Elongation Optimization of Bioplastic using Response Surface

Methodology

Trisita Novianti, Issa Dyah Utami

and Heri Awalul Ilhamsah

Department of Industrial Engineering, University of Trunojoyo, Jl. Raya Telang Kamal, Bangkalan, Indonesia

Keywords: bioplastic, corn starch, elongation, optimization, response surface

Abstract: Bio plastics are derived from plant sources such as corn starch, cassava, sugarcane, soybean, banana peel. Bio plastics are

environmental friendly and biodegradable, which is a material that can return to its natural state when buried in the ground

or soaked in the water. Microorganisms will break down into carbon dioxide and water. The aim of this study was

measuring elongation optimization in bio plastic, which made of glycerin and cornstarch as the base material.

For calculation, this study was using the surface response method with experimental design with 2 factors

(22), and experimental design were 13 experiments. Based on the calculation results, the desirability value

for elongation was 18.4. Moreover, the combination of the optimal parameters produced was 0.5 ml glycerin

and 3.81 g starch with the optimum elongation was 17.3%. The elongation of commercial plastic bag is

222.5%. The elongation of bioplastic sample in this research were below this number. Moreover, the bioplastic

sample, which was made of corn starch, cannot be used as commercial plastic bag. However, it can be used

in food packaging, pharmacy, and cosmetic which do not need high elongation, which is around 20%.

1 INTRODUCTION

Bioplastics are derived from plant sources such as corn

starch, cassava, sugarcane, soybean, banana peel. Bio

plastics are environmental friendly and biodegradable,

which is a material, returns to its natural state when buried

in the ground or soaked in the water (Ghayebzadeh et al.,

2020). Microorganisms will break down into carbon

dioxide and water. Bags are made of bio plastic can be

thrown away and buried (Zhang et al., 2020). This can

reduce plastic waste in the world, especially in the ocean

(Andrady, 2017). The fact, Indonesia has the second rank

for plastic waste in the ocean after China. This condition

can cause animal death, which is accidentally eat plastic

waste (Lestari and Trihadiningrum, 2019). Bio plastics can

be used for shopping bag, food packaging, gardening,

sanitary products, medical product (Jambeck et al., 2015).

Urbanization and industrialization combined an

increasing in the population has led to the

accumulation of boundless quantities of non-

biodegradable waste in the environment. Plastics

have turned to be an expected part of day-to-day life.

Deceleration in accessibility of petrochemical

residues has led to the dependence and development

of eco-friendly and biodegradable plastics of

commercial stuff, with improved worldly properties

than their synthetic (Umesh et al., 2018). Using non-

renewable packaging make a serious ecological

problem caused by their non-biodegradability. The

development of biodegradable edible film can replace

synthetic materials, thus protecting environment and

improving product quality (Araújo et al., 2018a).

Biodegradable films may be made of natural

polymers, for instance proteins, polysaccharides,

lipids, or a combination of these compounds (Abbas

et al., 2017).

In this study was used cornstarch for basic

material, because of its large availability, easily

available in Indonesia, and the price is cheap. For

making bio plastic, first this study had to assess the

mechanical properties of the bio plastic. This can be

indicated by measuring elongation which is one of

indicators of the flexibility of the material (Domene-

López et al., 2019). In accordance to Japanese

Industrial Standard, the percent extension or

flexibility is categorized as good if above 10% and

will be categorized very well if it exceeds 50%

(Miyamoto et al., 1984). The surface response

methodology was used to measure the optimum

composition for glycerine and corn starch to form bio

plastic material which has maximum elongation. This

response surface method is an optimization method

448

Novianti, T., Utami, I. and Ilhamsah, H.

Elongation Optimization of Bioplastic using Response Surface Methodology.

DOI: 10.5220/0010313300003051

In Proceedings of the International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies (CESIT 2020), pages 448-453

ISBN: 978-989-758-501-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

that is devoted to research using experiments

(Gaspersz, 1992, Akinoso et al., 2012).

2 METHODOLOGY

2.1 The Process of Making Bioplastics

The concentration of cornstarch and glycerin was

used in accordance pre-determined coding. Added 0.8

g carrageenan, then distilled r with 100 ml water. The

next process was heated using a hotplate with a

temperature of 95

o

C while stirring for 30 minutes.

Next step was preparing a mold made of square glass

with a size of 10 cm x 10 cm, after going through the

stirring process for 30 minutes, the bio plastic was

taken 15 ml and printed in the mold. Then the mixture

was dried in an oven at 65

o

C for 8 hours.

Furthermore, observations were made by forming

bio plastics which be tested using a Texture Analyzer

(de Azêvedo et al., 2020). A bio plastics sample,

which was analysed, was 1cm x 5 cm. The

measurement process by clamping the bio plastic

sample with the tool and stretch it until broke up.

When the biopassicator was broke, the tool

automatically stops pulling (Novianti et al., 2019)

2.2 Data Retrieval

Data retrieval process was carried out using the

Texture Analyzer tool. The tool can be used to

measure the elongation of bio plastics. The process of

retrieving data for elongation is as follows:

a. Making bio plastic sample, the size is 1 cm x 5

cm;

b. make initial settings with distance around 4 cm

between clamp 4 cm;

c. clamping the two ends of the bio plastic on the

clamp in the Texture Analyzer tool;

d. do the Running Texture Analyzer Tool

e. the tool will automatically stop when the object

(bio plastic) will be disconnected;

f. the results are the output peak force.

2.3 Elongation Assessment

Cornstarch has a level of elasticity in bio plastics.

Starch has amylase content and high plasticize in

glycerin which cause bio plastics are having a high

flexibility. The levels of amylopectin have an effect

to make bio plastic stable in flexibility (Ibrahim et al.,

2019, Reyes et al., 2020). Elongation testing in this

study by taking bio plastic samples by cutting 1 cm x

5 cm x 0.1 cm. Then it was tested and obtained the

maximum pull until the bio plastics break up. For

calculating elongation using a formula as follows:

Elongation=

100%

(1)

where are:

Elongation = Bio plastics elasticity (%)

b = additional length of sample when torn (cm)

a = sample length before it is pulled out (cm)

The following is a sample size of the bio plastic to

be tested using a texture analyzer:

Figure 1: Bioplastic sample.

The completion method that will be used is the

surface response method, which is a collection of

statistical and mathematical techniques that are useful

for analyzing problems about several independent

variables that affect non-independent variables

(Montgomery, 2017). The response surface method

has the goal of finding the optimum response (Biglari

et al., 2018). In this study identified the optimum

response from bio plastics to the concentration of

cornstarch.

The response surface method has the advantage of

the other methods, which is the number of

experiments is less so that the experimental costs can

be reduced, and can be used for multiple responses.

Then the output produced is an equation which will

be used to predict the response with different

independent variable values (Mäkelä and

Management, 2017).

The results of the response surface method are

countur plot and surface plot. Both will show the

optimal area and can determine the level of influence

of the independent variable on the response variable

(Dean et al., 2017). Next is the D-Otimaly Response

curve, which is a curve that will show the value of

desbirability from optimal conditions for both

responses. The equation as follows:

Elongation Optimization of Bioplastic using Response Surface Methodology

449

Y = B

0

+B

1

X

1

B

2

X

2

+B

3

𝑋

𝐵

𝑋

𝐵

X

1

X

2

(2)

From the data that has been obtained from the

experimental results, the data will be processed with

the calculation of the matrix, so that the coefficients

from the above equation will be obtained. The steps

of the response surface method to be carried out are

as follows (Sarabia et al., 2019):

a. Look for response surface coefficients by doing

matrix calculations (in this study was used

minitab for calculation);

b. assess model significance (ANOVA);

c. if the result is a significant, then the test will

continue to determine the optimal parameters

The following hypothesis on a significant test that

was conducted:

H

0

= Significant Model is proven

H

1

= Significant Model is not proven

If F

count

> F

table

and Sig < 0.05, then accept H

0

.

Furthermore, the test can be continued to next step

which is optimal parameter assessment. The next step

is to determine the optimum parameters by using the

response optimizer in the Minitab application. The

output of the process is calculated plot, surface plots

and D-Optimal Response curves (Myers et al., 2016).

To determine the optimum area, it can be seen

from the contour of the plot, while the surface plot

will show the parameters that most influence to the

response (Baş and Boyacı, 2007). D-Optimaly

response can show its optimum point. In this study

will show bio plastic parameters from the

composition of glycerin and cornstarch (Yolmeh et

al., 2017). Experimental design as follows:

Table 1: Experimental design.

Experimental

Design

Factors (k)

2 3 4 5

Factorial Design 2

2

2

3

2

4

2

5

α (2

(k/4)

) 1.414 1.682 2 2.378

Number of

central

repetition

5 6 7 10

α value can be derived as follow:

𝑎2

/

(3)

Whereas:

k = Number of factors

α = Error

Table 2: Treatment code of glycerin and starch.

Treatments Treatments Codes

-1.414 -1 0 1 1.414

Glycerin

(ml)

1 0.5 1 1.5 2

Starch (g) 2 2 3 4 5

The research was conducted using response which

was elongation optimal solution and using two

factors. By using the Central Composite Design

method, the number of experiments were 13 with the

following details.

N = 2

n

+ 2n + m

N = 2

2

+ 2(2) + 5

N = 4 + 4 + 5

N

= 13

(4)

Whereas:

N : Number of experiments

n : Number of factors

m : number of centre point repetition

The experimental data were generated using the

response surface method. The independent variable

used in this experiment were glycerine and corn

starch composition. While the dependent variables

was elongation. The complete experimental design is

as follows.

1. Factor:

a) X

1

for glycerin experimental code

b) X2 for cornstarch experimental code

c) G for glycerin real composition from 0.5 ml

to 2 ml

d) T for cornstarch real composition from 2 g to

5 g

2. Response:

Y for bio plastic elongation code

The values of T and G for α and - α which were

used as follows:

a. Value of cornstarch for α code (1.414)

T = x

i

(Δx

+1,-1

/ 2) + x

original

T = 1,414 ((4-2) / 2 ) + 3

T = 1,414 (1) + 3

T = 4,414 5 gram

b. Value of cornstarch for -α code (-1.414)

-T = x

i

(Δx

+1,-1

/ 2) + x

original

-T = -1,414 ((4-2) / 2 ) + 3

-T = -1,414 (1) + 3

-T = -2,414 2 gram

c. Value of glycerin for α code (1.414)

G = x

i

(Δx

+1,-1

/ 2) + x

original

G = 1,414 ((1,5-0,5) / 2 ) + 1

G = 1,414 (0.5) + 1

G = 1,707 2 ml

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

450

d. Value of glycerin for -α code (-1.414)

-G = x

i

(Δx

+1,-1

/ 2) + x

original

-G = -1,414 ((1,5-0,5) / 2 ) + 1

-G = -1,414 (0,5) + 1

-G = 0,293 1 ml

3 RESULT AND DISCUSSION

The higher of elongation, the elasticity of the bio

plastics will have more elastic and not easily broken

(Araújo et al., 2018b). The following was a

recapitulation of the elongation test:

Table 3: Elongation assessment.

No Factor

Code Composition Response

X

1

X

2

G

(ml)

T (g) Y (%)

1 0 0 1 3 10

2 0 0 1 3 12

3 0 0 1 3 14

4 0 0 1 3 11

5 0 0 1 3 9

6 -1,414 0 1 3 7

7 1,414 0 2 3 11

8 0 -1,414 1 2 7

9 0 1,414 1 5 6

10 -1 -1 0,5 2 8

11 1 -1 1,5 2 10

12 -1 1 0,5 4 9

13 1 1 1,5 4 9

Whereas:

X

1

= Treatment code for glycerin

X

2

= Treatment code for corn starch

G = Composition of glycerine (ml)

T = Composition of corn starch (g)

Y

= Bio plastic elongation (%)

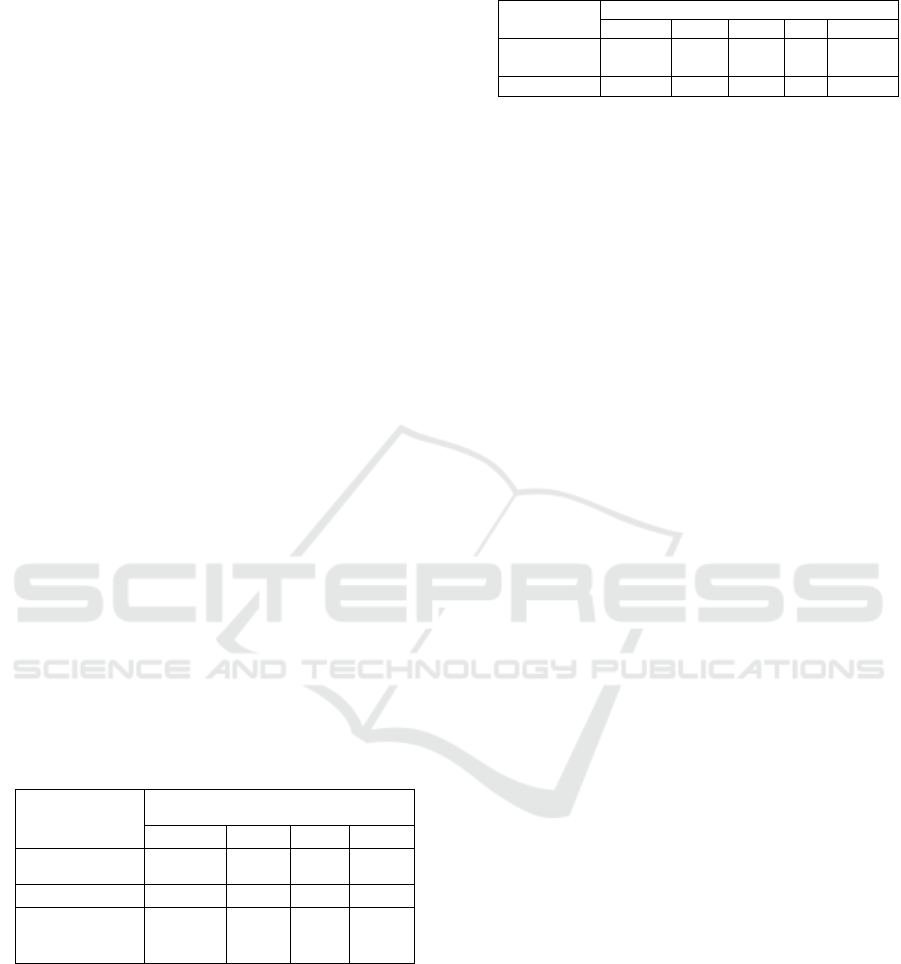

The following were the results of the coefficient

model output from the calculation of Minitab:

Figure 2: The calculation result.

Y = -0,084 - 0,141 X

1

+ 0,1845 X

2

+ 0,0974X

-

0,02085X

- 0,0505 X

1

X

2

(5)

Whereas:

Y = Maximum optimal solution for elongation

bioplastic

X

1

= Glycerin

X

2

= Cornstarch

Table 4: The result of Analysis of Varian (ANOVA).

Source DF Adj SS Adj

MS

F-

Value

P-

Value

Model 5 22.1318 4.43 8.7 0.006

Error 7 3.5613 0.508

Lack

of fit

3 2.5842 0.8614 3.53 0.127

Pure

error

4 0.9771 0.2443

Total 12 25.69

Based on the table, an elongation test of

cornstarch model, obtained F count was 8.7 then F

table obtained by the distribution table F with df

model was 5 and df error was 7. From the lack of fit,

test obtained p value = 0.127 which is greater than the

significance level α = 0.05, then the model accept H

0

. It can be interpreted that the regression model was

suitable and can be continued with the next model.

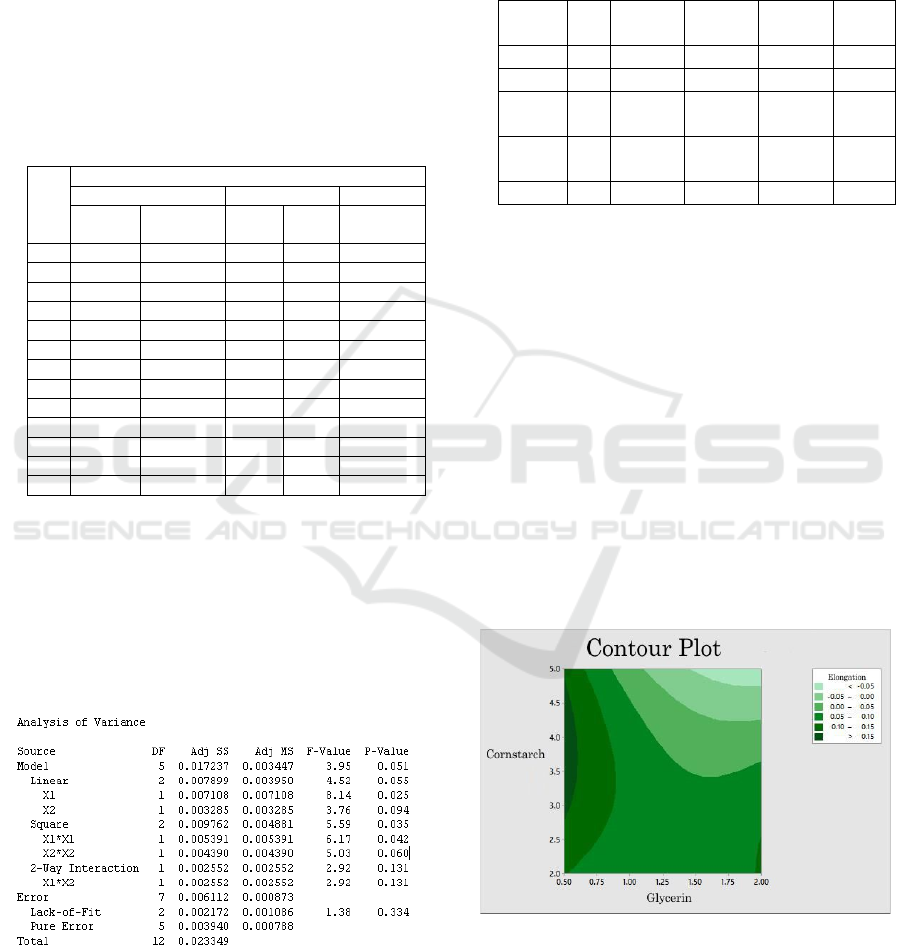

The next step was the optimal parameter

determination stage. The optimal area was derived by

using contour plots, surface plots on elongation tests,

and then the optimal combination of parameters for

elongation test using D-Otimaly Response, where the

two plots will show the range of parameters and

response. In this study there were two factors. The

following were plot contours and surface plots for

elongation test:

Figure 3: Elongation contour plot.

It can be shown in figure 3 that optimal solution is

between 2.0 g to 5.0 g of corn starch and 0.5 ml to

2.00 ml glycerine.

Elongation Optimization of Bioplastic using Response Surface Methodology

451

Figure 4: Elongation surface plot.

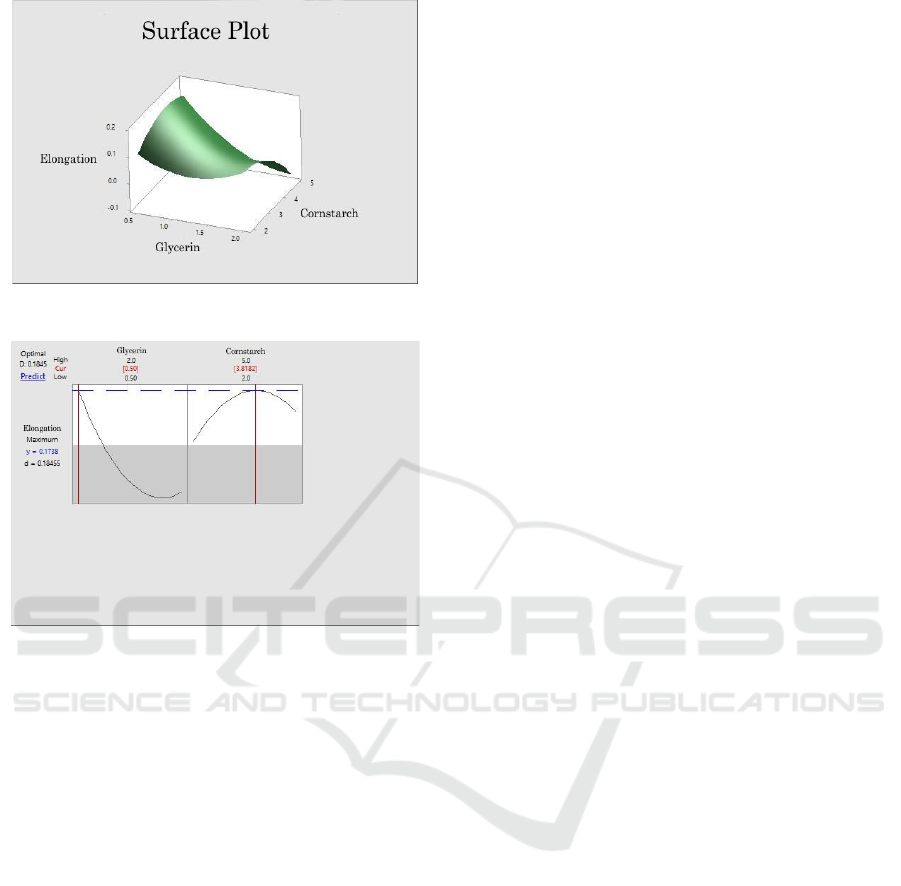

Figure 5: Elongation optimal solution area.

Based on the figure, elongation D-Optimaly

response was obtained by the value of the

desibrability function. Desirability value for

elongation was 18.4, then the combination of the

optimal parameters were 0.5 ml glycerin and 3.81 g

cornstarch along with the optimum elongation result

was 17.3%.

Elongation of this study also has met the standard,

according to the Japanese Industrial Standard,

elongation is categorized as good if above 10% and

will be categorized very well if it exceeds 50%. The

elongation of commercial plastic bag is 222.5%. The

elongation of bioplastic sample in this research were

below this number. Moreover, the bioplastic sample,

which was made of corn starch, cannot be used as

commercial plastic bag. However, it can be used in

food packaging, pharmacy, and cosmetic which do

not need high elongation, which is around 20%

(Gozan and Noviasari, 2018). Moreover, using

biodegradable packaging in the commercial or daily

usage can protect ecological system and save habitat

in the environment.

4 CONCLUSIONS

The optimal solution was derived by using the surface

response methodology which had 2 factors (2

2

) of

experimental design. Moreover, the study design was

using 13 experiments. Based on the figure, elongation

D-Optimaly response was obtained by the value of

the desibrability function. Desirability value for

elongation was 18.4, then the combination of the

optimal parameters were 0.5 ml glycerin and 3.81 g

cornstarch along with the optimum elongation result

was 17.3%. Elongation of this study also has met the

standard, according to the Japanese Industrial

Standard, elongation is categorized as good if above

10% and will be categorized very well if it exceeds

50% (Rudnik, 2019). The elongation of commercial

plastic bag is 222.5%. The elongation of bioplastic

sample in this research were below this number.

Moreover, the bioplastic sample, which was made of

corn starch, cannot be used as commercial plastic bag.

However, it can be used in food packaging,

pharmacy, and cosmetic which do not need high

elongation, which is around 20%. The combination

responses of tensile strength, elongation, modulus

young optimizing can be done in the future research

for improving edible film properties. Using

biodegradable packaging in the commercial or daily

usage can protect ecological system and save habitat

in the environment.

ACKNOWLEDGEMENTS

This publication was financed by University of

Trunojoyo.

REFERENCES

Abbas, H. K., Accinelli, C. & Shier, W. T., 2017. Biological

control of aflatoxin contamination in US crops and the

use of bioplastic formulations of Aspergillus flavus

biocontrol strains to optimize application strategies,

Journal of agricultural and food chemistry, 65, 7081-

7087.

Akinoso, R., Adeyanju, J. A. J. F. & Technology, B., 2012.

Optimization of edible oil extraction from ofada rice

bran using response surface methodology. 5, 1372-

1378.

Andrady, A. L. J. M. P. B., 2017. The plastic in

microplastics: A review. 119, 12-22.

Araújo, C., Rodrigues, A., Joele, M. P., Araújo, E. &

Lourenço, L., 2018a. Optimizing process parameters to

obtain a bioplastic using proteins from fish byproducts

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

452

through the response surface methodology, Food

packaging and shelf life, 16, 23-30.

Araújo, C., Rodrigues, A., Joele, M. P., Araújo, E.,

Lourenço, L. J. F. P. & Life, S., 2018b. Optimizing

process parameters to obtain a bioplastic using proteins

from fish byproducts through the response surface

methodology. 16, 23-30.

Baş, D. & Boyacı, I. H. J. J. O. F. E., 2007. Modeling and

optimization I: Usability of response surface

methodology. 78, 836-845.

Biglari, N., Dashti, M. G., Abdeshahian, P., Orita, I., Fukui,

T. & Sudesh, K. J. B., 2018. Enhancement of bioplastic

polyhydroxybutyrate P (3HB) production from glucose

by newly engineered strain Cupriavidus necator

NSDG-GG using response surface methodology. 8,

330.

De Azêvedo, L. C., Rovani, S., Santos, J. J., Dias, D. B.,

Nascimento, S. S., Oliveira, F. F., Silva, L. G., Fungaro,

D. A. J. J. O. P. & Environment, T., 2020. Study of

Renewable Silica Powder Influence in the Preparation

of Bioplastics from Corn and Potato Starch. 1-14.

Dean, A., Voss, D. & Draguljić, D., 2017. Response surface

methodology. Design and analysis of experiments.

Springer.

Domene-López, D., Delgado-Marín, J. J., Martin-Gullon,

I., García-Quesada, J. C. & Montalbán, M. G. J. I. J. O.

B. M., 2019. Comparative study on properties of starch

films obtained from potato, corn and wheat using 1-

ethyl-3-methylimidazolium acetate as plasticizer. 135,

845-854.

Gaspersz, P. J. T. B., 1992. Teknik Analisis dalam

Perancangan Percobaan. 719.

Ghayebzadeh, M., Aslani, H., Taghipour, H. & Mousavi, S.

J. M. P. B., 2020. Estimation of plastic waste inputs

from land into the Caspian Sea: A significant unseen

marine pollution. 151, 110871.

Gozan, M. & Noviasari, C. The effect of glycerol addition

as plasticizer in Spirulina platensis based bioplastic.

E3S Web of Conferences., 2018. EDP Sciences, 03048.

Ibrahim, M., Sapuan, S., Zainudin, E. & Zuhri, M. J. I. J. O.

B. M., 2019. Potential of using multiscale corn husk

fiber as reinforcing filler in cornstarch-based

biocomposites. 139, 596-604.

Jambeck, J. R., Geyer, R., Wilcox, C., Siegler, T. R.,

Perryman, M., Andrady, A., Narayan, R. & Law, K. L.

J. S., 2015. Plastic waste inputs from land into the

ocean. 347, 768-771.

Lestari, P. & Trihadiningrum, Y. J. M. P. B., 2019. The

impact of improper solid waste management to plastic

pollution in Indonesian coast and marine environment.

149, 110505.

Mäkelä, M. J. E. C. & Management 2017. Experimental

design and response surface methodology in energy

applications: A tutorial review. 151, 630-640.

Miyamoto, H., Kobayashi, H. & Ohtsuka, N., 1984.

Standard method of test for elastic-plastic fracture

toughness JIC recommended in Japan. Mechanical

Behaviour of Materials. Elsevier.

Montgomery, D. C., 2017. Design and analysis of

experiments, John wiley & sons.

Myers, R. H., Montgomery, D. C. & Anderson-Cook, C.

M., 2016.

Response surface methodology: process and

product optimization using designed experiments, John

Wiley & Sons.

Novianti, T., Anna, I. & Cahyadi, I. Optimization of

bioplastic’s tensile strength. Journal of Physics:

Conference Series., 2019. IOP Publishing, 012048.

Reyes, J. D. C., Tungol, J. M., Musngi, P. P., Magarro, A.

S., Guevarra, K. F., Santos, J. S. J. J. O. H. &

Development, E., 2020. Three Experimental Phases of

Cornstarch-Based Biodegradable Plastic. 2, 81-89.

Rudnik, E., 2019. Compostable polymer materials,

Newnes.

Sarabia, L. A., Ortiz, M. C. & Sánchez, M. S., 2019.

Response surface methodology.

Umesh, M., Mani, V. M., Thazeem, B. & Preethi, K., 2018.

Statistical Optimization of Process Parameters for

Bioplastic (PHA) Production by Bacillus subtilis

NCDC0671 Using Orange Peel-Based Medium.

Iranian Journal of Science and Technology,

Transactions A: Science, 42, 1947-1955.

Yolmeh, M., Jafari, S. M. J. F. & Technology, B., 2017.

Applications of response surface methodology in the

food industry processes. 10, 413-433.

Zhang, C., Wang, C., Cao, G., Wang, D. & Ho, S.-H. J. J.

O. H. M. 2020. A sustainable solution to plastics

pollution: An eco-friendly bioplastic film production

from high-salt contained Spirulina sp. residues. 388,

121773.

Elongation Optimization of Bioplastic using Response Surface Methodology

453