Motor-less and Gear-less Robots: New Technologies for Service and

Personal Robots

Claudio Rossi

1 a

, William Coral

2 b

and Julian Colorado

3 c

1

Centre for Automation and Robotics UPM-CSIC, Madrid, Spain

2

Department of Mechatronics Engineering, Corporaci

´

on Universitaria del Huila, Colombia

3

School of Engineering, Pontificia Universidad Javeriana, Bogot

´

a, Colombia

Keywords:

Artificial Muscles, Smart Materials, Bio-inspired Robots.

Abstract:

In the last years, we have been working on exploring alternative actuation technologies for the future service

and personal robots. These shall allow designing lighter and safer robots, devoid of conventional mechanical

transmission mechanisms i.e. motor-less and gear-less robots. Here, we summarise our work with Shape

Memory Alloys. We show that, despite their known limitations, by finding suitable niches of application,

dedicated mechatronics design, and ad-hoc control strategies, SMAs can effectively be used as an alternative

actuation technology for robotic systems.

1 INTRODUCTION

The current state of the art on actuation technology is

essentially based on hydraulic/pneumatic and electro-

magnetic technology (servo-motors, gearboxes etc.).

Although current commercial actuators have reached

a notable degree of refinement, such technologies

have their foundations in the mid nineteenth century,

and still rely on the same basic principles. We be-

lieve that such technology faces several fundamental

limitations and may not be suited for the future gen-

erations of service robots. Future robots will come

out of the factories and work in close co-operation

with humans, in small workshops as well as in domes-

tic environments, as co-workers and home assistants

(see Box 1)

1

. In this context, it is difficult to imag-

ine a clockwork-like system made of several motors

and hundreds of gears. If the robotic device is to op-

erate in close relationship with humans, the safety of

the system will be a central issue. Furthermore, cur-

rent technology hardly allows creating robots whose

aspect (”look and feel”) can raise social acceptance.

The need for different actuators for safe human-

robot interaction is widely acknowledged. Currently,

a

https://orcid.org/0000-0002-8740-2453

b

https://orcid.org/0000-0002-3971-9536

c

https://orcid.org/0000-0002-6925-0126

1

Source of Box 1: Antonio Bicchi, University of Pisa,

URAI Conference, 2011

Box 1: Examples of new applications.

1

a growing research activity addressing this issue. In

fact, industrial robots need stiff actuators, (see Box

2)

2

. However, most of such systems still adopt classi-

cal mechanics technology, in complex mechanical de-

vices. As such, current robots are electro-mechanical

devices that are hard-bodied, usually heavy, bulky and

complex. In fact, even the most advanced robots move

in extremely clumsy and often dangerous ways.

In our view, a radical change in actuation technol-

ogy is essential for building the smaller, lighter, sim-

pler and safer robots that can share living and working

space with humans.

New actuation technology in functional or ”smart”

materials has opened new horizons in robotics actua-

tion systems. Materials such as piezo-electric fiber

composites, electro-active polymers and shape mem-

2

Source of Box 2: Raffaella Carloni, Univ. of Twente,

RoboNed Conference, 2011.

414

Rossi, C., Coral, W. and Colorado, J.

Motor-less and Gear-less Robots: New Technologies for Service and Personal Robots.

DOI: 10.5220/0007955004140421

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 414-421

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Box 2: Comparison between needs in industrial and new

robotics applications.

2

ory alloys (see Tab. 1) are being investigated as

promising alternatives to standard servomotor tech-

nology (Pons, 2005).

Recent research at out Laboratory, the Bioinspired

Systems Lab

3

of Centre for Automation and Robotics

UPM-CSIC, has focused on the use of SMAs for

building muscle-like actuators. SMAs are extremely

cheap, easily available commercially

4

and have the

advantage of working at low voltages.

SMAs are used in many different applica-

tion fields (M. Hashimoto et al., 1985),(Kurib-

ayashi, 1986),(Raynaerts and Brussel, 1991),(Ikuta,

1990),(Hunter et al., 1991),(Waram, 1993). They can

be used to generate and sense movement and even for

storing energy. Their applications cover many sector,

like, e.g., in deployable satellite antennas, sensors,

machinery, robotics to materials for the construction

of suspension bridges or anti-seismic devices.

SMAs are also being used in many non-invasive

surgery devices (Liu et al., 2011),(Hashimoto et al.,

1999),(Shi et al., 2011),(Ho et al., 2011),(Li et al.,

2006) and biomedicine, in devices such as stents and

tubular prosthetic devices.

In classical robotic systems, the use of SMAs

as linear actuators provides an interesting alternative

to the mechanisms used by conventional actuators.

SMAs allow to drastically reduce the size, weight

and complexity of robotic systems. In fact, their

large force-weight ratio, large life cycles, negligible

volume, sensing capability and noise-free operation

make possible the use of this technology for build-

ing a new class of actuation devices. Nonetheless,

high power consumption and low bandwidth limit this

technology for robotics applications.

In fact, due to such limitations, SMAs have not

raised the attention of the robotics technology for sev-

3

http://www.disam.upm.es/crossi/Bio Inspired Systems

Lab

4

NiTi (Nickel-Titanium) such as NiTinol

R

are the most

commonly commercially available SMAs.

eral years. Here, we claim that careful control de-

sign that takes into account the particular character-

istics of the material coupled with proper mechanic

design, significantly increases effectivity of SMAs as

robotics actuators. In fact, It has been demonstrated

that suitable control strategies and proper mechani-

cal arrangements can dramatically improve on SMAs

performance, mostly in terms of actuation speed and

limit cycles. Also, from the mechatronics point of

view, niches of applications can be found that greatly

benefit from this technology. Bio-inspired artificial

systems are one such niches.

It is clear, however, that SMAs (and smart mate-

rials in general) cannot, nowadays, be thought as a

universal substitute for classical servomotor technol-

ogy.

From our point of view, the limitations of SMAs

represented a challenge that needed to be addressed

from both mechatronics and control perspectives in

order to overcome these drawbacks.

Our work of the last years has demonstrated that

by (i) finding suitable niches of application, (ii) ded-

icated mechatronics design, and (iii) ad-hoc control

strategies, SMAs can effectively be used as an alter-

native actuation technology in a wide spectrum of ap-

plications and robotic systems.

Several other SMAs-based robotic systems have

been proposed in the literature that confirm our claim.

These will be described later in this Section.

One of the advantages of SMAs is that although

they are mostly used as actuators, they also have sens-

ing capabilities. Despite most of the SMAs physi-

cal parameters are strongly related in a nonlinear hys-

teresis fashion, the electrical resistance varies linearly

with the strain of the alloy. Because strain is kinemat-

ically related to the motion of the actuator (either lin-

ear motion or rotational), the electrical resistance and

the motion produced by the actuator are both linearly

related. This linear relationship between resistance

variation and motion is achieved because the marten-

site fraction is kinematically coupled to the motion,

and the martensite fraction is what drives the resis-

tance changes. This issue is an advantage for devel-

oping closed-loop position controllers that regulate

the SMAs actuation. In fact, most of the applica-

tions involving position linear control of SMAs, feed-

back electrical resistance measurements to estimate

the motion generated by the actuator. This avoids the

inclusion of external position sensors for closing the

control loop.

Motor-less and Gear-less Robots: New Technologies for Service and Personal Robots

415

Table 1: Main characteristics of functional materials.

Kind Variant Principle Pros Cons

Shape memory Shape Memory Alloys (SMAs) Electric current Price, availability small strain, speed

Magnetic Shape Memory (MSM) Electric field Contraction speed High power fields

Piezo-electric Direct Electric field Price, availability Small strain

Wave Electric field Price, availability

Electro-active Polymers Electronic Electric field Large strain High voltages

Ionic Electric field Large strain, low voltages Must be kept ”wet”

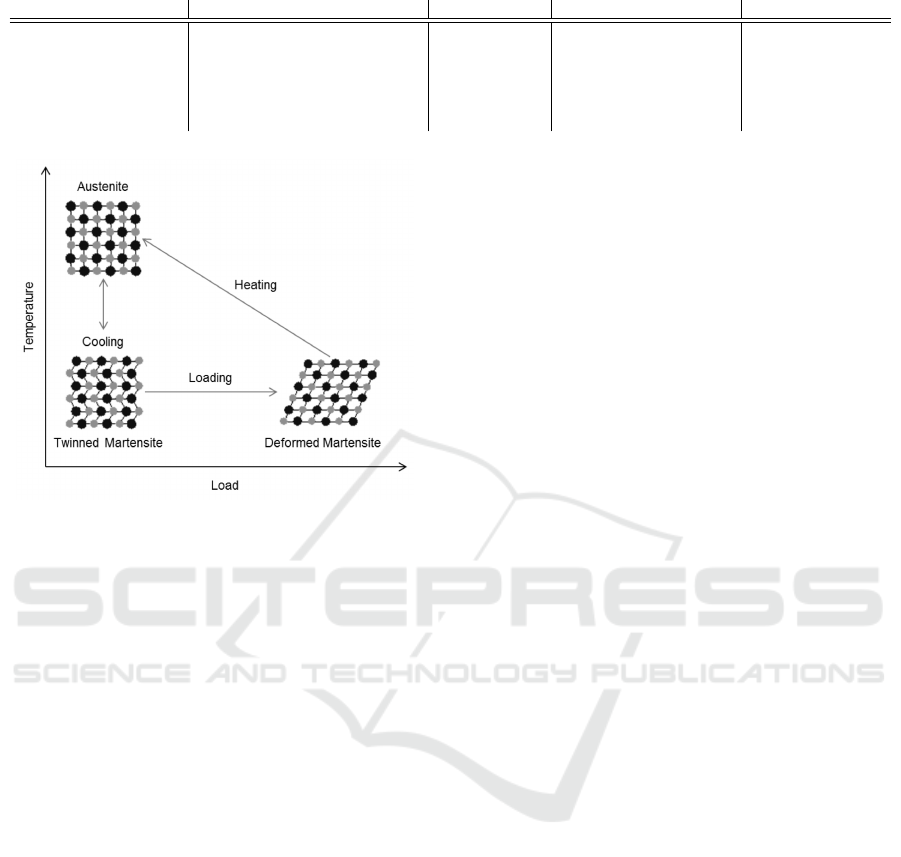

Figure 1: Microscopic viewpoint of the Shape Memory Ef-

fect.

1.1 SMAs Muscle-like Actuation for

Robotics

The use of SMAs as artificial muscles allows for more

”natural” actuation (Hunter and Lafontaine, 1992).

SMAs wires can act as muscle fibers. SMAs can pro-

vide an excellent actuation technology, in that they are

activated by electrical signals, have a large pull force

excellent strength-to-weight ratio.

We re fer the reader to (Coral et al., 2012) for a re-

view of the most representative robots and structures

that integrate SMAs as muscle-like actuation mecha-

nisms.

2 RECENT WORK AT THE

BIOINSPIRED SYSTEMS LAB:

iTuna, BR

3

AND BaTboT

In this section, we describe our recent results on two

SMAs-actuated bio-inspired robots. The iTuna and

the BR

3

are fish-like underwater robot whose main

feature is to use SMAs wires to bend the continuous

structure that constitutes the backbone of the fish. The

BaTboT is a Flapping Wings Micro Aerial Vehicle

(FWMAV) capable of changing its wings’ geometry

by means of SMAs-based muscles.

These prototypes have been conceived and de-

signed specially in order to exploit the particular fea-

tures of SMAs-based actuation. In fact, as mentioned

earlier, in order to make the best of SMAs-based ac-

tuation, we do not have to think at them as substi-

tute of other actuation techniques in already existing

mechanical setups. Specific application niches and

mechanical needs exist where SMAs are not only a

valid alternative, but even outperform classical actua-

tion means.

2.1 iTuna: A Bending Structure

Swimming Robotic Fish

The iTuna (Rossi et al., 2011) is a swimming fish-like

robot imitates some key features fish biomechanics.

Its actuation system takes inspiration from the ar-

rangement of the red or slow-twitch muscles. In real

fishes, such muscles are used for bending their flex-

ible backbone. Alike, the main mechnical structure

of the iTuna robot is a continuous flexible backbone,

composed of polycarbonate of 1mm thickness.

Three antagonistic pairs of SMAs-based actuators,

parallel to the body produce the independent bending

of three body segments of 8.5cm length. This actua-

tion is similar to the one produced by fish red mus-

cles. This antagonistic configuration of the SMAs

wires has the advantage that both directions of mo-

tion (contraction and elongation) can be actively con-

trolled.

In the iTuna, NiTi SMAs wires with a diameter

size of 150µm were adopted. These have a pull force

of 230grams − f orce at consumption of 250mA at

room temperature, and a nominal contraction time of

1 second.

Under nominal operation such SMAs could bend

the body segments up to 28 degrees, even if SMAs

wires only contract approximately 4% of their length.

By increasing the input electrical current and includ-

ing a suitable control that handles the overheating of

the SMAs, contraction time of 0.5s was achieved, and

strain could be increased up to 6%.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

416

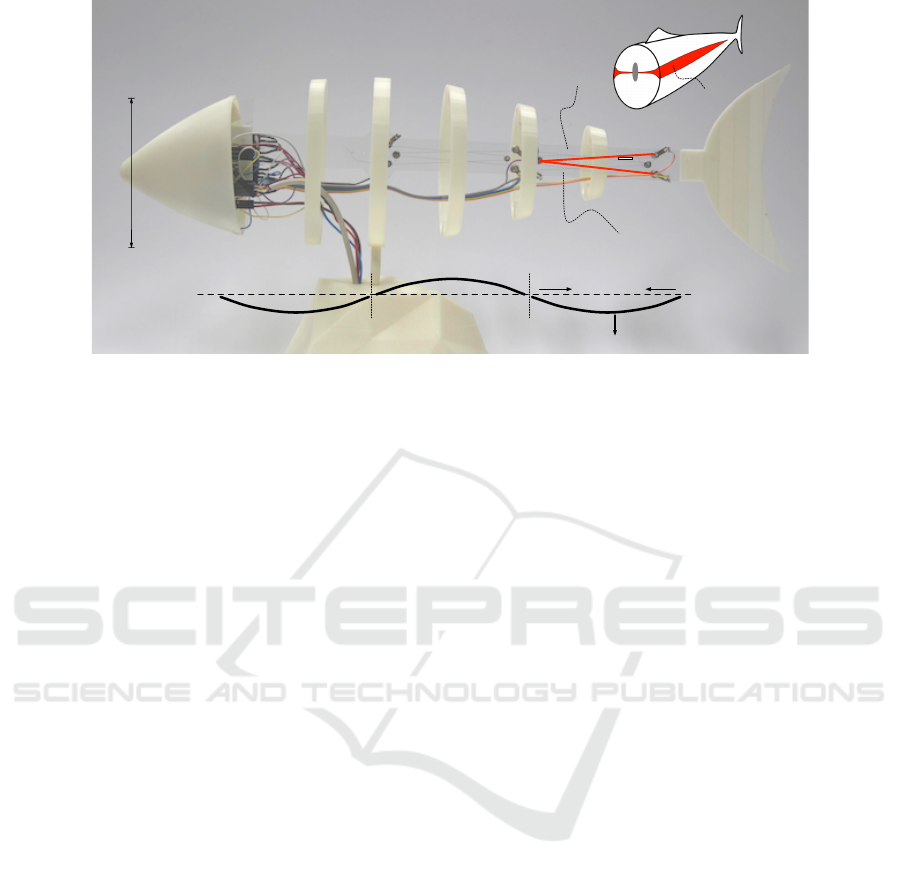

SMA Wire

1mm thick

polycarbonat

e backbone

Red muscles

Figure 2: Main structure of the iTuna robot fish.

2.1.1 SMAs Control in the iTuna

In order to address the two main limitations of SMAs

(slack in the fibers, and limited actuation speed) we

deigned a low-level PID controller. Slack issues are

due to a two-way memory effect during operation

(Featherstone, 2008), while actuation speed is limited

by to the switching time between cooling and heating

phases. To address the first problem, a pre-heating

mechanism was developed. The pre-heating prevents

the inactive alloys from complete cooling, thus short-

ening the heating phase (fiber’s contraction). Addi-

tionally, the antagonistic arrangement provides an ex-

ternal stress to the cooling wire by the active antag-

onistic wire, that sums to the stress provided both by

the elastic backbone. Working with an already-warm

wire allows for a faster stretch and slack issues are

avoided. Resistance measurements were used as a

feedback signal for closed-loop control. We refer the

reader to (Rossi et al., 2011) and (Rossi et al., 2010)

for more details.

The control developed also allowed overloading

the SMAs with up to 350mA peak current accelerating

the heating phase, but preventing it from overheating

that could cause physical damage of the SMAs. Over-

loading has allowed for achieving a 1Hz oscillation

time (i.e. 0.5 seconds contraction and cooling times)

and a bending angle of 36 degrees of each body seg-

ment.

The iTuna experience showed that an ad-hoc

mechatronics design and a suitable control (together

with a deeper understanding of the SMAs physics) al-

low taking advantage of SMAs and overcoming some

of their limitations.

2.2 Black Bass: The Evolution of iTuna

Then a second version of iTuna was created under

the name ”Bioinspired and Biomimetic Black Bass

Robot” (BR

3

) (Coral et al., 2018). This was based on

a new design, but still used to move the same working

principle of iTuna. It also included many significant

improvements related to mechatronic design and con-

trol algorithms. The main purpose was to get closer

to a commercial version of a robot fish that could be

used in the agro-alimentary sector. The robotic bass is

inspired by the Sea Bass due to its relevance because

this is the second most important species (in produc-

tion volumes) in Mediterranean aquaculture.

Similarly with the iTuna, the BR3 has a back-

bone made of flexible polycarbonate structure of 1

mm thick and 263 mm long, but it differs from it since

it has two rectangular holes along where the SMAs

are located. This allows us to reduce the effective

cross section of the structure by 50%, thus reducing

the force required to bend it and optimizing the force

made by the SMAs. These holes also prevent SMAs

from overstretching when the backbone is bent. Con-

sidering that the SMAs only contract 4% of their total

length, this overstretching causes the loss of contrac-

tion for which the bending angle is smaller and con-

sequently the thrust will be smaller. For this reason

these holes were one of the great improvements in the

BR3 with respect to the iTuna. Another of the im-

provements to the backbone was to include 20 spines

along the structure that support the solid ribs that were

printed using ABS plastic. These ribs increase the

mass of the robot and provide support to the skin al-

lowing obtain smoother body curves.

In order to obtain more precise bending angle

measurements, the BR

3

was equipped with four flex

sensors (see Fig. 3) distributed along the backbone.

Motor-less and Gear-less Robots: New Technologies for Service and Personal Robots

417

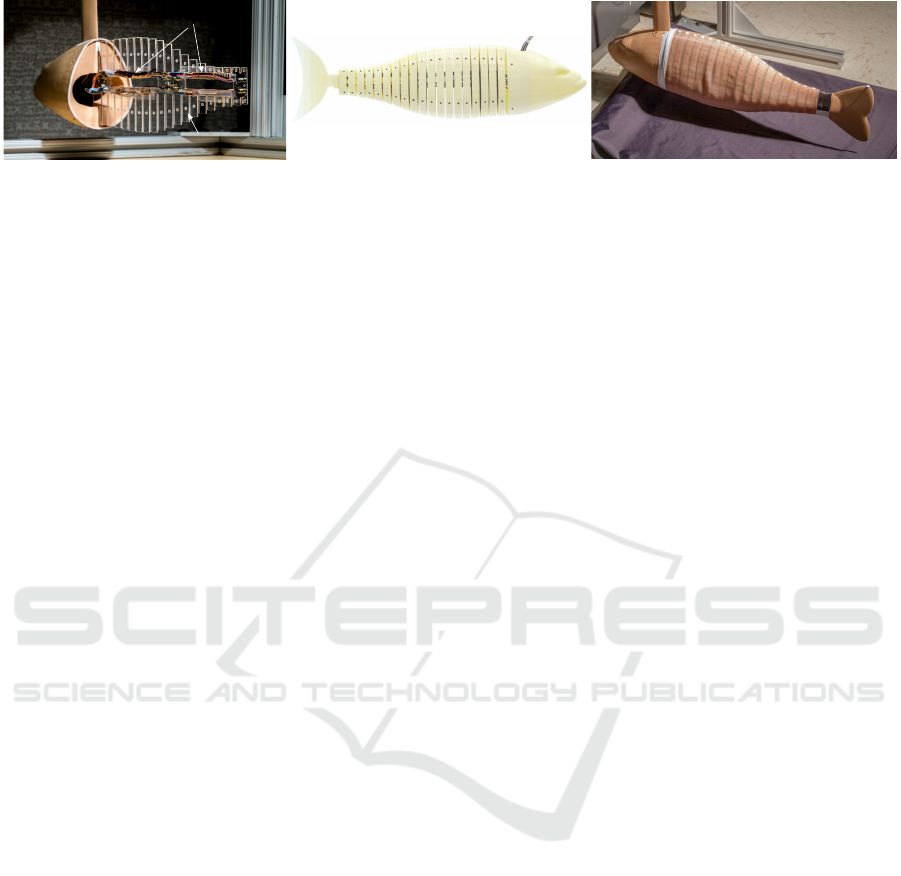

Flex Sensors

Backbone

Figure 3: Left: Backbone and flex sensor used to control the bending angle and frequency; Centre: Complete structure

printed with a 3D printer and ABS plastic; Right: Complete structure wearing our own fabricated microfiber lycra mesh

between two silicone layers, that we called skin.

These provide a less noisy signal with respect to the

current sensors used in the iTuna to compute SMAs

contraction. Current sensors were also used in the

BR

3

as a safety measure to prevent high currents on

the SMAs and avoid damaging them. Due to the use

of flex sensors the control of the SMAs is now based

on the measurement of the bending. Thus in the BR

3

we have a high level control that generates the swim-

ming patterns and a low level control that measures

the bending of the backbone and controls the amount

of electric current that is sent to the SMAs.

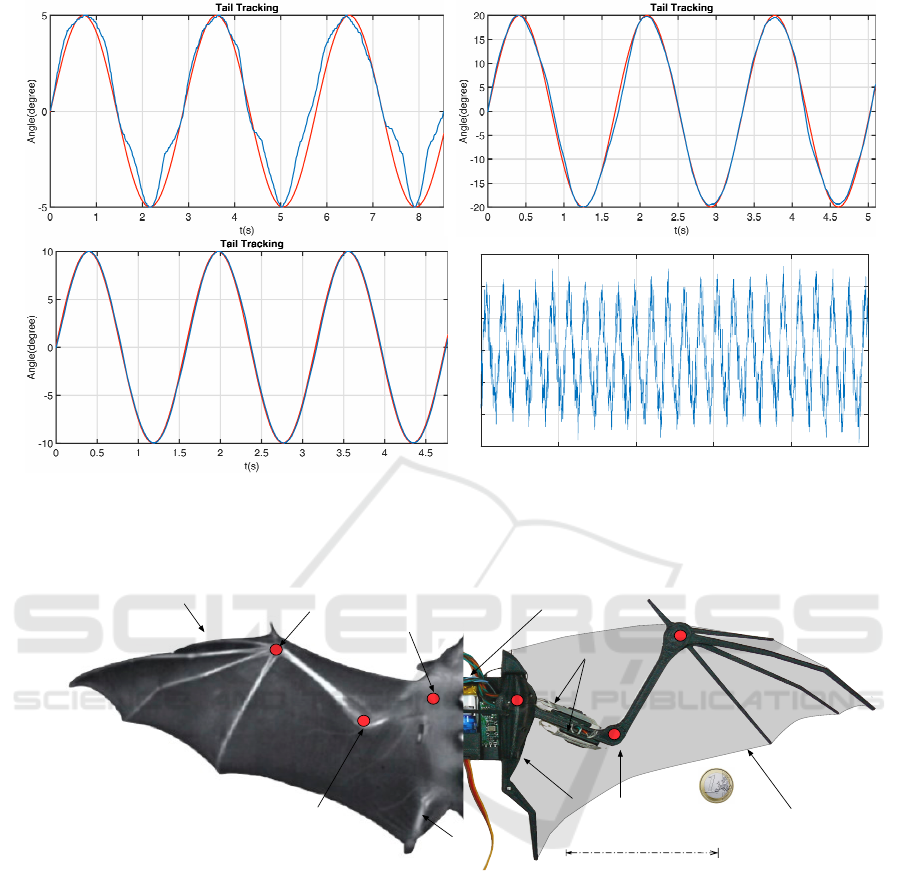

In order to determine if the BR3 can trace an accu-

rate trajectory we have tested in three different config-

urations: Air/Backbone without ribs, Air/Backbone

Ribs and Skin, and Water/Backbone Ribs and Skin.

For each one we set different amplitude and frequency

values. Figure 4 shows one of these tests including the

thrust generated by the fish in the water. We made a

Particle Tracking Visualisation (PTV) to trace the tra-

jectory of the tail by using a reference spot placed at

the top of the tail.

2.3 BaTboT: a Biologically-inspired

Bat-like Aerial Robot

BaTboT was one of the first a bio-inspired bat robot

that SMAs as artificial muscles for changing the ge-

ometry of the wings (Colorado et al., 2012). Wing ge-

ometry control is what makes biological bats capable

of extremely agile maneuvering at low flight speed.

Biological studies (Swartz et al., 2005), (Hedenstr

¨

om

et al., 2009), (Iriarte-D

´

ıaz et al., 2011), (Riskin et al.,

2010) have revealed that real bats are able to maneu-

ver because of the inertial forces and torques pro-

duced by the changing the wings’ shape during flap-

ping. Such features are highly desirable in Micro

Aerial Vehicles (MAVs).

With the BaTboT project we attempted to mimic

bats maneuvering system, reproducing the bio-

mechanical design of the wings, and tackling the chal-

lenge of controlling their shape. In Micro Aerial Vehi-

cles, the weight of the components is clearly a critical

issue. This is why ”classical” actuation technologies

were considered not suitable for the purpose. SMAs

were adopted because of their extremely low (actually

negligible) weight, and high force-to-weigh ratio.

In the BaTboT, the SMAs actuators used are the

commercial Migamotor NanoMuscle model RS-70-

CE (Migamotors, 2019). Each NanoMuscle consists

of several short strips of SMAs NiTi wire with a

thickness of 150µm attached to opposite ends of six

metal strips stacked in parallel. Each SMAs segment

pulls the next strip about 0.67mm relative to the pre-

vious strip, and the relative movements sum to make

a stroke of 4mm. Two Migamotors muscles have been

arranged into an antagonistic configuration working

as artificial biceps and triceps that provide the rota-

tion motion of the wing elbow’s joint. The range of

motion of the joint is about 60

◦

. Figure 5 shows the

detail of the BaTboT’s wing.

In (Colorado et al., 2012) we presented the proto-

type and the results of the experiments carried out, fo-

cused at evaluating the use of SMAs as artificial mus-

cles to change of wing’s morphology. Simulations

and experiments wern carried out aimed at quantify-

ing the Power-to-Force tradeoff of the SMAs muscles

working under two operation modes: nominal and

overloaded. Nominal-mode implies an input heating

current between 175mA and 350mA, and overloaded-

mode, between 400mA and 600mA.

AS for the iTuna, overloading allows for reducing

the heating-time of the SMAs, therefore increasing

the contraction speed and the overall actuation fre-

quency. Again, overloading was monitored to avoid

overheating issues that could cause physical damage

of the fibres.

In the work presented in (Colorado et al., 2012),

we also investigated SMAs fibers fatigue issues, and

how overloading can accelerate their appearance,

which causes a loss of performances as far as both

pull force and contraction speed is concerned. We

found that after approximately 5 minutes of contin-

uum SMAs overloaded operation, actuation speed

drastically decreases about 56%. This limitations in

SMAs bandwidth conducted us to investigate how to

achieve Batbot maneuvers while flapping and morph-

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

418

Time, s

110 115 120 125 130 135

Force, grams-force

-60

-40

-20

0

20

40

60

Swimming force

Figure 4: Carangiform swimming pattern for Top left:Air/Backbone without ribs at 0.34Hz and amplitude 5 degrees; Top

right:Air/Backbone Ribs and Skin 0.6Hz and amplitude 20 degrees; Bottom left:Water/Backbone Ribs and Skin 0.6Hz and

amplitude 10 degrees; Bottom right:Thrust at 1Hz and amplitude 10 degrees.

......

shoulder joint

elbow joint

wrist joint

leg

SMA actuators

3D-printed structure

and bones

On-board electronics:

(battery, IMU, SMA power

drivers, microcontroller)

10 cm

digits

0.1 mm thick

silicone membrane

Figure 5: BaTboT mechatronics compared to its biological counterpart.

ing the wings at low frequencies. In fact, some bats

are able to achieve both lifting and inertial forces by

just modulating wing inertia, thus, undergoing large

body accelerations. Since bat’s wings have heavy

muscles and bones, the inertial effect plays a signif-

icant role in a bats flying maneuvers, even more im-

portant than aerodynamic forces.

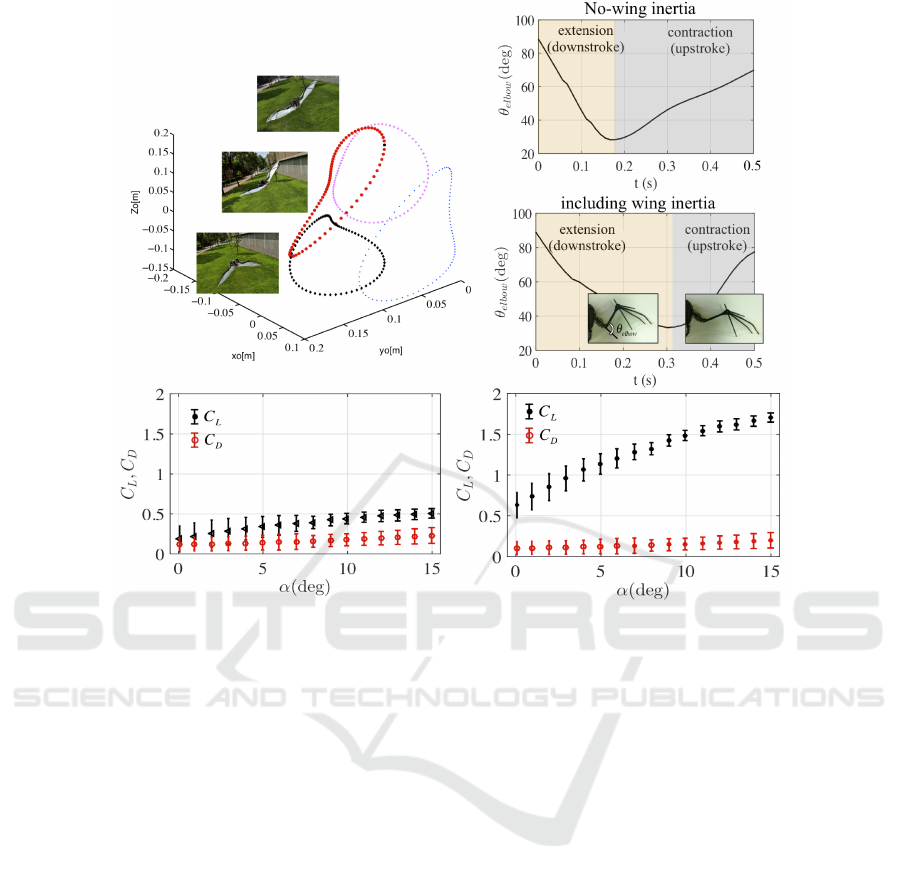

In (Colorado et al., 2013), we developed a novel

inertial-based controller to properly modulate wing

inertia to generate attitude movements. We inves-

tigated how to achieve forward and turning flight

maneuvers by just flapping and morphing BatBot’s

wings at 2Hz. Wind tunnel experiments showed that

net body forces increased about 23% thanks to the

bio-inspired contraction and extension of both wings

during a wingbeat (morphing modulation). More im-

portantly, thanks to the inclusion of inertial informa-

tion of both wings within the control law, causing that

the upstroke portion of the wingbeat cycle generates

more lift and less drag due to the fact that the elbow

joint contracts sufficiently to reduce the wing area at

minimum span. Figure 6 shows experimental results

supporting these conclusions.

Motor-less and Gear-less Robots: New Technologies for Service and Personal Robots

419

Figure 6: Different wing modulation profiles and their effect in lift and drag generation: Top Left: forward-turning maneuver

including wing-tip Cartesian trajectories. Top right: The plots detail wing contraction/extension during a wingbeat cycle. In

the upper plot, the wing inertial model is not considered, thus, the controller is not capable to compensate the drag payload of

the wings during the upstroke. In the lower plot, the upstroke time is reduced thanks to the inertial effect included. Bottom

left: lift and drag forces generated with the wing modulation from the upper plot in Top right:, wheres Bottom right: shows

lift and drag forces generated with the modulation from the lower plot in Top right:. As a result, lifting forces are tripled.

3 CONCLUSIONS

New generations of service and personal robots will

need new actuation technologies.

In our work, we have investigated the use of Shape

Memory wires as linear actuator for this purpose. Our

work has demonstrated that by

• Designing dedicated mechatronics

• Deepening the understanding of their physical be-

havior

• Developing ad-hoc control strategies

SMAs can provide an effective technology that allows

building simpler and lighter robots. Such features

that may contribute to their safety, and ultimately al-

low robots to share living and working space with hu-

mans.

Even if SMAs cannot substitute classical servo-

motor and hydraulic technology in general, we have

shown that they can effectively compete with, and

even outperform standard actuation technology.

We have also shown that, cleverly designed con-

trol strategies, that exploit the knowledge of the

physics of the material and of its behavior over time,

together with dedicated mechanic setups can help

overcoming their limitations.

We ha also found that, while some of the limita-

tions of the SMAs can be overcome, another limita-

tion, such as fatigue is seldom considered in the litera-

ture, an shall be further investigated in order to obtain

the best performance.

In conclusion, we can say that Shape Memory

Alloys, and functional materials in general, have a

great potential to be used in future robotic systems,

although they need to be investigated more. In com-

parison with electric motors and hydraulic actuators,

that have more than a century of history, functional

materials are still in their infancy.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

420

ACKNOWLEDGEMENTS

The research leading to these results has re-

ceived funding from RoboCity2030-DIH-CM Madrid

Robotics Digital Innovation Hub (”Rob

´

otica aplicada

a la mejora de la calidad de vida de los ciudadanos.

fase IV”; S2018/NMT-4331), funded by ”Programas

de Actividades I+D en la Comunidad de Madrid” and

cofunded by Structural Funds of the EU.

REFERENCES

Colorado, J., Barrientos, A., Rossi, C., and Breuer, K.

(2012). Biomechanics of smart wings in a bat robot:

morphing-wings using SMA actuators. Bioinspiration

& Biomimetics.

Colorado, J., Barrientos, A., Rossi, C., and Parra, C. (2013).

Inertial attitude control of a bat-like morphing-

wing air vehicle. Bioinspiration & Biomimetics,

8(1):016001.

Coral, W., Rossi, C., Colorado, J., Lemus, D., and Barri-

entos, A. (2012). Sma-based muscle-like actuation in

biologically inspired robots: A state of the art review.

In Berselli, G., Vertechy, R., and Vassura, G., editors,

Smart Actuation and Sensing Systems, chapter 3. Inte-

chOpen, Rijeka.

Coral, W., Rossi, C., Curet, O. M., and Castro, D. (2018).

Design and assessment of a flexible fish robot actuated

by shape memory alloys. Bioinspiration & biomimet-

ics, 13(5):056009.

Featherstone, R. (2008). An Architecture for Fast and

Accurate Control of Shape Memory Alloy Actua-

tors. The International Journal of Robotics Research,

27(5):595–611.

Hashimoto, M., Tabata, T., and Yuki, T. (1999). Develop-

ment of electrically heated SMA active forceps for la-

paroscopic surgery. IEEE International Conference

on Robotics and Automation Cat No99CH36288C,

3(May):2372–2377.

Hedenstr

¨

om, A., Johansson, L. C., and Spedding, G. R.

(2009). Bird or bat: comparing airframe design

and flight performance. Bioinspiration biomimetics,

4(1):015001.

Ho, M., McMillan, A. B., Simard, J. M., Gullapalli,

R., and Desai, J. P. (2011). Toward a Meso-

Scale SMA-Actuated MRI-Compatible Neurosurgical

Robot: Robotics, IEEE Transactions on. Robotics

IEEE Transactions on, PP(99):1–10.

Hunter, I. W. and Lafontaine, S. (1992). A comparison of

muscle with artificial actuators. In SolidState Sensor

and Actuator Workshop 5th Technical Digest IEEE,

pages 178–185.

Hunter, I. W., Lafontaine, S., Hollerbach, J. M., and Hunter,

P. J. (1991). Fast reversible NiTi fibers for use in mi-

crorobotics. In Micro Electro Mechanical Systems,

pages 166–170. Ieee.

Ikuta, K. (1990). Micro/miniature shape memory alloy ac-

tuator. In International Conference on Robotics and

Automation, volume 3, pages 2156–2161. IEEE Com-

put. Soc. Press.

Iriarte-D

´

ıaz, J., Riskin, D. K., Willis, D. J., Breuer, K. S.,

and Swartz, S. M. (2011). Whole-body kinematics

of a fruit bat reveal the influence of wing inertia on

body accelerations. Journal of Experimental Biology,

214(Pt 9):1546–1553.

Kuribayashi, K. (1986). A New Actuator of a Joint Mecha-

nism Using TiNi Alloy Wire. The International Jour-

nal of Robotics Research, 4(4):47–58.

Li, W. D., Guo, W., Li, M. T., and Zhu, Y. H. (2006). Design

and Test of a Capsule Type Endoscope Robot with

Novel Locomation Principle. 2006 9th International

Conference on Control Automation Robotics and Vi-

sion, 20(02):1–6.

Liu, X., Luo, H.-Y., Liu, S.-P., and Wang, D.-F. (2011). Pilot

study of SMA-based expansion device for transanal

endoscopic microsurgery. In 2011 International Con-

ference on Machine Learning and Cybernetics, pages

1420–1424. IEEE.

M. Hashimoto, Takeda, M., Sagawa, H., Chiba, I., and Sato,

K. (1985). Application of shape memory alloy to

robotic actuators. J. of Robotic Systems, 2(1):3–25.

Migamotors (2019). Migamotors Company, 2012, Avali-

able from: http://www.migamotors.com/.

Pons, J. L. (2005). Emerging Actuator Technologies: A Mi-

cromechatronic Approach. Wiley.

Raynaerts, D. and Brussel, H. V. (1991). Development of a

SMA high performance robotic actuator. In Fifth In-

ternational Conference on Advanced Robotics Robots

in Unstructured Environments, pages 61–66. Ieee.

Riskin, D. K., Iriarte-D

´

ıaz, J., Middleton, K. M., Breuer,

K. S., and Swartz, S. M. (2010). The effect of body

size on the wing movements of pteropodid bats, with

insights into thrust and lift production. Journal of Ex-

perimental Biology, 213(Pt 23):4110–4122.

Rossi, C., Colorado, J., Coral, W., and Barrientos, A.

(2011). Bending continuous structures with SMAs :

a novel robotic fish design. Bioinspiration biomimet-

ics, 045005(4):045005.

Rossi, C., Coral, W., and Barrientos., A. (2010). SMA Con-

trol for Bio-mimetic Fish Locomotion. In Interna-

tional Conference on Informatics in Control, Automa-

tion and Robotics (ICINCO), Madeira.

Shi, Z., Liu, D., Ma, C., and Zhao, D. (2011). Accurate con-

trolled Shape Memory Alloy Actuator for Minimally

Invasive Surgery. Self, pages 817–822.

Swartz, S. M., Bishop, K. L., and Ismael-Aguirre, M. F.

(2005). Dynamic complexity of wing form in bats:

implications for flight performance. Functional and

evolutionary ecology of bats, pages 110–130.

Waram, T. (1993). Actuator Design Using Shape Memory

Alloys. T.C. Waram.

Motor-less and Gear-less Robots: New Technologies for Service and Personal Robots

421