Research to Prevent Discoloration of Silver Traditional Handicrafts

Wonsub Chung

1

and Byunghyun Shin

2

1

Cultural Heritage Preservation Research Institute, Pusan National University, Busan (Korea)

2

Development of Material Science and Engineering, Pusan National University, Busan (Korea)

Keywords: prevent discoloration of silver, 1.5v battery, aluminum anode.

Abstract: Why does silver (Ag), which are classified as precious metals such as gold (Au), platinum (Pt), and palladium

(Pd), easily discolor in the atmosphere? The reason is that gold, platinum, and palladium do not react well

with the discoloration atmosphere to the extent that they exist as metals in nature. However, although silver

exists as natural silver, the amount is not large. Most of them exist in nature as silver oxide, silver chloride

and silver sulfide. For people to use it, it is much more effective to reduce it to pure metallic silver than silver

oxide, silver chloride, and silver sulfide (gloss, electrical and thermal conductivity, workability, etc.), so it is

unstable by using reducing agents such as carbon monoxide or hydrogen gas. It is made of metal and used.In

this study, as a result of conducting research to prevent discoloration of silver, the following results were

obtained.1) If the power of about 1.5v 2nd battery was connected in the air, the discoloration of silver could

be prevented by supply of electrons.2) It was possible to prevent discoloration of silver by promoting the

electrochemical reaction by contacting aluminum anode, which is a more active metal than silver.

1 INTRODUCTION

The silver (Ag) metal classified as a noble metal such

as gold (Au), platinum (Pt), and palladium (Pd), but

it well discolored in the atmosphere. This is because

gold, platinum, and palladium are not well reacted

with the discoloration atmosphere to the extent that

they exist in nature as a metal. But silver is a

compound rather than a silver pure metal. Mostly

silver oxide, silver chloride and silver sulfide exist in

nature. In order to smelt pure metallic silver, it must

be reduced by supplying energy from the outside. In

this case, the produced metal is easily discolored due

to internal energy non-uniformity and impurities

(copper, tin, etc.). The silver metal is also supplied

with energy from the outside when the external

energy required for the reduction of silver is added

and when it is made into chains or plates. Moving in

the direction of reducing this energy is more stable,

so it tends to discolor and decrease in intensity. For

these reason, the metal is in an unstable state, so the

metal itself is trying to return to stable oxides, sulfides

and chlorides, which is why the color of the metal

changes.

In particular, the discoloration is severe as shown

in the following Fig. 1.

Figure 1: The causes of discoloration of silver are as

follows. Silver metal is stable to water and oxygen but

reacts with ozone (O3) to form silver oxide (Ag2O) and

easily reacts with sulfur (S) or sulfur compounds (such as

hydrogen sulfide, H2S) In this case, the color is discolored.

This is because silver is blackened if it is used for a long

time.

Chung, W. and Shin, B.

Research to Prevent Discoloration of Silver Traditional Handicrafts.

DOI: 10.5220/0010304700003051

In Proceedings of the International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies (CESIT 2020), pages 135-138

ISBN: 978-989-758-501-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

135

4 Ag + O2 + 2 H2S → 2 Ag2S + 2 H2O

High temperature: Ag+(1/2)O2 =>AgO

Low temperature: Sulfide reaction (Ag+(1/2)S2

=>Ag2S)

Discoloration (Yellow->Brown -> Black)

Included in domestic household bathing agent

(containing sulfur such as sodium sulfate and lactate),

onion, gasoline burning (sulfur dioxide gas

generation), shampoo, kitchen detergent (including

surfactant), rubber product (rubber band etc.),

household bleach The silver metal is discolored by

the sulfur component.

At present, such discoloration problem cannot be

solved and organic coating is applied to prevent

contact with gas such as sulfur gas or chlorine gas.

And alloy technology is used by adjusting the

discoloration and strength by alloying the second

element or the third element as shown in the

following table. And silver plating and precious

metals such as palladium and rhodium are

electroplated on the silver surface to prevent

discoloration, but the complete method has not been

found yet.

For this reason, research is needed to prevent

discoloration of silver metal products.

In this study, an experiment to prevent

discoloration of silver products is conducted with an

electrochemical idea.

2 EXPERIMENTAL METHOD

Ag alloy used in this study is to prevent oxidation by

applying NaOH to Ag, Cu, and Nd in a graphite

crucible with a size of 40x 40 x 25mm as shown in

Table 1. It is melted at 1000°C and naturally stirred

for 30 minutes. An alloy was produced by air cooling.

The x-ray diffractometer (XRD, Rigaku Ultima

IV).The structure was observed using a field emission

scanning electron microscope (SEM, Hitachi S 4800),

and the elements were mapped using an energy

dispersive X-ray spectroscope (EDS), and the

corrosion potential and current of each specimen were

measured through a potentiometer (Versastat 4.0).In

order to measure, a coincidence polarization test was

performed. It was measured after grinding the

specimen with #600 SiC Paper before measurement.

The measurement range was from -0.4VSCE to

1.2VSCE, and a three-electrode cell was used. A

saturation sensation electrode (SCE) was used as the

reference electrode and a Pt network was used as the

counter electrode, and the experiment was conducted

using a 3.5 wt.% NaCl electrolyte.

The rate of discoloration between the 1.5V battery

contacted with the silver metal product to form an

electrochemical circuit and the battery not contacted

was measured visually. In addition, the same

experiment was performed for the presence or

absence of contact of the sacrificial aluminum anode.

Table 1: Composition of silver alloy.

92.5 wt % Ag

-75 wt. % Cu

92.5 wt % Ag

-75 wt.% Cu

-0.5 wt. % Nd

Ag (g) 37 37

Cu (g) 3 2.8

Nd (g) 0 0.2

Total (g) 40 40

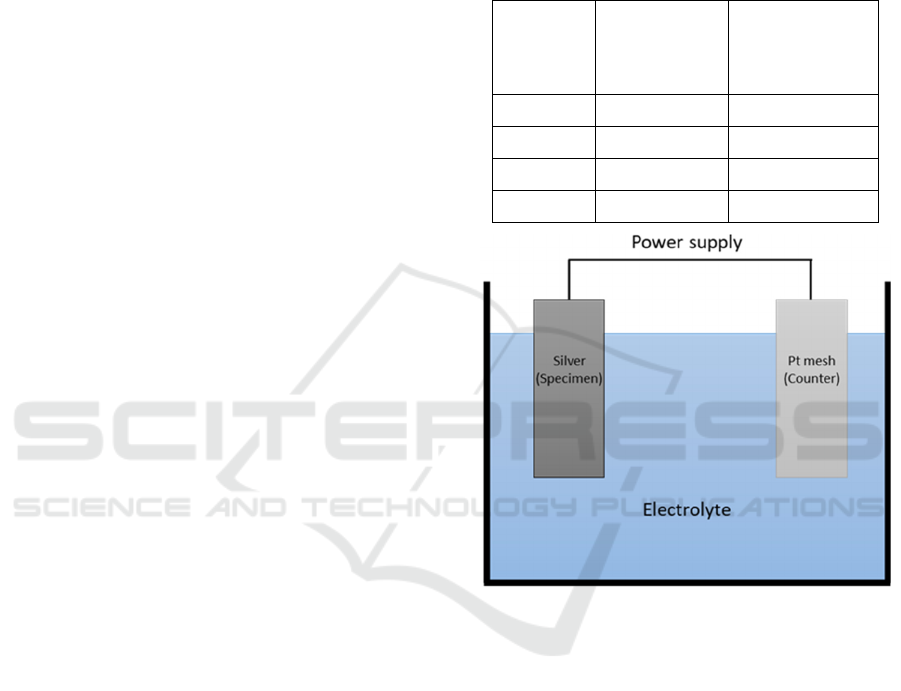

Figure 2: Schematic diagram of the experiment of ICCP

device.

Fig. 2 shows the schematic diagram of the

I.C.C.P(Impressed Current Cathodic Protection)

experimental apparatus. It is a device that measures

the discoloration of silver metal depending on

whether electrons are supplied from the outside into

the electrolyte, which is a corrosive atmosphere.

3 RESULTS AND DISCUSSION

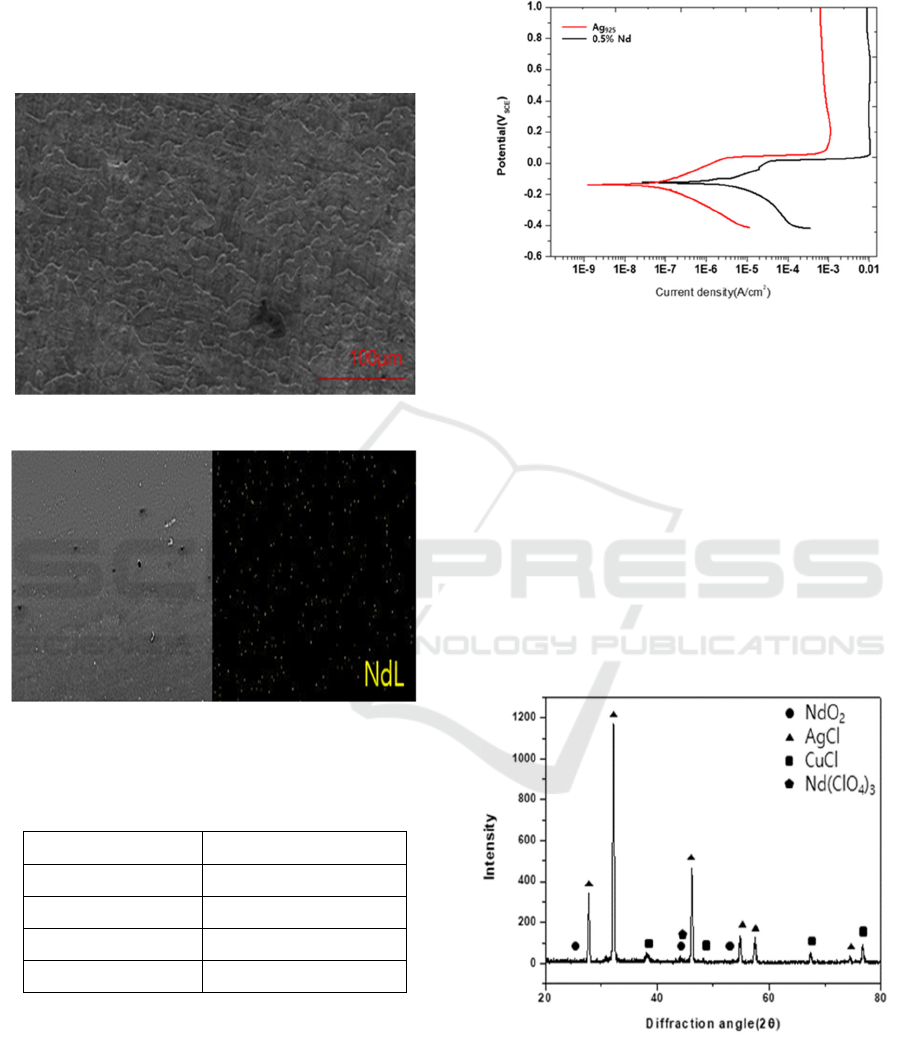

The structure of the specimen to which 0.5wt% of Nd

was added was observed through SEM, and the

results are shown in Fig. 3. No secondary phase

produced by the addition of Nd was found. In the

sterling silver composition, which is an alloy of Ag

and Cu, copper does not form a secondary phase of

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

136

the alloy and is known to be dispersed in one size, and

no other secondary phase was found even after the

addition of Nd. According to the previously studied

literature, it was confirmed that other phases do not

exist in the composition used in the present study

through the Ag-Cu-Nd ternary phase diagram.

Figure 3: Microstructure of siver alloy added 0.5wt% Nd.

Figure 4: SEM Image with EDS Mapping of silver alloy

added 0.5 wt. % Nd.

Table 2: Elemets and wt. % of each elements in silver alloy

added 0.5 wt. % Nd.

Element Wt%

Ok 01.90

Cul 06.73

Ndl 00.61

Agl 92.77

EDS analysis was performed to confirm the

addition of Nd. Table 2 shows the quantitative results

of the mapping shape in Figure 4. Mapping of the Nd

element was performed through EDS to confirm the

dispersion of Nd. As a result, Nd was homogeneously

distributed and oxidation occurred at high

temperature during casting, and oxygen was present,

and the same composition as the composition of the

synthesized alloy was detected. Based on this, it was

confirmed that the alloying was properly performed.

Figure 5: Potentiodynamic polarization curve of silver alloy

Ag925 and silver alloy added 0.5 wt% Nd.

Through the electrokinetic polarization

experiment, the corrosion resistance of the specimens

with Nd and without Nd was compared. In the

coincidence polarization test, the corrosion potential

represents the potential at the time when corrosion

occurs, and through this, it can be confirmed that the

corrosion resistance is improved. The results of the

comparison are shown in Fig. 5. It was confirmed that

the corrosion potential value was improved when

0.5% Nd was added compared to the alloy without the

addition of 16mV E(Corr) Nd. Through this, it was

confirmed that when Nd was added, Nd improved the

corrosion resistance under the atmosphere of Cl ion.

Figure 6: XRD peak after potentiodynamic polarization test

of 0.5 wt.% Nd.

Research to Prevent Discoloration of Silver Traditional Handicrafts

137

Table 3: Phase name and formula for after potentiodynamic

polarization test.

Phase name Formula

Neodymium Oxide Nd0

2

Chlorargyrite AgCI

Tolbachite CuCI

2

Neodymium Chloratte Nd(CIO

4

)

3

Corrosion products generated after electrokinetic

polarization were analyzed through XRD, and the

results are shown in Figure 6. The results of the XRD

analysis of the corrosion products of the specimen to

which Nd was added are shown in Table 3. It was

confirmed that AgCl, CuCl, NdO2, and Nd(ClO4)3

were generated after the electrokinetic polarization

experiment.

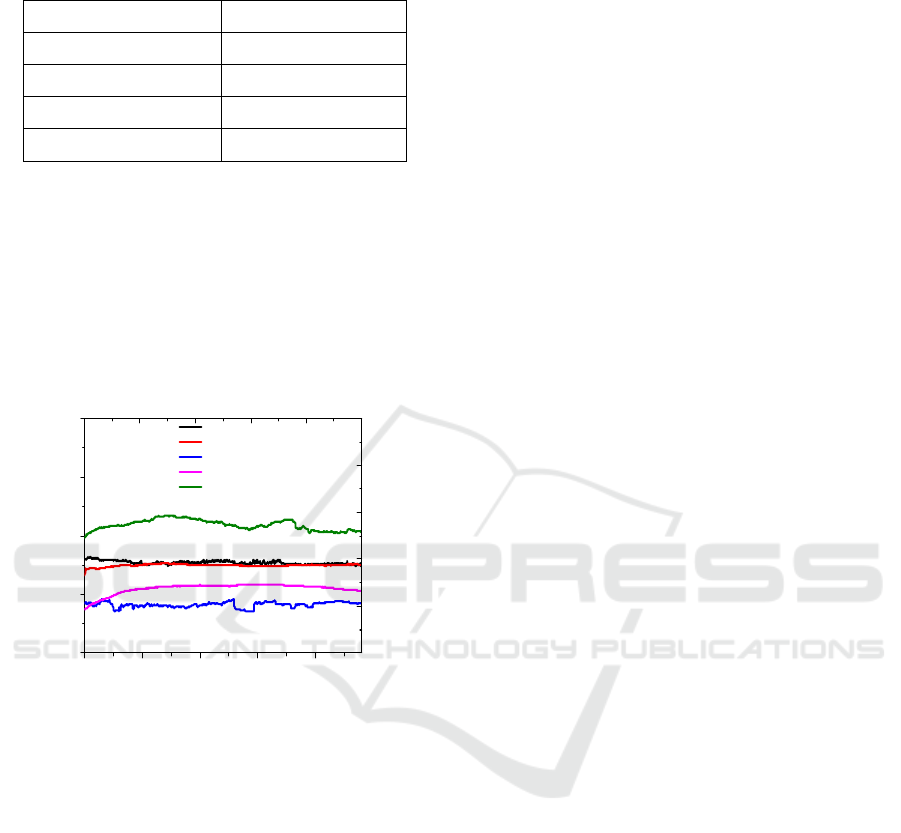

0 500 1000 1500 2000

0.6

0.8

1.0

1.2

1.4

Potential (V)

Time (sec)

Di water

1 wt. % H2SO4

1 wt.% NaCl

1 wt. % H2SO4 + 1 wt. % NaCl

2 wt. % H2SO4

Figure 7: Open circuit potential.

Figure 7 Represents Open circuit potential of each

electrolyte. Each electrolyte H2SO4, NaCl,

mixture(H2SO4 + NaCl) shows + potentials.

4 CONCLUSIONS

The corrosion resistance and corrosion properties of

the conventional silver alloy and the alloy containing

Nd added to the silver were compared under Cl

atmosphere. To prevent the corrosion of silver, ICCP

was connected to evaluate the anticorrosive ability

according to voltage, and the electrochemical

characteristics according to the electrolyte solution

were analyzed, and the following conclusions were

drawn.

1) It was confirmed that when 0.5wt% Nd was

added, it did not form another secondary phase

by bonding with Ag and Cu.

2) As a result of evaluating the polarization

potential, the corrosion resistance was

improved in the 3.5 wt% NaCl ion atmosphere

as Nd was added.

3) When Nd is added, when corrosion occurs in a Cl

ion atmosphere, NdO2 is formed on the

surface, and it is judged to improve corrosion

resistance by first reacting with Cl.

4) ICCP can prevent corrosion of silver by sulfuric

acid, and NaCl 1 cm2 with 1.5 voltage.

5) To prevent corrosion of silver, it is necessary to

adjust the voltage according to the environment

according to the solution.

6) Corrosion of silver can be prevented with ICCP,

and contact pressure control according to the

environment is required.

REFERENCES

Graedel, T. E. "Corrosion mechanisms for silver exposed to

the atmosphere." Journal of the Electrochemical

Society 139.7 (1992): 1963-1970.

Wiesinger, R. et al. "Influence of relative humidity and

ozone on atmospheric silver corrosion." Corrosion

Science 77 (2013): 69-76.

Lin, Huang, G. S. Frankel, and W. H. Abbott. "Analysis of

Ag corrosion products." Journal of the Electrochemical

Society 160.8 (2013): C345-C355.

Wan, Y., E. N. Macha, and R. G. Kelly. "Modification of

ASTM B117 salt spray corrosion test and its correlation

to field measurements of silver corrosion." Corrosion,

The Journal of Science and Engineering 68.3 (2012):

036001-1.

Bazzi, R., et al. "Optical properties of neodymium oxides at

the nanometer scale." Journal of luminescence 113.1-2

(2005): 161-167.

Kanghou, Zhang, He Chunxiao, and Chen Lili. "500° C

Isothermal section of the Ag Cu Nd (0–34 at.%

neodymium) phase diagram." Journal of alloys and

compounds 189.1 (1992): L31-L33.

Ferro, R., et al. "Phase equilibria in the silver-neodymium

system." Journal of the Less Common Metals 35.1

(1974): 39-44.

CESIT 2020 - International Conference on Culture Heritage, Education, Sustainable Tourism, and Innovation Technologies

138