Comparison of Activity Coefficient in ABE with MEP with

UNIQUAC Equation

Widi Wurjani

1

, Intan Purbasari

2

and Ni Ketut Sari

3

1

Departement of Agrotechnology, Universitas Pembangunan Nasional Veteran Jawa Timur, Indonesia

2

Departement of Computer Science, Universitas Pembangunan Nasional Veteran Jawa Timur, Indonesia

3

Department of Chemical Engineering, Universitas Pembangunan Nasional Veteran Jawa Timur, Indonesia

Keywords: Activity coefficient, ABE ternary system, MEP ternary system, UNIQUAC equations

Abstract: UNIQUAC equations in calculating the activity coefficient Acetone Butanol Ethanol (ABE) ternary system

using the Mat-lab programming language, then verified with a homologous series of alcohol Methanol

Ethanol Propanol (MEP) ternary system, to see if the mixture is an ideal or non-ideal solution. If the activity

coefficient is close to one, then the solution is the ideal solution, whereas if the activity coefficient is more

or less one, then the solution is a non-ideal solution so that in the separation of the solution, the activity

coefficient should not be assumed to be the same as one, the activity coefficient should be calculated the

actual value. The fixed variable consists of the temperature and Antoine parameter, the change variable

consists of the liquid composition and dimensionless time, then obtained the activity coefficient profile

function dimensionless time from the ABE and MEP ternary systems. With UNIQUAC equations obtained

activity coefficients of the ABE ternary system more than once, while MEP ternary system shows the

activity coefficient close to one, it can be concluded that the ABE ternary system is an a-zeotropic ternary

system.

1 INTRODUCTION

Studied by Rayleigh (1902) and then written in the

manual Separation Process Principles by Henley and

Seader (1998). In the chemical industry,

fermentation process is one way to get a chemical

compound with the help of microorganisms helped,

fermentation products enter the next stage of

separation (Sari, 2009).

Research by Rayleigh

(1902) and later research by Henley and Seader

(1998) book in the Principles of Separation Process.

In the chemical industry, the solution separation

process is an important process for collecting pure

components, one of which uses thermodynamic

theory of the coefficient of activity, to determine the

ideal solution (Sari, 2018). In the separation process,

thermodynamic data in the form of equilibrium data

is very dominant in the solution separation process.

One of the correlations of modern thermodynamics

to the equilibrium phase that is not ideal is the

UNIQUAC equation, the approximate balance and

prediction data can only be obtained in the

experimental data of binary systems. The coefficient

model of ternary system activity with UNIQUAC

equations is developed from a binary mixture, and

has the advantage of application in a multi-

component mixed system and requires no additional

parameters. But the disadvantages of not always

succeeding in predicting a mixed multi-component

balance system are not ideal, especially mixtures

that have limited solubility (Renanto, 1997).

Simulation of activities coefficients equation

ternary system has been investigated using rigorous

methods to DAEs models, where the completion of

the model equations numerically using the Euler

method using Mat-Lab language version 6.1 (Sari,

2006). Results of the simulation system binary

system acetone-butanol, acetone-ethanol, ethanol-

butanol and then validated with a binary system of

benzene-toluene.

Along with the development of information

technology, the program may evolve over time using

the programming methods applied lately that

program object-oriented, in addition to easy to be

developed at a time when that will come, the

software uses object-oriented programming methods

this has other benefits, too in 1 software projects can

use a variety of programming languages that support

Wurjani, W., Purbasari, I. and Sari, N.

Comparison of Activity Coefficient in ABE with MEP with UNIQUAC Equation.

DOI: 10.5220/0010369300003051

In Proceedings of the International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies (CESIT 2020), pages 605-609

ISBN: 978-989-758-501-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

605

sat

i

.P

i

x

P .

i

y

i

γ

object oriented programming, such as C#.Net and

VB.Net.

Simulation of batch distillation of binary systems

using Mat-lab programming language, which results

in the appearance of the graph using a spreadsheet

tool, less effective and efficient (Sari et al., 2007), so

it is necessary for the visualization of object oriented

programming language, in addition to easily be

developed at a time when that will come, have

another advantage is in the software projects can use

a variety of programming language that supports

object-oriented programming, such as C#.Net and

VB.Net (Sari, et al., 2013) .

This research aims to display simulation profile

coefficient activity function dimensionless with

Antoine equation and activity coefficients process

use Mat lab programming.

2 MATERIAL AND METHODS

Basic concepts of Object Oriented Programming

concepts emphasize the following (Aristarchus et al.,

2011): Class: the collection of data definitions and

functions in a unit for a particular purpose. Class is

the basis of modularity and structure in an object-

oriented programming. A class should typically be

recognizable by even a non-programmer domain

associated with the existing problems, and the code

is contained in a class should be (relatively)

autonomous and independent nature (as the code is

used if not using OOP). With modularity, the

structure of a program will be associated with

aspects of the problem to be solved through the

program. This way will simplify the mapping of the

problem to a program or vice versa. Object:

wrapping the data and functions together into a unit

in a computer program, object is the basis of

modularity and structure in an object oriented

computer program. Abstraction: The ability of a

program to bypass aspects of the information

processed by it, namely the ability to focus on the

core. Encapsulation: Ensuring the user of an object

cannot change the state of an object in a way that is

not feasible; just the method in which the object was

given permission to access the situation.

Polymorphism: through sending messages. Does

not depend on calling subroutines, object-oriented

language can send messages; particular method

associated with a message delivery depends on the

specific object in which the beam is sent. For

example, if a bird received "fast motion", he would

move his wings and fly. When a lion received the

same message, he will move his legs and ran. Both

answered a similar message, but in accordance with

the ability of these animals. This is called

polymorphism as a variable in the program single

can hold different types of objects while running the

program, and the text of the same program can call

several different methods at different times in the

same calling.

This is in contrast to functional languages

achieve polymorphism through the use of first-class

functions. By using the OOP in solving a problem

we do not see how to solve a problem is objects but

what can be done solving those problems. For

example, suppose we have a department that has a

manager, secretary, data and other administration

officials. Suppose the manager wants to obtain data

from the administrative manager of the bag does not

have to take it immediately but can be ordered

officers to take administrative bag. In that case, a

manager does not have to know how to take the data,

but the manager can get the data object through

administrative officer. So in order to solve a problem

with collaboration among existing objects because

each object has its own job description.

In making the application is used batch

distillation program makers and the language used to

create the program: Visual Studio 2010: is a

developer of software (Software Maker) issued by

one of the largest computer software company in the

world that is Microsoft. The advantage of this is that

Visual Studio 2010 has been adopted. Net

Framework 4.0 and the many languages that can be

used to create such software, such as C#.Net,

VB.Net, and so forth. Microsoft.NET Framework

(Microsoft Dot Net Framework) or better known as

the dot net is a software framework that runs

primarily on Microsoft's Windows operating system,

this time. NET Framework generally have been

integrated in the standard distribution of Windows

(starting from Windows Server 2003 Windows

versions and newer). The framework provides a

large amount of computer programming libraries

and supports several programming languages and

good interoperability allowing these languages to

serve one another in the development of the system.

At low pressure, the vapor phase so close to the

ideal gas low pressure liquid vapor equilibrium

becomes,

(3)

Equation (1) is also known as the modified

Raoult's equation. The constant of equilibrium

between the vapor phase and liquid phase is defined

as follows:

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

606

P

sat

i

.P

i

γ

i

x

i

y

i

K

i

C

P log -

i

A

i

B

sat

i

T

i

sat

i

T

i

x T

j

C

sat

1

P log -

j

A

j

B

T

e

T

)T(T

new

beginningnew

m

1j

jj

x

i

x

i

φ

i

i

φ

i

θ

ln

i

q

2

z

i

x

i

φ

ln

m

1j

m

1k

kj

τ

k

θ

ij

τ

j

θ

m

1j

ji

τ

j

θln1

m

j

r

j

x

i

r

i

x

i

φ

1j

m

1j

jj

ii

i

xq

xq

θ

RT

uu

expτ

iiji

ji

1)(r)q(r

2

z

iiii

(2)

Iteration procedure to find the temperature of

which is to seek price bubble saturation temperature

of pure component Ti

sat

on P (Prausnitz, et al., 2001:

Sari and Dira 2017).

(3)

where A, B, C are Antoine constants for species

i, for all initial estimates.

(4)

For i = 1, 2, 3.

Price T as the initial price will be used to

determine the saturated vapor pressure of a

substance to be estimated with the equation T

Antoine, prices were sought by the equation:

(5)

Then look for the error between the new T with

T the beginning with equation (6)

(6)

γ

i

activity coefficients obtained from:

ln

i

= ln

i

C

+ ln

i

R

(7)

ln

i

C

=

(8)

ln

i

R

=q

i

(9)

(10)

where the coordination number z is set equal to

10.

(11)

(12)

The parameters r, q is a constant component of

the molecular structure based purely on molecular

size and external surface area. For each binary

combination in multi-component mixtures, there are

two parameters that can be adjusted r, q:

(13)

jj

=

ii

= 1

(14)

Table 1: Antoine parameters Acetone-Butanol-Ethanol

Source: Prausnitz, 2001

Parameters Antoine

Com

p

onents A B C

Acetone 4.2184 4.6493 5.3365

Butanol 197.01 1395.14 1648.22

Ethanol 228.06 182.739 230.918

To calculate the saturated vapor pressure Antoine

equation is used data Antoine parameters such as

Table 1 (Prausnitz, 2001), where the temperature (T)

in units of K and saturated vapor pressure (P

SAT

) in

units of Bar.

Table 2: Feed composition of ABE

No. Acetone Butanol Ethanol

1 0,8 0,1 0,1

2 0,7 0,2 0,1

3 0,7 0,1 0,2

4 0,6 0,3 0,1

5 0,6 0,1 0,3

6 0,5 0,1 0,4

7 0,4 0,1 0,5

Feed composition (mole fraction)

The composition of the bait is taken 7 runs,

already represents the profile of the activity

coefficient function ABE ternary system

composition such as Table 2 (Sari and Dira, 2018).

Table 3: Feed composition of MEP

Run Methanol Ethanol Propanol

1 0,80 0,10 0,10

2 0,90 0,02 0,08

3 0,70 0,20 0,10

4 0,30 0,60 0,10

5 0,39 0,60 0,01

6 0,50 0,40 0,10

Feed composition (fraction mole)

The composition of the bait is taken 6 runs,

already represents the profile of the activity

coefficient function ABE ternary system

composition such as Table 3 (Sari and Dira, 2018).

Comparison of Activity Coefficient in ABE with MEP with UNIQUAC Equation

607

3 RESULTS AND DISCUSSIONS

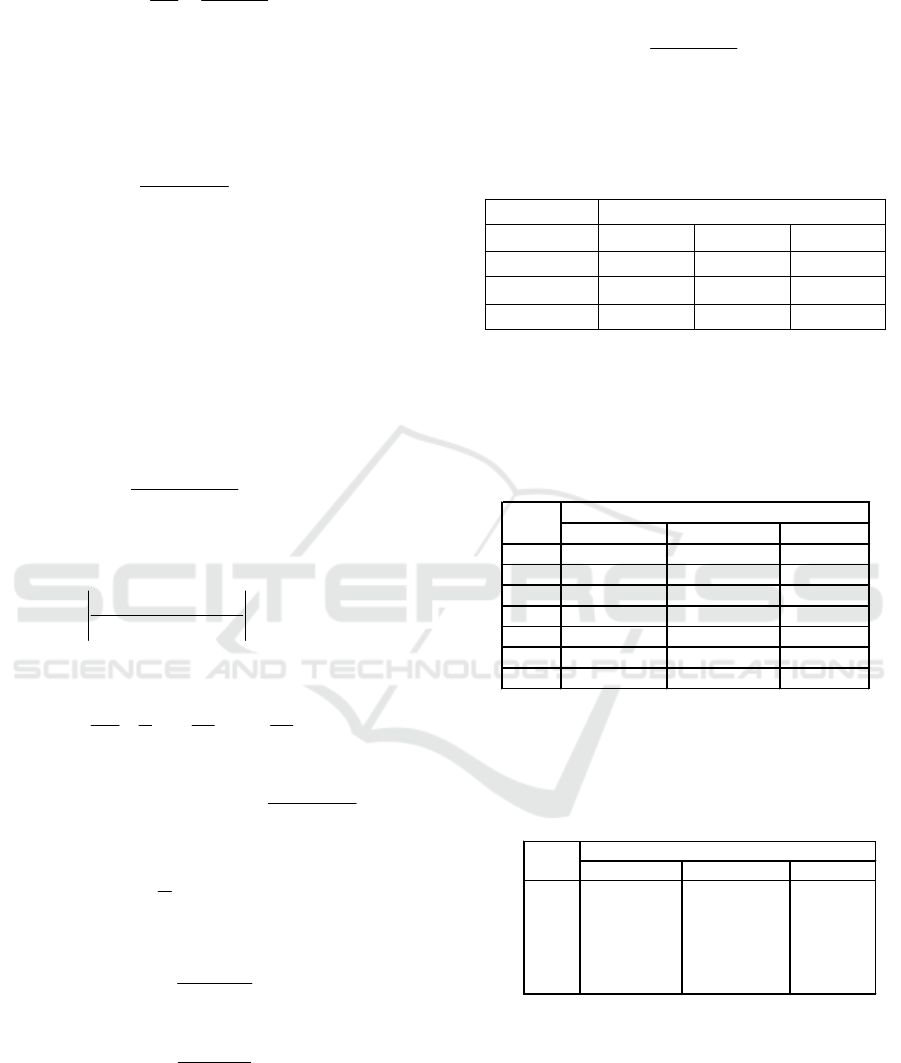

The temperature profile at the beginning of the

process indicates the propyl decreases to

dimensionless 0.25, as the adaptation process for the

process runs continuously. Temperature increase up

to dimensionless 2.5 for all composition feeds, for

Run 2 and Run 4 shows the highest temperature

achievement, because a large mixture of acetone and

butanol around 0.9, for the composition feed (Run 4)

that is volatile will indicate the highest temperature.

Run 1 Run 5

Run 2

Run 6

Run 3

Run 7

Run 4

Figure 1: Profile temperature ABE versus dimensionless

time

After dimensionless at a value of 3.5 all

composition feeds show a flat profile, a temperature

value with a range of 115 to 120 (

o

C), corresponding

to the mixed temperature of the ABE ternary system,

as shown in Figure 1.

Figure 2: Profile temperature MEP versus dimensionless

time

The temperature profile at the beginning of the

process indicates the propyl decreases to

dimensionless 0.25, as the adaptation process for the

process runs continuously. Temperature increase up

to dimensionless 3.5 for all composition feeds, for

Run 6 shows the highest temperature achievement,

because a large mixture of methanol and ethanol

around 0.9, for the composition feed (Run 4) that is

volatile will indicate the highest temperature. After

dimensionless at a value of 3.5 all composition feeds

show a flat profile, a temperature value with a range

of 78 to 95 (

o

C), corresponding to the mixed

temperature of the MEP ternary system, as shown in

Figure 2.

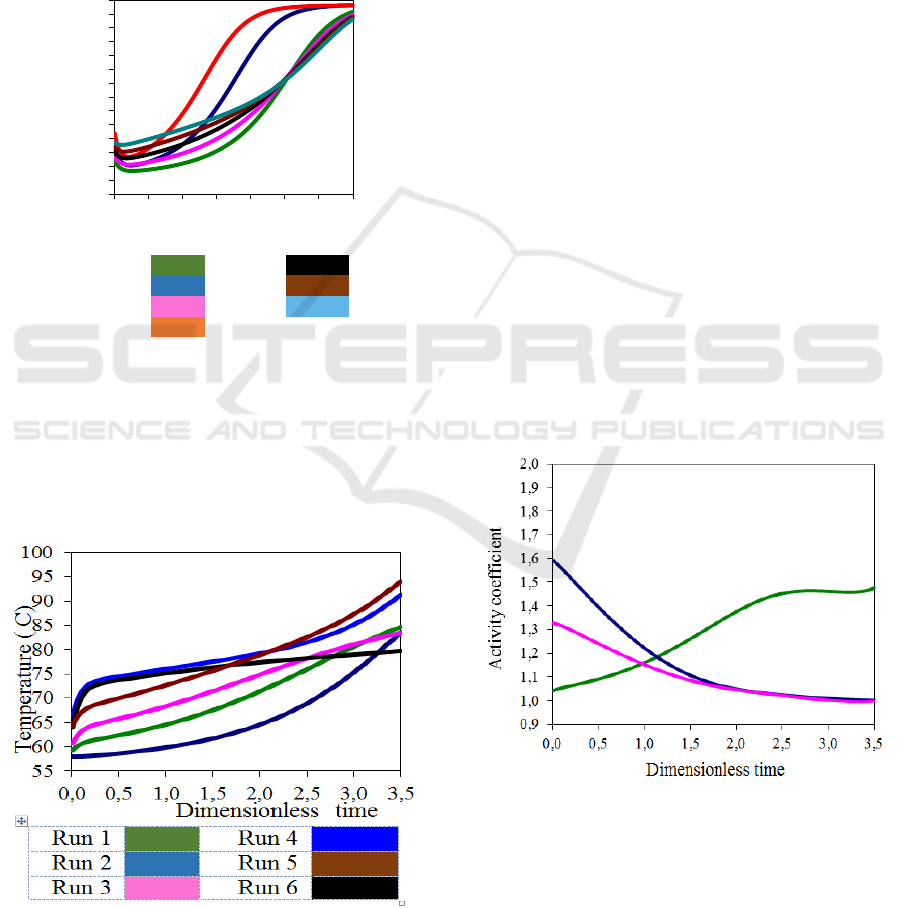

At the beginning of the process until the activity

coefficient shows a value of 1, Butanol and Ethanol

show a decreased activity coefficient profile,

Acetone shows a rising activity coefficient profile,

all three approaching the ideal solution. At an

activity coefficient value equal to 1.5 to 3.5, the

activity coefficient profile of Butanol and Ethanol

indicates an ideal solution, in which the process of

separation of the mixture of activity coefficients can

be assumed to be equal to 1. At an activity

coefficient value equal to 1.5 to 3.5, the coefficient

profile of Acetone, Butanol and Ethanol activity

coefficient indicates no ideal solution, in which the

process of separation of the mixture of activity

coefficients should be calculated using UNIQUAC

equations, as shown in Figure 3.

Figure 3: Profile activity coefficient of ABE versus

dimensionless time

At the beginning of the process until the activity

coefficient shows a value of 1, Methanol shows a

decreased activity coefficient profile, Ethanol and

Propanol show a rising activity coefficient profile,

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5

Temperature (

o

C)

Dimensionless time

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

608

all three approaching the ideal solution. At an

activity coefficient value equal to 1.5 to 3.5, the

coefficient profile of Methanol, Ethanol and

Propanol activity coefficient indicates no ideal

solution, in which the process of separation of the

mixture of activity coefficients should be calculated

using UNIQUAC equations, as shown in Figure 4.

Metanol Ethanol Pro

p

anol

Figure 4: Profile activity coefficient of MEP versus

dimensionless time

4 CONCLUSIONS

ABE temperature profile against dimensionless time

shows the profile corresponding to the boiling point

of each component, the temperature of range from

50 to 118 (

O

C). ABE activity coefficient profile

against dimensionless time (1.5 to 3.5) indicates a

value not equal to 1, ABE is not an ideal solution,

where in the process of separating ABE ternary

system, the activity coefficient should be calculated

using UNIQUAC equation. Verify the coefficient of

ABE activities with the MEP activity coefficient

against dimensionless time (1.5 to 3.5), indicating

the dimensionless time value is not equal to 1, so

that in the process of splitting the MEP ternary

system, the activity coefficient must be calculated

using UNIQUAC equations

ACKNOWLEDGEMENTS

The authors would like to acknowledge the financial

support of the Ministry of National Education of the

Republic of Indonesia with the Research-based

Competence Grant, Contract Number:

SPP/8/UN.63.8/LIT/III/2018.

REFERENCES

Aristarkhus A., Abdi I. N., 2011. Simulasi Rancangan

Rumah Asitektur Bali Berbasis Pemrograman

Berorientasi Objek, Skripsi Politeknik Negeri Bali,

Denpasar, Bali, Indonesia.

Handogo, R., and Wibawa G, 1997. Experiments and

Correlations of Vapor-Liquid Equilibria of Acetone-1-

Butanol-Ethanol Ternary Mixture, International

Conference on Fluid and Thermal Energy Conversion,

Yogyakarta, Indonesia.

Henley, E. J. and Seader J. D., 1998. Separation Process

Principles, pp. 586-712, John Wiley & Sons, Inc.,

New York.

Rayleigh, L., 1902. Phil. Mag. [Vi.], No. 4 (23), p. 521.

Sari N. K., Kuswandi, Nonot S., and Renanto Handogo,

2006. Komparasi Peta Kurva Residu Sistem Terner

ABE Dengan Metanol-Etanol-1-Propanol, Jurnal

REAKTOR, Jurusan Teknik Kimia UNDIP

Semarang, Vol. 13, No. 2.

Sari N. K., Kuswandi, Nonot S., and Renanto Handogo,

2007. Pemisahan Sistem Biner Etanol-Air Dan Sistem

Terner ABE Dengan Distilasi Batch Sederhana, Jurnal

INDUSTRI Jurnal Ilmiah Sains dan Teknologi,

Fakultas Teknik Industri ITS Surabaya, Vol. 6, No.5.

Prausnitz, J. M., 2001. The Properties of Gases and

liquids, ed. 5, Mc. Graw-Hill, New York.

Widagdo, S. and Warren D. Seider, 1996. Journal Review

Azeotropic Distillation, AIChE J., Vol. 42, No.1

Sari N. K., Aristarkhus A, and Abdi I. N., 2013. 20th

Regional Symposium on Chemical Engineering (RSCE

2013), Alona Kew White Beach Resort Panglao

Island, Bohol, Philippines 12–13 November 2013.

http://www.dlsu.edu.ph/conferences/rsce/registration_f

ee.asp

Sari N. K., and Ernawati D., 2018. Simulation of Liquid

Vapor Equilibrium in Batch Distillation Process from

Cellulose (Bamboo), Nusantara Science and

Technology Proceedings, 111-117

Sari N. K., and Ernawati D, 2017. Simulation of Activity

Coefficient System Ternary in Acetone Buthanol

Ethanol with Uniquac Equation, conference on

Information Technology and Busines

0,7

0,8

0,9

1,0

1,1

1,2

1,3

1,4

1,5

0,0 0,5 1,0 1,5 2,0 2,5 3,0 3,5

Koefisien Aktifitas

Dimensionless time

Comparison of Activity Coefficient in ABE with MEP with UNIQUAC Equation

609