Design Options for the Integration of Suppliers in Agile Development

Projects

Günther Schuh, Stephan Schröder, Florian Vogt and Ludwig Volbert

Laboratory for Machine Tools and Production Engineering (WZL), RWTH Aachen University, Aachen, Germany

Department of Technology Management, Fraunhofer-Institute for Production Technology IPT, Aachen, Germany

ludwig.volbert@ipt.fraunhofer.de

Keywords: supplier integration; agile product development; development cooperation.

Abstract: The shift from a seller’s to a buyer’s market catalyzes the rising demand for customer-individual products

and shortens product life- as well as innovation cycles. In consequence, many companies implement

iterative and flexible agile development processes instead of the well-established plan-driven approaches to

fasten their product development and to increase the fulfilled degree of customer requirements. At the same

time, nowadays hardly any development project can be implemented by a single company independently.

Both the increasing complexity of technical products and the paradigm shift from a high degree of value

added inside a company to the concentration on core competencies have led to the fact that the involvement

of suppliers and development partners in the development process is indispensable. Due to the

implementation of agile development processes, which are fundamentally different to the plan-driven

approaches, new requirements for the cooperation of companies and suppliers emerge. These requirements

are hardly addressed in existing literature and practice. Therefore, this paper aims at filling the research gap

by deriving a model to describe the design dimensions with their related design options for the integration of

suppliers in agile development processes for physical products.

1 INTRODUCTION

The high volatility of the market environment and

the ever-increasing demand for customer-specific

product solutions present companies with new

challenges (Cooper, 2017; Ehrlenspiel et al, 2014;

Schmidt, 2016). This transformation and the demand

for constant innovation results in shorter product life

cycles as well as shorter innovation cycles.

Consequently, a rapid market entry is becoming a

decisive competitive factor for companies (Schmidt,

2016; Abele and Reinhart, 2011; Minderhoud and

Fraser, 2005).

To meet these challenges, companies are

increasingly relying on agile development models,

since the today well-established plan-driven models

are less and less able to meet these new

requirements. In contrast to plan-driven approaches,

which are defined by a phase-oriented and linear

process, agile development models are characterized

by an iterative approach and focus on adaptability

instead of following a stringent schedule [6].

Hereby, agile development models aim for a fast,

flexible and efficient execution of projects, (Schmidt

and Paetzold, 2018; Schoeneberg, 2014) as well as

for a higher degree of customer satisfaction. In order

to achieve this, a rapid adaption to changes in

requirements and boundary conditions of the volatile

market is necessary (Herrmann et al, 2009; Nerur et

al, 2003). The targeted adaptivity makes it possible

to introduce and implement changes late in the

development process when using agile models

(Ahmed-Kristensen and Daalhuizen, 2015).

One major characteristic of agile development

approaches is the continous validation of

development hypotheses and results by the build-up

and testing of physical prototypes, even in the very

early project phases. This constant development of

physical prototypes pose a challenge in the agile

development of physical products, as the iteration

cycles – so called sprints of two to four weeks –

provide a tight timeframe for the completion of

physical prototypes. This completion depends

heavily on the availability and punctual development

and delivery of components e.g. by suppliers. In

addition to that manufacturing companies

Schuh, G., Schröder, S., Vogt, F. and Volbert, L.

Design Options for the Integration of Suppliers in Agile Development Projects.

DOI: 10.5220/0010308400003051

In Proceedings of the International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies (CESIT 2020), pages 325-332

ISBN: 978-989-758-501-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

325

increasingly focus on their own compentencies and

force a higher degree of outsourcing of development

services to suppliers, which makes the integration of

external partners a critical factor for success

(Dombrowski et al, 2015; Groher, 2003; Schuh et al,

2008; Spath and Dangelmaier, 2016).

Hereby the adaptability and flexibility striven for

by agile methods places new demands on the design

of supplier integration (Schmidt and Paetzold, 2016;

Gregory et al, 2016). In the plan-driven product

development, a predetermined schedule is followed

and all specifications are defined at the beginning of

the development process in form of a specification

sheet (Nerur et al, 2003; Nerur and Balijepally,

2007). Therefore, a supplier gets all the information

about his specific development activities at the

beginning of the development project. This nature

facilitates the management of the suppliers, since

precise framework conditions can be defined and

fixed. With the use of agile models previous forms

of supplier integration must be reconsidered, since

they don’t meet the requirements of an iterative

approach. Agile methodologies deal with the internal

organizational structure of development processes

and teams, but usually do not take supplier

integration into account (Becker, 2014; Dombrowski

and Karl, 2016). Also strategies, methods and

procedures available in literature for integrating

suppliers into the development process are based on

the application of plan-driven development

processes and are therefore no longer fully

applicable. Consequently, the introduction of agile

development approaches makes it necessary to adapt

the integration of suppliers according to the new

framework conditions (Dombrowski et al, 2015).

Therefore, this paper presents a description

model, which is part of an overall solution approach

for the demand-oriented design of supplier

integration in agile development projects. The

presented model comprises different design

dimensions with related design options for the

integration of suppliers in agile development

projects and represents one of five partial models of

an overall solution hypothesis for the development

of type-based supplier integration forms for agile

development processes (Schuh and Schröder, 2019).

The core of this work is therefore to identify

essential design dimensions of supplier integration

in agile development projects and to develop forms

or design elements that meet the new challenges of

agile development of physical products

2 LITERATURE REVIEW:

EXISTING APROACHES FOR

THE DESIGN OF SUPPLIER

INTEGRATION

In this paper, supplier integration is considered in

the context of product development and refers to the

organisation or design of the cooperation between

customer and supplier

(Becker,2014) In literature various approaches for

the design of supplier integration exist. These

approaches differ strongly in their concrete focus as

the design of supplier integration forms depends on

a number of different factors. In this section, the

most relevant existing approaches within this

research field will be introduced and evaluated in

terms of their relevance for the developed model.

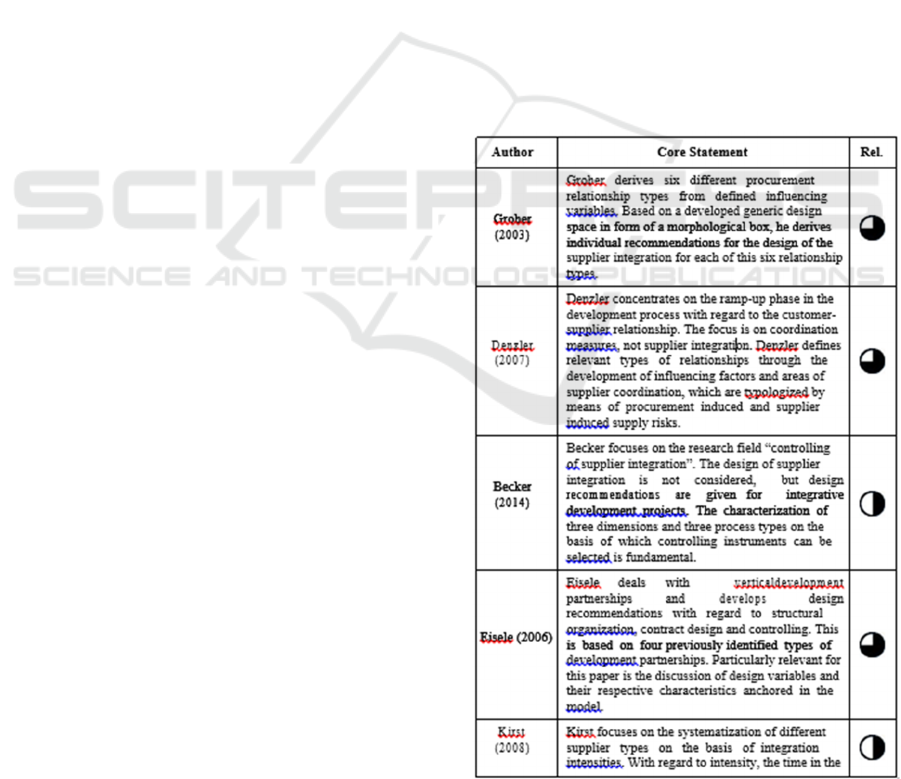

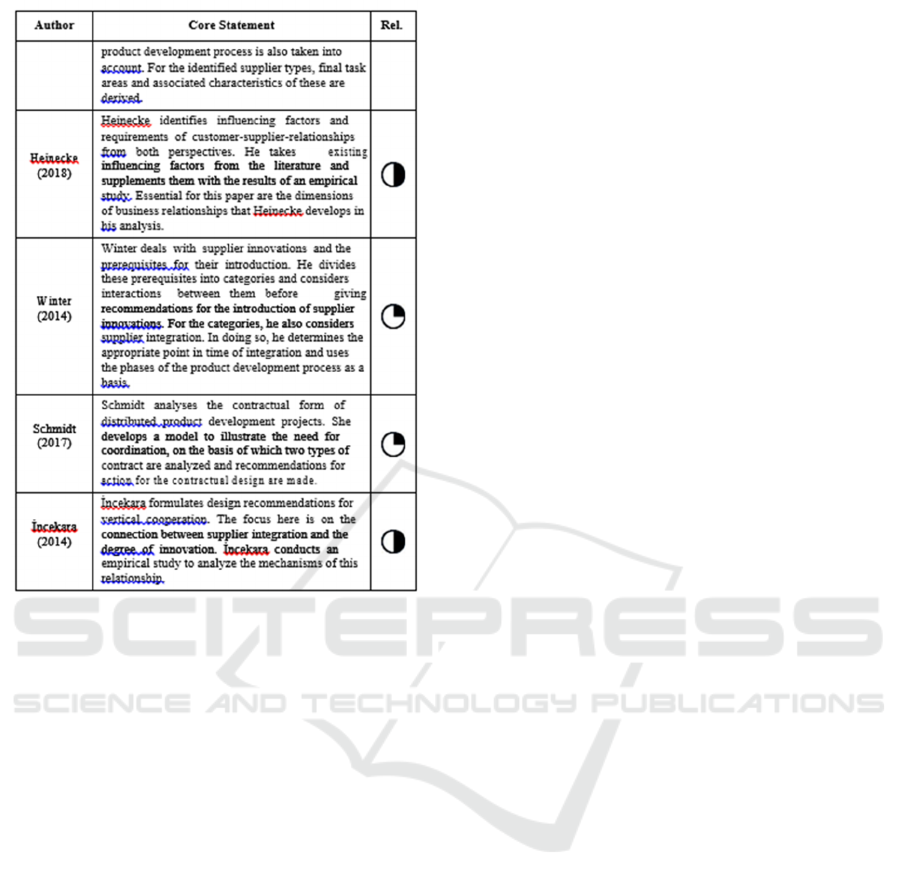

Tab. I depicts the core statements and the relevance-

evaluation of the analyzed approaches (visualized in

a discrete scale using Harvey balls).

Table 1: Supplier integration models.

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

326

The investigation of the existing literature shows

that there is already extensive research in the field of

supplier integration in new product development,

including very different perspectives and concrete

research issues. Groher e.g. presents a very holistic

model for the design of integration forms while

İncekara only investigates the influence of the

degree of innovation on the integration of suppliers.

But with regard to the outlined problem two major

deficiencies can be identified. First and major deficit

is the missing consideration of the effects and new

framework conditions of agile development

processes. Existing approaches neither analyze those

new requirements on the design of supplier

integration forms nor do they present new design

options of integration forms which are adapted to

those special needs of agile development processes.

In consequence, these approaches are not or not fully

applicable to agile development projects. As agile

development processes become more and more

common in the development of physical products, an

adaptation of the integration forms to these new

requirements is urgently necessary. The second

major deficit identified is the lacking consideration

of situational requirements and influencing factors in

the design of supplier integration. The description of

existing approaches is mainly based on different

characteristics of an influencing variable, which,

however, does not do full justice to the individuality

of customer-supplier relationships.

Thus the overall objective of the presented paper

is to identify the relevant dimensions for the

individual design of supplier integration forms,

evaluate their suitability for the use

in agile

development processes and adapt them, if

necessary to the new requirements of these agile

processes.

3 RESULTS: DEVELOPMENT OF

A DESCRIPTION MODEL

The central intention of this paper is to derive a

description model that outlines the design

dimensions including the design options for a needs-

oriented integration of suppliers in agile

developments projects. In this context, a situational

approach is necessary due to the complex and

individual requirements in customer-supplier-

relations as well as the involvement of many

stakeholders in the development process. To develop

a suitable and comprehensive model, two

consecutive steps will be conducted. First, existing

approaches for the design of supplier integration

forms have to be examined and the included design

dimensions have to be evaluated in terms of their

relevance for the scope of this paper. Subsequently,

the identified research gap serves as a starting point

for the development of the description model or, in

other words, the derivation of relevant design

dimensions and their related design options. To

execute these two steps and provide a framework for

the model development, a basis for evaluation is

necessary. Thus, criteria for the evaluation of

existing approaches in literature and the subsequent

selection of relevant design dimensions are

determined in a prefixed step. Agile approaches for

the development of physical products are practice-

driven, leading to a limited number of available

academic literature (Cooper and Sommer, 2016).

Consequently, existing approaches and possible

design dimensions were mainly derived from

literature about supplier management as well as

literature concerning adjacent research fields, like

sourcing strategies, communication and cooperation

in supply chains and organizational forms of vertical

relationships. In addition, the authors’ own

experience from coaching and conducting agile

development projects were an important input for

the model development.

Design Options for the Integration of Suppliers in Agile Development Projects

327

3.1 Framework and Requirements of

the Model

In order to systematically develop the model, four

criteria for the selection of relevant design

dimensions and the evaluation of existing

approaches of supplier integration were initially

determined. These criteria were derived from the

overall objective of this paper to address new

paradigms for the cooperation and communication

between customers and suppliers in agile

development projects of physical products.

Furthermore, these selection criteria can be assigned

to either the object area or the target area. The

criteria belonging to the object area examine the

content consistency between the overall scope of

consideration of this paper and the regarded

approach from literature. The object area comprises

the following criteria.

Physical product development: The model is

limited to design dimensions referring to

development projects with a focus on physical

products.

Agile methodologies: The model is limited to

design dimensions that are applicable for the

implementation of agile methodologies in

development projects

On the other hand, the criteria belonging to the

target area take into account, if the goals of the

regarded approach from literature are congruent to

those of this paper. The target area comprises the

following criteria.

Design of supplier integration: The selected

dimensions have to contribute directly to the

organizational or processual design of the supplier

integration.

Customized design: The model user has to be

able to choose between the different design

options within the identified design

dimensions according to requirements and the

prevailing development situation.

Based on these four criteria the total of 18 design

features identified in the literature were evaluated

and consecutively the relevant design dimensions

and their belonging design options determined for

the description model, developed in this paper. The

description model and the selected design

dimensions are explained in more detail in the

following section

3.2 Design Dimensions and Options

This section depicts and explains the design

dimensions and belonging design options of the

description model for the needs-oriented integration

of suppliers in agile development projects. The

procedure described above for the evaluation of the

identified design dimensions resulted in a selection

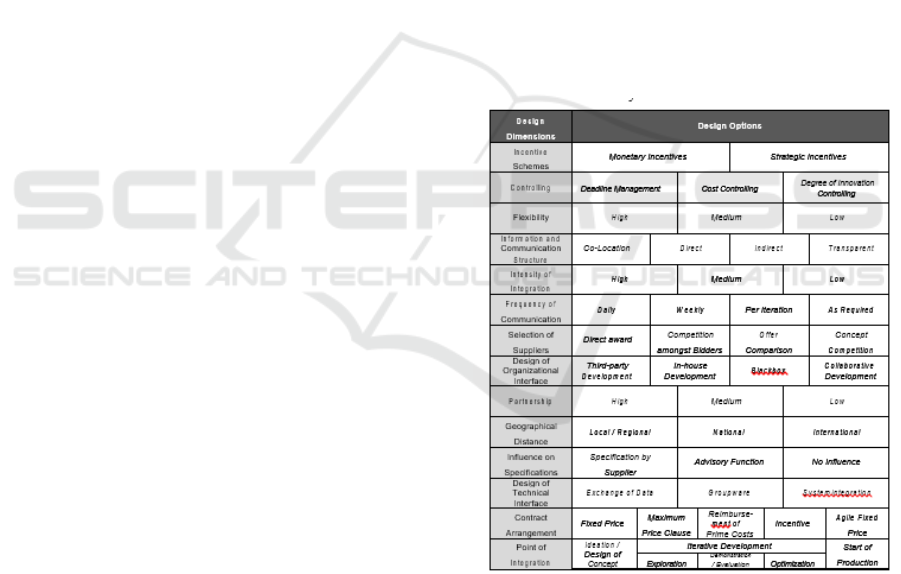

of 14 essential characteristics for the design of

supplier integration in agile development projects.

These 14 dimensions and their belonging design

options are depicted in Fig. 1. In the following a

selection of these dimensions is described in details.

3.2.1 Information and Communication

Structure

The integration of suppliers into the product

development process requires an exchange of

information and knowledge in order to put the ideas

and contributions of suppliers in the right place and

develop the product according to the customer’s

requirements (Jaspers and van den Ende, 2006). Not

only the quality of the information exchange is

relevant but also the efficiency, to minimize the

costs of communication and reduce information

asymmetries.

Figure 1: Design dimensions and options for supplier

integration

Regarding the differentiation of communication

types as well as information channels, academic

literature offers a variety of approaches. FREITAG

e.g. differentiates types of communication, like

Direct (e.g. Face-to-Face) and Indirect (e.g.

Telephone, e-mail) (Freitag et al, 2011).

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

328

To minimize communication costs and ensure

efficiency, an intensive and direct form of

communication may not always be the best choice for

all types of supplier integration. Rather, in many cases

indirect forms of communication should also be taken

into account. Due to the varying intensity of

cooperation between suppliers and customers, both

types of communication depict possible scenarios and

were added as design options to the description model.

Joint development projects with a high degree of

supplier integration require a constant access to all

relevant project information (Spath and Dangelmaier,

2016). To ensure a high accessibility to information for

different users involved in agile development projects,

in practice, so called social-business-platforms are used

to ensure information transparency by creating an

environment for wiki-systems consisting of project-

related information that are collaboratively collected by

project participants (Schröder, 2017

Flad, 2015).

Hence, the design option Transparent was added to the

description model, which implies the exchange of

information in agile development projects with a

variety of participants and a dynamic information

stand, e.g. through the utilization of social-business-

platforms. Last but not least, the establishment of a Co-

location poses a further intensification of the direct

communication form. This concept comprises the

spatial integration of cross-company teams, which

creates the continuous opportunity for face-to-face

communication and exchange and reduces the

likelihood for the not value-adding duplication of

efforts (Groher, 2003).

3.2.2 Intensity of Integration

In the context of this paper, the intensity of

integration refers to the point within the value chain

where the supplier’s services begin. In other words,

it is considered how deeply suppliers’ services

intervene in the internal processes of customers

(Engelhardt et al, 1993). Against the background of

shorter product life cycles and the associated

shortened development times, the intensive

integration of suppliers has gained importance in

recent years (Gassmann, 2006). Literature often

points out correlations between the competences of

suppliers, the time of integration and the intensity of

integration. In this context, high competencies have

a positive effect on the intensity of integration into

development projects (Schuh et al, 2008). The

evaluation of suppliers’ competencies is carried out

by means of the specific development task to be

fulfilled or the characteristics of the object to be

procured. To describe the intensity of supplier

integration, the three qualitative design options

High, Medium and Low were determined. When

choosing an adequate intensity of supplier

integration, companies have to consider the rising

number of communication interfaces and growing

coordination efforts which result from a higher

degree of integration (Groher,2003).

3.2.3 Frequency of Communication

This dimension specifies how often or at what

frequency the communication between customer and

supplier should ideally take place. A high

communication frequency is advisable for

development projects with a strong involvement of

suppliers, since the regular and quick exchange of

information is of great importance for this form of

cooperation. Agile procedures generally require a

fast and highly frequented communication

(Schröder, 2017). However, this general statement

only applies to internal projects and must be

considered separately with regard to external project

communication and different possible scenarios. If

the procurement object is precisely specified and its

development can be conducted by the supplier

without considerable influence of the customer, the

frequency of the customer-internal project

communication may be high, while the interface for

external communication is rather low frequented.

Another possible scenario is the close collaboration

and mutual influence during development projects.

In this case, the external communication pattern is

dictated by the internal communication frequency of

the project, which is primarily determined by the

obligatory meetings within iteration cycles of agile

development. The spectrum of the required

communication frequency can therefore range from

irregular, demand-oriented to high-frequency

communication. Following this argumentation, the

four possible design options As Required

(communication only on demand), Per Iteration

(periodic communication at the beginning / end of

an iteration cycle), Weekly and Daily (participation

at daily Scrum) were derived for the design

dimension frequency of communication.

3.2.4 Contract Arrangement

Contracts provide the legal basis for cooperation

between customer and supplier. Despite supplier

relationships based on trust, the formulation of

contracts should not be waived in order to avoid

discrepancies and conflict situations (Groher,2003)..

Within the framework of supplier integration, the

drafting of contracts is of great importance, since the

selection of the right type of contract influences the

development efficiency of the product covered by

Design Options for the Integration of Suppliers in Agile Development Projects

329

the contract (Schmidt, 2016). The thematic focus of

the design dimension contract agreement is on price

conditions, as these constitute a key factor in the

contractual design of supplier integration (Schmidt,

2016). Against the background of volatile product

requirements and imprecise specifications that may

even be modified over the course of a project,

contractual regulations on price conditions are

particularly relevant for agile product development

(Opelt et al, 2012; Peterhoff, 2016). SCHMIDT

distinguishes between different contract types in

supplier-customer relationships based on the price-

fixing mechanism. In the case of so-called Fixed

Price contracts, the price and scope of services are

precisely defined. This type of contract is therefore

only suitable for procurement objects with known

product specifications and a low degree of

technological uncertainty (Schmidt, 2016). Contracts

with a Maximum Price Clause are suitable for the

conclusion of contracts characterized by higher

uncertainties and offer greater flexibility compared

to fixed price contracts in terms of price conditions

(Schmidt, 2016). A guaranteed maximum price is a

limit on the amount that the customer has to pay to

the supplier, regardless of the actual expenditure the

supplier had to afford for the project. Moreover,

Incentive contracts provide the opportunity to

determine the procurement price depending on the

supplier’s performance. By paying bonuses or

charging penalties for not meeting defined targets,

development risks are more evenly split between

customer and supplier. As the product specifications

do not have to be defined precisely from the outset,

incentive contracts are particularly suitable for agile

development processes (Schmidt, 2016). For the

formulation of product specifications, so called Cost

Reimbursement contracts offer the highest

flexibility. Here, the contractor is paid the prime cost

for development and production plus an additional

fee for overheads depending on the final project

scope. This procedure requires the complete

disclosure of all project related activities and costs

through the supplier and shifts the cost risk towards

the customer. Cost reimbursement contracts are

frequently used where a prompt start of production

or development is required even though the

specification sheet is not completed yet and may

alter during the process (Schmidt, 2016). Another

promising design option are so called Agile Fixed

Price contracts proposed by OPELT (Opelt et al,

2012). Here, a cooperation model between the

contractors is stipulated beforehand, which does not

insist on a strict binding of the contracting parties

and regulates the scope of the project as well as the

cost framework in order to facilitate an easier exit

from the project if necessary. Furthermore, the

subject matter of the contract is defined on the basis

of an adequately detailed vision, which can be

reviewed and adapted within intended checkpoint

phases. All of the above described contract types are

applied in the context of agile product development

with a shift in significance towards the more flexible

contract types and were thus included in the

description model as design options for the contract

arrangement.

3.2.5 Point of Integration

The choice of the necessary or most suitable time to

integrate the supplier into the development process

is a major concern and thus probably the most

frequently discussed design dimension in literature

(cf. e.g. (Groher,2003; Denzler, 2007; Kirst, 2008;

Winter, 2014)). The optimal timing depends on

influencing factors such as the complexity of the

procurement object and the competencies of the

suppliers. Existing approaches in literature

determine the point of integration on the basis of the

different stages of the product development process,

such as ideation, phase of product definition,

concept development, product development and

production start (Groher, 2003). For this paper, the

point of integration was also determined with the

different stages of the product development project,

in additional consideration of changes through agile

approaches. In contrast to plan-driven approaches, a

major part of the clarification of technical

specifications no longer happens in the product

conception phase, but rather empirically through

hypothesis formulation and validation within the

framework of the subsequent iterative development

phase. Consequently, the time slice of the

conception phase is significantly lower in agile

development projects and is thus consolidated in the

design option Ideation / Design of Concept. To

distinguish between different design options for the

point of supplier integration within the subsequent

Iterative Development phase, a classification of the

different iteration types according to

KANTELBERG was used. Accordingly, the design

options Exploration (pre-development iteration),

Demonstration and Evaluation (design and

development iteration) and Optimization

(optimization iteration) result (Kantelberg, 2018).

Finally, the startup phase of production after the

product development also constitutes a possible

point of supplier integration at a late stage in product

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

330

development and is expressed through the design

option Start of Production.

4 CONCLUSIONS

An increasing number of companies is implementing

agile development processes to meet the challenges

of increasing innovation pressure. But in the world

of physical product development, with its

significantly decreased depths of added value over

the last decades, an implementation of agile

approaches can only be beneficial if suppliers are

successfully integrated into these new processes. As

discussed in this paper, a needs oriented design of

the customer-supplier-relationship and the

integration form is mandatory for an effective and

efficient supplier integration. The presented model

in this paper therefore seeks to provide a first

solution for the design space of the supplier

integration into agile development processes. Based

on an evaluation of existing approaches in literature

and the authors’ experience from own agile

development projects the developed model

summarizes the relevant design dimensions and their

different design options, suitable for the use in agile

development projects. The developed description

model of the design space is thereby just a partial

model of an overall method for the situational design

of supplier integration forms. Dependent on the

respective procurement object and the prevailing

situation in the development project the most

suitable design options have to be selected for an

effective and efficient development project. Both the

time and monetary expenditure for implementation

and the associated added value or influence on the

overall development project differ greatly between

the various design options. Thus, to complete this

method, especially a logic to select the most suitable

design options according to the concrete situation

has to be developed in future research. A useful

application of the presented design options in

operational practice is therefore only possible in

combination with this logic.

REFERENCES

Cooper, R. G., 2017. Idea-to-Launch Gating Systems:

Better, Faster, and More Agile,” Research-Technology

Management, vol. 60, no. 1, pp. 48–52.

Kostengünstig Entwickeln und Konstruieren:

Kostenmanagement bei der integrierten

Produktentwicklung, 7th ed. Berlin: Springer Vieweg,

2014.

Schmidt, K., 2016. Vertragsbasierte Koordination

verteilter Produktentwicklungsprozesse. Dissertation.

[S.l.]: Gabler.

Abele, E., Reinhart, G., 2011. Zukunft der Produktion:

Herausforderungen, Forschungsfelder, Chancen. s.l.:

Carl Hanser Fachbuchverlag.

Minderhoud, S., Fraser, P., 2005 Shifting paradigms of

product development in fast and dynamic markets,”

Reliability Engineering & System Safety, vol. 88, no.

2, pp. 127–135.

Habermann, F., 2013. Hybrides Projektmanagement:

Agile und klassische Vorgehensmodelle im

Zusammenspiel, in HMD - Praxis der

Wirtschaftsinformatik, vol. 293, Web Monitoring, M.

Blattner and A. Meier, Eds., Heidelberg: dpunkt, pp.

93–102.

Schmidt, T. S., Paetzold, K., 2016. Agilität als Alternative

zu traditionellen Standards in der Entwicklung

physischer Produkte:Chancen und

Herausforderungen,” in Design for X: Beiträge zum

27. DfX-Symposium Oktober 2016, D. Krause, K.

Paetzold, and S. Wartzack, Eds., Hamburg, Hamburg:

TuTech Verlag, TuTech Innovation GmbH, pp. 255–

267.

Schoeneberg, K.-P., Ed 2014. Komplexitätsmanagement

in Unternehmen: Herausforderungen im Umgang mit

Dynamik, Unsicherheit und Komplexität meistern.

Wiesbaden: Springer Gabler.

Herrmann, T. A., Kleinbeck, U., Ritterskamp, C., Eds

2009. Innovationen an der Schnittstelle zwischen

technischer Dienstleistung und Kunden. Heidelberg:

Physica-Verlag.

Nerur, U., Karl, A., Schmidtchen, K., 2015. Schmidtchen,

Lieferantenintegration im

Produktentstehungsprozess,” ZWF, vol. 110, no. 10,

pp. 625–629.

Groher, E. J., 2003. Gestaltung der Integration von

Lieferanten in den Produktentstehungsprozess, 1st ed.

München: TCW, Transfer-Centrum für Produktions-

Logistik und Technolgie-Management.

Schuh, G., Stölzle, W., Straube, F., Eds 2008.

Anlaufmanagement in der Automobilindustrie

erfolgreich umsetzen: Ein Leitfaden für die Praxis.

Berlin, Heidelberg: Springer.

Spath, D., Dangelmaier, M., 2016. Produktentwicklung

Quo Vadis,” in Handbuch Produktentwicklung, U.

Lindemann, Ed., München: Hanser, pp. 3–7.

Gregory, P.., Barroca, L.., Taylor, K.., Salah, D.., Sharp,

H.., 2015. Agile Challenges in Practice: A Thematic

Analysis,” in Lecture Notes in Business Information

Processing, vol. 212, Agile Processes, in Software

Engineering, and Extreme Programming: 16th

International Conference, XP 2015, Helsinki, Finland,

May 25-29, 2015, Proceedings, C. Lassenius, T.

Dingsøyr, and M. Paasivaara, Eds., Cham: Springer

International Publishing; Imprint; Springer, pp. 64–80.

Design Options for the Integration of Suppliers in Agile Development Projects

331

Nerur, S., Balijepally, V., 2007. Theoretical reflections on

agile development methodologies,” Commun. ACM,

vol. 50, no. 3, pp. 79– 83.

Becker, U., 2014. Wertschöpfung durch

Lieferantenintegration. Wiesbaden: Springer

Fachmedien Wiesbaden.

Dombrowski, U., Karl, A., 2013. Systematic Improvement

of Supplier Integration within the Product

Development Process,” Procedia CIRP, vol. 57, pp.

392–397.

Schuh, G., Schröder, S., 2017. Agil innovieren mit

Entwicklungspartnern - Lieferantenintegration in agile

Entwicklungsprozesse,” in Verlagsschriftenreihe des

Heinz Nixdorf Instituts, Band 374, Vorausschau und

Technologieplanung: 13. Symposium für Vorausschau

und Technologieplanung : 23. und 24. November 2017

Berlin, J. Gausemeier, Ed., Paderborn: Heinz Nixdorf

Institut, Universität Paderborn, pp. 203–2019.

Cooper, R. G., Sommer, A. F., 2016. The Agile-Stage-

Gate Hybrid Model: A Promising New Approach and

a New Research Opportunity,” J Prod Innov Manag,

vol. 33, no. 5, pp. 513–526.

Jaspers, F., van, J., Ende, 2006. The organizational form

of vertical relationships: Dimensions of integration,”

Industrial Marketing Management, vol. 35, no. 7, pp.

819–828.

Freitag, M., Müller, C., Rusch, G., Spreitzer, T., Eds 2011.

Projekt kommunikation: Strategien für temporäre

soziale Systeme. Wiesbaden: VS Verlag für

Sozialwissenschaft.

Schröder, A., 2017. Agile Produktentwicklung: Schneller

zur Innovation -erfolgreicher am Markt. München:

Hanser.

Flad, M. 2015. Social Business Plattformen in global

verteilten Produktentwicklungsvorhaben, Dissertation,

KIT; Karlsruher Institut für Technologie, Karlsruher

Institut für Technologie.

Engelhardt, W. H., Kleinaltenkamp, M.,

Reckenfelderbäumer, M., 1993. Kanban:

Reckenfelderbäumer,“Leistungsbündel als

Absatzobjekte : ein Ansatz zur Überwindung der

Dichotomie von Sach- und Dienstleistungen,”

Schmalenbachs Zeitschrift für betriebswirtschaftliche

Forschung : ZfbF Wiesbaden : Springer Gabler, no.

45, pp. 395–426.

Gassmann, O., 2006. Opening up the innovation process:

towards an agenda,” R&D Management, vol. 36, no.

3, pp. 223–228.

Opelt, A., Gloger, B., Pfarl, W., Mittermayr, R., 2012.

Mittermayr, Der agile Festpreis: Leitfaden für wirklich

erfolgreiche IT-Projekt-Verträge. München: Hanser,

Carl.

Peterhoff, W., 2016. Recht und Compliance,” in

Handbuch Produktentwicklung, U. Lindemann, Ed.,

München: Hanser, pp. 319–347.

Denzler, F., 2007. Modellanalyse von

Lieferantenbeziehungen in Anlaufprozessen:

Einflussgrößen, Gestaltungsparameter und Methoden

für die Koordination des Anlaufmanagements von

Abnehmern und Lieferanten ; eine empirische

Modellanalyse, 1st ed. München: TCW, Transfer-

Centrum.

Kirst, P., 2008. Lieferantenintegration im

Produktentstehungsprozess,” in VDI-Buch,

Anlaufmanagement in der Automobilindustrie

erfolgreich umsetzen: Ein Leitfaden für die Praxis, G.

Schuh, W. Stölzle, and F. Straube, Eds., Berlin,

Heidelberg: Springer, pp. 93–105.

Winter, S., 2014. Management von

Lieferanteninnovationen: Eine gestaltungsorientierte

Untersuchung über das Einbringen und die Bewertung.

Zugl.: Dresden, Techn. Univ., Diss., 2013. Wiesbaden:

Springer Gabler.

Kantelberg, J., 2018. Gestaltung agiler

Entwicklungsprozesse technischer Produkte,”

Dissertation, RWTH Aachen; IIF - Institut für

Industriekommunikation und Fachmedien GmbH.

Modellanalyse, 1st ed. München: TCW, Transfer-

Centrum.

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

332