Application on Survey Implementation of Dredging and Structure for

Energy Reducing Spillway Building at Ladongi Dam

Meivy Carolina Pandey

1

, Muhammad Zainuddin Lubis

1

, Agung Permana

2

, Sidik Dwi Pamungkas

3

and Muhammad Adam

4

1

Geomatics Engineering, Politeknik Negeri Batam, Batam, Indonesia

2

Pejabat Pembuat Komitmen, Ladongi Dam Project, Kolaka Timur, Indonesia

3

Geodetic Engineering, Ladongi Dam Project, Kolaka Timur, Indonesia

4

Civil Engineer, Ladongi Dam Project, Kolaka Timur, Indonesia

sidikdwipamungkas93,adamlawa024}@gmail.com

Keywords: Energy Reduction Building, Role of Survey, Excavation and Structure, Volume.

Abstract: The Energy Reduction Building planned at Ladongi Dam utilized the Type II Olakan Flat Pond Type (USBR

II). Energy absorbers in spillway buildings are very important to reduce the energy of water flow and avoid

damage to rivers. The purpose of this study is to determine the role of the survey in the implementation of

excavation and also the structure buildings in the field and be able to process and present measurement data.

Data field collection consists of 3 working stages: excavation work, working work floor and working wall

structure. The calculation of excavation volume in this final project is carried out by measurement using the

Cross Section and in volume calculation using the Mean Area method. The results from this study are, the

role of the survey in the construction of energy reduction building, the volume of excavation and foundry of

work floors, the dental importance of wall structures, cross-section, 3-dimensional view of excavated land.

LW 33 block dental volume is 138.99 m

3

starting from an elevation of +60.11 to an elevation of +64.50. In

Block LW 33 - LW 35, a landslide occurred in the zone 3 slopes parallel to the structural parapet (El. +64.5 -

El. +67.5) therefore dental filling was carried out, the total required dental volume was 164,954 m

3

. The total

volume of excavation to the work floor elevation is 505,609 m

3

, and the total volume of additional landslide

structures is 893,329 m

3

.

1 INTRODUCTION

Indonesia's rapid population growth makes the role of

water sources significant. The volume of water is

relatively fixed, but the water demand continues to

rise, making humans continue to strive to manage

water sources (Prastumi, 2012). One source of water

that has the potential to be driven to reach the growing

need for water is the river.

Judging from the geographical location and

infrastructure of Southeast Sulawesi Province, East

Kolaka Regency has an equitably large irrigation area

and rivers that have the potential to irrigate

agriculture, natural water sources, etc. One of the

rivers in East Kolaka that can be exploited is the

Ladongi River in Ladongi District. To take advantage

of this potential, the Central Government through

Sulawesi River Region IV Kendari Ministry of

PUPR. Ladongi Dam is planned to have a capacity of

45 million m

3

and is expected to irrigate an area of

3604 ha.

The embankment dam was built by piling up

materials such as a rock, gravel, sand, and soil in a

unique composition with the function of to lift the

water surface in the reservoir (Sosrodarsono, 1977),

Ladongi Dam construction it was engineered to use

the rock fill type dam. Ladongi Dam consists of

several main building constructions, namely main

Dam, spillway, and tunnel, each of which has an

essential and interrelated role. Spillway buildings

have the function to overflow water in dam reservoirs

and to avoid overtopping on dams (Asiyanto, 2011).

The spillway at Ladongi Dam uses Ogee type

overflow type with light level elevation +119.8

meters. Ladongi Dam at spillway area consists of 4

main construction parts, namely flow control,

launchers, energy absorbers, and drainage channels.

40

Pandey, M., Lubis, M., Permana, A., Pamungkas, S. and Adam, M.

Application on Survey Implementation of Dredging and Structure for Energy Reducing Spillway Building at Ladongi Dam.

DOI: 10.5220/0010351400400047

In Proceedings of the 3rd International Conference on Applied Engineering (ICAE 2020), pages 40-47

ISBN: 978-989-758-520-3

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

The energy reducer building planned at Ladongi

Dam uses the Olakan Flat Type II (USBR II) Pool

type. This type is suitable for flow with high

hydrostatic pressure and massive outflow

(Sosrodarsono, 2016). Energy absorbers in spillway

buildings are very important to reduce the energy of

water flow and avoid damage to rivers. Damage that

occurs is usually in the form of scouring on the river

body caused by high energy content and supercritical

flow due to changes in the slope of the dam lighthouse

(Ratnawati, 2009). Therefore, before the flow of

water flowing into the river, it has to slow down and

changed in sub-critical flow conditions, so that no

scouring occurs, which causes degradation on the

riverbed (Prastumi, 2012).

In the implementation of the construction of the

energy reducer structure has some factors that must

be considered, such design structure, plan elevation,

geological structure, and the strength of the slope

structure. During the execution of the Ladongi Dam

spillway, landslides have occurred at the slope

structure in the launch area that caused by geological

conditions in the area. The existence of landslides in

the area resulted in changes in the method in the

excavation process and the energy reducer structures.

The role of surveys is very important in the

implementation of spillway work. In the field

implementation, the survey team is generally tasked

with determining location, controlling the excavation

of structural work, and controlling the work of

structures. The purpose of this study was to determine

the role of the survey in the implementation of

excavation and the structure of the Ladongi Dam

energy reducer building, to know the handling and

role of the survey in the landslide area of the energy

reducer at Ladongi Dam. In this final project data

collection is divided into 3 (three) parts, namely:

excavation work, floor work, and wall structure work.

2 RESEARCH METHODS

2.1 Research Design

The results of the study are focused on providing a

picture of the actual state of the object in the study.

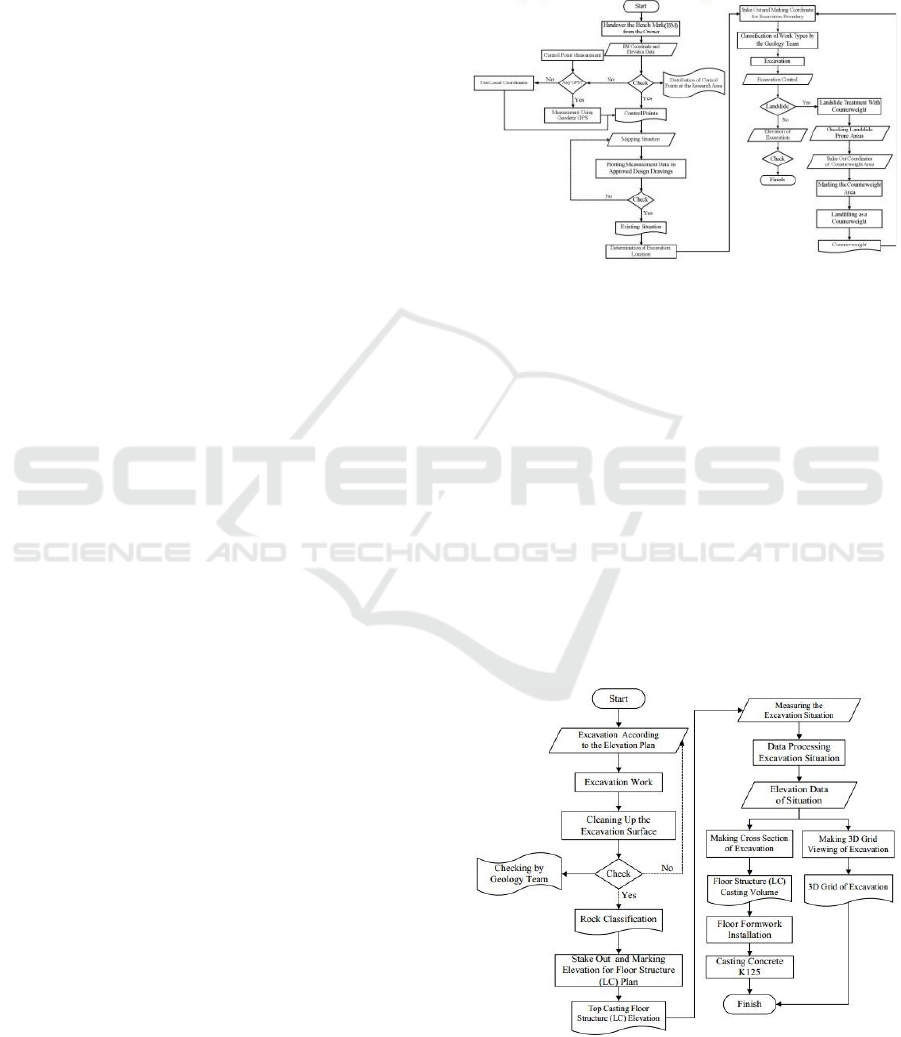

Stages of research to be carried out can be seen in

Figure 1.

Data collection techniques used in this study were

carried out by collecting primary data and secondary

data. Primary data was obtained by collecting the data

field directly through field observations and

measurements. Secondary data in this study were

obtained by the Office of the Ladongi Dam

Supervision Consultant PT Binatama Wirawredha

KSO PT Arga Pasca-Rencana and also by the Office

Contractor PT Hutama Karya Bumi Karsa KSO.

Figure 1: Research flowchart.

2.2 Research Location and Time

This research was conducted at Ladongi Dam

Construction Project in East Kolaka Regency,

Southeast Sulawesi Province, where the geographical

location was on coordinates of 4° 08’ 52” – 4° 08’ 53”

South latitude and 121° 52’ 43” – 121° 53’ 34” East

longitude (Figure 2). In this study the location

observed was an energy-absorbing building in an

overflow building (Spillway). The data retrieval and

processing last for 6 months.

2.3 Tools and Materials

In measurement activities, of course, equipment is

needed to support this research activity in data

retrieval and processing as follows:

Software: Microsot Word 2010, Microsoft

Excel 2010, Autocad Civil 2017, SketchUp

2017, Surfer 9.

Figure 2: Research location.

Application on Survey Implementation of Dredging and Structure for Energy Reducing Spillway Building at Ladongi Dam

41

Hardware: Total Station Topcon ES 101,

Waterpass Topcon AT-G6, Statif, Prisma, Bak

Ukur, Meteran, Drone.

2.4 Dredging Works

Dredging work is the initial stage in carrying out the

work of a building structure, where this excavation

work is carried out to provide land for the building

structure. Stages of dredging works can be seen in

Figure 3.

Before the work is carried out, there are

preparatory stages that need to be considered to

support the implementation of work in the field from

start to finish such as Provision of Data and Working

Drawings, Inspection of Survey Equipment, and

mobilization of Personnel Equipment. In excavation

work, some main things must be considered as

follows:

Point Benchmark (BM), the initial stage in

carrying out survey work in the field surveyors

need to have Benchmark data (BM). BM has a

fixed position value in the form of coordinates

with the appearance of a monument/pale in the

field, which is used as a reference point (Adi &

Aghastya, 2017). BM procurement can be done

by measuring using Geodetic GPS through the

static method or using local coordinates. In this

study, the procurement of BM points was not

carried out because the reference points of BM

were evenly distributed in the research

location.

A Mapping Situation is a mapping activity to

get a detailed description of the work area

project (Susetyo, Tri, & Saputra, 2013). The

measurement for mapping is discovering the

horizontal position and vertical position of each

point in the field (Kustarto, 2012). The

mapping situation in this study concerns for

carried out to find how the topography before

the excavation stage and also use as a factor of

data field checking based on the design

drawings.

Excavation stage, implementation on the field

for excavation work begins with the

determination of the excavation location.

Fixing the area of the excavation is done by

stake out the coordinates and marking the land

boundaries. The coordinate stakeout is to select

the point above the earth's surface using the

coordinates [9], the coordinate stakeout can be

done by using the Total Station. If the

excavation location has been decided,

excavation work can be started. One of the

obstacles that occur during the excavation in

the field is some areas have the potential for

landslides, so during the excavation stage, if a

landslide occurs, it is necessary to handle it by

installing a counterweight.

Figure 3: Dredging work flow chart.

2.5 Work Floor Work

In the implementation of the work floor of a building

structure, the availability of the work floor structure

land must be ensured. Figure 4 is the following stages

in work floor activity.

Measurement of detail points is needed to

describe the situation of the measurement area in

more detail, measurement of detail points can be done

using the tachymetry method. The tachymetry

method is a measuring method of detail points used

in determining the coordinates and height of the detail

points from tie points (Maulidin, 2016). Measuring

height or elevation is the measurement of the height

difference between two points.

Figure 4: Work flow chart of floor.

ICAE 2020 - The International Conference on Applied Engineering

42

Measurement of height difference can be done

with a flat slope measurement tool, measuring the

height difference with a flat slope is the process of

determining elevation or finding a different height

between measured points (Masrul & Anjasmara,

2015). The role of the survey is to ensure that the

excavation area and/or work floor elevation are

following the plan. If the excavation has matched

with the design elevation plan, the geological team

will check to ensure that the excavated land as

compared to the specifications with planning design

by the geological team, height between measured

points (Masrul & Anjasmara, 2015). The role of the

survey is to ensure that the excavation area and/or

work floor elevation are following the plan. If the

excavation has matched with the design elevation

plan, the geological team will check to ensure that the

excavated land as compared to the specifications with

planning design by the geological team.

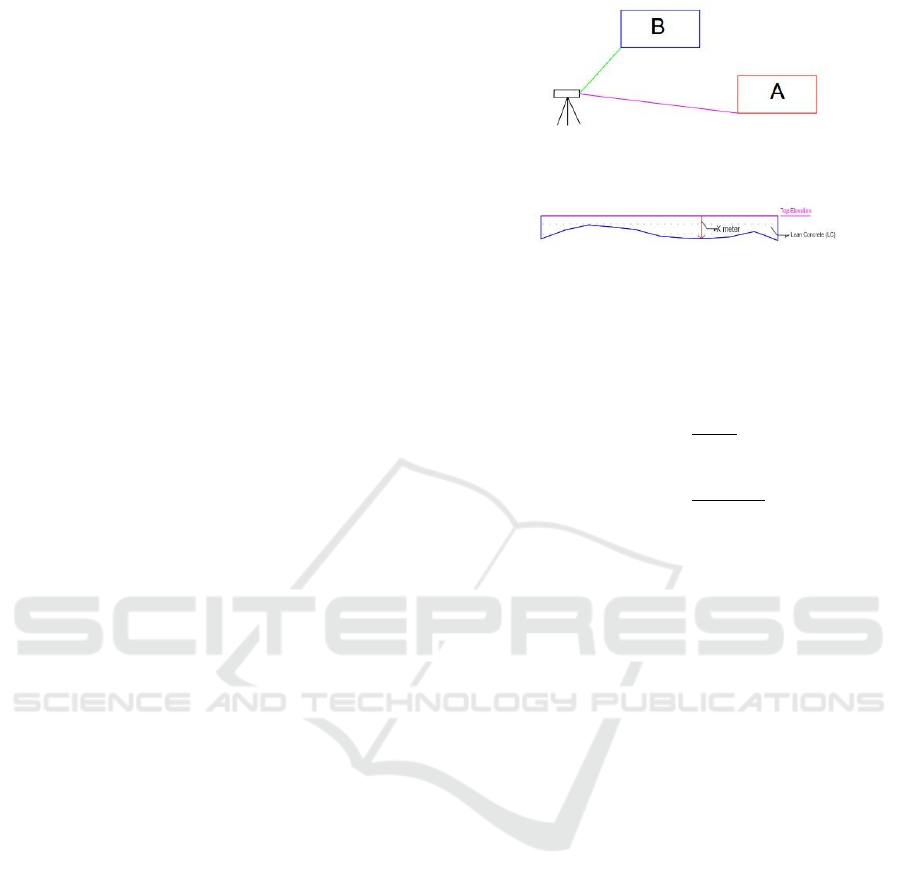

Stake out elevation and work floor marking,

stake out elevation is to determine the point that

will be the elevation limit of the work floor plan

if the excavation of the land has passed the

work floor plan design (Figure 5). In the

implementation of stake out, fixing and

checking reference points is the first step that

must be taken (TS-04, 2011). To fix the work

floor elevation limit, it can be fixed by using

measurement tools, i.e. a water pass, the

accuracy of deter- mining the size depends on

the tools used as well as on the accuracy of

measurement and what can be executed (Frick

& Heinz, 1984). After obtaining the work floor

elevation limit, the work floor boundary

marking is carried out to obtain the work floor

top cast. The implementation of stake out

elevation in the field is carried out using the

formula below, i.e:

Re f Ele(A)WP = Re f Ele(A) + Re f Signs(A) (1)

SignsRead(B) = Re f Ele(A)WP–CastTEle(B) (2)

The excavation situation was measured using

wa- ter pass and meter. Water pass is used to

get full cast from the work floor and work floor

bound- aries (Figure 6). Excavation situation

data is taken by cross technique taken per 1

meter. Through the measurement of the

excavation situation, it can be seen how the

cross-section of excavated land is through the

results of the profile lengthwise and the

transverse profile.

Figure 5: Stake out and work floor elevation marking

techniques.

Figure 6: Data retrieval technique for dredging situation.

The results of this measurement will be processed

to obtain the volume of work floor casting using the

cross-section method with the Mean Area equation

with the following formula (Adi & Aghsatya, 2017):

𝑉

𝐿 (3)

𝑉

𝐿 (4)

Where:

V

n

: nth section average volume (m

3

),

A

1

: Cross-sectional area 1 (m

2

),

A

2

: Cross-sectional area 2 (m

2

),

L : Distance between each section (m).

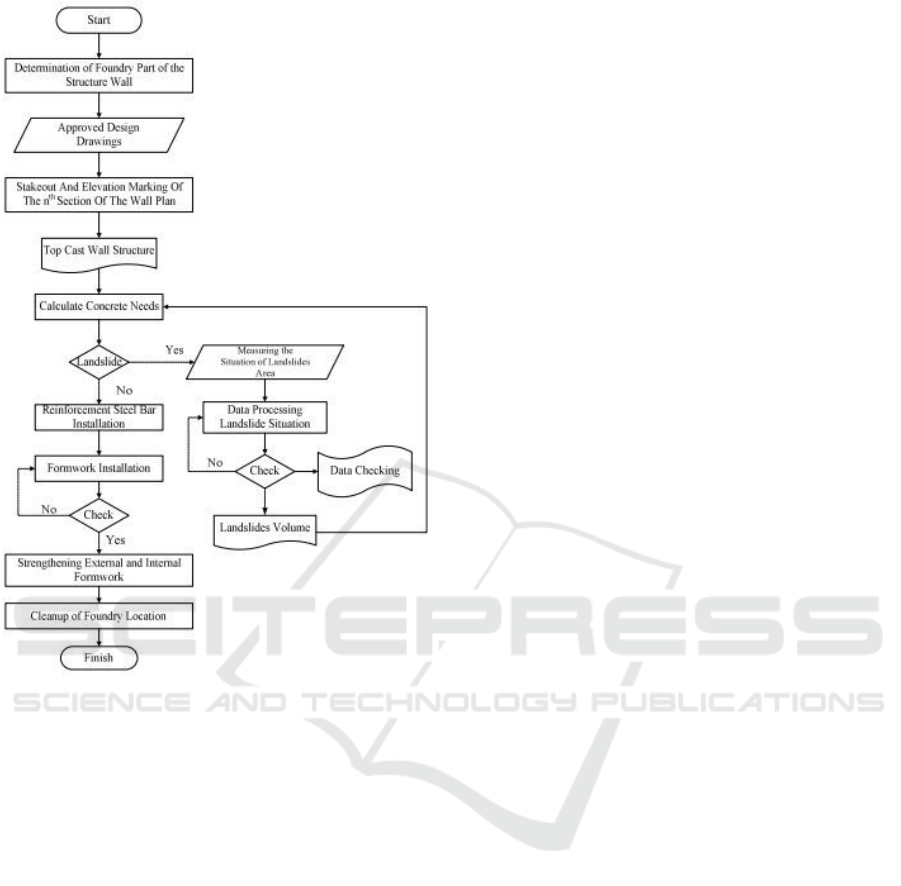

Figure 7 is the stage of the wall structure work,

which is the final stage in developing the energy

reducing construction. Stakeout and marked elevation

of the nth section from wall design, Stakeout

elevation or vertical stakeout is the measurement of

the main points position and the vertical details of the

building. The first step is, of course, the determination

of the foundation elevation at a predetermined

location through the measurement of horizontal

stakeholder outs. After determining the elevation of

the working wall plan, estimation of the volume of

concrete needed for casting can be estimated. If

landslides occur in the wall structure area, the need

for concrete for casting will increase. The landslide

result, fillings and/or dental casting are carried out to

cover the landslide area so that the initial concrete

requirements according to the plan based on the work

drawings are added to the volume of the landslide.

Calculating volume of the landslide, the survey team

took measurements of the situation of the landslide

area, in this measurement using a meter by calculating

the distance between the structure of the building and

the area affected by the landslide.

Application on Survey Implementation of Dredging and Structure for Energy Reducing Spillway Building at Ladongi Dam

43

Figure 7: Structure work flow diagram.

3 RESULTS AND DISCUSSION

3.1 Dredging

The excavation process begins with a stakeout and

marking the boundaries of excavated land to be

worked. Excavation work for wall structure work

floors is carried out up to +54.00 m elevation, while

elevations for work floors are required up to +55.00

m elevation.

In the excavation work, the survey team has the

role of controlling the excavation to ensure that the

excavation is following the design elevation. In the

field implementation, there were obstacles in the form

of landslides during the excavation process.

Therefore, it is necessary to handle landslides by

installing counterweights (Figure 8). A counterweight

is a pile of soil that is made at the slope, and the

functions are to prevent scouring and provides

counter forces that restrain soil movement so it can

increase the value of the safety factor (Kusuma,

2014). In handling and preventing landslides, the

survey team play a role within plotting the boundaries

of the land area that will be installed by

counterweights.

3.2 Survey of Employment on Floor of

Work

The role of the survey in this work flooring initially

begins with ensuring the elevation of excavation

matches the work drawings and also controlling the

excavation again when over-excavation is needed to

obtain the appropriate rock type. Checking the work

floor elevation is ensured by conducting stake

elevation. Stakeout elevation is to determine the point

that will be the elevation limit of the work floor plan

if the excavation of land has passed through the work

floor plan design.

After obtaining the work floor elevation limit, the

work floor marking is carried out in order to obtain a

work floor top cast. After getting the top cast work

floor, the next step is to measure the dredging

situation.

3.3 Work Floor Dredging Volume

Through the measurement of the excavation situation,

it can be seen how the cross-section of the excavated

land is and can be calculated cast volume for the work

floor. The calculation for the volume of work floor

casting is using the method of cross-section or cross

profile. A cross-section is a vertical section or a

section perpendicular to the project axis (Wijayanto,

Sunarjono, Abdurrosyid, 2013). The work floor

elevation for the Right Wall (RW) and Left Wall

(LW) wall structure is at +54.00 m elevation while the

Center Floor (CF) elevation is at +54.00 m for footing

and +55.00 m for work floor. The elevation is used as

a casting reference or commonly called Top Cast for

the marking limit of work floor elevation when there

has been over-excavation so that the land is cast to

match the elevation of the work floor design.

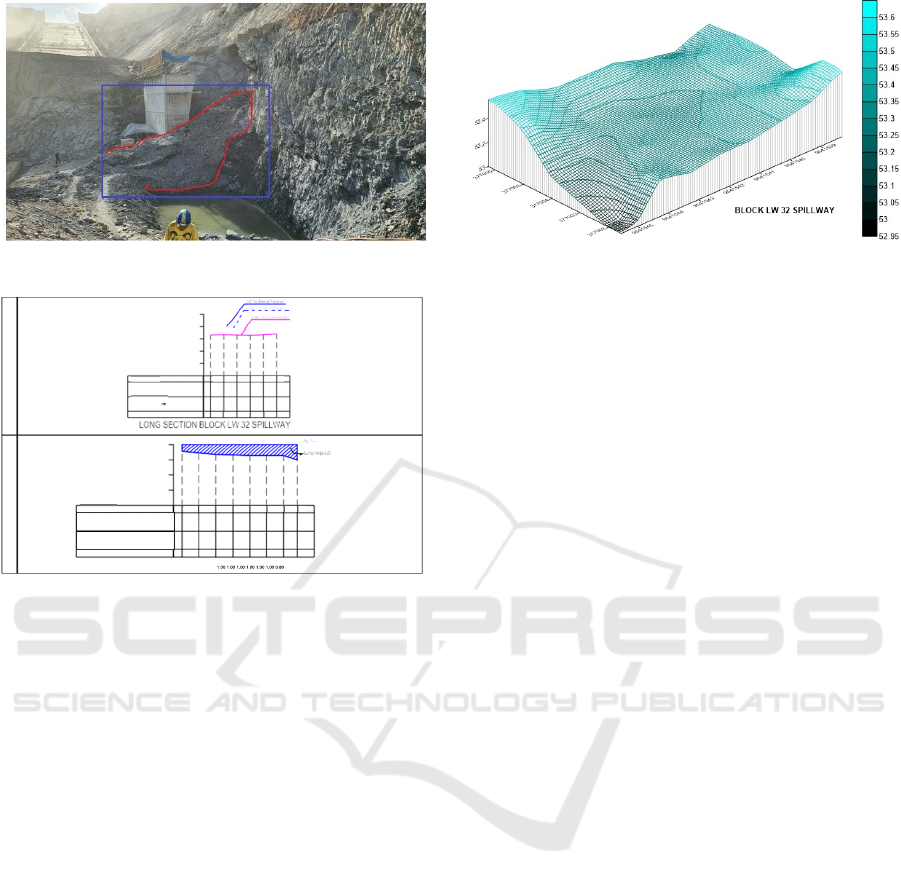

In the field implementation, the average length of

excavation was 6.90 meters, and the width of the LW

32 excavation block was 4.75 meter. Figure 9 shows

the results of the long section profile and one of the

results of the cross-section. Block LW 32 is divided

into 6 cut lines or 6 crosses starting from 0 meters at

the start of the block with a per-cross distance interval

of 1 meter and the last cross continuing from the end

of the block boundary about 0.75 meters.

ICAE 2020 - The International Conference on Applied Engineering

44

Figure 8: Counterweight installation.

Figure 9: Situation profile of the spillway block LW 32 LW.

The elevation of the cast top floor of the LW 32

block is at +54.00 m. The highest excavation

elevation is +53.60 m with a difference in height

difference of 0.40 meters from the elevation of the top

cast, for the lowest elevation at +52.95 m with a

difference of 1.05 meters from the top cast elevation.

The volume of casting on the LW 32 Block's work

floors was 22,345 m

3

.

Based on Figure 10, it can be seen the

visualization of the 3d grid showing the situation of

the LW 32 Block excavation surface. The results of

excavation show that various elevations are caused by

soil surface geological factors. The number of

working floor blocks in this study was 15 blocks, total

volume from excavation to the work floor elevation

was 505,609 m

3

, and the highest volume was in the

LW 35 Spillway block of 63,854 m

3

.

Figure 10: 3D grid viewing block LW 32 spillway.

3.4 Field Survey in Wall Structure

In the implementation of the building, structure work

is done in stages, usually, the work on the structure is

done by dividing it into several segments. The

Ladongi Dam damper structure works are separated

into 4 segments. Segment 1 is at an elevation of

+55.00 m, segment 2 is at an elevation of +56.00 m,

segment 3 is at an elevation of +64.50 m, and segment

4 is at an elevation of +67.50 m. The segmentation is

carried out to simplify the process of ironing,

installing formwork, and also the process of casting

the building structure.

In the excavation and also the structure work of

the energy-absorbing building walls, landslides occur

around the LW 33, LW 34, and LW 35 blocks. The

existence of landslides is caused by geological factors

in the area and the potential for landslides on the slope

above the building plan structure. The consequence

of the landslide occurred, dental fillings and/or

casting were carried out to cover the landslide area,

so that the original concrete requirements according

to the plan based on the design of the drawing were

calculated to the total volume of landslides. In

calculating the volume of the landslide, the survey

team had to measure the situation of the landslide

area. This measurement was using meters by

measuring the distance between the edge of the

building structure and the area affected by landslides.

In collecting the landslide data at block LW 34

Spillway, it was carried out by dividing it into 5

crosses starting from the 0 meters from the first block

and the interval distance for each cross is 2.5 meter,

the landslide cross measurements can be seen in

Figure 11.

Application on Survey Implementation of Dredging and Structure for Energy Reducing Spillway Building at Ladongi Dam

45

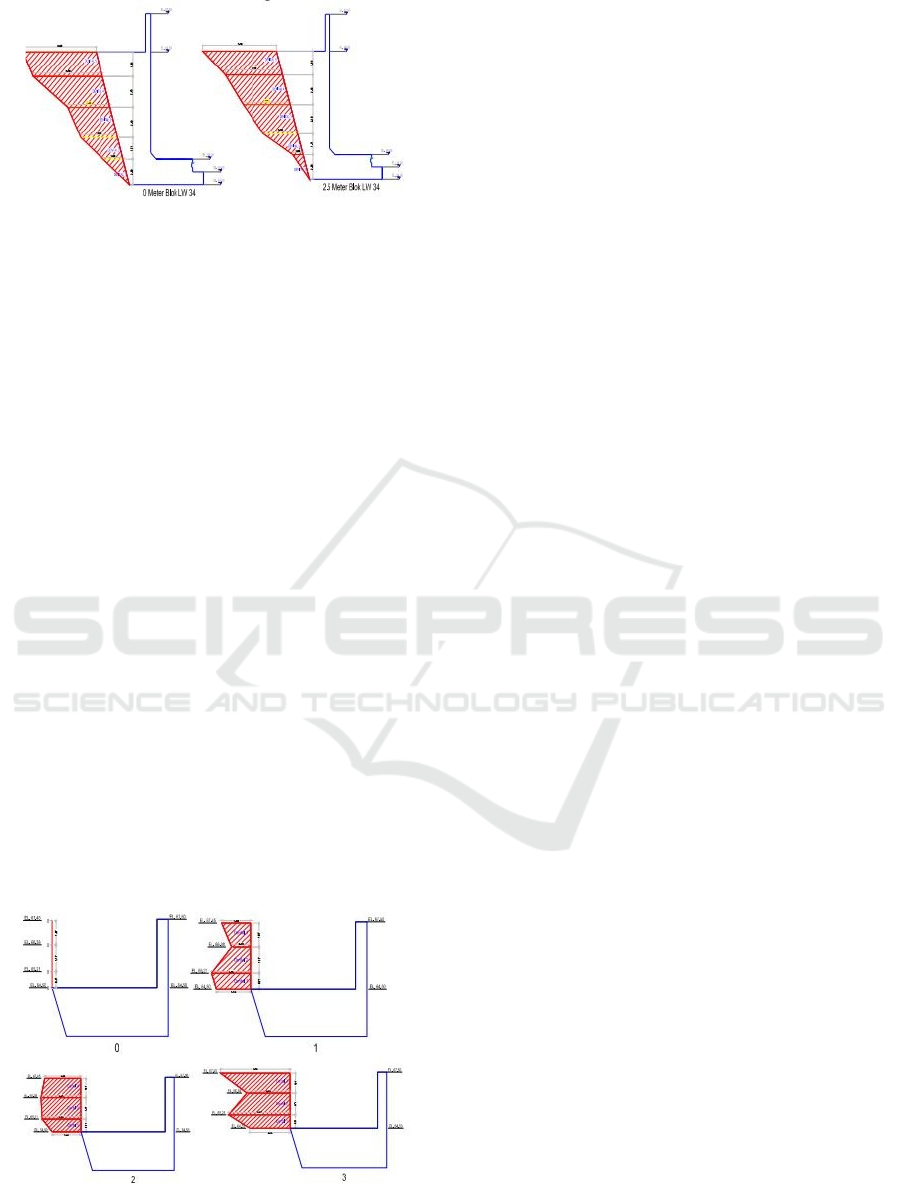

Figure 11: Cross landslide measurement block LW 34.

Dental casting for the LW 34 Spillway Block

Avalanche area is divided into 5 segments, namely

Dental 1, Dental 2, Dental 3, Dental 4, and Dental 5.

Segment Dental 1 is at an elevation of +54.00 m to an

elevation of +56.00 m, Segment dental 2 is at

elevation +56.00 m to an elevation of +57.71 m,

Segment dental 3 is at an elevation of +57.71 m to an

elevation of +60.11 m, Segment dental 4 is at an

elevation of +60.11 m to an elevation of +62.54 m,

and the segment dental 5 is at an elevation of +62.54

m up to +64.50 m elevation. The dental volume for

casting the landslide area of the LW 34 Spillway

Block was 347,959 m

3

.

The location of the energy reducing structure is

right under the slope of zone 3 spillway, and there was

a landslide right to the building structure on Block

LW 33 to Block LW 35 (El. +64.5 - El. +67.5). To

prevent further landslides in the slope area that can

affect structural damage and hinder other work, so to

prevent further landslides and establish the structure,

patching of the landslide area is carried out using

dentals. Cross landslide measurements are carried out

starting from the LW 33, LW 34, and LW 35 blocks

together. The number of crosses is 22 crosses and

starting from the first 0 meters of LW 33 Spillway

Block, and with 1-meter intervals between each cross,

the results of cross landslide measurements can be

seen in Figure 12.

Figure 12: Cross Landslide Block LW 33, 34, 35 (+65.21 -

+67.45).

Dental casting for the landslide area LW 33 Block

– LW 35 Spillway Block is divided into 3 segments,

namely Dental 1, Dental 2, and Dental 3. Segment

Dental 1 is at an elevation of +64.50 m to an elevation

of +65.21 m, and segment Dental 2 is at elevation +

65.21 m to an elevation of +66.38 m, the Dental 3

segment is at an elevation of +66.38 m to an elevation

of +67.45 m. The volume of LW 33, LW 34, and LW

35 Spillway block dental casting is 164,945 m3. The

total volume of additional landslide structures is

893,329 m

3

.

4 CONCLUSIONS

Handling of landslides is done by installing

counterweights in areas affected by landslides, and

those have the potential for landslides. The results

from the excavation situation measurement are used

to calculate the volume of the work floor casting

using the Mean Area equation. The total excavated

volume of elevation of the work floor is 505,609 m

3

.

The LW 33 Block dental volume is 138.99 m3

starting from +60.11 elevation to +64.50 elevation. In

Block LW 33 there was a landslide in zone 3 slopes

parallel to the structural parapet (El. + 64.5 - El. +

67.5) then dental filling was made, the total dental

volume needed was 164,954 m

3

.

ACKNOWLEDGEMENTS

The authors would like to thank all the Ladongi Dam

Project parties to the Balai Wilayah Sungai Sulawesi

IV Kendari, especially the Consultants PT Binatama

Wirawreda - PT Arga Pasca Rencana, KSO and

Contractor Hutama Karya – Bumi Karsa, KSO. They

have permitted and facilitated all efforts in data

collection.

REFERENCES

Adi, W. T., Aghastya, A, 2017. Penggunaan total station

dan autocad civil 3D untuk perencanaan grading.

Jurnal Perkeretaapian Indonesia.

Asiyanto, I, 2011. Metode Konstruksi Bendungan, Penerbit

Universitas Indonesia (UI-Press). Jakarta.

Frick, I., Heinz, 1984. Ilmu dan alat ukur tanah, Penerbit

Kanisius. Semarang.

Kustarto, D. H., 2012. Ilmu ukur tanah metode dan

aplikasi: bagian kedua, Penerbit Dioma. Malang, 1

st

edition.

ICAE 2020 - The International Conference on Applied Engineering

46

Kusuma, R. C., 2014. Evaluasi Desain Tahap 1 Disposal

Swd 11 Pit.

Masrul, Anjasmara, I. M., 2015. Pemantauan penurunan

muka tanah di kawasan Watukosek menggunakan

metode sipat datar, Geoid.

Maulidin, R. F., 2016. Studi penentuan volume dengan total

station dan terrestrial laser scanner, Institut Teknologi

Sepuluh Nopember.

Muda, I., 2008. Teknik Survei dan Pemetaan, Direktorat

Pembinaan Sekolah Menengah Kejuruan. Jakarta.

Prastumi, 2012. Pengaruh variasi tipe peredam energi

terhadap karakteristik hidrolika saluran pelimpah

bendungan studi kasus uji model pelimpah bendungan

Jehem—Bali, Rekayasa Sipil, pp. 153- 160.

Program Studi Teknik Geologi Tambang Batubara Distrik

Baya Desa Separi, Kecamatan Tenggarong Seberang,

Kabupaten Kutai Kartanegara, Kalimantan Timur.

Geological Engineering E-Journal.

Ratnawati, H., 2009. Pelimpah bertangga sebagai peredam

energi pada kolam olak tipe solid roller bucket,

Universitas Muhammadiyah Surakarta.

Sosrodarsono, D. I., 1977. Bendungan type urugan, PT.

Balai Pustaka (Persero). Jakarta, 4

th

edition.

Sosrodarsono, D. I., 2016. Bendungan Urugan, PT. Balai

Pustaka (Persero). Jakarta, 6

th

edition.

Susetyo, D. B., Tri, H., Saputra, L. R., 2013. Standarisasi

Aplikasi Survey Pemetaan Terestris Dalam Bidang

Konstruksi Struktur Bawah Bangunan.

TS-04, M., 2011. Melakukan stake out dan monitoring:

materi pelatihan berbasis kompetensi sektor konstruksi

sub sektor bangunan gedung.

Wijayanto, H., Sunarjono, S., Abdurrosyid, J., 2013.

Pengaruh Ketelitian Hasil Pengukuran Topografi

Terhadap Desain Irigasi Gonggang, Universitas

Muhammadiyah Surakarta.

Application on Survey Implementation of Dredging and Structure for Energy Reducing Spillway Building at Ladongi Dam

47