Activity-based Fatal Four Rate Assessment for Effective Safety

Planning Utilizing 4D-BIM

Kieu-Trang Pham, Duc-Nghia Vu, Numan Khan, Si Van-Tien Tran, Do-Yeop Lee, Chan-SikPark

Dept. of Architecture Engineering, Chung-Ang University, Seoul, South Korea

Index Terms: Fatal Four assessment (FFA), accident cases, 4D-BIM, temporary safety facility (TSF), safety management,

safety prevention, real-time safety planning (RTSP).

Abstract: The unprecedented growth and integration of the innovative technologies in information and

communication tech-nology (ICT) promotes rapid evolution of conventional construc-tion to smart

construction. Advanced technology application brings impressive benefits such as time and cost reduction,

especially safety management improvements in the construction where accidents and fatalities always

happen due to the unsafe and risky working environment. In the sense that the fatality rate is one of the main

quantitative measurements that reflects safety performance, numerous public agencies giving accident

reports and safety standards to recommend for the construction stakeholders. However, incidents in

workplace remain unin-terrupted because of the deficiency of safety information and understanding the root

causes of accidents in specific conditions. Moreover, many construction companies do not have managers

who have particularly technical and professional expertise related to safety area. It leads to pressures in

controlling the whole process of construction within safety implementation, and so on, the workers face

difficulties in approaching and understanding the complicated safety document. As a result, the manager’s

burden increase and sometimes vital information get ignored. To address this issue, this paper proposed a

Real-Time Safety Planning (RTSP) System supported by 4-Dimensional Building Information Modeling

(4D-BIM), which consist of risk severity assessment based on the temporal and spatial conditions before

giving priorities of major hazard protection. To accomplish this, the study evaluated and distributed the

severity of 320 fatalities cases in relation to Fatal Four (four major fatality causes in construction industry)

reported from various public resources, which specifically illustrative of accident concentrate rate in an

individual work task. A simulation of RTSP system for the Exterior building wall with major hazard

consideration and designated Temporary Safety Facilities (TSF) utilizing 4D-BIM is presented as a proof of

concept. It is expected that the novel approach could decrease the safety manager workload and will make

the construction safety planning process more comprehensible.

1 INTRODUCTION

The dynamic unique and complex construction site

en-vironment are the causes of the high fatal

accident rate and safety risks for the jobsite worker.

According to OSHA reports, worker fatalities in the

construction industry in 2017, accounted for 20.7%

with 971 cases, the higher rate than any sector. It is

quite clear form the literature that four types of

hazards are responsible for the majority of injury

and death in the construction sites, what we called

Fatal Four and that includes falls, struck-by-object,

electrocutions, and caught-in-between (OSHA,

2014). By the US Bureau of Labor Statistics reports,

these Fatal Four were responsible for more merely

60% among the construction worker deaths in 2017,

and become the leading causes of accidents in

construction. The fact that the construction working

environment required labors haS to be well-

equipped knowledge, professional experience, and

skills, particularly in the safety aspect, immediately

from pre-construction phase (Behm, 2005).

Therefore, identify and eliminate root causes

accidents for appropriate prevention decisions from

early-stage play an essential role in the success of

making project planning.

On the other hand, the high proportion of

accidents have witnessed the ineffectiveness of

safety planning provision. It should be emphasized

that the actual health and safety implementation

308

Pham, K., Vu, D., Khan, N., Tran, S., Lee, D. and Park, C.

Activity-based Fatal Four Rate Assessment for Effective Safety Planning Utilizing 4D-BIM.

DOI: 10.5220/0010308200003051

In Proceedings of the International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies (CESIT 2020), pages 308-315

ISBN: 978-989-758-501-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

performance in the industry still inadequate and need

strengthening. Explaining about causes, while some

construction enterprises claimed that the biggest

restricting factor for safety compliance was felt to be

time constraints, others believed that cost was a

problem prevent them (Chi, Chang, and Ting, 2005).

Actually, when injuries and fatal accident occur,

significant cost and time resources were lost because

of rework and training for replacement personnel

(Arboleda and Abraham, 2004). Moreover, accidents

affect the quality of the project, increases direct and

indi-rect costs for additional payments (Chi, Chang,

and Ting, 2005). By enhancing safety planning and

eliminating hazards factors, would not only save

hundreds of worker’s life but also reflect the

sustainable development of construction companies,

increasing working efficiency, competitiveness, and

profitability project.

The research focuses on a visualization approach

to improve safety planning and contribute towards a

better understanding of the conditions and causes of

accidents. Accordingly, the main goal was providing

the severity of fatality in each work-ing activity and

suggest preclusion measures respectively. The

proposed system, hopefully, will effective assist

construction managers, reduce the number of

accidents, thus creating a safer environment for the

labors working on construction projects.

Figure 1: Effective safety planning development based on

FFA.

2 MANUSCRIPT PREPARATION

2.1 Current Status of Safety Planning

Effective safety planning played a vital part in

construction project success. Sufficient safety

planning not only able to predict time and

circumstance accidents occur on project but also

develop adequate hazard mitigation plans (Choe and

Leite, 2017). The best way to keep a safe

construction workplace is by preventing hazards

from the pre-arising period. Failing to identify risks

from safety planning may increase significantly

accidents and defections in Job-site (Chi,Chang, and

Ting, 2005). However, conventional safety plan-

ning accomplishing in the construction sector

remains several drawbacks. Safety planning is still a

shortage of specific information and separate among

other planning functions, such as time, cost, and

quality (Choe and Leite, 2017). Accordingly,

construction safety analysis relies on manual efforts

or individual experi-ence of safety managers to

recognize potential hazards (Kim, Cho, and Zhang,

2016). Additionally, limited attention has been given

to safety from the planning and design phase since

the long-term impact was not considered or

understand. Limited attention has been given to

safety field from the planning and design phase

since the long-term impact was not considered or

understand (Zou, Kiviniemi, and Jones, 2017),

(Wong, Wang, Law, and Lo, 2016). Furthermore,

due to the overwhelming number of safety rules and

the complexities inherent with them, detecting the

appropriate safety contents and communicating them

to the right person or the right working condition

becomes a challenge. These problems require well-

defined and structured safety information that can be

identified and applied auto-matically by building

models software with the least human interaction.

Safety planning is obliged to instantly accessible,

effortlessly; standardized and visualized input

information; close communication with the routine

works and workers (Choe and Leite, 2017).

2.2 Using BIM for Safety Planning

Even BIM is broadly used for design and

monitoring, BIM is not yet widely applied for safety

planning [9]. Zhang and Kim (Zhang et al, 2013),

(Kim, Cho, and Kim, 2018) declared that most

accidents could be decreased and prevented with the

proper safety planning process that well planned by

the integration of BIM. The innovation of BIM

application has paved the way for safety

performance by providing a rich profusion of

information, reducing paper-based 2D drawing,

improving realistic visualization of safety prevention

(Zhang et al,2013 ), (Khan et al, 2019). In addition,

4D-BIM is known as a collaboration intelligent

linking between 3D digital model, schedule-related

information and safety contents (Kim, Cho, and

Kim, 2018). The BIM environment accommodates

visual information, a highly collaborative, and

plentiful parameter that is an appropriate condition

for simulation safety features. Prior involvement of

safety leaders using BIM from the planning process

made benefits to detect unsafe designs and risk

factors (Kim, Cho, and Kim, 2018), (Hongling,

Yantao, Weisheng, and Yan, 2016), provided

necessary safety measures (Zhang et al, 2015).

Activity-based Fatal Four Rate Assessment for Effective Safety Planning Utilizing 4D-BIM

309

2.3 Need for an Effective

Activity-based Safety Planning

The investigated studies indicated that hazards

identification and mitigation are necessary to enrich

construction safety from planning to execution.

Moreover, the application of BIM can overcome

impediments in the traditional safety planning

process. However, the literature revealed that the

current integration of BIM merely provided

subjective safety preven-tion without any authentic

evidence. Hence, the provision of safety information

in these cases seems more like passively memorized

without foundation in reality. The objective of this

study is to emphasize the main causes of accidents in

each work task in order to enhance understanding of

nature behind the reasons why safety protection

needs to use in specific situations. This paper

proposes an innovative approach which

accommodated safety information including Fatal

Four assessment (FFA) and TSF in specific

conditions with spatial and temporal simulating in

BIM environment. The process of developing RTSP

based on FFA is illustrated in Fig. 1. The accident

root causes are analyzed and evaluated by FFA

process. Then, the virtual reality simulation for the

prioritizing welfare facilities at work was designated

and incorporated re-spectively. The visual-spatial

environment including modeling components

fastened on specific activities duration and real-time

TSF collectively navigated. By developing

Naviswork plugin that will allow intuitively

distributing FFA and TSF, which will enhance

safety planning by forecasting critical TSF that

remind managers and simplify the access of other

project participants.

3 DATA ANALYSIS AND

ASSESSMENT

3.1 Current Status of Safety Planning

There are many methods available for collection and

analy-sis of accidents and the purpose of such

methods are clarifies the leading causes of the

incident, the defection in working process from

subjective aspects existences (such as organi-

zational level, control measures, installation and

maintenance, training, management factors) to

objective existences problems like environmental

issues (Hale et al, 2012). Relevant researches

highlighted correlations among various accident

characteristics with causes and construction stages

(Betsis et al, 2019). Currently, the study found that

fall-related hazards are major concerns (Chi, Chang,

and Ting, 2005), (Wong et al, 2019), (Zhang et al,

2015), and most construction accidents and fatalities

in small or medium firms (Betsis, Kalogirou,

Aretoulis, and Pertzinidou, 2019). Therefore, the

analysts collected and extracted critical information

from available sources and classify it into the

method formation. When analyzing fatal data, the

literature methods cover different factors for

specifying re-search contents. For illustration, the

interviews for a human factors specialist were

conducted by Hale (Hale et al, 2012) to classify and.

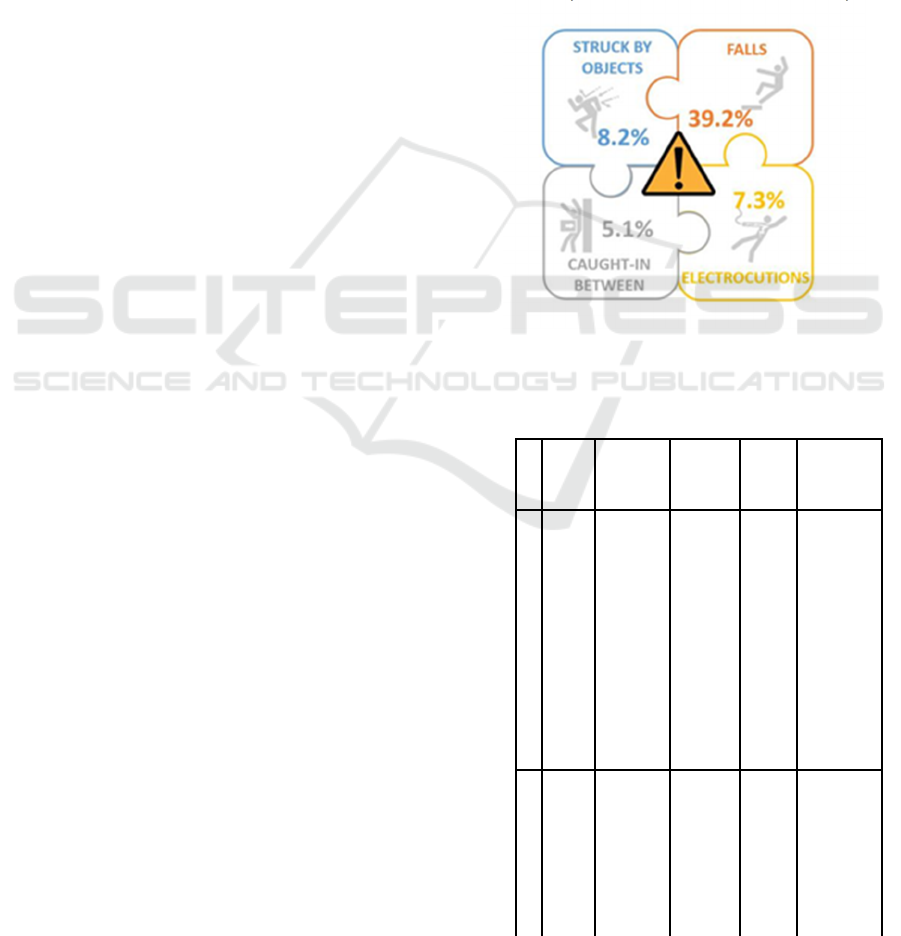

Figure 2: The proportion of fatal four in construction

reported by OSHA.

Table 1: Partical references example of case databased.

N

oNo.

Accit

case

Fatal Four

t

yp

e

Work

activit

y

Main

causes

Repor

t

1

13NY0

80

Two

constructio

n workers

fatally

crushed

when ce-

ment

formwork

collapsed.

Caught-

in-

Between

Concret

e Work

1.Inadequa

te design

of

formwor

k

2.nonconfo

rmance of

b

raced and

tied

3.No

proper

training

4.No

standard

operating

procedure

2

12NY0

18

Mechanic

el

ectrocuted

when a

mobile

light tower

contacted

p

owerline.

Electrocut

ions

Electric

al work

1.Lack of

power

lines

hazards

control

2.No

training

and

education

3.No clear

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

310

manual

guide for

the

equipment

operation

3

15MA0

37

Commerci

al roofer

falls 30

feet

through a

skylight

while

installing

roof

insulation

Falls

Roof

Coating

s

1. Ignoring

job hazard

analysis

2.No

training for

fall

protection

3.No using

fall

protection

4

15MA0

37

Carpenter

fat

ally

injured

after

Falling

from an

extension

ladder

Massachus

etts.

Falls

Roof

Coating

s

1. Ignoring

job hazard

analysis

2.No

training for

fall

protection

3.No using

fall

protection

5

14NJ07

4

Day

laborer,

first day

on the job,

struck and

killed by

backhoe

bucket.

Struck by

an Ob-ject

Foundat

ion

1. Lack of

communic

ation

between

the worker

and

operator

2.No

personal

protective

equipmen

t

underlying the levels of risk factors and their

inter-relation associated with inadequacies in

planning and risk assessment. Other research for the

real causes behind Fatal Fall-from-Height in Hong

Kong, (Wong et al, 2016) weigh all the inquest from

the government agencies and witnesses involved in

the accidents. Regarding the roots causes of fatalities

in trenching operations, Arboleda (Arboleda and

Abraham, 2004) established the major relationships

between the condition and reason of the trenching

fatalities.

By conducting the investigations of several

public re-ports such as Occupational Safety and

Health Administration (OSHA), Bureau of Labor

and Statistics (BLS), the National Institute for

Occupational Safety and Health (NIOSH), this study

focuses on Fatal Four related fatalities which makes

up a major proportion of worker death caused. In

other words, FFA data provides a foundation for the

development of effective intervention measures and

subsequently minimizing the main causes of

hazardous conditions in Jobsite. Fig. 2 shows the

individual Fatal Four percentages. It is observed that

the main cause belongs to Falls which occupies

39.2% of the total fatal causes while all others made

up less than 10%. Internally, the OSHA and BLS

data is gathered from the reports of employers or the

news media while the figure of NIOSH depended on

death certificate data. The investigated data consists

of more than 300 fatalities reported cases of Fatal

Four that were collected from OSHA website. In the

reviewed OSHA fatalities reports for the last 3 years

since 2017, the inspection report includes Case

Status, Basic Information of victim, employer,

working condition, Violation Summary, Violation

Items, Investigation Summary.

3.2 FFA for Safety Planning

Safety planning is an essential part of the planning

process, this stage aims at providing sufficient safety

information and facilities for welfare of workers and

working operations (Azhar, 2017). However, safety

information is abstract and dynamic, it leads to a

complicated accomplishing process consisted of

various legal documents, regulations and accident

records (Guo, Yu, and Skitmore, 2017). There is an

abundance of hazards close implicated in each

working activity. Meanwhile, conventional safety

planning lack of in-tuitive method automatic

exporting safety contents in chrono.

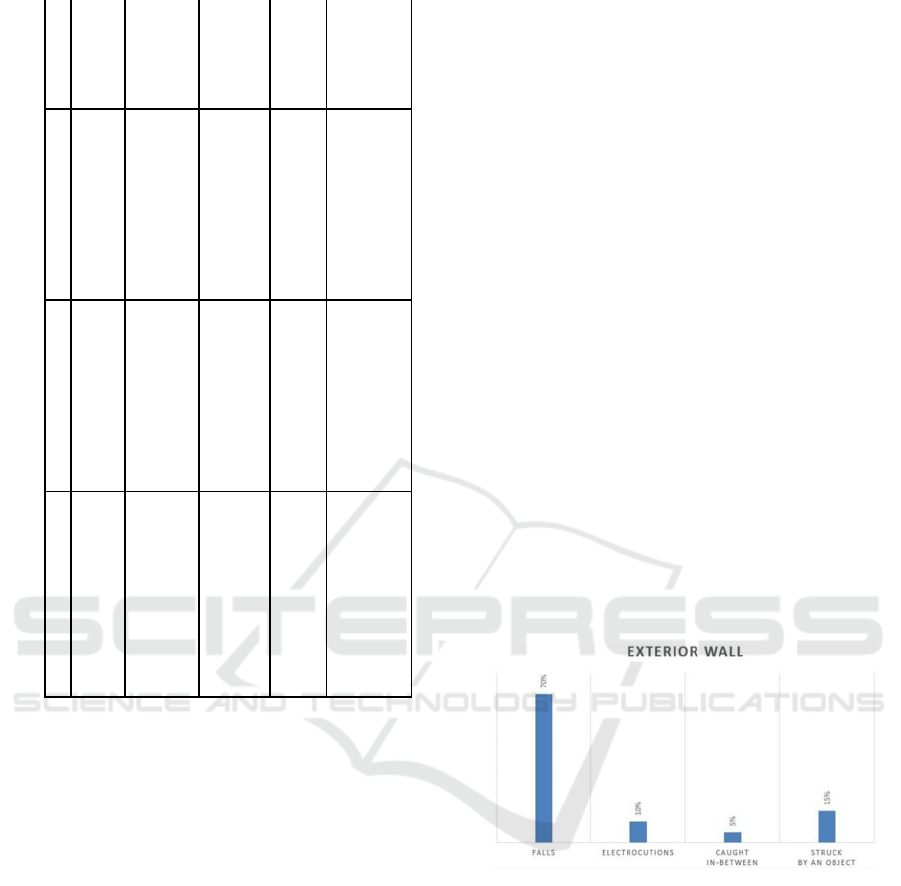

Figure 3: The severity of fatal four in boundary wall work.

logical order and hazardous priority. To solve

these problems, FFA data was provided as a

comprehensive explanation for prevention methods

that required install in safety planning. The study

focus on the evaluate the most frequent occurrences

regarding construction Fatal Four and at the same

time identify correlations among the various

parameters associated with working activities.

Besides, Fatal Four occurred frequently in

construction projects during many activities. To

developing significance safety planning, the study

considers broad reports of accidents in construction

industry to indicate essential risks in each working

stage. The evaluated information was taken verbatim

Activity-based Fatal Four Rate Assessment for Effective Safety Planning Utilizing 4D-BIM

311

from the initial report database held by OSHA

covering the name of reports, the type of accident,

time and location, age and employment status of the

victim, the geographical region, size of Jobsite,

nature of the project, the reason of incident and

recommendation. The critical information was

selected to input as initial data and display in excel

format. Table. I presented a part of classification

data for construction fatal cases that happened. More

than 500 fatalities were analyzed and 320 Fatal Four

related cases were evaluated and classified into four

categories (Falls, Electrocutions, Struck by Objects,

Caught-in-Between) with activity types (

Excavation, Foun-dation, Concrete forming,

Reinforcing, Masonry, etc.). After identifying the

main causes of fatal in specific work conditions.

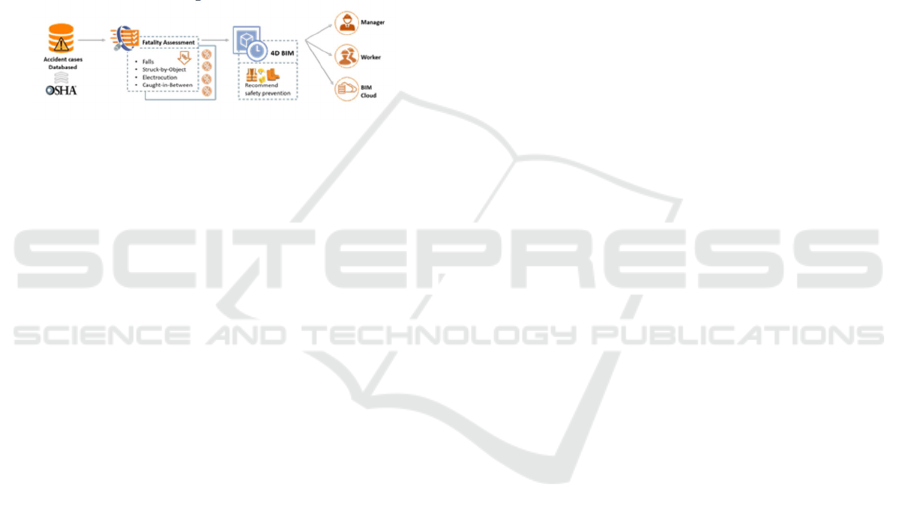

Figure 4: The 4D-BIM-based RTSP framework.

best-practice prevention was recommended. The

results of FFA could impact the entire safety

management process by what prime accident arrive

and how they were eliminated during working stage.

Each working activity was expressed FFA result in

percentage (refer to Fig. 3). It can be seen that FFA

information is useful to emphasize the hazardous

factor and remind reasonable safety protection needs

to be designated. In order to develop effective safety

planning, FFA data, project schedule, and safety

contents are required to identify and incorporate

closely in a visual presentation.

4 RTSP SYSTEM FRAMEWORK

In order to reduce manager workload and enhance

safety planning procedure, RTSP can be a useful

alternative for traditional method of integrating

reasonable safety protection with FFA-based. The

term real-time is in the sense that the prevention

methods were presented immediately to the dynamic

changing of project in model environment. It means

that when the schedule was integrated into 3D

model, the real-time 4D simulations for working

sequences were established with construction

progress activity visualization. The develop-ment of

RTSP based on 4D-BIM is automatically extracting

reasonable safety contents in a visual-spatial

environment, that encompassed the severity of

accident and prioritizing safety prevention.

This can be achieved via five steps:

1) 4D-BIM preparation by integrating project

schedule and digital 3D model.

2) Analysis FFA data.

3) TSF development based on FFA data.

4) RTSP collaborative simulation.

5) Data upload to BIM-cloud and User acquired

RTSP data

The RTSP framework consists of four modules

including Fatalities reports investigation, FFA, 4D-

BIM simulation, Par-ticipants interaction are

graphically presented in Fig. 4. In order to guarantee

safely workplace, the participant including managers

and workers has a responsibility to understand and

complete many safety requirements. In particular,

RTSP is purposely designed to help users understand

the insight causes of accident and dangerous

occurrence protection methods in Jobsite. Based on

visualization material with prioritized prevention

simulations, its easy approach, and flexible inter-

actions. RTSP system potential to provides a better

solution for preparing an effective and efficient

safety planning to con-struction participants and

creating critical safety data for local databased

(project databased, contractor databased, company

accident databased, agency databased, etc.).

5 4D-BIM-BASED RTSP DESIGN

4D-BIM-based RTSP aims to provide visualizations

of construction sites through an innovative digital

approach. To accomplish this, a combination of FFA

data, project schedule, Temporary safety facility

(TSF) and 3D building model plays a vital role in

the success of the entire system. Fig. 5 illustrates the

4D-BIM-based RTSP architecture in detail.

5.1 4D-BIM Preparation

Spatial environment in BIM becomes an effective

commu-nication and management method where

critical information (dimension, quantity, quality,

schedule, safety) and temporary facilities could be

linked that enable visualized, distributed and

addressed safety contents (Hossain et al, 2018). By

embedding schedule information in a digital model,

a 4D-BIM simulation was developed. In this section,

a three months schedule for the residential project

was created in MS project and a 3D digital model

was developed simultaneously in Revit environment.

After that, Navisworks was chosen to implement

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

312

4D-BIM collaboration. The 4D-BIM solution

contains parametric at-tributes that offer several

interesting opportunities to indicate safety contents

in the safety planning process. Especially, in order to

mitigating risk in construction site, the Family

Editor tools in Revit enables to create prevention

facilities data.

5.2 TSF Development

Temporary safety facility (TSF) system is the

provision of temporary welfare facilities for

employees in each work task in Jobsite. After

identifying important risk factors along with each

activity based on FFA (mentioned in the previous

section), TSF positively influences construction

safety by focusing on best practices prevention.

With an abundance of safety contents in

construction, workers or even designers or

contractors possibly are unaware or ignore some

requirements in non-typical conditions or in a short

period, and so accident appears in the scenario. For

instance, normally, in the pri-vate residential

construction, Exterior wall work task at each

building level often complete for 1 or 2 days. FFA

result showed that the highest fatality proportion in

the Exterior wall.

Figure 5: 4D-BIM-based RTSP system architecture.

work is Falls, as illustrated in Fig. 6. Consider

risk factors of Exterior wall work such as floor level

height, bounding space is sheltering or empty,

materials or equipment delivering, framing and

erecting walls, etc. The TSF priority needed to

implement in this work should be the guardrail

system. The place needs to install is the un-build

exterior wall spaces or opening on the built wall.

Figure 6: TSF for exterior wall work.

5.3 RTSP System Simulation

The main objective of this research is to develop

com-prehensive FFA data and recommend TSF (or

best practices prevention) which enhance the RTSP

system in order to eliminate hazards and show

activity-based TSF automatically. The RTSP

development is detailed described as follows:

1) Non-model accident severity data were

collected and analyzed then converted to the

bar chart diagram to make it visualized

graphically. When appended safety contents in

the Naviswork environment, the FFA

categories need clearly linked to explicit

models of how and when po-tential hazards

can occur. This process has been done in

Construction safety information Tab with the

help of Data Tools from Navisworks.

2) Using the API .NET programming interface

offered by Navisworks. The custom plug-ins

drive the safety pre-vention products in

construction safety tab and create the

connection access to model and schedule task.

A navigate plugin is developed based on

Application Programming Interface (API)

provided by Naviswork Platforms. This plugin

will be integrated into Navisworks

environment and show the safety information

as well as prevention products according to

3D digital model and work tasks.

3) Whenever a new TSF is created, RTSP system

imple-ments the time for installation and

removal of all TSF into the schedule. After

that, it can be added to the TSF

Fmily. All the safety issues related to FFA

data always updated to suggest and install TSF

appropriately.

4) Finally, the 4D-BIM-based TSF can be

coordinated and made available to users

(workers, managers, owners, and

Activity-based Fatal Four Rate Assessment for Effective Safety Planning Utilizing 4D-BIM

313

stakeholders) for simple approach,

understandable safety planning, and other

advanced communication purposes.

6 DISCUSSION AND

CONCLUSION

This paper proposes an innovative approach based

on the severity of fatalities, construction activities

for constructing a 4D-BIM-based RTSP to provide

adequate TSF recommenda-tion in specific spatial

and temporal simulation. The studied approach has

the potential to identify the most dangerous risk

factors among fatality causes, corresponding

prioritize providing safety prevention automatically.

The system en-ables to update the best practice

safety measures in order of importance, improve

safety management process, and finally reducing

errors in searching and using safety data. To fulfill

the objective, the various accident reports associated

with Fatal Four were analyzed and carefully

evaluated. Based on this investigation, scenario of

the unsafe conditions were identified for the purpose

of providing TSF simulation. By taking advantage of

4D-BIM, a plugin was built to allow upload and

navigate FFA data and TSF system in an intuitive

way.

Proposed system able to enhance safety

management, re-duce manager responsibility, and

simplify worker’s approach. It resulting in

impressive efficiencies in reducing risks and

accidents happening in construction. In the research,

there are multiple steps which were executed for

developing RTSP system. This works also reveals

some limitations that it is nec-essary for developing

an ideal and accurate 4D-BIM platform to

accomplish specific safety tasks and conditions

update. The aim of the assessment method is Fatal

four, the remaining factors that take part 40 percent

of construction fatality cause would explore in

further investigation. Agruablelly, the accu-rate of

RTSP concept depends on the number of fatality

cases evaluated in producing severity accident rate.

Further research would be necessary to collect more

fatalities data and scope down on fatalities rate in the

small and medium enterprises (SMEs). Besides, the

FFA-based computer vision application to remotely

monitor calculate the severity of accident occur-

rences of workers will be experimental perform.

Additionally, it would also be worthwhile to

consider the effect of utilizing Artificial intelligence

(AI) to automatically complete FFA pro-cess and

recommend accurately risk prevention. On the other

hand, we also going to integrate the system with

Augmented reality (AR) technologies to brings real

experiences method to users. The experiment

implementation will be evaluated in the real

construction site in Viet Nam and South Korea to

compare the practical application of this system in

developing and developed country.

ACKNOWLEDGEMENTS

This work was supported by the National Research

Foun-dation of Korea(NRF) grant funded by the

Korea govern-ment(MSIP). (No. NRF-

2019R1A2B5B02070721); Chung-Ang University

[research grant in 2019].

REFERENCES

OSHA, 2014. Commonly used statistics,”Available:

https://www.osha.gov/oshstats/commonstats.html.

Behm, M., 2005. Linking construction fatalities to the

design for construction safety concept,” Safety

science, vol. 43, no. 8, pp. 589–611.

Chi, C.-F., Chang, T.-C., Ting, H.-I., 2005. Accident

patterns and prevention measures for fatal

occupational falls in the construction industry,”

Applied ergonomics, vol. 36, no. 4, pp. 391–400.

Arboleda, C. A., Abraham, D. M., 2004. Fatalities in

trenching operations-analysis using models of accident

causation,” Journal of Construction Engineering and

Management, vol. 130, no. 2, pp. 273–280.

Choe, S., Leite F., 2017. Construction safety planning:

site-specific tem-poral and spatial information

integration, Automation in Construction, vol. 84, pp.

335–344.

Kim, K., Cho, Y., Zhang, S., 2016. Integrating work

sequences and temporary structures into safety

planning: Automated scaffolding-related safety hazard

identification and prevention in bim,” Automation in

Construction, vol. 70, pp. 128–142.

Zou, Y.,Kiviniemi A., Jones, S. W., 2017. A review of

risk management through bim and bim-related

technologies,” Safety science, vol. 97, pp. 88–98.

Wong, L., Wang, Y., Law, T., Lo, C. T., 2016.

Association of root causes in fatal fall-from-height

construction accidents in hong kong,” Journal of

Construction Engineering and Management, vol. 142,

no. 7, p. 04016018.

Zhang, S., Sulankivi K., Romo, I., Eastman, M., Teizer, J.,

2015. Bim-based fall hazard identification and

prevention in construction safety planning,” Safety

science, vol. 72, pp. 31–45.

Zhang, S., Teizer, J., Teizer, J., Lee, J.-K., Eastman, C.

M., Venugopal, M., 2013. Building information

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

314

modeling (bim) and safety: Automatic safety checking

of construction models and schedules,” Automation in

Con-struction, vol. 29, pp. 183–195.

Kim, K., Cho, Y., Kim, K., 2018. Bim-driven automated

decision support system for safety planning of

temporary structures,” Journal of Con-struction

Engineering and Management, vol. 144, no. 8, p.

04018072.

Khan, N., Ali, A. K., Skibniewski, M. J., Lee, D. Y., Park,

C., 2019. Excavation safety modeling approach using

bim and vpl,” Advances in Civil Engineering, vol.

2019.

Hongling, G.., Yantao, Y.., Weisheng, Z.., Yan, L.., 2016.

Bim and safety rules based automated identification of

unsafe design factors in construction,” Procedia

engineering, vol. 164, pp. 467–472.

Hale, A., Walker, D., Walters, N., Bolt, H., 2012.

Developing the under-standing of underlying causes of

construction fatal accidents,” Safety science, vol. 50,

no. 10, pp. 2020–2027.

Betsis, S., Kalogirou, M., Aretoulis, G., Pertzinidou, M.,

2019.

Work accidents correlation analysis for

construction projects in northern greece 2003–2007: A

retrospective study,” Safety, vol. 5, no. 2, p. 33.

Azhar, S., 2017. Role of visualization technologies in

safety planning and management at construction

jobsites,” Procedia engineering, vol. 171, pp. 215–226.

Guo, H., Yu, Y., Skitmore, M., 2017. Visualization

technology-based construction safety management: A

review,” Automation in Construction, vol. 73, pp.

135–144.

Hossain, M. A., Abbott, E. L., Chua, D. K., Nguyen, T.

Q., Goh, Y. M., 2018. Design-for-safety knowledge

library for bim-integrated safety risk reviews,”

Automation in Construction, vol. 94, pp. 290–302.

Activity-based Fatal Four Rate Assessment for Effective Safety Planning Utilizing 4D-BIM

315