Selecting Energy Carrier Combinations using Energy Hub Model

Weny Findiastuti, Retno Indriartiningtias, Rullie Annisa, and Mufidatul Latifah

Department of Industrial Engineering, University of Trunojoyo Madura

mufidatul28@gmail.com

Keywords: Energy Carrier, Energy Hub, Green

Abstract: This paper aims to select the energy-carrier combination for minimal total consumption of 5 processes.

Basic multi input-output Energy Hub (EH) concept has been simply modified into multi input-output for

multi process purposes. The modified concept affects its matrix model development which represent each

combination for multi process. Given 3 scenarios, 3 energy carriers and 5 processes involving effectivity

percentages of each energy carrier and process for a certain power plant. Considered energy carriers are

natural gas, water, and electricity which are processed by processes P1 to P5. The result shows that minimal

energy consumed for the processes is scenario 3with the process of 100% natural gas, 30% water and 30%

electricity effectiveness. Scenario 3 has total Natural Gas consumed for 261.63 MMBtu/Ton, 2,069,088.5

m

3

water, and 33,298,620.6 kW electricity.

1 INTRODUCTION

Energy scarcity has remained challenging high-price

energy problem. It is evidenced that using various

resources of energy generally becomes common

approach dealing with high price of electricity.

These common problems refer to the term of Energy

Hub (EH). It was first presented by (Geidl and

Andersson, 2007)to assemble many different energy

carriers and assist in obtaining economic

combination of those energy.

Energy hub (EH) approach proposes coupling

model among different energy carriers. The model

combines multi energy-carrier for optimized power

consumption (Geidl and Andersson,

2007).Correspondingly, for green manufacturing

reasons, EH is also claimed to reduce emission by

optimizing energy consumption and combining

renewable and unrenewable energy resources. Some

studies done by (Pazouki, Haghifam and Olamaei,

2013; Le Guen et al., 2017; Lin et al., 2017; Wang

et al., 2018; Miao et al., 2020; Ivatloo, Abapoura

and Shafiee, 2021) proposed combinations of

renewable and unrenewable energies using EH for

green manufacturing reasons. EH concept was also

introducedas a system model(Geidl and Andersson,

2007).As a system description, energy hub as a

process of integrating, conversing, and combining

multi-energy inputs into desirable combinations of

outputs (Zhang et al., 2015).

EH concept of coupling various energy carriers

have been wide-ranging used to simulate cost and

consumed energy carriers. Previous studies in EH

were about minimizing cost of multi energy e.g.

(Kienzle, Ahčin and Andersson, 2011; Parisio,

Vecchio and Vaccaro, 2012; Adamek, Arnold and

G. Andersson, 2014), planning and scheduling each

energy carriers used done with EH by (Pazouki,

Haghifam and Olamaei, 2013). Accommodating

uncertainty was also done by (Kienzle, Ahčin and

Andersson, 2011). In broader level, combining EH

for multi agent such as commercial agent,

environmental agent, demand agent, hub-element

agent, and integrated dispatch agent was completed

by (Lin et al., 2016, 2017).

Combining different energy carriers with EH

offers well organized integration of renewable and

unrenewable energies as well as lowering total

energy operation cost(Jiang and Hong, 2013; Du et

al., 2016). However, planning a combination of

multi energy carriers requires well-planned and

robust scenario to provide the profitable one. An

efficient energy carrier combinations outputs depend

on each conversion effectiveness within the different

processes in the hub.

Given 3 scenarios of natural gas, water, and

electricity energy carriers combinations of a

generator plant process, this paper aimed to analyze

256

Findiastuti, W., Indriartiningtias, R., Annisa, R. and Latifah, M.

Selecting Energy Carrier Combinations using Energy Hub Model.

DOI: 10.5220/0010307200003051

In Proceedings of the International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies (CESIT 2020), pages 256-261

ISBN: 978-989-758-501-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

and decide most minimal energy consumed by each

energy carriers. Therefore, basic multi input-output

EH model has been simply modified into that of

model for multi-process purpose. Modification has

been done on vector matrix of input and output of

matrix model to encounter unprocessed energy

carrier on any converter. For example, natural gas

energy carrier cannot be processed on Cooling

Tower which only processes water energy carrier.

Similar study on selecting energy carrier

processes was conducted by (Seyyed Mostafa

Nosratabadi, Jahandide and Nejad, 2020) which

simulated planning of electricity, gas, cooling

energy, and water for bus distribution network

energy-consumption. The research result proposed

minimal cost for bus distribution tes network. A

study was also done by (Pazouki, Haghifam and

Olamaei, 2013) in planning and scheduling EH

research which resulted robust model for amount of

each energy, which processes are used, and when

processes are done. (Zhang et al., 2015) generated

coupled energy carriers models associating with

reliability, efficiency and emission. Simplified by

given percentage of each energy carriers in

scenarios, the research selected optimal model by

comparing total energy consumed each scenario

model. Optimal planning and strategies for

electricity and gas were conducted by (Ghanbari,

Karimi and Jadid, 2020) as objectives proposed by

the paper.

2 ENERGY HUB (EH)

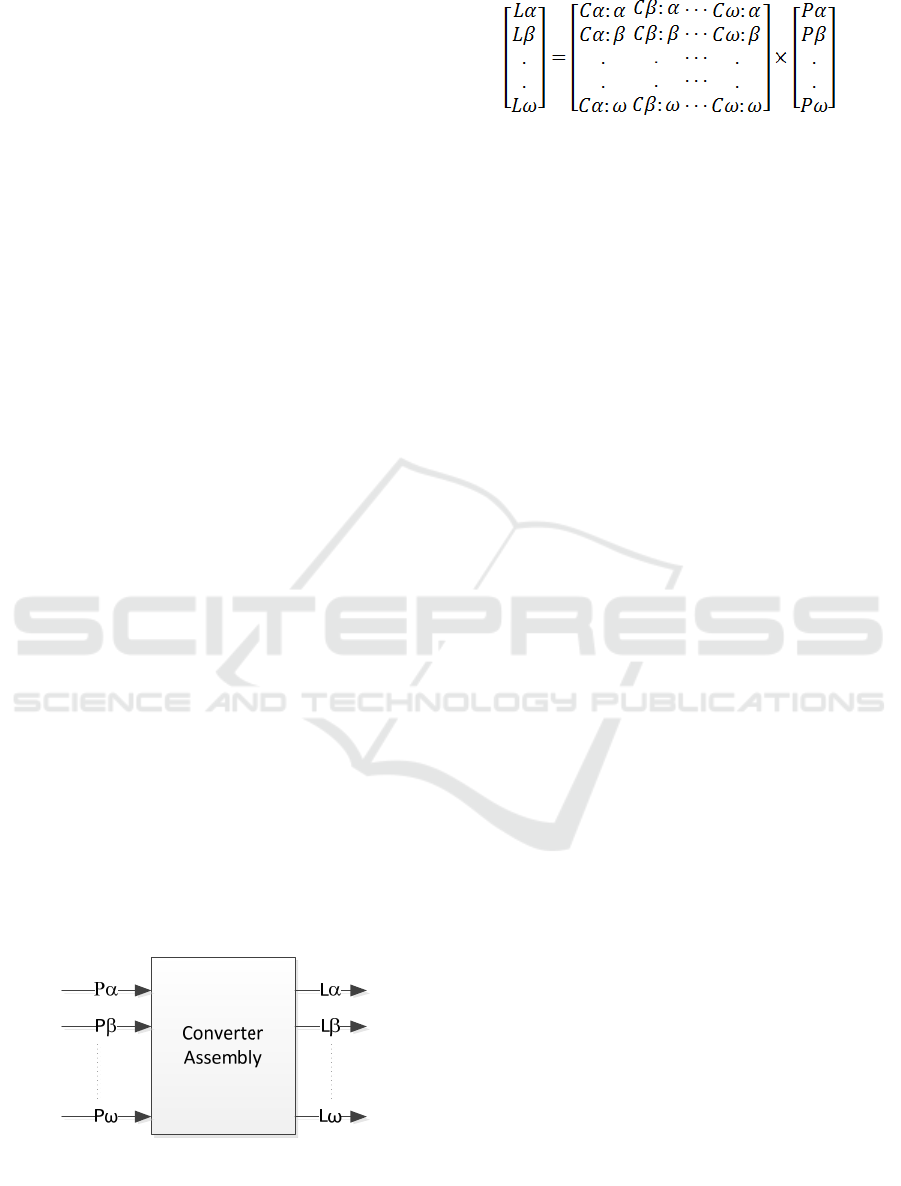

Figure 1 describes EH as a simple system that

processes input L into output P. The process refers

to converter assembly box. It is a basic multi input-

output EH system developed by(Geidl and

Andersson, 2007). Symbol α,β,..ω denotes energy

carriers. For the system concept, matrix model also

was stated as in (1):

Figure 1. Multi input-output EH system

(1)

Equation (1) expresses matrix model of multi

input-output EH system (Geidl and Andersson,

2007). Matrix C is coupling matrix for energy carrier

conversion. It represents how effective energy

conversion from one energy carrier into another one.

In equation (1), C𝛼:β denotes coupling factor for

conversion of energy carrier α to β. For example,

C𝛼:β = 0.3 means conversion energy carrier 𝛼 into

energy carrier 𝛽 is 0.3 effective, therefore 𝛽 = 0.3 𝛼.

Generally, this coupling factor represents

effectiveness of conversion process. Thus, output Lβ

represents conversion output of energy carrier α into

β and can be expressed as in equation (2):

Lβ = Cαβ x Pα (2)

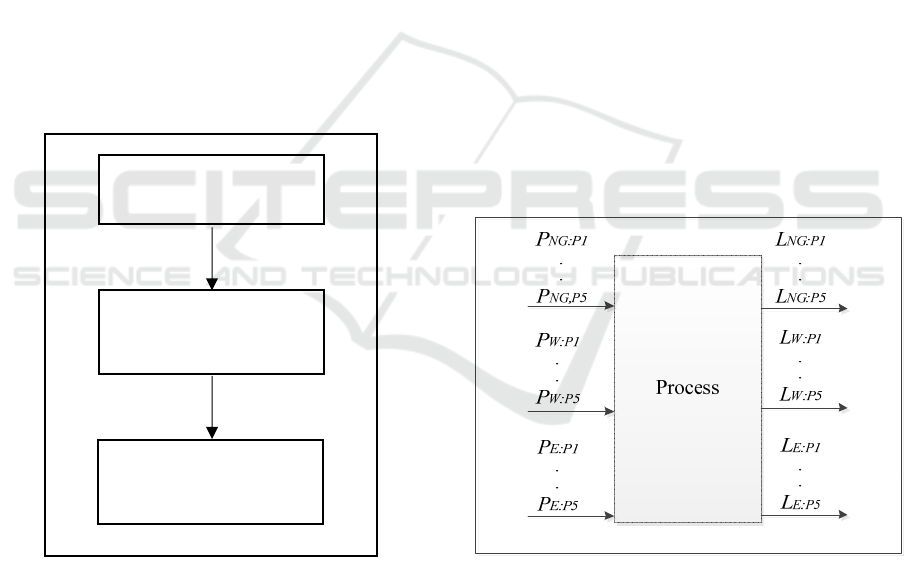

3 RESEARCH FRAMEWORK

Based on EH concept developed by (Geidl and

Andersson, 2007), this research framework has been

built as a system concept. It begins with problem

definition and developing a EH system according to

the problem (see Figure 2). Here, entities of the

system were identified including inputs, outputs and

the processes.

Inputs: Energy carriers involved that will be

transformed and/or combined such as

electricity, water, and natural gas

energy carriers. Inputs were stated as

loads or each energy amount. These

energies produce electricity power,

cooling, and heating which are used as

combinations in outputs

Outputs: Energy carriers inputs that have been

transformed and/or combined and

stated as loads or each combination

amount. They are formed as power

that is resulted from energies

combination.

Process: Process of transforming and/or

combination energy carriers. The

process works depend on effectiveness

of each transformation and

combination process. For example,

electricity and natural gas are

combined as 100% and 30% into

Selecting Energy Carrier Combinations using Energy Hub Model

257

power. 100% means electricity is fully

transformed into power, while natural

gas is only 30% transformed into

power.

Next step of the framework is building a matrix

mathematical model as stated as equation 1. Matrix

L represents outputs of EH system process, matrix P

represents inputs, and matric C is effectiveness of

the process.

Third step is assessing each combination or

energy carriers and determine maximal power result

for minimal energy consumed. In this step, some of

research may need optimization method added as

studies done by (Pazouki, Haghifam and Olamaei,

2013; Seyyed Mostafa Nosratabadi, Jahandide and

Nejad, 2020) that used mixed-integer linear

programming (MILP), (Vahid Pakdel, Sohrabi and

Mohammadi-Ivatloo, 2020) that used fuzzy

approach, and (Mansouri et al., 2020) that used

particle swarm optimization (PSO). However, this

paper does not include the optimation method due to

objectives of the paper were completed by the

matrix mathematical model.

Figure 2 Research Framework

4 EH MATHEMATICAL MODEL

DEVELOPMENT

Basic EH mathematical model written as equation

(1) and (2) needs to be adapted to existing problem.

For the next sub section is developing EH

mathematical model in accordance with the problem.

4.1 System and Problem Definition

X company is a green manufacturing committed

company in renewable and unrenewable energy

resources consumption. Electricity (E), Natural Gas

(NG) and Water Energy (WE) carriers which are

processed for Lime Softening, Cooling,

Demineralize Plant, Gas Generator, and Heat Boiler

noted as P1, P2, P3, P4, and P5 respectively.

However, for the last two years they have been

facing inconsistent water resources that need to be

replaced by other energy carriers, i.e. gas and

electricity.3 Scenarios of combination of three

energy carriers with their percentage of effectiveness

were developed by company’s engineers for energy

generation.These scenarios were defined as:

Scenario 1: Process of 100% natural gas, 30%

water, and 50% electricity effectiveness,

Scenario 2: Process of 100% natural gas, 50%

water, and 30% electricity effectiveness,

Scenario 3: Process of 100% natural gas, 30%

water and 30% electricity effectiveness.

Concerning this interacting energy carrier system

problem, the identified problem for this paper is

selecting the developed scenarios for minimal

consumed energy on outputs. Selected scenario will

be planned for the energy carriers combinations.

Figure 3 Modified EH system

Referring to EH model built by(Geidl and

Andersson, 2007), energy system showed in

Figure.1 and Figure 3 is a modified basic EH system

adapted for the X company problem. The system

converts multi-input energy carriers of PNG, PW,

and PE into multi-output energies consumed LNG,

LW, LE by combining 5 processes P1 to P5.

On Inputs, PNG:P1,…,PNG:P5,

PW:P1,…,PW:P5, and PE:P1,…,PE:P5 denote

Problem and System

Definition

Matrix Mathematical

Model Development

Assessing The

Mathematical Model

Resul

t

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

258

inputs or available energy carriers which through

processes P1 to P5. PNG:P1represents input of

energy available from Natural Gas that processed

through P1.

Outputs represent consumed energies of that on

processes P1 to P5while outputs LNG, LW, LE

represent consumed energy of Natural Gas, Water,

and Electricity by processes P1 toP5. Accordingly,

LNG:P1,…,LNG:P5, LW:P1,…LW:P5, and

LE:P1,…LEP5 denote inputs or available energy

carriers Natural Gas (NG), Water (W), and

Electricity (E) on processes P1 to P5.

Table 1 lists available energy-carriers on

processes P1 to P5 as input in the system. Number of

0 means that of energy carrier is not available for

that of process. For example, Natural Gas is not

available on process P1, but then 54.7 MMBtu/Ton

of natural gas available for P4.

Table 1: Available Energy for Each Process

Pro

ces

s

Available Ener

gy

Carriers

Natural Gas

(NG)

(MMBtu/To

n

)

Water (W)

(m

3

)

Electricity (E)

(kW)

P1 0 3,308,534 628,737

P2 0 3,521,105 98,911,128

P3 0 63,990 3,833,899

P4 54.7 0 7,621,638

P5 206.92 0 0

Tot

al

261.63 6,893,629 110,995,402

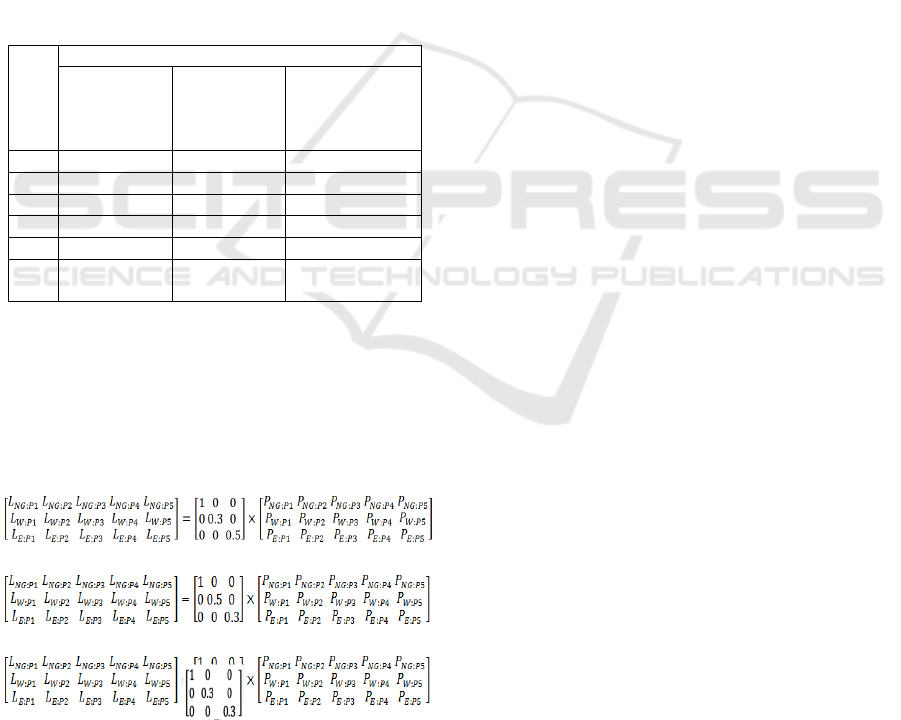

4.2 Adapted EH Mathematical Model

According to given scenarios and vector matrix built

by (Geidl and Andersson, 2007), mathematical vector

model of developed EH system are stated as in

equation (3), (4), and (5) respectively for scenario

1,2, and 3.

(3)

(4)

(5)

Differences in scenarios EH model are stated in

factor couple matrix which stated each percentage of

energy carriers. Here, in equation (3) which

represents scenario 1, numbers of 1, 0.3, and 0.5 at

factor couple matrix represent effectiveness of

natural gas, water and electricity. 1 means that input

is full effectively processed into output. 0.3 means

only 30% of input is effectively processed into input,

while 0.5 is for 50% effective process into output.

Computed using equation (3) and input data in

Table.1, output L

NG

:

P1,

…L

NG:P5

of scenario

1

can be

stated as in equation (6).

L

NG:P1

= (1x P

NG:P1

) + 0 + 0 = 0

L

NG:P2

= (1x P

NG:P2

) + 0 + 0 = 0

L

NG:P3

= (1x P

NG:P3

) + 0 + 0 = 0

L

NG:P4

= (1x P

NG:P4

) + 0 + 0 = 54.71

L

NG:P5

= (1 x P

NG:P5

) + 0 + 0 = 206.92

(6)

Number of 0 for LNG:P1,…LNG:P3 is a result

that natural gas is not processed in P1, P2, P3. Then,

total output or energy consumed for process P1 to P5

using natural gas is 261.63 MMBtu/Ton.

Accordingly, output L

W

and L

E

for equation (3) for

scenario 1can be also stated as in equation (7) and

equation (8):

L

W:P1

= 0+(0.3x P

W:P1

)+0 = 0.3 x 3,308,534 =

992,560

L

W:P2

= 0+(0.3 x P

W:P2

)+0 = 0.3 x 3,521,105

=1,056,331

L

W:P3

= 0+(0.3 x P

W:P3

)+0 = 0.3 x 63,990 = 19,177

L

W:P4

= 0+(0.3 x P

W:P4

)+0 = 0

L

W:P5

=0+(0.3x P

W:P5

)+0 = 0

(7)

Equation (7) calculated scenario 1 for Water (W)

energy carrier. First line of the equations represents

calculation of input PW 3,308,534 m

3

of water

energy carrier processed by P1 into output LW with

effectiveness of 30% and resulted output of 992,560

m

3

water energy carrier consumed.

L

E:P1

=0+0+(0.5x P

E:P1

)= 0.5 x 628,737 =

314,368.5

L

E:P2

=0+0+(0.5x P

E:P2

)=0.5 x 98,911,128=

49,455,564

L

E:P3

=0+0+(0.5xP

E:P3

) = 0.5 x 3,833,899=

1,916,949.5

L

E:P4

=0+0+(0.5xP

E:P4

)=0.5x7,621,638=3,810,81

9

L

E:P5

= 0+0+(0.5 x P

E:P5

) = 0

(8)

Equation (8) calculated scenario 1 for Electricity

(E) energy carrier. First line of the equations

represents calculation of input P

E

628,737 kW of

Electricity energy carrier processed by P1 into

output L

E

with effectiveness of 50% and resulted

output of 314,368.5 kW Electricity energy carrier

consumed.

Selecting Energy Carrier Combinations using Energy Hub Model

259

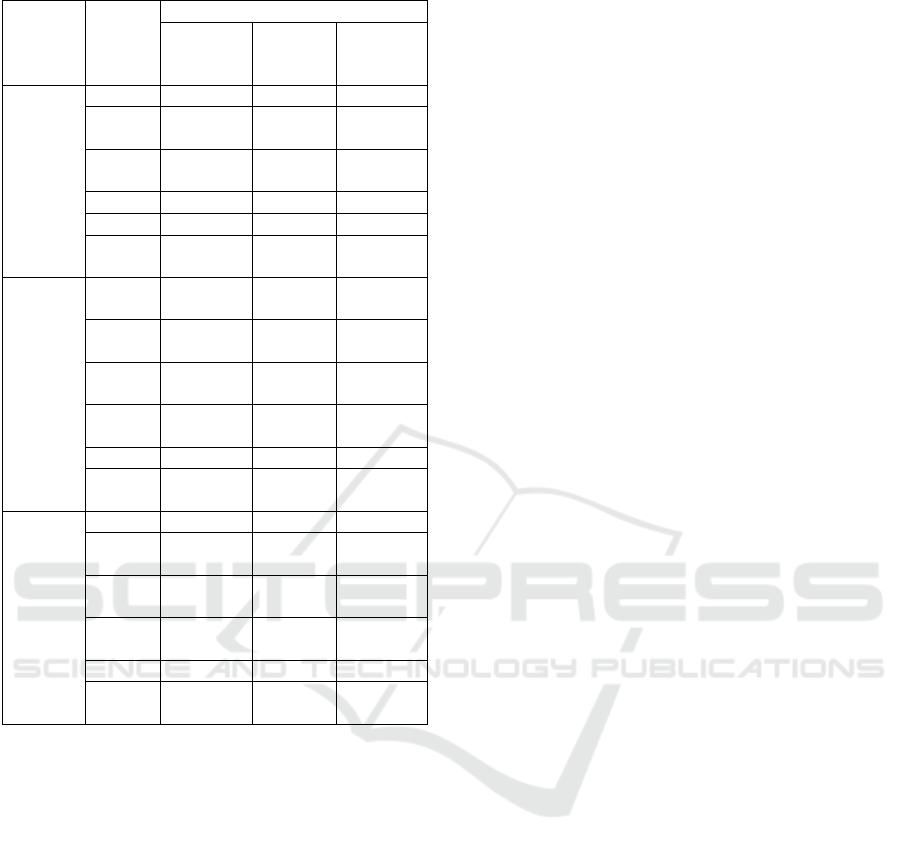

Table 2. EH Output for Scenario 1,2, and 3

Scenario Process

Ener

gy

Natural

Gas(MMB

tu/Ton

)

Water

(m

3

)

Electricity

(kW)

1

P1 0 992,560 314,368.5

P2 0 1,056,33

1

49,455,56

4

P3 0 19,177 1,916,949.

5

P4 54.7 0 3,810,819

P5 206.92 0 0

Total 261.63 2,069,08

8.5

55,497,70

1

2

P1 0 1,654,26

7

188,621.1

P2 0 1,760,55

2.5

29,673,33

8.4

P3 0 31,995 1,150,169.

7

P4 54.7 0 2,286,491.

4

P5 206.92 0 0

Total 261.63 3,446,81

4.5

33,298,62

0.6

3

P1 0 992,560 188,621.1

P2 0 1,056,33

1

29,673,33

8.4

P3 0 19,177 1,150,169.

7

P4 54.7 0 2,286,491.

4

P5 206.92 0 0

Total 261.63 2,069,08

8.5

33,298,62

0.6

5 RESULTS

Table 2. lists output of EH Model for scenario 1,2,

and 3 as a result of matrix in equation (3) for

scenario 1, equation (4) for scenario 2, and equation

(5) for scenario 3. It shows results of processes

P1,…,P2 for all scenarios as explained as:

a. Natural Gas energy carrier,

All scenarios resulted the same same

consumed natural gas energy carriers 261.63

MMBtu/ton.

b. Water energy carrier,

Scenario 1 and 3 resulted the same energy

consumed of 2,069,088.5 m

3

, and higher

energy consumed of 3,446,814.5 m

3

for

scenario 2

c. Electricity energy carrier,

For electricity energy carrier scenario 1

resulted highest energy consumed of

55,597,701kW and the same energy consumed

of 33,298,620.6 kW for scenario 2 and 3.

For these results, scenario 1 and 3 are chosen for

the same water energy consumed. At the same

condition, scenario 3 has lowest energy consumed of

electricity energy carrier. In context of minimizing

energy consumed of all scenarios, it can be

concluded that scenario 3 has lowest energy

consumed for all energy carrierswith . As listed at

Table 2, scenario 3 has total Natural Gas consumed

for 261.63 MMBtu/Ton, 2,069,088.5 m

3

water, and

33,298,620.6 kW electricity with process of 100%

natural gas, 30% water and 30% electricity

effectiveness

6 CONCLUSION

This paper selects minimal energy consumed which

involved 3 energy carrier i.e. Natural Gas (NG),

Water (W), and Electricity (E) and 5 different

processes i.e. Lime Softening (P1), Cooling (P2),

Demineralizing Plant (P3), Gas Generator (P4), and

Heat Boiler(P5). Combination of energy carriers and

processes are provided as 3 scenarios of

combination’s percentage of effectiveness. Based on

EH concept developed by (Geidl and Andersson,

2007), research framework was built to solve the

problem.

Problem system were built with amount of

energies available as inputs and energies consumed

as outputs. Basic mathematical matrix model of EH

Model has been extended for multi process purpose

based on Table 1.

Using 3 equations of (3), (4), and (5) represented

3 scenarios policies in each energy carrier

percentage of effectiveness, the result showed that

scenario 3 consumed most minimal energy for total

process. scenario 3 has total Natural Gas consumed

for 261.63 MMBtu/Ton, 2,069,088.5 m

3

water, and

33,298,620.6 kW electricity with process of 100%

natural gas, 30% water and 30% electricity

effectiveness.

REFERENCES

Adamek, F., Arnold, M. and G. Andersson (2014) ‘On

Decisive Storage Parameters for Minimizing Energy

Supply Costs in Multicarrier Energy Systems’, IEEE

Transactions on Sustainable Energy, 5, pp. 102–109.

Du, E. et al. (2016) ‘Exploring the flexibility of CSP for

wind power integration using interval optimization’,

IEEE Power and Energy Society General Meeting

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

260

(PESGM), pp. 1–6.

Geidl, M. and Andersson, G. (2007) ‘Optimal power flow

of multiple energy carriers’, IEEE Transaction on

Power System, 22, pp. 145–155. doi:

10.1109/PESGM.2016.7741940.

Ghanbari, A., Karimi, H. and Jadid, S. (2020) ‘Optimal

planning and operation of multi-carrier networked

microgrids considering multi-energy hubs in

distribution networks’, Energy, 204, p. 117936. doi:

10.1016/j.energy.2020.117936.

Le Guen, M. et al. (2017) ‘Achieving energy sustainability

in future neighborhoods through building

refurbishment and energy hub concept: A case study

in Hemberg-Switzerland’, Energy Procedia, 122, pp.

265–270. doi: 10.1016/j.egypro.2017.07.320.

Ivatloo, M. Z. O. B. M., Abapoura, M. and Shafiee, M.

(2021) ‘Techno-economic and environmental

assessment of the coordinated operation of regional

grid-connected energy hubs considering high

penetration of wind power’, Journal of Cleaner

Production, 280 part 1(124275).

Jiang, Q. and Hong, H. (2013) ‘Wavelet-Based Capacity

Configuration and Coordinated Control of Hybrid

Energy Storage System for Smoothing Out Wind

Power Fluctuations’, IEEE Transactions on Power

Systems, 28(2), pp. 1363–1372.

Kienzle, F., Ahčin, P. and Andersson, G. (2011) ‘Valuing

Investments in Multi-Energy Conversion, Storage, and

Demand-Side Management Systems Under

Uncertainty’, IEEE Transactions on Sustainable

Energy, 2(2), pp. 194–202.

Lin, H. et al. (2016) ‘Agent-based Modeling of Electricity

Consumption in an Office Building under a Tiered

Pricing Mechanism’, Energy Procedia, 104, pp. 329–

335. doi: 10.1016/j.egypro.2016.12.056.

Lin, H. et al. (2017) ‘A multi-agent based optimization

architecture for energy hub operation’, Energy

Procedia, 142, pp. 2158–2164. doi:

10.1016/j.egypro.2017.12.621.

Mansouri, S. A. et al. (2020) ‘Two-stage stochastic

framework for energy hubs planning considering

demand response programs’, Energy, 206, p. 118124.

doi: 10.1016/j.energy.2020.118124.

Miao, P. et al. (2020) ‘Optimal emission management of

photovoltaic and wind generation based energy hub

system using compromise programming’, Journal of

Cleaner Production, p. 124333. doi:

10.1016/j.jclepro.2020.124333.

Parisio, A., Vecchio, C. Del and Vaccaro, A. (2012) ‘A

robust optimization approach to energy hub

management’, International Journal of Electrical

Power & Energy Systems, 42(1), pp. 98–104.

Pazouki, S., Haghifam, M. R. and Olamaei, J. (2013)

‘Economical scheduling of multi carrier energy

systems integrating Renewable, Energy Storage and

Demand Response under Energy Hub approach’,

Smart Grid Conference 2013, SGC 2013, pp. 80–84.

doi: 10.1109/SGC.2013.6733803.

Seyyed Mostafa Nosratabadi, Jahandide, M. and Nejad, R.

K. (2020) ‘Simultaneous planning of energy carriers

by employing efficient storages within main and

auxiliary energy hubs via a comprehensive MILP

modeling in distribution network’, Journal of Energy

Storage, 30(101585).

Vahid Pakdel, M. J., Sohrabi, F. and Mohammadi-Ivatloo,

B. (2020) ‘Multi-objective optimization of energy and

water management in networked hubs considering

transactive energy’, Journal of Cleaner Production,

266, p. 121936. doi: 10.1016/j.jclepro.2020.121936.

Wang, Y. et al. (2018) ‘Automatic and linearized

modeling of energy hub and its flexibility analysis’,

Applied Energy, 211(November 2017), pp. 705–714.

doi: 10.1016/j.apenergy.2017.10.125.

Zhang, X. et al. (2015) ‘Optimal Expansion Planning of

Energy Hub with Multiple Energy Infrastructures’,

IEEE Transactions on Smart Grid, 6(5), pp. 2302–

2311. doi: 10.1109/TSG.2015.2390640.

Selecting Energy Carrier Combinations using Energy Hub Model

261