The Effectiveness of Activated Carbon and PAC in Reducing

Phosphate Levels in Laundry Liquid Waste

Hartono, Victor Trimanjaya Hulu, Frans Judea Samosir, Santy Deasy Siregar, Eva Ellya Sibagariang,

Marlinang I

. Silalahi and Apriliya Adha

Public Health Department, Universitas Prima Indonesia, Jl. Sekip, Medan, Indonesia

evasibagariang@yahoo.com

Keywords: laundry liquid waste, phosphates, activated carbon, PAC

.

Abstract: The presence of excessive phosphates in water bodies causes a phenomenon of eutrophication that

significantly enables algae and aquatic plants to multiply rapidly. The result of the laboratory test showed

the average initial phosphate content of laundry liquid waste before the study was 18

.4 mg/l. This research

aimed at comparing the efficacy of activated carbon and Poly Aluminum Chloride (PAC) in minimizing the

phosphate levels in liquid waste laundry X. The method used was a quasi-experiment research type with

pre-test and post-test design

. The population was all laundry X’s liquid waste as much as 18 liters from the

process of washing clothes collected by purposive sampling technique. The result of the research indicated

that there was a decrease in the average level of phosphates after the addition of activated carbon of 1 gr, 3

gr, 6 gr by 8

.16 mg/l while PAC of 1 gr, 3 gr, 6 gr by 4.66 mg/l. Thus, there is different effectiveness of

activated carbon and PAC in reducing phosphate levels. The addition of PAC with a dose of 6 grams is

more effective in reducing phosphate levels in laundry liquid waste.

1 INTRODUCTION

The increasing number of populations is directly

proportional to the growing needs for goods and

services. One of the fastest-growing industries

nowadays is the laundry service (Wasserbaur et al.,

2020). However, it could have both positive and

negative impacts. The positive implications for

service users are the affordable costs, time and

energy saving, and less burden of household

activities. By contrast, its negative impact is the

occurrence of pollution and environmental damage

due to the direct discharge of laundry liquid waste to

water bodies (Gordon et al., 2009). Laundry liquid

waste contains chemicals with high concentrations,

one of which is phosphate (Ahmad and EL-

Dessouky, 2008).

Phosphate is one of the nutrients which aquatic

plants need to grow and develop their lives (Xiong et

al., 2017). The presence of excessive phosphate in

water bodies causes a eutrophication phenomenon

(Miyazato et al., 2020). Therefore, in the laundry

industry, liquid waste that has been produced must

not be discharged directly to the environment. It

must be treated in advance so that it has a quality

that is in accordance with the established regulations

(Khosravanipour et al., 2019). For this reason, there

are several conventional techniques for treating

industrial laundry liquid waste, one of which is

chemical treatment using activated carbon and Poly

Aluminum Chloride (PAC) (Manouchehri and

Kargari, 2017).

A study showed that administering a dose of

activated carbon of 1 g L

-1

can reduce the maximum

phosphate content of 102 mg g

-1

(Mojoudi et al.,

2019). Likewise, the administration of an activated

carbon dose of 3 grams can reduce the highest levels

of phosphate, which is around 1.89 mg/l (Majid et

al., 2017). On the other hand, a study portrayed that

after being treated with the addition of PAC with

each dose of 0.3 gr; 0.4 gr; 0.5 gr; 0.6 gr; and 0.7 gr,

the phosphate levels decreased by 1.83 mg/l

(43.69%), 1.48 mg/l (54.46%), 1.43 mg/l (56%),

1.34 mg/l (58.77%) and 1.08 mg/l (66.77%). The

results of these studies indicate that the

administration of PAC has been effective in

reducing phosphate levels to reach the quality

standards of the Central Java regional regulation that

is equal to 2 mg/l (Andriani, Darundiati and

Dangiran, 2017). Also, the study by Chhetri et al.

174

Hartono, ., Hulu, V., Samosir, F., Siregar, S., Sibagariang, E., Silalahi, M. and Adha, A.

The Effectiveness of Activated Carbon and PAC in Reducing Phosphate Levels in Laundry Liquid Waste.

DOI: 10.5220/0010292201740180

In Proceedings of the International Conference on Health Informatics, Medical, Biological Engineering, and Pharmaceutical (HIMBEP 2020), pages 174-180

ISBN: 978-989-758-500-5

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

(2017) showed that giving a dose of PAC 7.5 mg

Al/L can reduce phosphate levels up to 28%. In

accordance with that, PAC also can reduce

phosphate levels up to 72% (Chu et al., 2018).

The research methods used in the previous

researches were descriptive research utilizing

laboratory experiments starting from the preparation

stage, such as the preparation of activated carbon

solutions, namely making ready-to-use solutions for

the examination of phosphate parameters by

repeating the treatment two times (Majid et al.,

2017). On the other hand, research conducted by

Andriani, Darundiati and Dangiran (2017) used a

true experimental research method with the posttest

control group design. This study used only one

treatment medium and did not make any

comparisons.

This study conducted a quasi-experimental

method with pre-test and post-test design. The

reduplication of the treatment was three times,

which was more than the study of Majid et al.

(2017). Thus, the result was far more accurate than

the two times repetition of the treatment. Even, a

research conducted by Andriani, Darundiati and

Dangiran (2017) only used activated carbon alone.

We can infer that the more treatment comparison

media used, the better it will be to know which one

is far more effective. Based on the above context,

research using activated carbon and PAC is required

to highlight the comparison of the efficacy of the

adsorbent and coagulant ingredients in reducing

phosphate levels in laundry liquid waste.

2 METHOD

The location of the study was at the Laboratory of

the Center for Environmental Health Technology

and Disease Control Class I Medan. The population

in the study was laundry X’s liquid waste from

clothes washing activities. In this study, the total

number of samples required was 18 liters. Each

treatment required one liter with three repetitions.

The samples in the study were collected by

purposive sampling technique based on the

considerations made by the researchers themselves.

The inclusion criteria were the laundry liquid waste

should be from the first washing process that comes

out of the disposal outlet and has not yet been

treated.

The materials used were laundry liquid waste,

activated carbon, PAC, and aquades. The instrument

used to measure phosphate levels at the pre and

posttest was spectrophotometry. There were several

stages, namely: the preparation stage where the

laundry liquid waste samples were carried out using

dilution because it was too concentrated; Then,

prepare the entire test sample, then pipette 2.5 ml

into an Erlenmeyer, then add aquades then cover it

and after make it homogeneous. For the pretest

sample, the stages were: a sample that had been

diluted before was pipetted as much as 10 mL,

added ten drops of PO4

-1

reagent into a test tube,

made in the vortex until being homogeneous, added

PO4

-2

reagent of 2 micro spoons (vertically done

when adding reagents), made in the vortex until

being homogeneous and wait for time reaction for

up to five minutes, then turn on the

spectrophotometry NOVA A-60 spectrophotometer,

select an auto selector for phosphate, insert the

prepared sample into a rectangular 50 mm cell and

record the results indicated on display.

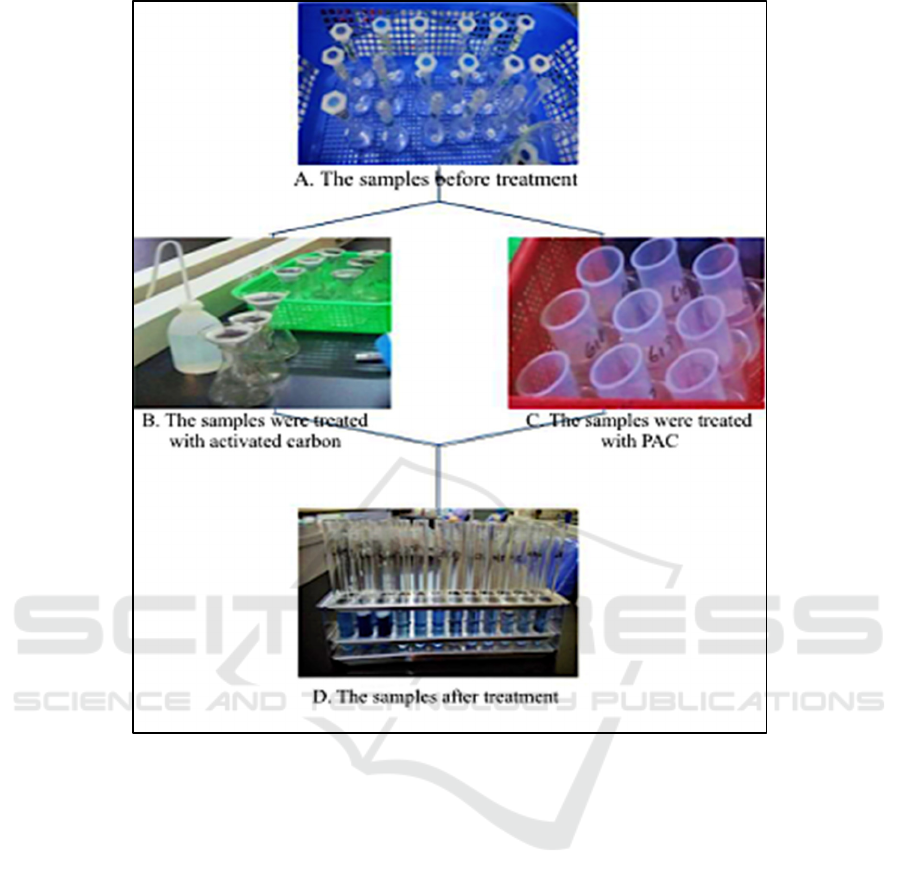

For activated carbon and PAC posttest sample: a

sample that had been diluted was put into tubes and

given the addition of activated carbon and PAC as

much as 1 gram, 3 grams, 6 grams in each tube, then

put into a centrifuge to be stirred with speed 400

rpm for 15 minutes. For the activated carbon sample,

the solution was filtered with filter paper. In

contrast, for the PAC sample, the solution was

precipitated for 30 minutes for the coagulation and

flocculation processes, then separate the filtrate from

the sludge when finished and do the same steps as in

the pretest. The research flow can be seen in Figure

1 below.

The Effectiveness of Activated Carbon and PAC in Reducing Phosphate Levels in Laundry Liquid Waste

175

Figure 1: Research flow

Univariate analysis was used to describe each

variable from the research results in a table, namely

the independent variable and the dependent variable.

Firstly, the bivariate approach used in this research

was the Shapiro-Wilk test for the test of normality,

as the number of samples was less than 50.

Secondly, a T-test was conducted to determinate the

differences in the efficacy of the pre-test and post-

test using activated carbon and PAC (Hulu and

Sinaga, 2019).

3 RESULTS AND DISCUSSION

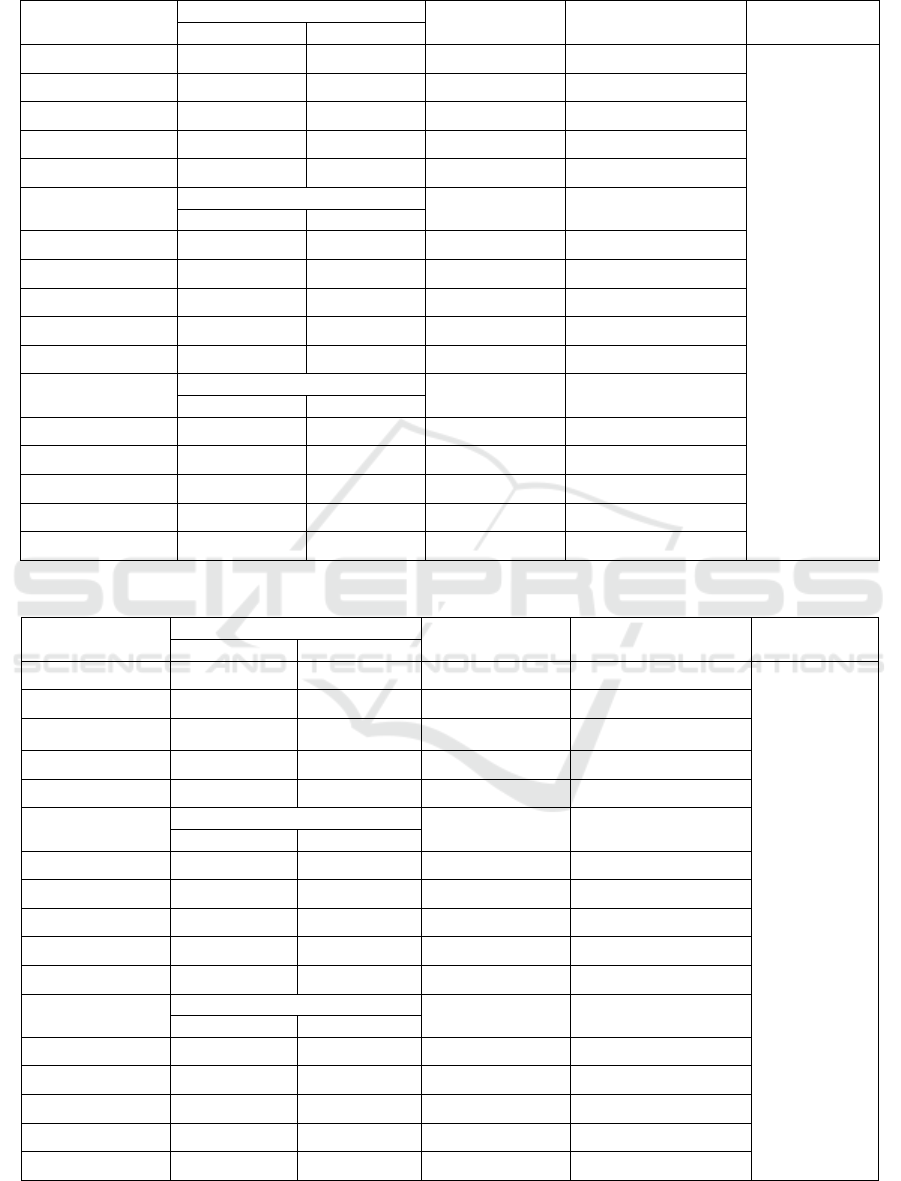

Table 1 depicts the laboratory examination results of

phosphate levels with the addition of activated

carbon. From table 1, each of the highest phosphate

levels in activated carbon 1 gr, 3 gr, and 6 gr occurs

in the third repetition of 7.3 mg/L (38.8 %); 11.9

(65.0%) and 13.8 mg/L (75.0%). Based on the

average active carbon research of 1 gr, 3 gr, 6 gr, it

was obtained that the average decrease in phosphate

levels as much as 12.1 mg/L (34.7 %); 7.3 mg/L

(60.2%) and 5.1 mg/L (72.5%). However, that result

has not been in accordance with the value of the

threshold of phosphate allowed by PerMenLH No.

05 of 2014 about the standard quality of liquid waste

of soap industry and detergent, namely 2 mg/L

HIMBEP 2020 - International Conference on Health Informatics, Medical, Biological Engineering, and Pharmaceutical

176

Table 1: The results of laboratory tests on phosphate levels before and after the addition of activated carbon 1 gr, 3 gr, 6 gr.

Repetition

Activated Carbon 1 g

r

Difference

(mg/l)

Effectiveness (%) NAB *

Pre Post

1

18

.1 12.7 5.4 29.8

2 mg/l

2

18

.7 12.1 6.6 35.3

3

18

.8 11.5 7.3 38.8

Total

55

.6 36.3 19.3 104.0

Average

18

.5 12.1 6.4 34.7

Repetition Activated Carbon 3

gr

Difference

(mg/l)

Effectiveness (%)

Pre Post

1

18

.5 7.5 11.0 59.5

2

18

.0 7.9 10.1 56.1

3

18

.3 6.4 11.9 65.0

Total

54

.8 21.8 33.0 180.6

Average

18

.3 7.3 11.0 60.2

Repetition Activated Carbon 6

gr

Difference

(mg/l)

Effectiveness (%)

Pre Post

1

18

.9 5.5 13.4 70.9

2

18

.6 5.3 13.3 71.5

3

18

.4 4.6 13.8 75.0

Total

55

.9 15.4 40.5 217.4

Average

18

.6 5.1 13.5 72.5

Table 2: The results of laboratory tests on phosphate levels before and after the addition of PAC 1 gr, 3 gr, 6 gr.

Repetition

PAC 1

gr

Difference (mg/l) Effectiveness (%) NAB *

Pre Post

1

18

.8 10.0 8.8 46.8

2 mg/l

2

18.2 9.0 9.2 50.5

3

18.1 7.6 10.5 58.0

Total

55.1 26.6 28.5 155.4

Average

18

.4 8.9 9.5 51.8

Repetition

PAC 3

gr

Difference (mg/l) Effectiveness (%)

Pre Post

1

18

.3 4.6 13.7 74.9

2

18

.0 4.0 14.0 77.8

3

18

.7 1.6 17.1 91.4

Total 55

10.2 44.8 244.1

Average

18

.3 3.4 14.9 81.4

Repetition

PAC 6

gr

Difference (mg/l) Effectiveness (%)

Pre Post

1

18.9 2.3 16.6 87.8

2

18.6 2.2 16.4 88.2

3

18.5 0.7 17.8 96.2

Total 56

5.2 50.8 272.2

Average

18

.7 1.7 16.9 90.7

The Effectiveness of Activated Carbon and PAC in Reducing Phosphate Levels in Laundry Liquid Waste

177

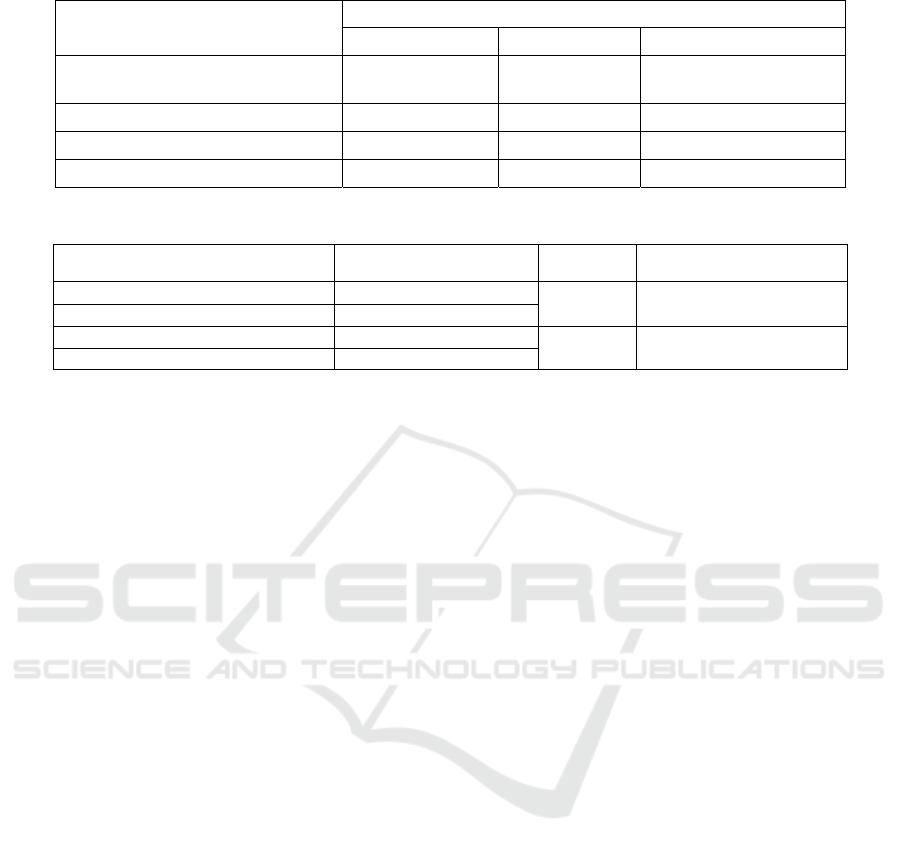

Table 3: The result of normality test Shapiro-Wilk.

Treatment

Sha

p

iro-Wil

k

Statistic Df Si

g

.

Before the addition of activated

carbon

.968 9 .875

After the addition of activated carbon .875 9 .139

Before the addition of PAC .951 9 .704

After the addition of PAC .902 9 .263

Table 4. The result of Sample Paired T-Test.

Treatment Mean Difference p-value

Pre-test of activated carbon 18.48

10.31 0.0001

Post-test of activated carbon 8.17

Pre-test of PAC 18.46

13.79 0.0001

Post-test of PAC 4.67

Table 2 indicates the laboratory examination of

phosphate levels with the addition of PAC. From

table 2, it is known that each of the highest decline

of phosphate levels in PAC of 1 gr, 3 gr, and 6 gr

occurs in the third repetition as 10.5 mg/l (58.0%);

17.1 mg/l (91.4%) and 17.8 (96.2%). The average

research results of PAC of 1 gr, 3 gr, 6 gr showed a

decrease in the average phosphate levels as much as

8.9 mg/L (51.8%), 3.4 mg/l (81.4%), and 1.7 mg/L

(90.7%). Based on the results, it shows that PAC

with dose 6 gr is already in accordance with the

value of the threshold of phosphate allowed by

PerMenLH No. 05 of 2014 about the standard

quality of liquid waste of the soap Industry and

detergent, namely 2 mg/L.

Table 3 shows the results of the Shapiro-Wilk

normality test for phosphate levels of laundry liquid

waste with various treatments. The p-value > 0.05 is

found in the procedures, so it can be confirmed that

the data distribution was normally distributed.

Because the data was normally distributed, it could

be continued with the Sample Paired T-Test.

Table 4 illustrates the results of the Sample

Paired T-Test. It shows the pre-test and post-test on

each activated carbon and PAC with treatment of 1

gr, 3 gr, 6 gr obtained a significance value (p-value)

of 0.0001 (<0.05). So, Ha was accepted with the

meaning that there was a difference in the average

effectiveness between activated carbon and PAC to

minimize phosphate levels in laundry liquid waste.

The average results of pretests and posttests of

activated carbon amounted to 18,48 mg/L and 8,17

mg/l with a difference of 10.31. Meanwhile, the

average result of pretests and posttests of the PAC

amounted to 18.46 mg/l and 4.67 mg/l with a

difference of 13.79. This suggests that PAC is more

effective at lowering phosphate levels with a much

higher difference than activated carbon.

This study shows that using activated carbon of 1

gr, 3 gr, and 6 gr did not indicate a phosphate

decline under the quality standards established by

PerMenLH No. 05 of 2014. Thus, the results are not

in line with the research conducted by Majid et al.

(2017) that described the initial level of laundry

liquid waste phosphate before being treated was 4.98

mg / l , then after being treated with activated carbon

as much as 1 gr, 2 gr, 3 g, the phosphate levels

decreased to 3.35 mg / l; 2.59 mg / l; 1.89 mg / l

respectively. From the result of the study, it can be

concluded that the administration of 3 grams of

activated carbon dosage was able to reduce the

highest levels of phosphate, which was around 1.89

mg / l. This research is also not in line with the study

of Utomo et al. (2018) regarding the reduction of

anonic surfactant and phosphate levels in laundry

wastewater. It described that the initial phosphate

content before adsorption was 14.148 ppm, then

after being treated with activated carbon with

particle variations, namely -60, -120 and -200 mesh,

it decreased. The result of lower phosphate level

with activated carbon showed that the phosphate

content after the treatment process was significantly

reduced below the detection limit. This is because,

based on the researchers' assumptions, this research

was not carried out by discharging wastewater into a

column whose surface contained activated carbon

adsorbents. In contrast, according to Perrich in

Maretha, Oktiawan and Rezagama (2014), the

process of activated carbon adsorbing phosphate

should be done by flowing liquid waste into the

column, resulting in contact and pressure between

HIMBEP 2020 - International Conference on Health Informatics, Medical, Biological Engineering, and Pharmaceutical

178

the adsorbent with liquid waste. Not only that, but

the size of activated carbon particles also affects the

adsorbent process. This study did not carry out

particle measurements, so the expected adsorption

process was also insignificant. While activated

carbon has a certain adsorption capacity. Thus, the

ability of activated carbon to adsorb phosphate is

limited to a value. Calculation of activated carbon

adsorption capacity of various particle sizes shows

that the smaller the particle size of activated carbon,

the higher the adsorption capacity. This can be

caused by the smaller particle size, which has a

larger surface area so that more activated carbon

sites or surfaces can be used as phosphates adsorbed.

The process of absorption by an adsorbent is

influenced by many factors and also has a specific

isothermal pattern of adsorption. Factors that

influence the adsorption process include the type of

adsorbent, the type of substance absorbed, the

surface area of the adsorbent, the concentration of

the adsorbed substance (Utomo et al., 2018). PH is

also considered to be an essential role during the

adsorption process, which affects adsorbate species

and surface charge density in adsorbents (Qu et al.,

2019).

Because of these factors, each adsorbent that

absorbs one substance with another substance will

not have the same pattern of adsorption isotherms.

This shows that the adsorption process that occurs

between activated carbon and phosphate is more

physical, where the bonds formed are physical bonds

with there being more than one surface layer

(multilayer). Besides, despite being able to create a

multilayer layer on the surface of activated carbon,

the anionic surfactant adsorption capacity also

remains influenced by the surface area of activated

carbon (Kurniyati, Sumarni and Latifah, 2015).

Meanwhile, after the addition of 1 gr, 3 gr, and 6 gr

PAC, there was a significant decrease in the 6 gr

PAC dose that was 1.7 mg / l (90.7%). This shows

that PAC is more effective in reducing phosphate

levels until it meets the established quality standard

of 2 mg / l.

This study is in line with the results of the

research by Andriani, Darundiati and Dangiran

(2017) that showed that the phosphate content in the

effluent liquid waste samples before treatment was

2.92 mg / l; 3.46 mg / l; 3.10 mg / l; 3.17 mg / l; and

3.59 mg / l. However, after being given the addition

of PAC treatment with each dose of 0.3 gr; 0.4 gr;

0.5 gr; 0.6 gr; and 0.7 gr the phosphate level

decreased, namely 1.83 mg / l (43.69%), 1.48 mg / l

(54.46%), 1.43 mg / l (56%), 1.34 mg / l (58.77%)

and 1.08 mg / l (66.77%). From the results of this

study, it can be concluded that the administration of

PAC has been effective in reducing phosphate levels

so that it is below the quality standard of the Central

Java Regional Regulation, which is 2 mg / l.

The low level of phosphate produced after the

addition of PAC shows that PAC can reduce the

level of phosphate, which is under the acceptable

threshold of the environmental quality standards.

The addition of PAC coagulants to the waste causes

colloids and other suspended particles to combine to

form heavy particles (floc). The coagulation process

can remove contaminants such as solid impurities

that cannot be removed by ordinary filtration.

Adding PAC coagulant to the waste will neutralize

negatively charged particles. That is because PAC

has a high positive charge and can bind colloids

strongly to form aggregates (Rohaeti, Febriyanti and

Batubara, 2010).

The addition of PAC coagulants causes elements

in liquid waste to experience instability. When the

PAC coagulant is added to the wastewater, PAC will

dissociate and the metal ions will undergo hydrolysis

and produce hydroxy complex ions, which are

positively charged so that they are adsorbed on the

negative colloidal surface. PAC has positive charge

characteristics and can bind aggregates tightly so

that it can attract and combine suspended particles in

the liquid waste (Rohaeti, Febriyanti and Batubara,

2010).

4 CONCLUSIONS

The average phosphate content before the study was

18.4 mg / l and still exceeds the quality standard set

in PerMenLH No. 05 of 2014. The addition of a 6 gr

PAC dose is more effective in reducing phosphate

levels in laundry liquid waste with an average

decrease amounted to 1.7 mg / l (90.7%). It was

below the quality standard of PerMenLH No.05 of

2014 concerning Wastewater Quality Standards for

Business Activities of Soap, Detergent, and

Vegetable Oil Products Industry that is equal to 2

mg / l. So it is recommended for the laundry service

industry to treat the liquid waste first before being

discharged into water bodies using a 6 gr PAC dose.

It is recommended for subsequent researchers to use

other coagulants such as alum to compare with the

PAC so that they can measure which one is more

effective in reducing phosphate liquid waste levels

in the laundry area, whether using an effective dose

of 6 grams or more.

However, this study has limitations, which are:

the study only examined one laundry center and only

The Effectiveness of Activated Carbon and PAC in Reducing Phosphate Levels in Laundry Liquid Waste

179

checked phosphate levels with two comparison

media. Therefore, future studies can involve more

industrial laundry premises and use more than two

coagulants or adsorbents that can be compared with

a larger number of samples.

ACKNOWLEDGMENTS

We sincerely appreciate the Universitas Prima

Indonesia that has provided great supports.

REFERENCES

Ahmad, J. and EL-Dessouky, H., 2008. Design of a

modified low cost treatment system for the recycling

and reuse of laundry waste water. Resources,

Conservation and Recycling, 52(7), pp.973–978.

Andriani, F., Darundiati, Y.H. and Dangiran, H.L., 2017.

Efektivitas PAC (Poly ALuminium Chloride) dalam

Menurunkan Kadar Fosfat pada Limbah Cair Rumah

Sakit Jiwa Prof. Dr. Soerojo Magelang. Jurnal

Kesehatan Masyarakat (e-Journal), 5(5), pp.659–665.

Chhetri, R.K., Klupsch, E., Andersen, H.R. and Jensen,

P.E., 2017. Treatment of Arctic wastewater by

chemical coagulation , UV and peracetic acid

disinfection.

Chu, Y., Li, M., Liu, J., Xu, W., Cheng, S. and Zhao, H.,

2018. Molecular insights into the mechanism and the

efficiency-structure relationship of phosphorus

removal by coagulation Yong-Bao. Water Research.

Gordon, A.K., Muller, W.J., Gysman, N., Marshall, S.J.,

Sparham, C.J., Connor, S.M.O. and Whelan, M.J.,

2009. Science of the Total Environment Effect of

laundry activities on in-stream concentrations of linear

alkylbenzene sulfonate in a small rural South African

river. Science of the Total Environment, The, 407(15),

pp.4465–4471.

Hulu, V. and Sinaga, T., 2019. ANALISIS DATA

STATISTIK PARAMETRIK APLIKASI SPSS DAN

STATCAL (Sebuah Pengantar Untuk Kesehatan).

Medan: Yayasan Kita Menulis.

Khosravanipour, A., Tareq, A., Carabin, A., Drogui, P.

and Brien, E., 2019. Journal of Water Process

Engineering Development of combined membrane fi

ltration , electrochemical technologies , and adsorption

processes for treatment and reuse of laundry

wastewater and removal of nonylphenol ethoxylates as

surfactants. Journal of Water Process Engineering,

28(February), pp.277–292.

Kurniyati, R., Sumarni, W. and Latifah, 2015. Pengaruh

Chitosan Beads dan Chitosan Beads Sitrat Sebagai

Penurun Kadar Fosfat dan ABS (Alkyl Benzene

Sulfonate). ndonesian Journal of Chemical Science,

4(2252).

Majid, M., Amir, R., Umar, R. and Hengky, H.K., 2017.

Efektivitas Penggunaan Karbon Aktif Pada Penurunan

Kadar Fosfat Limbah Cair Usaha Laundry Di Kota

Parepare Sulawesi Selatan. pp.978–979.

Manouchehri, M. and Kargari, A., 2017. Water recovery

from laundry wastewater by the cross flow

microfiltration process: A strategy for water recycling

in residential buildings. Journal of Cleaner

Production.

Maretha, A., Oktiawan, W. and Rezagama, A., 2014.

Pengolahan Limbah Laundry Dengan Penambahan

Koagulan Poly Alumunium Chloride (PAC) Dan Filter

Karbon Aktif. 3(4).

Miyazato, T., Nuryono, N., Kobune, M., Rusdiarso, B. and

Otomo, R., 2020. Journal of Water Process

Engineering Phosphate recovery from an aqueous

solution through adsorption- desorption cycle over

thermally treated activated carbon. Journal of Water

Process Engineering, 36(April), p.101302.

Mojoudi, N., Soleimani, M., Mirghaffari, N., Belver, C.

and Bedia, J., 2019. Uncorrected Proof through

physical and chemical activation Uncorrected Proof.

pp.1–12.

Qu, J., Meng, X., Zhang, Y., Meng, Q., Tao, Y. and Hu,

Q., 2019. A combined system of microwave-

functionalized rice husk and poly- aluminium chloride

for trace cadmium-contaminated source water puri fi

cation : Exploration of removal e ffi ciency and

mechanism. 379(June).

Rohaeti, E., Febriyanti, T.N. and Batubara, I., 2010.

Pengolahan Limbah Cair Dari Kegiatan Praktikum

Analisis Spot Test Dengan Koagulasi Menggunakan

Polialuminium Klorida. pp.141–148.

Utomo, W.P., Nugraheni, Z. V, Rosyidah, A., Shafwah,

O.M. and Naashihah, L.K., 2018. Penurunan Kadar

Surfaktan Anionik dan Fosfat dalam Air Limbah

Laundry di Kawasan Keputih , Surabaya

Menggunakan Karbon Aktif. 3(1), pp.127–140.

Wasserbaur, R., Sakao, T., Ljunggren, M., Plepys, A. and

Dalhammar, C., 2020. Resources , Conservation &

Recycling What if everyone becomes a sharer ? A

quantification of the environmental impact of access-

based consumption for household laundry activities.

Resources, Conservation & Recycling, 158(January),

p.104780.

Xiong, W., Tong, J., Yang, Z., Zeng, G., Zhou, Y. and

Wang, D., 2017. Journal of Colloid and Interface

Science Adsorption of phosphate from aqueous

solution using iron-zirconium modified activated

carbon nanofiber : Performance and mechanism.

Journal of Colloid And Interface Science, 493, pp.17–

23.

HIMBEP 2020 - International Conference on Health Informatics, Medical, Biological Engineering, and Pharmaceutical

180