Effect of Surface Treatment on the Behavior of Square Concrete

Members Confined by JFRP Composites

Yasmina Ed-Dariy

1a

, Nouzha Lamdouar

1

, Toufik Cherrad

1

, Ancuta Rotaru

2

, Marinela Barbuta

3

,

Petru Mihai

3

, Loredana Judele

3

1

Department of Civil Engeneering, Mohammadia School of Engineers, Mohammed V University of Rabat, Morocco

2

Department of Transportation Infrastructure and Foundations, Gheorge Asachi Technical University of Iasi, Faculty of

Civil Engineering and Building Services, Romania

3

Department of Concrete Structures, Building Materials, Technology and Management, Gheorge Asachi Technical

University of Iasi, Faculty of Civil Engineering and Building Services, Romania

barbuta31bmc@yahoo.com, petru.mihai@tuiasi.ro, ljudele@yahoo.co.uk

Keywords: JFRP composites, NaOH solution, fibers treatment, KOH solution, reinforced concrete.

Abstract: This paper presents the behavior of concrete square columns reinforced by jute fibers fabrics composites. The

fibers are treated for 24h in 2% of the KOH and 4% of the NaOH solution. Eighteen specimens are evaluated

by using the compression test. The results are presented in terms of the ultimate load, and the composites

morphology. An increase of the ultimate load capacity was noted in the case of specimens reinforced by fibers

treated in 4% NaOH. On the other hand, the maximum load capacity noted a decrease in the case of specimens

treated in 2% of KOH solution comparing to untreated ones. At the microscopic level, the resin was distributed

uniformly in both cases of specimens in which the fibers are treated.

1 INTRODUCTION

The use of composites based on synthetic fibers for

the rehabilitation of civil engineering structures has

been successful in recent years (Al Nuaimi and al.,

2020; Hawileh and al., 2011; Naser and al., 2012,

2019; Nawaz and al., 2016). Increases in both

strength and rigidity as well as a reduction in cracks

have been observed with the bonding of concrete by

strips or fabrics based on fibers (carbon and glass)

(Hawileh and al., 2015). However, these types of

materials are not of natural origin because their

production causes strong impacts on the environment.

Faced with these problems, the trend in recent years

is the gradual replacement of old materials by new

ecological materials (Thakur and al., 2014). The use

of natural fiber-reinforced polymer composites such

as flax fibers, increases the maximum load-bearing

capacity, ductility, and energy absorption capability

(Cervantes and al., 2014; Chakraborty and al., 2013;

Huang and al., 2016; Kumar and Sharma, 2007;

Wang and al., 2019; Yan et al., 2013). According to

a

https://orcid.org/0000-0003-1078-9853

(Tan and al., 2015), wrapping concrete columns with

jute fibers reinforced polymer increased the ultimate

load of the columns (Ed-dariy and al, 2020).

Nevertheless, these fibers are hydrophilic, which

confers low compatibility with resins and leads to a

decrease in mechanical properties (Gholampour and

Ozbakkaloglu, 2020; Sugiman and al., 2020).This

negatively influences the quality of the fiber-matrix

interface as the effectiveness of the reinforcement

depends, to a large extent, on the charge transfer to

the concrete-fiber interface. Hence, the improvement

of this interface can enhance the behavior of the

reinforced element and, in order to adjust it, the

modification of the surface of fibers could be a

solution (Ed-dariy and al, 2020). Several treatments

can reduce the problems caused by the nature of the

fiber namely, the chemical, thermal and mechanical

treatments. The most used surface modification to

improve the resistance is the alkali treatment(Gupta,

2020; Huang et al., 2016; Van de Weyenberg et al.,

2006; Vinayagamoorthy, 2020). On the contrary,

natural fibers can be destroyed by using the excessive

treatment. (Benedetti and al., 2016; Salama et al.,

2019, Ed-dariy and al, 2020). In this context, this

study describes the mechanical behavior of square

concrete members reinforced with composite

materials using both untreated jute fibers and treated

fibers in 2% potassium hydroxide and treated fibers

in 4% NaOH solution, respectively. All the samples

are subjected to the compression test. The materials

and the methodology are presented in the first section.

The second section resumes the results obtained from

the compression test in terms of maximum load

capacity and the third section illustrates the influence

of alkali solution on the composite morphology.

2 METHODOLOGY

2.1 Treatment of Jute Fibers by Alkali

Solution

The fibers are treated for the first category in a liquor

ratio of 10:1 of 2% of KOH solution and for the

second one in 4% of NaOH solution.The both of them

have been left for 24 hours, under 88% of relative

humidity and 18°C of temperature.

So as to remove residues of the alkali solution the

fibers are washed in distilled water whose PH reaches

7 and they are dried for 6 hours at 100°C.

2.2 Preparation of Specimen

The jute fiber fabrics are applied to the concrete using

the epoxy resin which the properties are presented on

the table 1. The 4:1 is mixing ratio of the resin and

hardener used. The samples are left for curing under

the ambient conditions for 7 days.

3 TESTING

3.1 Compression Test

As presented on the Table. 2 the code abbreviations

of the eighteen samples, which three are the reference

specimens and the others ones reinforced with the

Jute fibers fabrics. All the specimens are tested in the

laboratory of Composite Materials, of the Faculty of

Civil Engineering and Building Services, Gheorge

Assachi Technical University, Iasi, Romania. And are

subjected to the compression test which the loading

speed applied was 4kN/s. The results are obtained

using the data acquisition system Maxtest software.

Table 1: Properties of Sikadur 330

Resin

Density

Kg/dm

3

mixed

Compressive

strength fc[MPa]

Tensile

strength ft[MPa]

Module of elasticity

E[GPa]

Elongation at break

ɛ

u

[%]

Sika-dur

330

1.3 30(7 days + 23°C) 33.8 (7 days + 23°C) 4.5 (7days + 23°C) 0.9

Table 2: Abbreviations

Code

Signification

C1-R

Plain concrete (reference)

C1-JFRP JFRP reinforced concrete

C1-JFRP-NaOH JFRP reinforced concrete with fibers treated during 24 hours in liquor ratio of 10:1

of 4% of NaOH

C5-R Plain concrete (reference)

C5-JFRP JFRP reinforced concrete

C5-JFRP-KOH

JFRP reinforced concrete with fibers treated during 24 hours in liquor ratio of 10:1

of 2% of KOH

4 RESULTS

4.1 Maximum Load Capacity

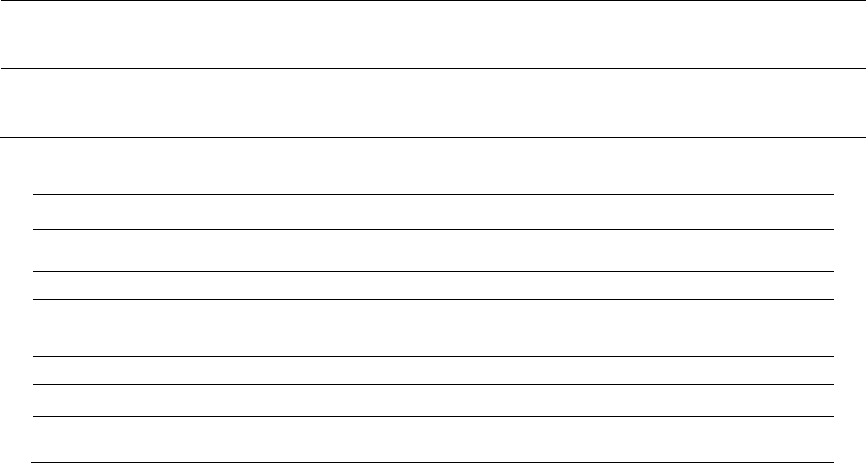

Figures 1 and 2 represent the maximum load capacity

for specimens reinforced with untreated fibers and

with fibers treated in 4% of NaOH and 2% of KOH

solution, respectively. The reinforcement of concrete

with the JFRP composites, have increased the

capacity of concrete from 294.2 kN to 332.2 kN as

compared to unreinforced concrete members, which

is an increase of 13%.

And in the case of treated fibers in 4% of NaOH

solution, the capacity was increased from 294.2 to

357.9 kN, which is an increase of 21.65%. In the

second category, the specimens reinforced by

untreated jute fibers an increase of 14.63% of the

concrete capacity was noted. A decrease of 13.91%

was noted in the case of specimens reinforced who

the fibers are treated in 2% of KOH (Fig.2).

Figure 1: Maximum load capacity for specimens reinforced

with fibers treated in 4% of NaOH solution.

Figure 2: Maximum load capacity for specimens reinforced

with fibers treated in 2% of KOH solution

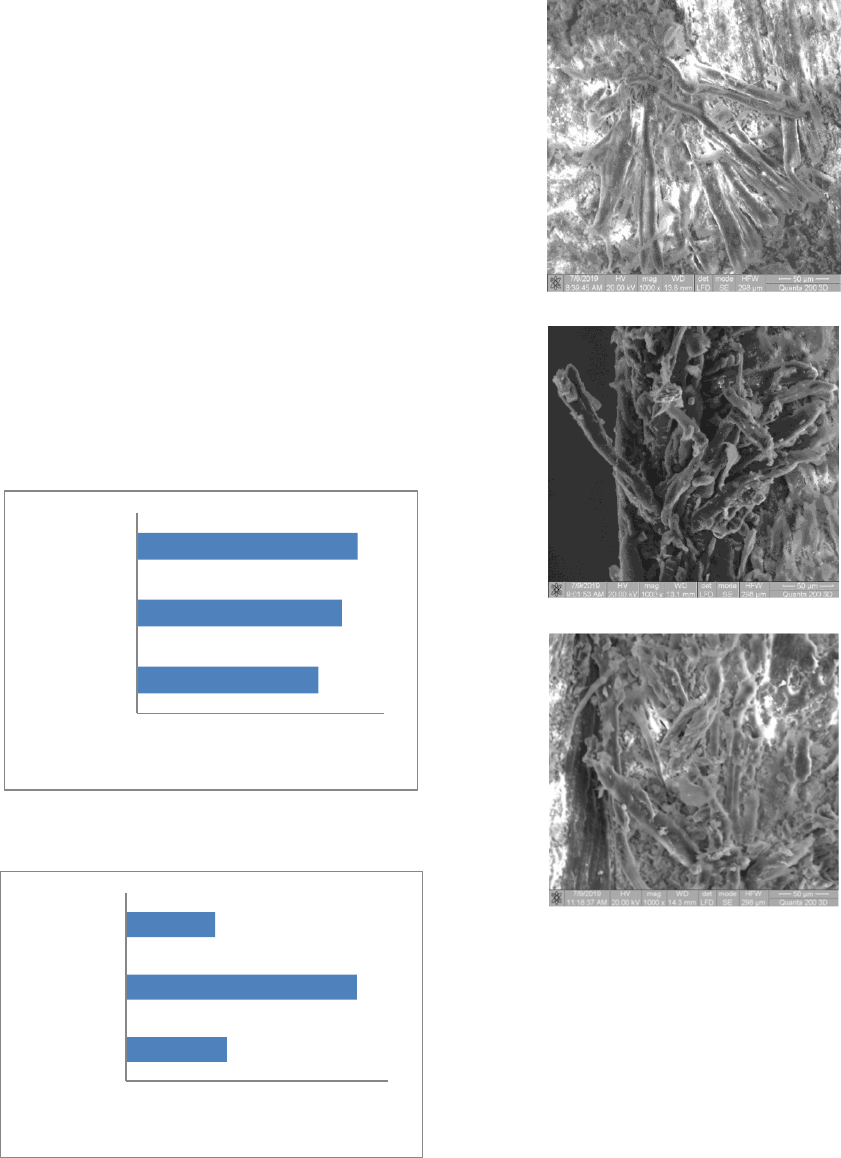

a) Untreated fibers

b) Treated with NaOH

c) Treated with KOH

Figure 3: Microscopic (SEM) view of composites

4.2 Composites Morphology

The influence of the alkali treatment on composite

morphology is presented on figure 3 which at the

microscopic level, the resin was distributed correctly

in both cases in the case of 2% of KOH and in the

case of 4% NaOH. And as shown, the fibers treated

are surrounded by more particles, which is not the

case for untreated fibers, in which an average void

ratio was observed between the fibers and the matrix.

The increase in resistance shown in the case of fibers

0 100 200 300 400

C1-R

C1-JFRP

C1-JFRP-NaOH

Maximum load capacity

240 260 280 300 320

C5-R

C5-JFRP

C5-JFRP-KOH

Maximum load capacity

treated with 4% of NaOH can be explained that the

improvement is due to a combination of a better

mechanical connection by dint of a rougher

topography and a larger number of individual fibrils

(Van de Weyenberg and al., 2006). It’s the effect of a

better chemical bond due to the surface of the purified

fiber, which made it possible to form more hydrogen

bonds between the hydroxyl groups of the cellulose

and the resin. On the other hand, the 2% of KOH was

enough to degrade the fibers; this is why the

maximum load capacity has noted a decrease.

5 CONCLUSIONS

The following conclusions are drawn from the results

of this study:

The reinforcement of the concrete using the

jute fibers fabrics increase the maximum load

capacity.

Using 4% of NaOH can improve the

properties of the fibres which lead to an

increase of the maximum load capacity of the

specimens

The 2% of KOH deteriorates the properties of

the fibers, which negatively influences the

maximum load capacity of the specimens

reinforced with Jute fibers fabrics.

ACKNOWLEDGEMENTS

We would like to acknowledge the great support of

Sika Company and also to show our gratitude to all

the persons, who worked along with us on this paper,

especially Mr. Marinescu and Mr. Poenaru from the

Faculty of Civil Engineering and Building Services,

and Mr. Istrate from the Faculty of Mechanical

Engineering, “Gheorghe Asachi” Technical

University of Iasi, Romania.

REFERENCES

Al Nuaimi, N., Sohail, M.G., Hawileh, R.A., Abdalla, J.A.,

Douier, K., 2020. Durability of Reinforced Concrete

Beams Strengthened by Galvanized Steel Mesh-Epoxy

Systems under Harsh Environmental Conditions.

Compos. Struct. 112547.

Benedetti, A., Fernandes, P., Granja, J.L., Sena-Cruz, J.,

Azenha, M., 2016. Influence of temperature on the

curing of an epoxy adhesive and its influence on bond

behaviour of NSM-CFRP systems. Compos. Part B

Eng. 89, 219–229.

Cervantes, I., AungYong, L., Chan, K., Ko, Y.-F., Mendez,

S., 2014. Flexural retrofitting of reinforced concrete

structures using Green Natural Fiber Reinforced

Polymer plates, in: ICSI 2014: Creating Infrastructure

for a Sustainable World. pp. 1051–1062.

Chakraborty, S., Kundu, S.P., Roy, A., Basak, R.K.,

Adhikari, B., Majumder, S.B., 2013. Improvement of

the mechanical properties of jute fibre reinforced

cement mortar: A statistical approach. Constr. Build.

Mater. 38, 776–784.

Gholampour, A., Ozbakkaloglu, T., 2020. A review of

natural fiber composites: properties, modification and

processing techniques, characterization, applications. J.

Mater. Sci. 1–64.

Gupta, M.K., 2020. Investigations on jute fibre-reinforced

polyester composites: Effect of alkali treatment and

poly (lactic acid) coating. J. Ind. Text. 49, 923–942.

Hawileh, R., Abdalla, J.A., Al-Tamimi, A.K., 2011.

Flexural performance of strengthened RC beams with

CFRP laminates subjected to cyclic loading, in: Key

Engineering Materials. Trans Tech Publ, pp. 697–702.

Hawileh, R.A., Abu-Obeidah, A., Abdalla, J.A., Al-

Tamimi, A., 2015. Temperature effect on the

mechanical properties of carbon, glass and carbon–

glass FRP laminates. Constr. Build. Mater. 75, 342–

348.

Huang, L., Yan, B., Yan, L., Xu, Q., Tan, H., Kasal, B.,

2016. Reinforced concrete beams strengthened with

externally bonded natural flax FRP plates. Compos.

Part B Eng. 91, 569–578.

Kumar, S.P., Sharma, S., 2007. Effect of Alkali treatment

on jute fibre Composites.

Naser, M., Abu-Lebdeh, G., Hawileh, R., 2012. Analysis of

RC T-beams strengthened with CFRP plates under fire

loading using ANN. Constr. Build. Mater. 37, 301–309.

Naser, M.Z., Hawileh, R.A., Abdalla, J.A., 2019. Fiber-

reinforced polymer composites in strengthening

reinforced concrete structures: A critical review. Eng.

Struct. 198, 109542.

Nawaz, W., Hawileh, R.A., Saqan, E.I., Abdalla, J.A.,

2016. Effect of longitudinal carbon fiber-reinforced

polymer plates on shear strength of reinforced concrete

beams. ACI Struct. J. 113.

Salama, A.S.D., Hawileh, R.A., Abdalla, J.A., 2019.

Performance of externally strengthened RC beams with

side-bonded CFRP sheets. Compos. Struct. 212, 281–

290.

Sugiman, S., Setyawan, P.D., Anshari, B., 2020. Water

Absorption and Impact Strength of Alkali-Treated

Bamboo Fiber/Polystyrene-Modified Unsaturated

Polyester Composites. J. Appl. Sci. Eng. 23, 9г20.

Symington, M.C., Banks, W.M., West, O.D., Pethrick,

R.A., 2009. Tensile testing of cellulose based natural

fibers for structural composite applications. J. Compos.

Mater. 43, 1083–1108.

Tan, H., Yan, L., Huang, L., Wang, Y., Li, H., Chen, J.,

2015. Behavior of sisal fiber concrete cylinders

externally wrapped with jute FRP. Polym. Compos.

Thakur, M.K., Gupta, R.K., Thakur, V.K., 2014. Surface

modification of cellulose using silane coupling agent.

Carbohydr. Polym. 111, 849–855.

Van de Weyenberg, I., Chi Truong, T., Vangrimde, B.,

Verpoest, I., 2006. Improving the properties of UD flax

fibre reinforced composites by applying an alkaline

fibre treatment. Compos. Part Appl. Sci. Manuf. 37,

1368–1376.

Vinayagamoorthy, R., 2020. Influence of fibre

pretreatments on characteristics of green fabric

materials. Polym. Polym. Compos.

0967391120943461.

Wang, H., Memon, H., AM Hassan, E., Miah, M., Ali, M.,

2019. Effect of jute fiber modification on mechanical

properties of jute fiber composite. Materials 12, 1226.

Yan, L., Duchez, A., Chouw, N., 2013. Effect of bond on

compressive behaviour of flax fibre reinforced polymer

tube–confined coir fibre reinforced concrete. J. Reinf.

Plast. Compos. 32, 273–285.

Y. Ed-Dariy, N. Lamdour, T. Cherradi, A. Rotaru, M.

Barbuta, P. Mihai, L. JUDELE. « Experimental

investigation of the effects of NaOH and KOH solution

on the behavior of concrete square columns reinforced

by JFRP Composites », 5th World Congress on Civil,

Structural, and Environmental Engineering, Lisbon,

Portugal, Oct. 18-20, 2020.

Y. Ed-Dariy, N. Lamdour, T. Cherradi, A. Rotaru, M.

Barbuta, P. Mihai, « Effect of alkali treatment of Jute

fibers on the compressive strength of normal-strength

concrete members strengthened with JFRP

composites », J. Appl. Sci. Eng., vol. 23, no 4, p.

677‑685, 2020.

Y. Ed-Dariy, N. Lamdour, T. Cherradi, A. Rotaru, M.

Barbuta, P. Mihai, L. JUDELE. « The behavior of

Concrete Cylinders confined by JFRP composites:

Effect of KOH solution », 5th World Congress on Civil,

Structural, and Environmental Engineering, Lisbon,

Portugal, Oct. 18-20, 2020.