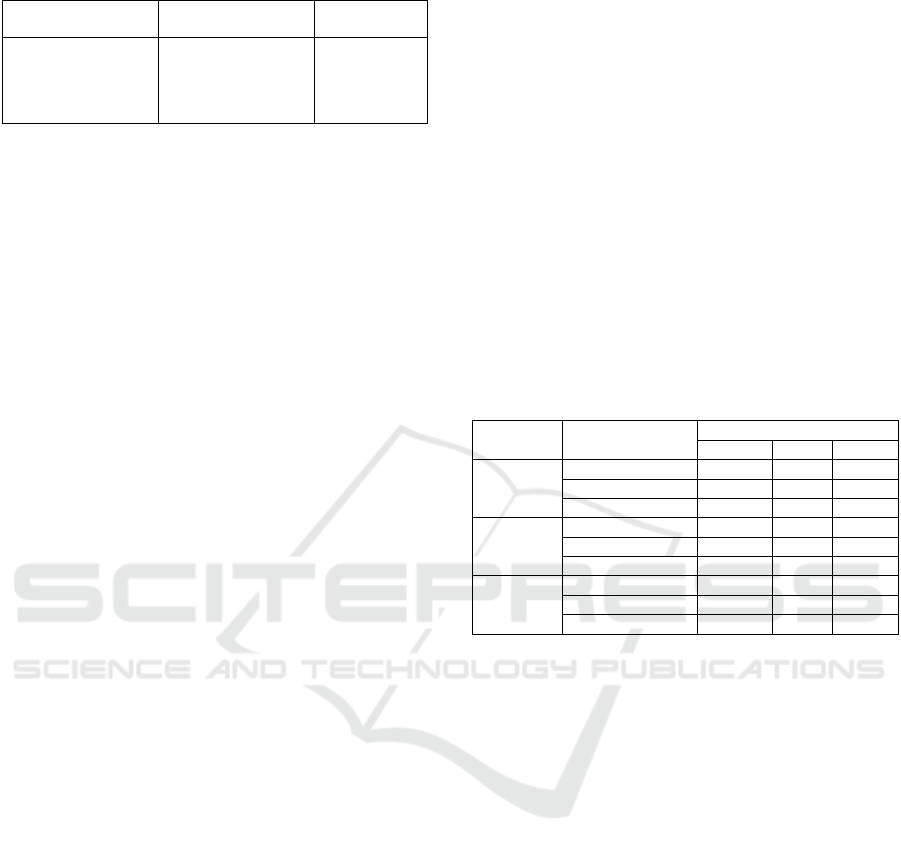

Table 1: Formulations for making rice supplements.

D: M (S)

Fe-

fumarate

(F), (ppm)

Thiamine (T),(ppm)

(t

1

)300 (t

2

)400 (t

3

)500

(s

1

) 4 : 1

(f

1

) 200 s

1

f

1

t

1

s

1

f

1

t

2

s

1

f

1

t

3

(f

2

) 300 s

1

f

2

t

1

s

1

f

2

t

2

s

1

f

2

t

3

(f

3

) 400 s

1

f

3

t

1

s

1

f

3

t

2

s

1

f

3

t

3

(s

2

) 7 : 3

(f

1

) 200 s

2

f

1

t

1

s

2

f

1

t

2

s

2

f

1

t

3

(f

2

) 300 s

2

f

2

t

1

s

2

f

2

t

2

s

2

f

2

t

3

(f

3

) 400 s

2

f

3

t

1

s

2

f

3

t

2

s

2

f

3

t

3

(s

3

) 3 : 2

(f

1

) 200 s

3

f

1

t

1

s

3

f

1

t

2

s

3

f

1

t

3

(f

2

) 300 s

3

f

2

t

1

s

3

f

2

t

2

s

3

f

2

t

3

(f

3

) 400 s

3

f

3

t

1

s

3

f

3

t

2

s

3

f

3

t

3

D: M = Maltodextrin: Skim Milk

2.2.3 Third Stage Research

This third phase of research is a test of the nutritional

stability of the rice supplements. Rice cooking is

carried out with 500 g of IR 64 rice, after washing

were added 300 g of water and 25 g of rice

supplement. Each time the rice is cooked, the rice is

previously added / mixed with each rice supplement

whose nutritional composition varies. After cooking,

the rice produced is then tested for nutritional content

of protein, calcium, iron and thiamine. So that it can

be seen the nutritional stability before and after

cooking rice. At the same time, organoleptic or

sensory testing is also carried out on the parameters

of color, taste, and aroma.

3 RESULTS AND DISCUSSION

The first stage of research is the analysis of IR 64 rice

raw materials. The analysis carried out in this first

stage research was to determine the nutritional

composition of rice before the fortification

experiment and testing of the nutritional stability of

cooked rice were carried out, namely testing the

levels of protein, calcium, iron and thiamine.

The results of the analysis can be produced as

follows:

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

26

Table 2: Results of Analysis of IR 64 Rice and Skim Milk.

Nutritional

Components

IR 64 White Rice Skim Milk

Protein

Calcium

Fe

Thiamine

5.82%

51.60 ppm

8.55 ppm

1.24 ppm

32.45 %

113.40 ppm

6.42 ppm

3.50 ppm

According to the World Food Program (2015), the

iron content in rice to be enriched with iron should

not be less than 40 mg / kg and no more than 48

mg/kg. According to the nutritional label reference

for processed food (2016), the daily nutritional

adequacy figure required for thiamine intake is 1.4

mg/day. Based on the nutritional adequacy ratio

(RDA), the protein requirement in adults is 62-65 g

per day, 13-26 mg iron per day and 1.4 mg thiamine

per day. To meet the needs of daily nutritional intake

(daily intake) a food-based approach can be carried

out, namely by improving food or food fortification.

Based on the results of the analysis of IR 64 rice

on protein, calcium, iron, and thiamine, it can be

concluded that the rice consumed by the public shows

a deficiency in the micronutrients of calcium, iron,

and thiamine. So that fortification efforts are needed,

one of which is by adding rice supplements that have

been enriched with iron sources from Fero Fumarate,

calcium from skim milk, and thiamine from pure

thiamine. Meanwhile, the body's need for protein can

be supplied from animal protein food sources.

The results of the second stage of research with

the formulations in table 1, the nutritional

concentrations (protein, calcium, iron, and thiamine)

are as follows:

Protein and calcium content for every 100 g of rice

supplements,

- for comparison of maltodextrin : Skim milk (4:1)

contains protein = 6.49 % and calcium 22.68 ppm.

- for comparison of maltodextrin : Skim milk (7:3)

contains protein = 9.735 % and calcium 34.02 ppm.

- for comparison of maltodextrin : Skim milk (3:2)

contains protein = 12.98 % and calcium 45.02 ppm.

Iron content for every 100 g of rice supplement,

- for comparison of maltodextrin : Skimmed milk (4

: 1), mixed with 200 ppm ferrous fumarate, contains

iron = 671,284 ppm; mixed with 300 ppm ferrous

fumarate, contains iron = 1006.28 ppm; mixed with

400 ppm ferrous fumarate, contains iron = 1341.28

ppm.

- for comparison of maltodextrin : Skimmed milk (7

: 3), mixed with 200 ppm ferrous fumarate, contains

iron = 671.293 ppm; mixed with 300 ppm ferrous

fumarate, contains iron = 1006.93 ppm; mixed with

400 ppm ferrous fumarate, contains iron = 1341.93

ppm.

- for comparison of maltodextrin: Skimmed milk (3 :

2), mixed with 200 ppm ferrous fumarate, contains

iron = 672.568 ppm; mixed with 300 ppm ferrous

fumarate, contains iron = 1007.568 ppm; mixed

with 400 ppm ferrous fumarate, contains iron =

1342.567 ppm.

The protein, calcium, and iron content in the process

of making rice supplements did not change, while the

thiamine content changed as follows.

The changes that occur from thiamine before and

after the process of making rice supplements are due

to the heat process, namely during drying and milling,

resulting in a decrease in the thiamine content in

powdered rice supplements.

Table 3: Thiamine content (ppm) for every 100 g of rice

supplement.

D: M (S)

Fe-fumarate (F),

(ppm)

Thiamine (T),(ppm)

300 400 500

4 : 1

200 216 332 420

300 234 328 444

400 230 323 432

7 : 3

200 224 329 425

300 210 320 432

400 239 330 425

3 : 2

200 222 324 419

300 218 328 438

400 230 331 430

D : M = Maltodextrin : Skim Milk

This third stage of research is the application of

rice supplements that are added when the rice cooking

process is about to be carried out using a rice cooker.

The results of the third stage research can be

shown as follows:

Protein and calcium content for every 500 g of rice,

- for comparison of maltodextrin : Skim milk (4 : 1)

contains protein = 30.7225 g (4.76 %) and calcium

26.367 mg (40.879 ppm).

- for comparison of maltodextrin : Skim milk (7 : 3)

contains protein = 31.5338 g (4.89 %) and calcium

26.651 mg (41.319 ppm),

- for comparison of maltodextrin : Skim milk (3 : 2)

contains protein = 32.345 g (5.015 %) and calcium

26.934 g (41.785 ppm).

Iron content for every 500 g of rice,

- for comparison of maltodextrin : Skimmed milk (4

: 1), mixed with 200 ppm ferrous fumarate, contains

iron = 32.646 ppm; mixed with 300 ppm ferrous

fumarate, contains iron = 45.62 ppm; mixed with

400 ppm ferrous fumarate, contains iron = 58.615

ppm

Study the Characteristics of Rice Supplements Made by Formulating the Composition of Skim Milk, Ferrous Fumarate, and Thiamine

27

- for comparison of maltodextrin: Skimmed milk (7 :

3), mixed with 200 ppm ferrous fumarate, contains

iron = 32.647 ppm; mixed with 300 ppm ferrous

fumarate, contains iron = 45.63 ppm; mixed with

400 ppm ferrous fumarate, contains iron = 58.64

ppm

- for comparison of maltodextrin: Skimmed milk (3 :

2), mixed with 200 ppm ferrous fumarate, contains

iron = 32.651 ppm; mixed with 300 ppm ferrous

fumarate, contains iron = 45.66 ppm; mixed with

400 ppm ferrous fumarate, contains iron = 58.71

ppm.

Protein, calcium, and iron in the process of processing

rice supplements in the second stage of the study

showed that they did not change or decrease

significantly, this may be because there are no factors

that cause protein destruction. While for calcium and

iron are relatively stable to the effects of oxidation or

reduction, so they are relatively stable or do not

experience change / decrease. Meanwhile, there was

a relatively slight decrease in thiamine, but in this

second stage the decrease was not significant.

Based on the results of the third stage research, it

shows that the amount of protein, calcium, and iron is

not significantly different or does not

change/decrease the weight content of protein,

calcium and iron before cooking and after cooking, so

the content (weight) is relatively the same. The

protein, calcium and iron content in this third stage

experiment showed the same stability as in the second

stage experiment for the same reasons. However, the

concentration of the three has increased. This happens

because the process of cooking rice into rice does not

have any activities that separate or degrade the

components of protein, calcium and iron.

The results of this study can be identified that the

protein, calcium, and iron content increased

compared to cooked rice without the addition of rice

supplements made in the second stage.

Based on the results of the third stage research, it

showed that there was a change or decrease in

thiamine either in quantity or concentration

significantly, but there was an increase in thiamine

content when compared to rice cooked with the

addition of rice supplements (made in the second

stage) and rice cooked without the addition of rice

supplements.

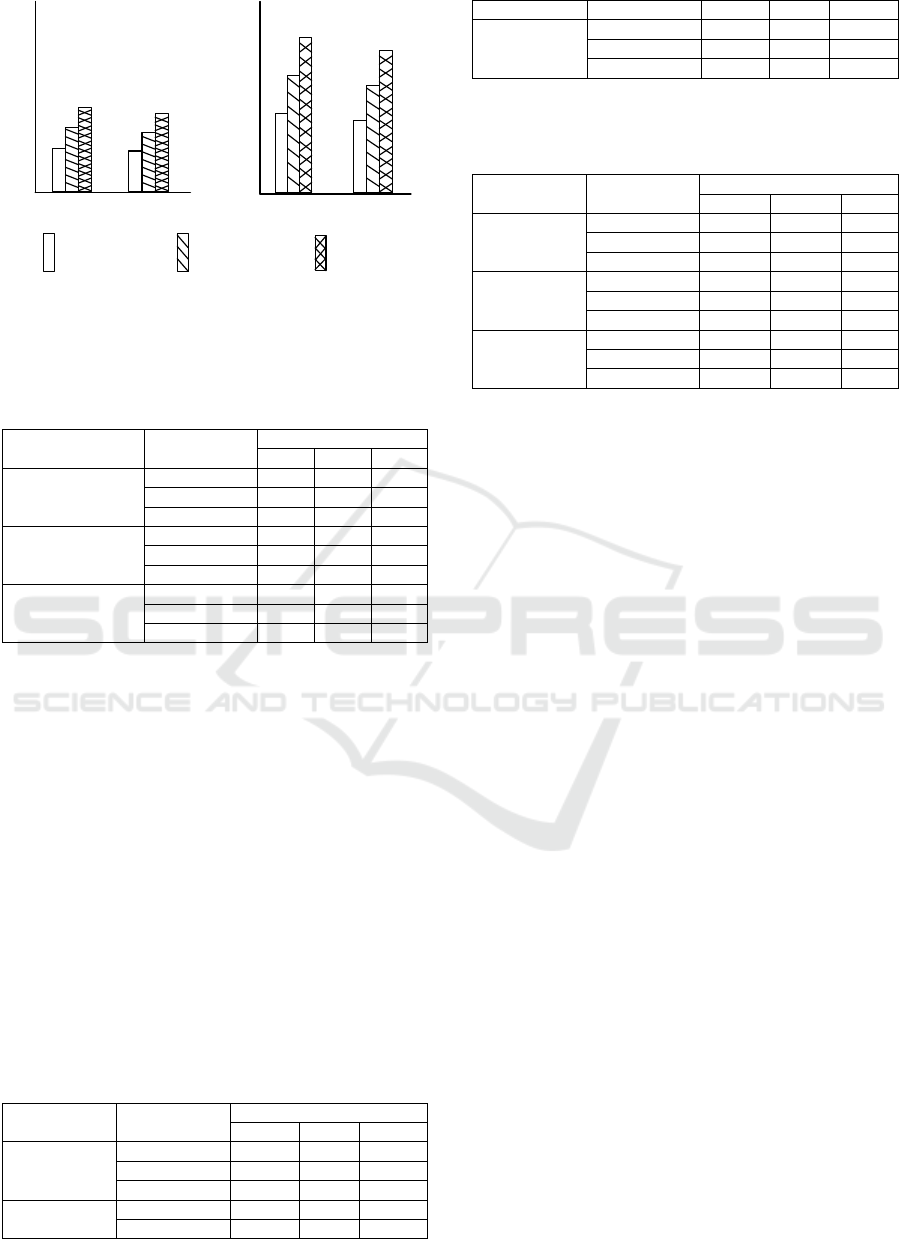

Table 4: Thiamine content (mg) for every 500 g of rice.

D : M (S)

Fe-fumarate

(F), (ppm)

Thiamine (T),(ppm)

300 400 500

4 : 1

200 4.65 6.54 8.70

300 4.44 5.91 7.90

400 4.56 5.70 8.40

7 : 3

200 4.82 6.77 8.90

300 5.00 6.20 8.20

400 4.64 5.90 8.80

3 : 2

200 5.00 7.10 9.20

300 5.60 6.43 9.10

400 5.20 6.20 9.30

D : M = Maltodextrin : Skim Milk

The decrease in the amount or concentration of

thiamine in cooked rice may be due to the effect of

heating, resulting in some thiamine degradation. So it

can be assumed that the temperature and duration of

cooking can affect the reduction in thiamine content,

so with the rice supplements that are added before

starting cooking, it can be used as an effort to

maintain the thiamine content according to the

established standard of normal human needs, namely

1.4 mg/day.

Table 5: Thiamine content (ppm) for every 500 g of rice.

D: M (S)

Fe-fumarate

(F), (ppm)

Thiamine (T),(ppm)

300 400 500

4 : 1

200 9.30 13.10 17.40

300 8.88 11.80 15.80

400 9.20 11.40 16.80

7 : 3

200 9.60 13.20 17.80

300 10.00 12.40 16.40

400 9.20 11.80 17.60

3 : 2

200 10.00 14.20 18.40

300 11.20 12.80 18.20

400 9.90 12.40 18.60

D : M = Maltodextrin : Skim Milk

Thiamine decreased, this is because thiamine is

relatively unstable by heat, which is in accordance

with the chemical properties of thiamine, is stable at

acidic pH, but is not stable in alkaline solutions, and

is not stable to heat, but is stable during storage in

frozen conditions. In addition, thiamine is also

unstable when exposed to ultraviolet rays and gamma

ray irradiation. The lack of stability in thiamine may

also be the result of a strong reaction to the Maillard

reaction.

The organoleptic/sensory test results with the rice

color attribute showed no significant difference for

each addition of rice supplements, which appeared to

be slightly yellowish in color. The yellowish color of

the cooked rice is due to the presence of Fero

Fumarat which is reddish orange in color, which has

an effect on the color of the rice Therefore, the more

Fero Fumarat content in the rice supplement, the

more it affects the color of the rice. So the use of rice

supplements based on this research is recommended

to supplement rice with the addition of 200 ppm and

this can meet the iron needs in rice for consumption

by normal humans.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

28

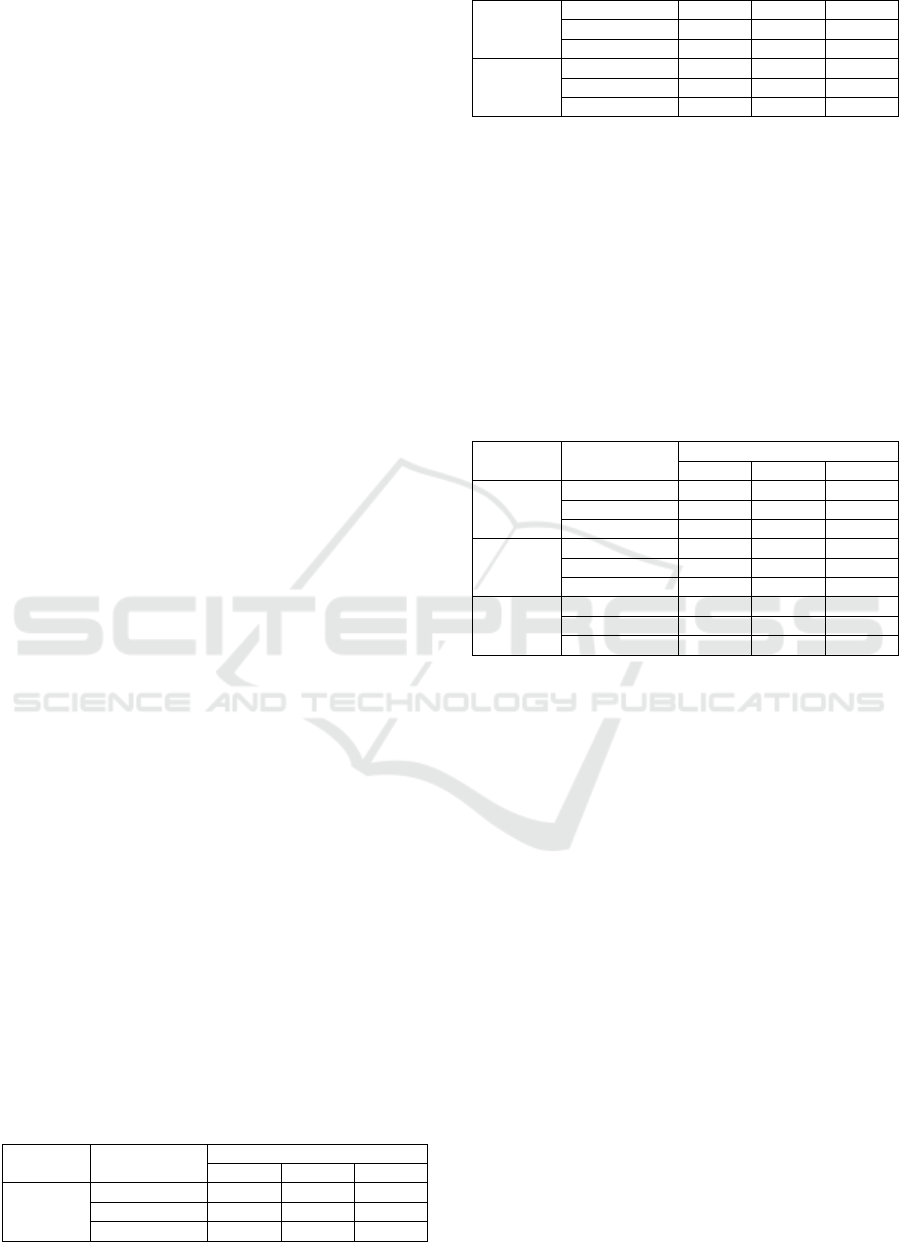

Thiamine (mg)

10

20

Weight of thiamne

Before cooking

Weight of thiamine

after cooking

20

10

Concentration of

thiamine Before

cooking

Concentration of

thiamine after

cooking

Thiamine (ppm)

The addition of

thiamine (300 ppm)

in rice supplement

processing

The addition of thiamine

(500 ppm) in rice

supplement processing

The addition of thiamine

(400 ppm) in rice

supplement processing

5

Figure 1: Comparison of the quantity and concentration of

Thiamine in rice before and after cooking to which rice

supplements are added.

Table 6: Organoleptic test results with color attributes for

every 500 g of rice.

D : M (S)

Fe-fumarate

(F), (ppm)

Thiamine (T),(ppm)

300 400 500

4 : 1

200 2.4 2.6 2.6

300 2.7 2.7 2.6

400 2.8 2.8 2.7

7 : 3

200 2.5 2.5 2.4

300 2.6 2.6 2.5

400 2.7 2.7 2.8

3 : 2

200 2.4 2.6 2.5

300 2.6 2.7 2.6

400 2.7 2.7 2.6

D : M = Maltodextrin : Skim Milk

The organoleptic/sensory test results with the rice

aroma attribute showed a significant difference for

each addition of rice supplements, namely rice added

with rice supplements with 200 ppm Fero fumarate

content was relatively preferred, and the more ferrous

fumarate content the less preferred.

The organoleptic/sensory test results with the rice

taste attribute showed a significant difference for each

addition of rice supplements, namely rice added with

rice supplements with 200 ppm Ferrous fumarate

content was relatively preferred and the more ferrous

fumarate content the less preferred. so with the

addition of thiamine in this amount can be

recommended, so that it can be considered minimally

and efficiently.

Table 7: Organoleptic test results with aroma attributes for

every 500 g of rice.

D : M (S)

Fe-fumarate

(F), (ppm)

Thiamine (T),(ppm)

300 400 500

4 : 1

200 4.3 4.4 4.3

300 3.7 3.7 3.6

400 3.1 3.0 3.1

7 : 3

200 4.4 4.5 4.4

300 3.6 3.6 3.7

400 2.7 3.1 2.8

3 : 2

200 4.3 4.1 4.6

300 3.5 3.7 3.6

400 2.7 2.7 2.6

D : M = Maltodextrin : Skim Milk

Table 8: Organoleptic test results with taste attributes for

every 500 g of rice.

D : M (S)

Fe-fumarate

(F), (ppm)

Thiamine (T),(ppm)

300 400 500

4 : 1

200 4.8 4.8 4.6

300 3.4 3.5 3.3

400 3.1 3.2 3.2

7 : 3

200 4.6 4.5 4.5

300 3.6 3.6 3.4

400 2.8 3.1 2.9

3 : 2

200 4.5 4.5 4.5

300 3.5 3.4 3.3

400 2.6 2.6 2.6

D: M = Maltodextrin : Skim Milk

4 CONCLUSION

Based on this research, three-stage experiments have

been carried out, namely nutritional analysis of IR 64

rice and skim milk, rice supplement processing, and

application trials in rice cooking, it can be concluded

that the protein, calcium, and iron content did not

significantly decrease in rice cooking process. While

the thiamine content decreased in the rice cooking

process, it could still contribute to rice fortification

and was acceptable to consumers.

Experiments of this research can recommend that

optimal rice supplement is the mixing formulation of

Maltodextrin : Skim milk (4 : 1); Ferrous fumarate

200 ppm; and thiamine 300 ppm. The reason for the

formula recommendation is that it can meet the

nutritional standard requirements, is acceptable to

consumers, and is relatively efficient from the rice it

produces.

REFERENCES

Atungulu, G., Pan Z., 2014. Rice industrial processing

worldwide and impact on macro- and micronutrient

content, stability, and retention. Ann N Y Acad

Sci.;1324:15–28.doi:10.1111/ nyas. 12492.

Billiris, M. A., Siebenmorgen, T. J., Meullenet, J. F., &

Mauromoustakos, A., 2012. Rice degree of milling

effects on hydration, texture, sensory and energy

characteristics. Part 1. Cooking using excess water.

Journal of Food Engineering. 113(4), 559–568.

https://doi.org/10.1016/j.jfoodeng.2012.07.005.

Study the Characteristics of Rice Supplements Made by Formulating the Composition of Skim Milk, Ferrous Fumarate, and Thiamine

29

Codex Alimentarius. Codex standard for rice. CODEX

STAN198–1995 (www.fao.org/input/download/

standards/61/CXS_198e.pdf, accessed 28 March 2018).

Daniel, 2014. Rendang Tin Rice: Evaluation of

Microbiology, Chemistry, and Organoleptic. Thesis.

Department of Food and Agricultural Product

Technology Faculty of Agricultural Technology,

Gadjah Mada University, Yogyakarta.

Hardinsyah, I., Briawan, D., Budianto, S., Hustina, P,

Ghifari, N, Suhandono, S., 2016. Production and

clinical impact study of micronutrients fortified rice for

teen girls in Islamic boarding school in Medan,

Indonesia. Final report. West Java: Food and Nutrition

Society of Indonesia (Pergizi Pangan Indonesia);

(http://www.better-rice-initiativeasia.org/admin/upload

/resources/06-12-2016-1481018862.pdf, accessed 29

March 2018).

Hussain, SZ, Singh, B, Rather, AH., 2014. Efficacy of

micronutrient fortified extruded rice in improving the

iron and vitamin A status in Indian schoolchildren. Int

J Agric Food Sci Technol; 5(3):227–38.

Malik, A., Nawaz, Shu Fukai & Bhesh Bhandari., (2017).

In situ analysis of cooking properties of rice by thermal

mechanical compression test method, International

Journal of Food Properties, 20:5, 1174-1185.

Martins, C., Bandeira, A., Duarte, H., Sena, R., Silva, S.,

Mattos, C. et al., 2017. Effect of cooking methods on the

stability of thiamin and folic acid in fortified rice.

International Journal of Food Science and Nutrition,

68(2):179–187.

Mayowa, S., Sanusia, Rahman, A., and Nahemiah, D.,

(2017). Evaluation of Physical, Milling and Cooking

Properties of Four New Rice (Oryza Sativa.) Varieties

in Nigeria. International Journal of Food

Studies.6(2),245–256.

Muthayya, S., Hall, J., Bagriansky, J., Sugimoto, J.,

Gundry, D., Matthias, D. et al., 2012. Rice fortification:

an emerging opportunity to contribute to the

elimination of vitamin and mineral deficiency

worldwide. Food Nutrition Bull; 33:296307.

Pinkaew, S., Wegmuller, R., Hurrell, R., 2012. Vitamin A

stability in triple fortified extruded, artificial rice

grains containing iron, zinc and vitamin A. Int J Food

Sci Technol; 47:2212–20.

Rather, T. A., Malik, M. A., & Dar, A. H., (2016). Physical,

milling, cooking, and pasting characteristics of

different rice varieties grown in the valley of Kashmir

India. Cogent Food & Agriculture, 2(1),

1178694.doi:10.1080/23311932.2016.1178694.

Ridwan, R., Syafaruddin, L., 2016. Prospek Teknologi

Pembuatan Beras Bergizi Melalui Fortifikasi Iodium. J.

Pangan,Vol 19, no 3. E-ISSN 2527-6239. DOI

10.33964/jp.v19i3.145.

Steiger, G., Müller-Fischer, N., Cori, H., Conde-Petit, B.,

2014. Fortification of rice: technologies and nutrients.

Ann N Y Acad Sci.;1324:29–39. doi:10.1111/

nyas.12418.

Villota, S. M. A., Tuates, Jr., A. M., & Capariño, O. A.,

(2016). Cooking Qualilites and Nutritional Contents of

Parboiled Milled Rice. Asian Journal of Applied

Sciences, 4(5). Retrieved from https://ajouronline.com/

index.php/AJAS/article/view/4154.

Wieringa, FT., Laillou, A., Guyondet, C., Jallier, V.,

Moench-Pfanner, R., Berger, J., 2014. Stability and

retention of micronutrients in fortified rice prepared

using different cooking methods. Ann N Y Acad Sci.

2014;1324:40–7.doi:10.1111/nyas.124 97.

Yu, L. et al. 2017. Review of the Effects of Different

Processing Technologies on Cooked and Convenience

Rice Quality. Trends in Food Science and Technology

59: 124–38.

6th FiAC 2020 - The Food Ingredient Asia Conference (FiAC)

30