A Study of the Impact of the Organizational Purchasing Structure on

Supplier’s Performance in the Hospital Sector

Kaoutar Jenoui

Laboratory Smartilab, Moroccan School of Engineering Sciences (EMSI) Rabat, Morocco

Keywords: Purchasing, Hospital sector, performance, supplier, healthcare organization.

Abstract: The purchasing function plays a key role in the hospital sector. To achieve economies of scale in process costs,

one of the questions that arises as a healthcare organization is whether to centralize or decentralize purchasing

activities. Several managers of hospital systems mentioned the problem of choosing a better purchasing

structure. In most cases, the choice of the organizational purchasing structure directly involves an impact on

supplier’s performance. However, this impact has never been considered in this decision. Organizational

innovation is a major issue for the performance of hospitals, but the performance of suppliers also has a heavy

impact on the improvement of health infrastructure. Nowadays supplier’s performance is an essential element

for improving the quality process of hospital care. In this context, we propose to analyse whether considering

supplier’s performance could affect the decision regarding the organizational purchasing structure in the

hospital sector. We verify the influence of purchasing structures on both the objectives of the hospital

purchasing process, as well as on the performance of suppliers, through a study-test carried out in CHIS Rabat-

Morocco.

1 INTRODUCTION

In Morocco, the Ministry of Health has undertaken

several actions to make medical products available

and accessible to the population. It has a national list

according to the last revision, which was carried out

in 2011. The pharmaceutical products covered by this

list benefit from an annual budget allocated by the

Ministry of Health, to ensure their availability at the

level of public hospitals and health care facilities.

This budget increased by 67% between 2002 and

2012, reaching the sum of 1.6 billion dirham (

Cheng

E.W.L, 2001

). Despite the efforts made by the

ministry, access to medications and medical devices

in hospitals remains insufficient (Charles Collins

1994). The main factor that reduces the availability of

medical products is the inability to achieve good

supplier performance. Experiences have shown that it

is possible to improve access to these products by

making the best use of resources, and by streamlining

management processes (

Modi,2007). Indeed, the

choice of the purchasing structure could help to

develop the performance of the supplier's supply

chain. As it could also involve a variety of risks that

harm this performance. This change itself leaves an

indirect impact on the performance of the hospital's

supply chain. Choosing the right organizational

purchasing structure is essential for improving the

performance of the supplier's system. Therefore, our

study aims to highlight the improvement of the

organizational purchasing structure, and

simultaneously evolve the quality of services and

pharmaceutical products from suppliers. We propose

to organize this paper as follows. We will detail the

problematic in section 2. In Section 3, we will present

the two scenarios: centralized and decentralized

purchasing. In section 4, we will present the study-

test framing, followed by a discussion and analysis of

results. Finally, we will conclude with some

perspectives.

2 PROBLEM DESCRIPTION

From 1980 there have been six changes made to the

hospital purchasing system. Sometimes they are

based on the centralized structure, sometimes on the

decentralized structure, (see Table 1). After 2003, the

choice was to take the centralized structure as the

unique and stable choice. The application of each

structure has generated advantages and disadvantages

for hospitals. The budgets allocated to the purchasing

of pharmaceuticals products by the Ministry of Health

are of the order of 2 billion dirhams annually. This

budget has experienced a spectacular increase over

the past 12 years, as the budget for 2003 did not

exceed 300 million dirhams (

Juran, J.M. 1990).

Table 1: A brief history of the health care supply system

1917 Centralization Creation of the central

pharmacy in Casablanca

1980 Decentralization With many difficulties

encountered by the central

pharmacy, there was an

introduction of the direct

delivery system by

manufacturers to health

facilities.

1985-

1986

Centralization

The aggravation of problems

due to the small size of the

premises and the storage

spaces implies a return to

centralization. They installed

the new Berrechid unit for

the storage and distribution

of pharmaceuticals.

1994 Decentralization Creation of the supply

division under the general

secretariat of the Ministry of

Health.

1995 Centralization Implementation of the

Berrechid unit to centralize

medical products

purchases.

1997 Decentralization Decentralization of

purchasing

2001 Centralization Centralization of supply

(purchasing, storage,

distribution) by the

purchasing division.

2003 Decentralization Decentralization of

purchases in view of the

difficulties of regular

supplies.

In the face of all these changes and developments

in the organizational purchasing structure, Moroccan

hospitals continue to suffer from insufficient quality,

unavailability of pharmaceuticals products and rising

costs (

Deming, W.E. 1950). Storage and distribution

centers cost up to one billion Dirhams per year. In

addition, the storage and distribution of medical

products in Morocco costs the Ministry of Health

over 30 million Dirhams per year (

K. Jenoui,2017; A.

Abouabdellah, 2014). This shows huge costs due to the

poor performance of the supplier and the

inappropriate choice of organizational purchasing

structure. In this optic, we propose to study the impact

of the purchasing structure on the supplier’s

performance through a study-test to validate the main

causes of the variation in their performance and look

for possible solutions. We set two main objectives:

- Simulation of both scenarios with suppliers:

centralized structure, and decentralized structure,

with studying the impact of each of them on the

development of hospital objectives.

- Assessment of supplier performance in terms of

total cost and delivery date and analyse the impact of

implementing each purchasing structure on their

performance.

3 SCENARIOS MODELING:

CENTRALIZED AND

DECENTRALIZED

We will propose a model, which allows us to make a

comparison that relates to the differences between the

results of both scenarios. According to the suppliers

interviewed, we take stock of the costs, which are

presented in two types:

3.1 Variable or Operational Costs

Variable costs are costs constituted only by charges

that vary with the volume of activity of the company,

for example, the quantities produced and/or sold,

without necessarily being an exact proportionality

between the variation in charges and the variation in

the volume of products obtained.

3.2 Fixed Costs

Fixed costs correspond to the charges generated by

administration or sustainable investments. They are

not proportional to the quantities produced. To follow

sales price creation, variable costs are considered one

of the main issues for suppliers (

A. Marie, 2006; D.

Serrou, 2016

). Although the production cost is the

most important to indicate, it is often necessary to be

able to break down the cost structure into several

costs. In this study we have focused on the following

types:

The production cost, which consists of

making all direct expenses that were made to

produce a good, including the purchase and

consumption of materials, labor,

maintenance of equipment (

J. Dumoulin,

2004

).

The distribution cost, which includes all the

charges necessary for the distribution and

sale of the product. It includes expenses due

to the management of the stock of products,

transport to sale, but also additional

expenses directly linked to the distribution

of products (

P. Trouiller, 2013).

The preparation cost, which is the cost

associated to an order, includes all the

expenses necessary to prepare an order,

which depends of the number of parcels and

the number of units of parts, such as the costs

of handling, picking and packaging.

In our model, the notation used is shown in Table 2.

Table 2.

E: Central pharmacy

H: Number of hospitals, each represented by the

index i, where i ϵ {1, 4}

S: Number of suppliers, each is represented by the

index j, where j ϵ {1, 10}

Q

: Quantity of products ordered from each

supplier j

Dh

: The requirement date imposed for each

supplier j

TCc

: Total cost in centralization structure for

each supplier j.

TCd

: Total cost in decentralization structure

for each supplier j.

GC

: Gap time in centralization structure for

each supplier j.

GD

: Gap time in decentralization structure for

each supplier

j

.

Centralization Decentralizati

on

Unit price for

each product j

U

U

Distance

covered

Distance

between

supplier j and

central

pharmacy D

Distance

between

supplier j and

hospital i D

Preparation

cost per

product j

Cc

Cd

Delivery cost

per product j

Tc

Td

Labor cost for

distribution

per hour

Pc

Pd

Number of

parcels

delivered by

each supplier j

Nc

Nd

The delivery

date indicated

by each

supplier j

Dc

f

Dd

f

Number of

hours for

distribution

Distribution of

product j to the

central

pharmacy d

Number of

hours for the

distribution of

product j to the

hospital i d

The time

remaining to

the start of the

validity period

indicated by

each supplier j

for each

product i

Tc

Td

Total cost

TCc

Q

∗

U

Q

∗

Cc

Pc

∗

Tc

∗ D

+

d

∗ P

TCd

Q

∗

U

Q

∗

Cd

Pd

∗

Td ∗ D

+ d

* P

4 STUDY-TEST FRAMING

The CHIS Ibn Sina Rabat is one of the most important

hospital structures in Morocco. It brings together ten

specialized hospitals with a multi-site platform

created since 1954. The CHIS is implementing

significant resources to improve its daily efficiency.

In this context, our study aims to optimize logistics

activities. Currently, the hospital is leading a project

to regroup pharmacies, which must consider the

management of supplier performance. Consequently,

activities are carried out in redundancy in several

establishments and sometimes in several departments

within the same hospital. The strategy of pooling

resources was born because of several observations.

In most cases, the aim of the consolidation is to

reduce operating costs and increase the efficiency of

the system. It is in this optic that we are interested in

studying the impact of the organizational purchasing

structure on supplier performance. To implement the

test-study, we approached it by looking for 20

suppliers who would probably accept our test-study.

We contacted them by email, explaining the

objectives behind our study, and then we made

several phone calls with several potential participants

to discuss a short survey to assess needs. 80% of

suppliers indicated that they are not satisfied with the

organizational purchasing structure established by

healthcare organizations, and 45% of them are

interested in our test study, while 35% of suppliers do

not care about any change. 20% of suppliers show

interest in the hospital purchasing strategy, however,

only 45% of them are interested in participating in

this study, making a total of nine suppliers as

indicated in figure 1. The major challenge is to clearly

communicate the plan to each supplier, in a form that

they can understand and put into practice (Figure 2).

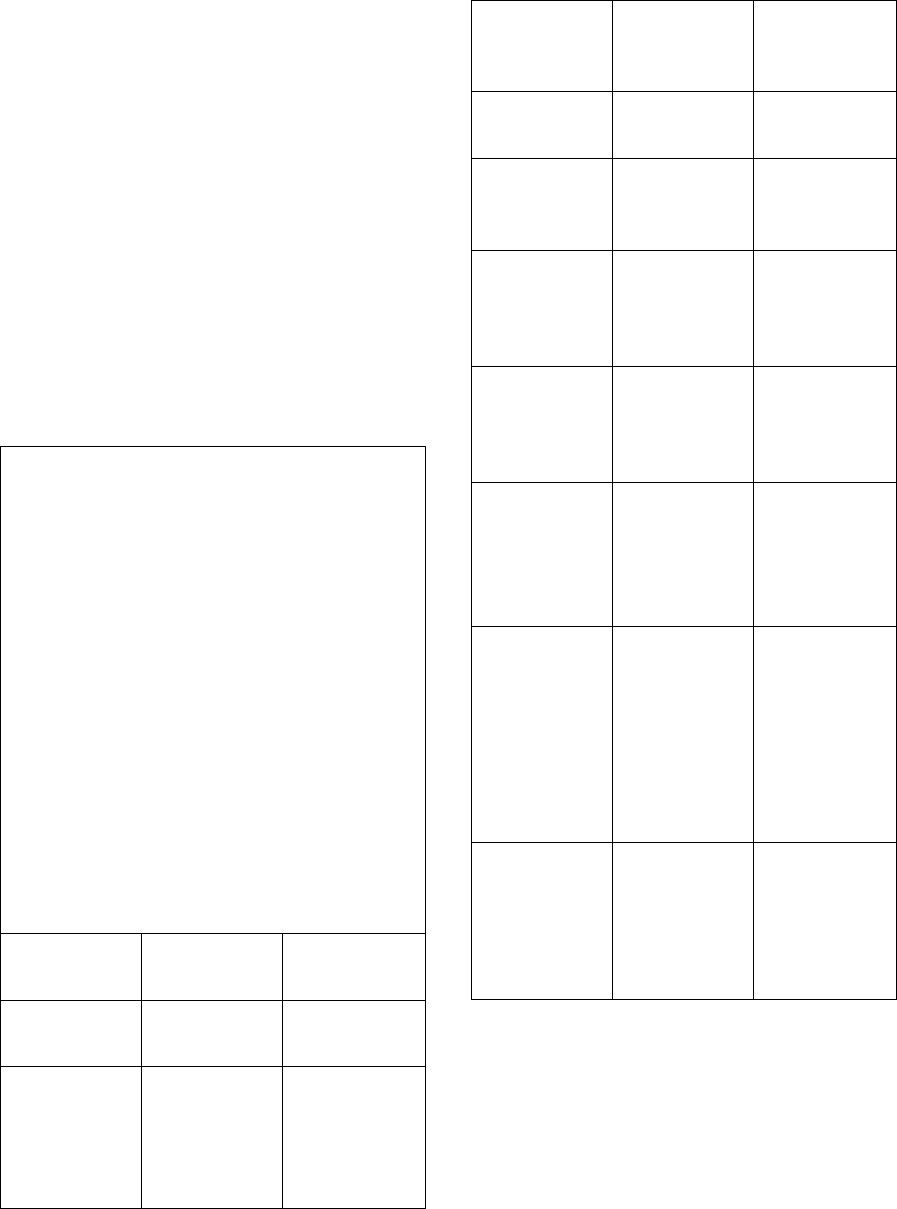

Figure 1 : Survey results

5 RESULTS ANALYSIS

Suppliers return responses to our study after three

months. Each of them prepared answers to our test,

using a team of experienced specialists in the medical

field.

Figure 2 : Input and Output flow

5.1 Unit Price and Distribution Costs

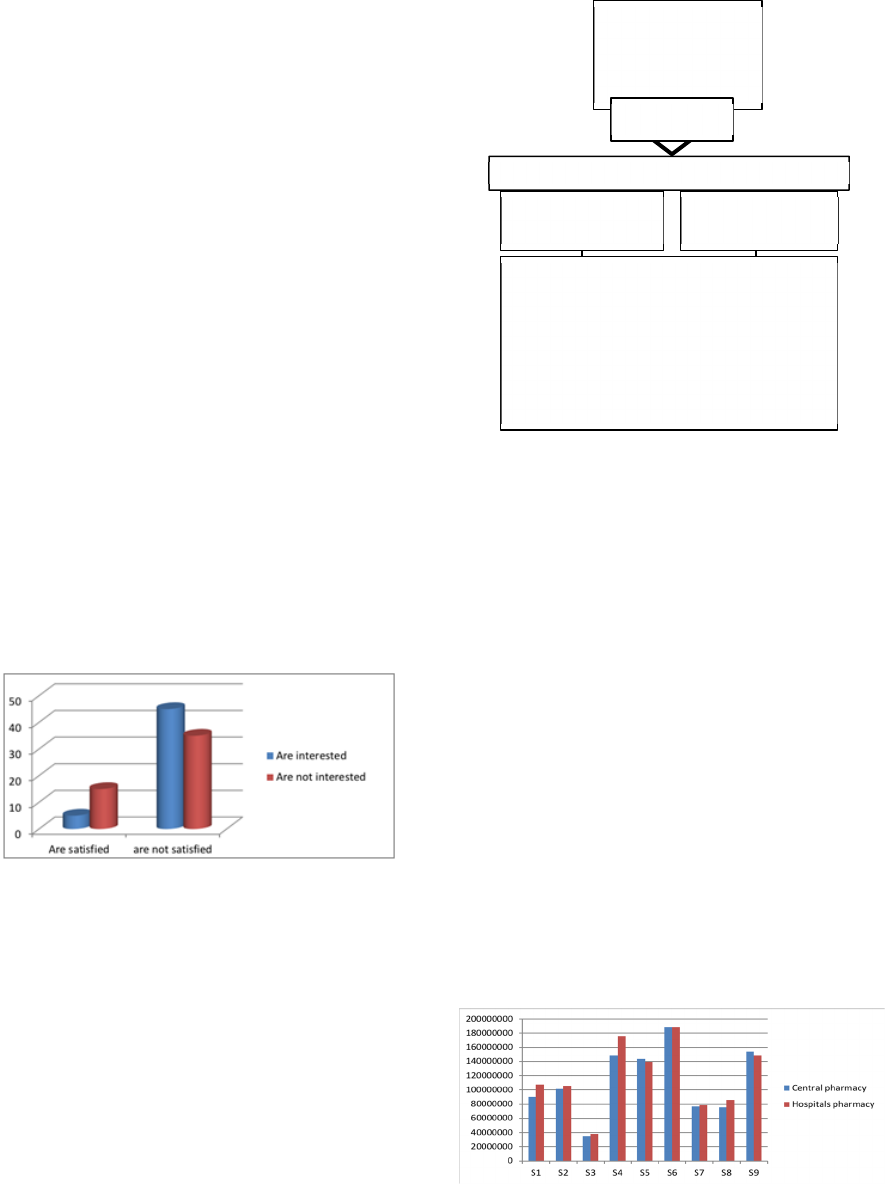

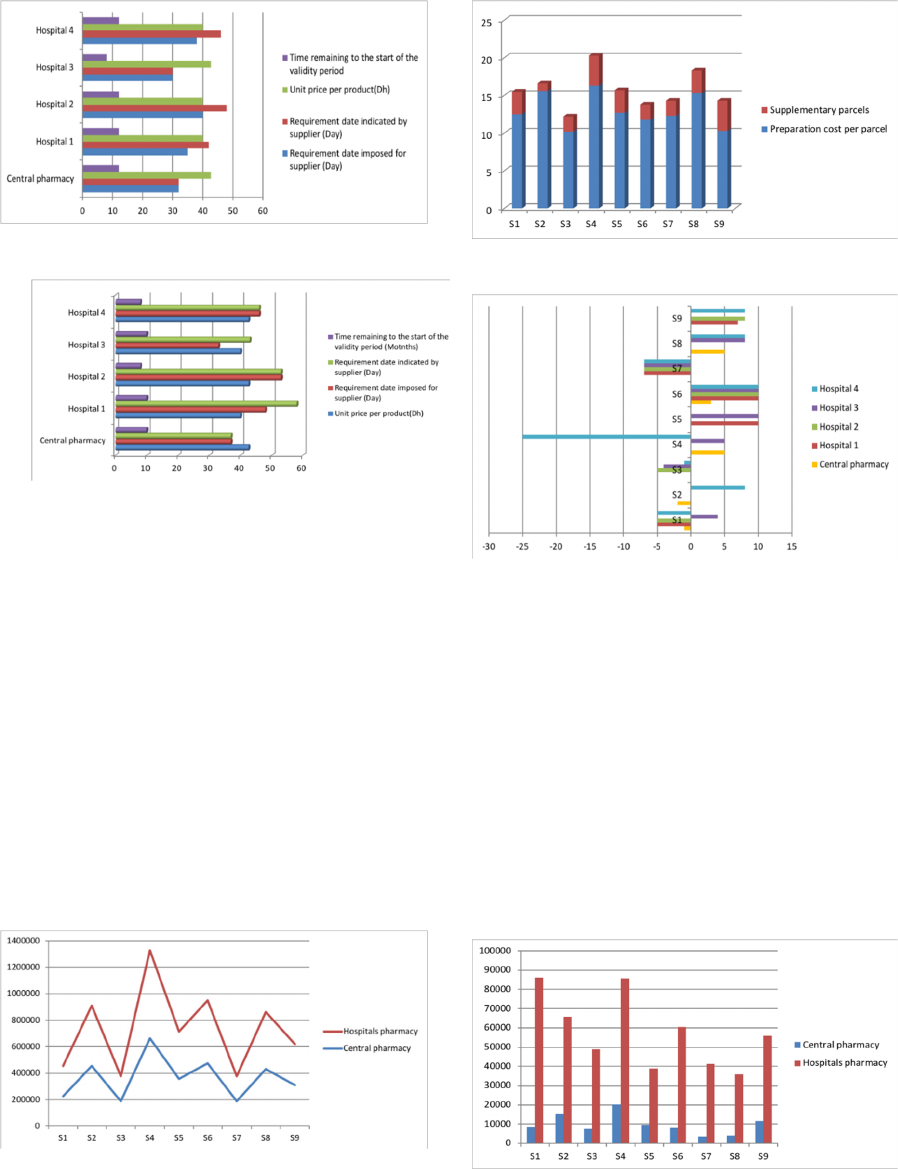

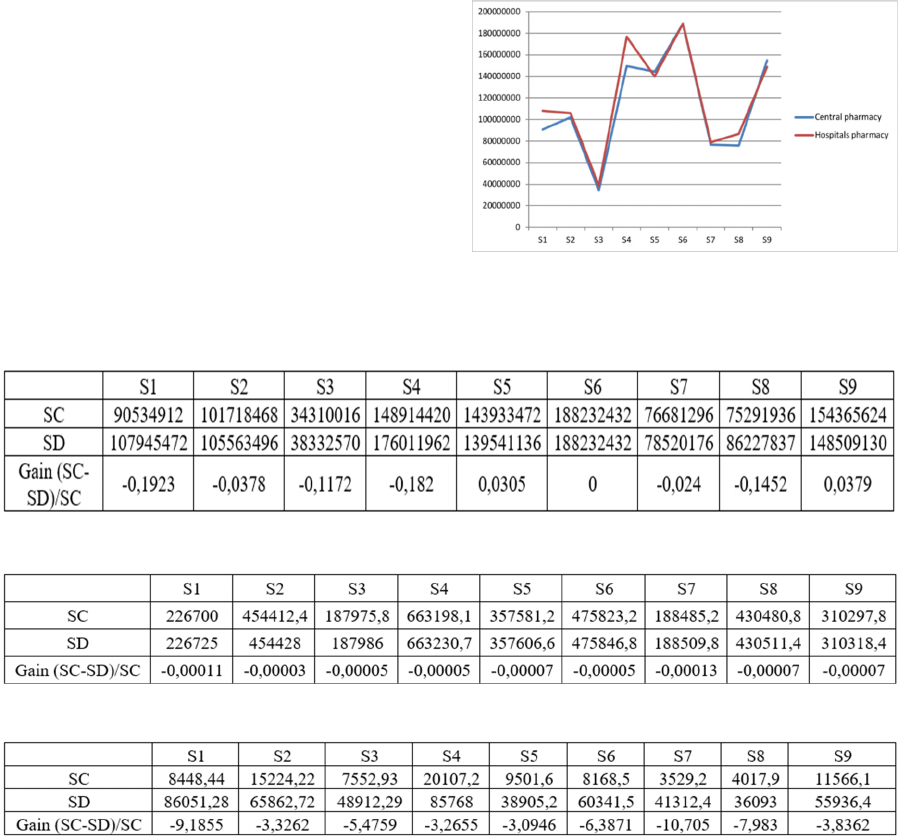

As shown in figure 3 and table 3, the unit price

increases in case of decentralization for most of

suppliers except suppliers 5 and 9. To understand this

behaviour, we show in figure 4 and 5, the details of

each supplier. As for supplier 9, he meets the delivery

time requirements for H3 and for the central

pharmacy; he delays delivery eight days for H1, H2

and H4. While supplier 9 has only 40% of the order

in the stock, either he will meet the delivery date for

Hospital 3 and delay delivery for others while

reducing the unit price, or he will deliver the central

pharmacy on time, while keeping the same initial

price and making urgent production. Following the

previous case, with only 50% of order in stock,

supplier 5 has two choices, either he delivers 30% to

H4 and 20% to H2 on time with the initial price, and

delays delivery for H1 and H4 while reducing the unit

price, or he choose to deliver the central pharmacy on

time with urgent production while keeping the initial

price.

Figure 3: Comparison of unit prices in both purchasing

structures

- Unit price

- Number of parcels

- Preparation cost

- Delivery cost

- Delivery time

- Time remaining for the

start of the validit

y

date

Out

p

ut flow

Input flow

- Quantity

requested

- Delivery date

9 suppliers

Decentralized

structure

Centralized

structure

Figure 4: Results obtained for supplier 9

Figure 5: Results obtained for supplier 5

5.2 Preparation Costs

As shown in Figure 6 and table 4, preparation costs

are higher in the case of decentralization. The small

difference is justified by the number of optimized

parcels in the case of centralization. In addition, the

preparation cost per parcel, which differs from one

supplier to another.

Supplier 4 is distinguished by a maximum total

preparation cost, and a considerable cost difference

between both structures, which amounts to 0.07% of

the total cost. This difference is justified by the

additional number of parcels in the case of

decentralization (figure 7), and a high preparation

cost compared to other suppliers, which amounts to a

5.2% difference.

Figure 6: Comparison of preparation costs in both

purchasing structures

Figure 7: Additional parcels for each supplier

Figure 8: Delivery dates proposed by suppliers

5.3 Delivery Costs

As shown in Figure 9 and Table 5, the delivery costs

incurred by suppliers in case of decentralization are

much higher than in case of centralization. The

increasing number of delivery costs has been realized

due to the multiplication of possible routes to deliver

to several dispersed points. A large difference in the

delivery costs (up to 18%) is allocated to the delivery

of the order between both structures, which is

justified by the number of kilometers recorded by

each supplier traveling to each hospital, and the unit

cost delivery that differs from one supplier to another.

Figure 9: Comparison of delivery costs in both purchasing

structures

5.4 Change in Variable Costs

The results generated on the variable costs, for

different suppliers in both cases are indicated as

follows:

- The variable costs are strictly higher in the case of

decentralization:

In this case, the variable costs are higher for 55.6% of

suppliers, this being due to the increase of preparation

and delivery costs. The centralization system helps

suppliers to manage parcels in a better way by

enabling efficient optimization that can achieve

savings of up to 2.7% of the total cost. It is a small

gain, but still significant. In addition, most of

suppliers offer lower prices to purchasers in case of

centralized system, which is due to the large quantity,

which motivate suppliers to make urgent production,

to keep the market.

- The variable costs are higher or equal in the case

of centralization:

The time remaining to the start of the validity period

of medical products is imposed by hospitals to be at

least 18 months at the time of delivery. 22.2% of

suppliers respect this constraint for all orders, which

pushes them to increase prices. Variable product costs

are almost the same in both purchasing structures for

22% of suppliers.

Figure 10: Comparison of variable costs in both purchasing

structures

Table 3: Total order price generated in each structure

Table 4: Preparation costs in both structures

Table 5: Delivery costs values in both strategies

6 CONCLUSIONS

The hospital system must ensure an irreproachable

quality of service and optimize its supply chain.

Managers need to choose the most appropriate

organizational structure that helps pharmaceutical

suppliers improve their performance. Centralization

is a system in which decision-making and

administrative acts are organized around a single

center of power. In this study the centralized hospital

system gave better results, it is more efficient in terms

of variable costs, cost effectiveness and reduction of

expired medical products. However, this study does

not take into account the hidden costs generated by

suppliers, which will be taken into account in our next

study in which we will develop a decision-making

approach in the hospital sector for the choice of the

organizational purchasing structure.

REFERENCES

Cheng E.W.L, Li H. (2001) « Analytic hierarchy process:

An approach to determine measures for business

performance », Measuring Business Excellent, Vol 5,

N0 3, pp. 30-36

Charles Collins, Andrew Green. - Decentralization and

primary health care: some negative implications in

developing countries, 1994 - International Journal of

Health Services, Vol 24 (3), 459-475

Rapport de la commission « approvisionnement du secteur

public en médicaments et consommables médicaux»

Février 2008.

Modi, S.B. & Mabert, V.A. (2007). Supplier development:

Improving supplier performance through knowledge

transfer. Journal of operations management, 25, 42 -64

Juran, J.M. 1990. China’s Ancient History of Managing for

Quality, Quality Progress, July 1990, page 32

Deming, W.E. 1950. Elementary Principles of the

Statistical Control of Quality, JUSE

K. Jenoui, A. Abouabdellah, “Estimating supplier’s hidden

quality costs with Taguchi quality loss function and

Topsis method”. In 10th International Colloquium on

Logistics and Supply Chain Management, Rabat,

Morocco, 2017.

A. Abouabdellah, A. Cherkaoui, "Decision Support System

for Predicting the degree of a cancer patient's

empowerment". Journal of Theoretical and Applied

Information Technology, 60(3), 517-523, 2014.

A. Marie, C. Giuliani, A. Abouabdellah, A. Cherkaoui,

"The empowerment of patients factoring: Reporting to

a holonic approach". In 9th Conference on service

systems and service management, Troyes, France,

2006.

D. Serrou, A. Abouabdellah, “Logistics in the hospital:

Methodology for measuring performance”. ARPN

journal of engineering and applied sciences, 11(5), 250-

256, 2016.

P. Trouiller, Technical support for improving the

management and organization of hospital pharmacies,

2013.