Synthesis of Glycerol –– Castor Oil Fatty Acid and Glycerol –– Oleic Acid

Esters, as Emulsifier and Antibacterial Agent, Using Candida rugosa Lipase

Elmira Vania Denada

1

, Sri Handayani

1

Sumi Hudiyono

1

and Siswati Setiasih

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Indonesia, Depok 16424, West Java,

Indonesia

Keywords: Castor Oil, Glycerol, castor oil fatty acid, ester, oleic, emulsifier, antibacterial, Candida rugosa

Abstract: The research’s objective is to synthesize glycerol – castor oil fatty acid and glycerol oleic acid esters using

Candida rugosa lipase in n-hexane. Molar fatty acid to glycerol ratio that used in esterification varied from

1:1, 1:2, 1:3, and 1:4. The ester products then being analysed by using FTIR. The spectra for glycerol-castor

oil fatty acid ester and glycerol-oleic acid absorption peak at wave number 1735.37 cm

-1

and 1748.25 cm

-1

respectively, which indicate the existence of C=O ester groups. Conversion percentage in esterification was

conducted using titrimetric method. The highest conversion percentage was reached at the molar ratio 1:4

with the value of 92.4% respectively for glycerol-castor oil fatty acid and 86.2% for glycerol oleic ester.

Emulsifier test was performed to observe the stability and the type of emulsion, using ester product as

emulsifier. The properties of the emulsifier in both esters are obtained by type of water in oil. Antimicrobial

assay were also conducted for both esterification product using disc diffusion method against

Propionibacterium acne and Staphylococcus epidermidis. The antimicrobial assay showed that glycerol-

castor oil fatty acid esters has antimicrobial activity, but glycerol-oleic esters did not show the antimicrobial

activity.

1 INTRODUCTION

Castor oil from castor bean plant has many benefits,

such as biodiesel source, plantation commodities,

pharmacology, natural insecticides, and also as basic

materials for moisturizers and cosmetics (Alvarez

and Rodiguez, 2000; Amir and Hartono, 2013;

Santoso et al, 2014). Generally, 89% from all of

fatty acid in castor oil is ricinoleic (Omari et al,

2015). Ricinoleic can be obtained by hydrolysis of

castor oil which involves high pressure and

temperature in the presence of catalyst (Yamamoto

and Fujiwara, 1995). This reaction will produce

glycerol and ricinoleic fatty acid.

Ricinoleic fatty acid from castor oil may gain

higher economic value by converting them into lipid

derivate compounds. Lipids in the form of

monoglycerides or diglycerides are often used as

emulsifiers for cosmetics. Fatty acid monoesters are

one of the compounds from lipid derivates, which

have the highest antibacterial activity against gram

positive and gram negative bacteria (Zhao et al,

2015).

The esterification reaction between fatty acid and

glycerol is capable of producing glycerol derivative

compounds such as monoglycerides, diglycerides,

and triglycerides. The glycerol monoester compound

has significant applications in food, pharmaceutical,

cosmetics, and even detergent industries (Pouilloux

et al, 2000). Mono- and diglycerides may also serve

as emulsifiers. In addition, Kosová, et al (2015) and

Handayani, et al (2018), stated that fatty acid

glycerol ester has antimicrobial activity. In

conventional chemical methods, esterification

processes often involve acid catalysts. However, this

method provides an unwanted by-product (Zaidi et

al 1995), so that esterification using enzymes – such

as lipase – is more commonly used in modern

chemical methods.

Lipase is a hydrolase enzyme. Candida rugosa

lipase often used as catalyst in the reaction of

triglyceride hydrolysis. Candida rugosa lipase can

also be used as a catalyst in esterification reactions.

However, it should be in a certain condition, namely

the small amount of water and the use of organic

solvents (Zaks and Klibanov, 1984).

62

Denada, E., Handayani, S., Hudiyono, S. and Setiasih, S.

Synthesis of Glycerol â

˘

A ¸Sâ

˘

A ¸S Castor Oil Fatty Acid and Glycerol â

˘

A ¸Sâ

˘

A ¸S Oleic Acid Esters, as Emulsifier and Antibacterial Agent, Using Candida rugosa Lipase.

DOI: 10.5220/0008357500620068

In Proceedings of BROMO Conference (BROMO 2018), pages 62-68

ISBN: 978-989-758-347-6

Copyright

c

2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 MATERIALS AND METHODS

2.1 Materials

Aquades, Candida rugosa lipase (2.45 U/mg)

from Sigma-Aldrich, 96% ethanol, castor oil,

commercial glycerol, Clindamycin, DMSO 10%,

eosin, hydrogen chloride, n-hexane, nutrient broth,

nutrient agar, oleic acid, phenolphthalein, phosphate

buffer pH 8, potassium hydroxide, sodium

hydroxide, Propionibacterium acnes and

Staphylococcus epidermidis bacteria, are materials

used in this study.

2.2 Methods

2.2.1 Hydrolysis of Castor Oil

Castor oil hydrolysis conducted by mixing 100

grams of the compound with 100 mL KOH 5 M in

ethanol, heated and stirred using hotplate for 2 hours

at 70±2

o

C. The mixture were then allowed to reach

room temperature and added by 50 mL HCl 5 M

while stirring for two hours. The castor oil fatty acid

was obtained by let the mixture stand for 24 hours

until two phased formed. The upper phase were

taken as castor oil-fatty acid.

2.2.2 Esterification Reaction

Esterification delivered by mixing fatty-acid,

glycerol, n-hexane (as a solvent) and Candida

rugosa lipase as biocatalyst. Solvent to substrate

ratio was 1:1 (v:v) while fatty acid to glycerol ratio

were varied among 1:1, 1:2, 1:3, and 1:4 (mol:mol)

and for enzyme use was 5% of the substrate’s total

mass. Horizontal incubator was used to incubate the

mixture. The incubation process was carried out on

18 hours at 200 rpm and 37

o

C. Termination for the

esterification reaction obtained by heating the

mixture at ±80

o

C to denaturate the enzyme. To

separate the mixture, centrifugation process was

executed at 3400 rpm in 15 minutes. Each of the

layers formed were separated and the middle one

was taken as an ester product.

2.2.3 Conversion Percentage Determination

The percentage of conversion determined by

titrimetric method. 0.1 N NaOH employed to titrate

the hexane phase (upper-phase), and

phenolphthalein was involved as an indicator.

2.2.4 Ester Product Characterization using

FTIR

FTIR was used to characterized the ester product,

castor oil, oleic acid, and castor oil-fatty acid.

2.2.5 Emulsifier Test

Oil and water mixed with 0.1 g ester products to

test the emulsion properties. The oil and water

amounts shown on Table 1. The mixture were

shaken using vortex for 30 seconds and the stability

of the emulsion was observed.

Table 1. Oil and Water Amount

Water (mL)

Oil (drops)

Variation

One

2

10

Water (drops)

Oil (mL)

Variation

Two

10

2

2.2.6 Emulsion Type Determination

A drop of emulsion and eosin respectively were

mixed on an object glass. Then the mixture was

observed under the microscope to define the type of

emulsion, whether oil in water (o/w) or water in oil

(w/o).

2.2.7 Antimicrobial Activity Assay

Clindamycin which used as positive control are

involved in Antimicrobial activity assay. The

activity was performed with disc diffusion method

towards castor oil, castor oil-fatty acid, ester

products, glycerol, n-hexane and DMSO as solvent,

and oleic acid. In a sterile petri dish, 20 mL nutrient

agar mixed aseptically with 2 x 10

2

μL aliquot of

Propionibacterium acnes suspension which its cell

density is 1 x 10

8

cells/mL. The medium were then

allowed to harden. Then, the top of the medium

placed by paper disc and 400 x 10

-2

μL sample was

dropped to it. Incubation for the medium was held at

37

o

C for 24 hours. The microbial activity calculated

based on the diameter of the clear zone on the

medium. This assay were also done for

Staphylococcus epidermidis.

Synthesis of Glycerol â

˘

A¸Sâ

˘

A¸S Castor Oil Fatty Acid and Glycerol â

˘

A¸Sâ

˘

A¸S Oleic Acid Esters, as Emulsifier and Antibacterial Agent, Using

Candida rugosa Lipase

63

3. RESULT AND DISCUSSION

3.1 Castor Oil Hydrolysis

The catalyst used for hydrolysis reaction was

potassium hydroxide. Ethanol, as a semi polar

compound, used for this reaction to be an

intermediary of potassium hydroxide and

triglycerides which leads the reaction to be occurred.

The mixture was then added by HCl to acidify and

form the fatty acid. Yield percentage obtained was

87.5%.

3.2 Esterification

This reaction was catalysed by Candida rugosa

lipase in organic solvent with small amount of water.

Although Candida rugosa as hydrolase enzyme, it is

often used as a catalyst in hydrolysis reaction. In this

case it can also be used as a catalyst in the

esterification reaction with requirement of organic

solvent and small amounts of water (Zaks and

Klibanov, 1984). In this study, n-hexane was used as

solvent in the enzymatic esterification. n-hexane, the

non-polar compound, is capable to dissolve fatty

acid. Phosphate buffer pH 8 was used to optimize

Candida rugosa lipase and dissolve glycerol.

Candida rugosa lipase has a low activity when the

pH used is less than 6.0 or more than pH 8.0

(Öztürk, 2001).

The molar ratio variation of fatty acid:glycerol

were intended to observed the optimum formation of

ester and also to keep the reaction equilibrium in the

direction of the ester. The highest ester product

produced by using molar ratio 1:4. The ester formed

supposed to be mono- or diglycerides since the

amount of fatty acid used was lower than the

glycerol.

3.3 Conversion Percentage Determination

The three layers from centrifugation process on

esterification were separated and the top layer was

used to determine the conversion percentage.

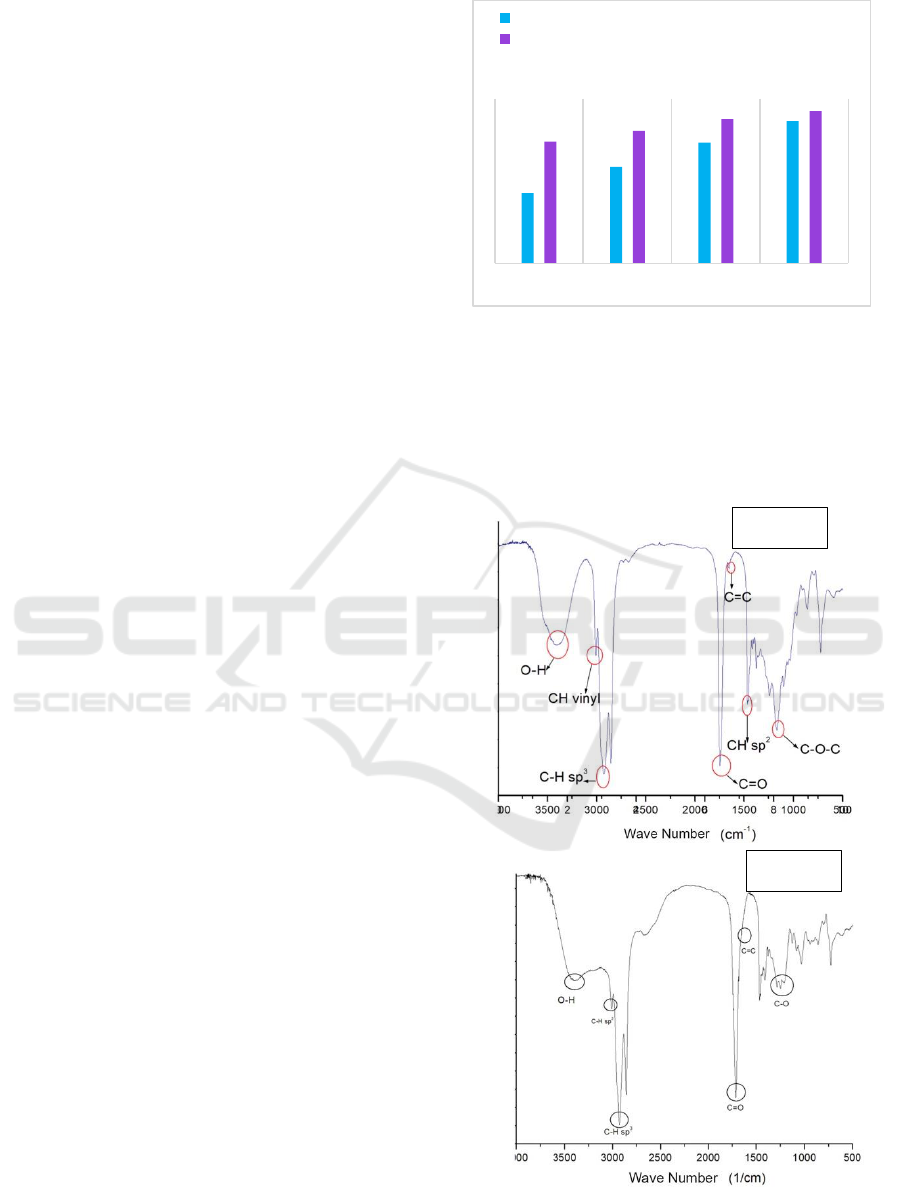

Figure 1 describe the conversion percentage from

all of variations (mol:mol). The highest percentage

was reached at the molar ratio 1:4 (fatty

acid:glycerol) with value of 92.4% for ester

glycerol-castor oil fatty acid and 86.2% for ester

glycerol oleic acid.

Figure 1. The Curve of Variation of Mol vs Percentage of

Convertion

3.4 Ester Products Characterization by FTIR

Figure 2 and Figure 3 below show the IR

spectrum of castor oil, castor oil-fatty acid, oleic

acid and ester products.

[VALUE]%

[VALUE]%

[VALUE]%

[VALUE]%

[VALUE]%

[VALUE]%

[VALUE]%

[VALUE]%

1 : 1 1 : 2 1 : 3 1 : 4

Ester Glycerol Oleic

Ester Glycerol Castor Oil - Fatty Acil

a)

b)

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

64

Figure 2. FTIR Spectrum of a) Castor Oil, b) Castor Oil-

fatty acid, c) Oleic Aid

FTIR spectrum above shows the presence of CH

sp

2

vinyl group which indicates the presence of

double bonds in castor oil and castor oil-fatty acid

hydrolysis. In addition, there is also a C=O

functional group detected in castor oil, but its wave

number shifts when the castor oil has been

hydrolysed to fatty acids. The C=O functional group

in castor oil is identified as C=O carboxylate at wave

number 712.97 cm

-1

(Figure 2a). Then on the castor

oil-fatty acid, the functional group identified as C=O

ester at wave number 1745.65 cm

-1

(Figure 2b). Oleic

acid has a typical functional group, specifically C=O

carboxylate (714.61 cm

-1

) and CH sp

2

vinyl

(3009.97 cm

-1

) (Figure 2c). CH sp

2

vinyl group

indicates the presence of double bond of the

compound. As well known, oleic acid has a double

bond on C

9

and C

10

.

Figure 3. a) Ester Glycerol Oleic, b) Ester Glycerol-Castor

Oil Fatty Acid

Figure 3a. proves that oleic acid has been

esterified, since the spectrum states the presence of

C=O ester groups at wave number 1748.25 cm

-1

. In

addition, there are also OH groups (3319.63 cm

-1

)

whose peaks look widened. The presence of a

widened OH group caused by the hydroxyl group

present in glycerol is not fully esterified.

Furthermore, the absorption band of the carboxylate

group is still visible, so it can be said the ester

glycerol oleic still contain oleic acid.

Figure 3b. shows the absorption band of the OH

functional group of the compound (3410.07 cm

-1

).

The carbon chain of the ester compound is shown by

the functional group CH sp

3

(2923.53 cm

-1

). The

identical group of esters, obtained as the C=O ester

group (1735.37 cm

-1

) has been shown. It can be said

that the castor oil-fatty acid results have been

esterified.

Those functional groups as existed in Silverstein

et al (1981), the spectrum of CH sp

2

vinyl is in the

range 3010 - 3100 cm

-1

, whereas C=O ester is in the

range 1735 - 1750 cm

-1

and C=O carboxylic acid at

1700-1725 cm

-1

, also OH is at 3200 - 3400 cm

-1

, and

CH sp

3

at 2850 - 3000 cm

-1

.

3.5 Emulsifier Test

Result of the emulsifier test indicates that the

ester glycerol oleic and ester glycerol-castor oil fatty

acid have emulsifier properties.

The emulsifier test showed that ester glycerol-

castor oil fatty acid and ester glycerol oleic have

emulsifier properties. The emulsion of ester glycerol

-castor oil fatty acid more stable than the emulsion

of ester glycerol oleic (Figure 4). The emulsions

stable up to 36 hours for ester glycerol-castor oil

fatty acid and 24 hours for ester glycerol oleic.

b)

c)

a)

Synthesis of Glycerol â

˘

A¸Sâ

˘

A¸S Castor Oil Fatty Acid and Glycerol â

˘

A¸Sâ

˘

A¸S Oleic Acid Esters, as Emulsifier and Antibacterial Agent, Using

Candida rugosa Lipase

65

Figure 4. Emulsion test results; a) Variation Two of Ester

Glycerol-Castor Oil Fatty acid, b) Variation One of Ester

Glycerol-Castor Oil Fatty Acid, c) Variation One of Ester

Glycerol-Oleic, d) Variation Two of Ester Glycerol-Oleic.

3.6 Emulsifier Type Determination

Figure 5. Emulsion type of; a) Ester Glycerol-Castor Oil

Fatty Acid, b) Ester Glycerol Oleic

Emulsion’s type was determined through

observation under a microscope. Eosin was added

as a water-soluble dye because of its polar nature. So

that the water phase will change colour to red. The

presence of eosin makes it easy to observe the type

of emulsion because the water phase and the oil

phase will have different colours.

The ester glycerol casto oil-fatty acid and ester

glycerol oleic have a water-in-oil emulsion type

(w/o) (Figure. 5). The red droplets are water, and the

yellow environment is oil.

3.7 Antibacterial Activity Assay

Propionibacterium acnes and Staphylococcus

epidermidis were used in this study. Ester glycerol-

castor oil fatty acid as well as ester glycerol oleic,

were varied in 20%, 40%, 60%, and 80% (w/w).

This variation were used to determine the best

concentration of esters that can inhibit bacterial

growth. Table 2 shows the classification of

antimicrobial effectiveness substances (Greenwood,

1995). Table 3 shows the antimicrobial activity.

Table 2. Classification of Antimicrobial Effectiveness

Inhibition Zone

Diameter

Response of Growth

Barriers

> 20 mm

Strong

16 – 19 mm

Average

10 – 15 mm

Poor

< 10 mm

Ineffective

Table 3. Inhibition Zone of Various Compounds in Antibacterial Activity Assay

Sample

Inhibition Zone Diameter (mm)

Classification

P. acnes

S. epidermidis

Ester Glycerol-Castor Oil Fatty Acid 20%

-

-

No Activity

Ester Glycerol-Castor Oil Fatty Acid 40%

7

9

Ineffective

Ester Glycerol-Castor Oil Fatty Acid 60%

9

9

Ineffective

Ester Glycerol-Castor Oil Fatty Acid 80%

12

10

Poor

Ester Glycerol Oleic 20%

-

-

No Activity

Ester Glycerol Oleic 40%

-

-

No Activity

Ester Glycerol Oleic 60%

-

-

No Activity

Ester Glycerol Oleic 80%

-

-

No Activity

Castor Oil Fatty Acid 50%

12

14

Poor

Castor Oil Fatty Acid 100%

13

15

Poor

Oleic Fatty Acid

-

-

No Activity

Castor Oil 100%

-

-

No Activity

n-hexane 100%

-

-

No Activity

Glycerol 100%

-

-

No Activity

DMSO 100%

-

-

No Activity

Clindamycyn 0.5%

18

15

Average

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

66

The data above shows that there was no

antimicrobial activity from oleic acid and esters

glycerol oleic against Staphylococcus epidermidis

and Propionibacterium acnes. The absence of

antimicrobial activity also found in glycerol, n-

hexane, and DMSO. It clearly shows that the solvent

used in this study has no antimicrobial activity.

In general, the increases of concentration in test

compounds were able to produce larger inhibition

zone diameters for both types of bacteria (Table 3).

Ester glycerol-castor oil fatty acid has the highest

value at 80% concentration by producing 12 mm

inhibition zone for Propionibacterium acnes

bacteria. In the same concentration, the ester is

capable of providing 10 mm inhibition zone for

Staphylococcus epidermidis bacteria. Thus, it can be

said that ester glycerol-castor oil fatty acid has a

stronger inhibitory effect against P. acnes.

The inhibition zone can also be found in castor

oil-fatty acid. The highest diameter at 100%

concentration with 13 mm and 15 mm, respectively

for P. acnes and S. epidermidis. Castor oil fatty acid

and ester glycerol-castor oil fatty acid are in the

same classification of inhibitory resistance, which is

poor. Inhibition zones of clindamycin are 18 mm

for P. acnes and 15 mm for S. epidermidis. This

researched showed that ester glycerol-castor oil fatty

acid have the activity for antimicrobial agent.

4 CONCLUSIONS

Glycerol – castor oil fatty acid and glycerol –

oleic esters were successfully synthesized using

Candida rugosa lipase as catalyst. Both ester

products can be used as emulsifier for water in oil

(w/o) emulsion type. Only glycerol-castor oil fatty

acid ester has antimicrobial activity.

ACKNOWLEDGEMENTS

This researched was funded Hibah Kompetensi

Publikasi Internastional Terindeks Untuk Tugas

Akhir Mahasiswa (PITTA), Universitas Indonesia

2018.

REFERENCES

Alvarez, Antonio M R., Maria L G Rodiguez., 2000.

Lipids in Pharmaceutical and Cosmetic

Preparation. Grasas y Aceites, 51 (1-2), 74 – 96.

doi: 10.3989/gya.2000.v51.i1-2.409

Amir, Andi M., Joko Hartono., 2013. Toksisitas

Insektisida Nabati Minyak Biji Jarak Kepyar

(Ricinus communis L.) Terhadap Thrips

Selenothrips rubrocinctus Giard. Seminar

Nasional Inovasi Teknologi Pertanian. Balai

Penelitian Tanaman Pemanis dan Serat Malang,

Malang.

Greenwood., 1995. Antibiotics Susceptibility

(Sensitivity Test), Antimicrobial and

Chemotheraphy. USA: McGraw Hill Company.

Handayani, S., Putri, A. T., Setiasih, S., &

Hudiyono, S., 2018. Enzymatic Synthesis of

Glyserol-Coconut Oil Fatty Acid and Glycerol-

Decanoic Acis Ester as Emulsifier and

Antimicrobial Agents Using Candida rugosa

Lipase EC 3.1.1.3. IOP Conference Series:

Materials Science and Engineering,299, 012019.

Kosová, M., Hrádková, I., Mátlová, V., Kadlec, D.,

Šmidrkal, J., & Filip, V., 2015. Antimicrobial

effect of 4-hydroxybenzoic acid ester with

glycerol. Journal of Clinical Pharmacy and

Therapeutics,40(4), 436-440.

Santoso, Bambang B., et al., 2014. Hasil dan Kadar

Minyak Jarak Kepyar pada Berbagai Umur

Pemangkasan Batang Utama. J. Agron. Indonesia

42 (3) : 233 -249

Omari, Athumani., et al., 2015. Fatty Acid Profile

and Physio-Chemical Parameters of Casor Oils

in Tanzania. Green and Sustainable Chemistry 5:

154-163

Öztürk, Banu., 2001. Immobilization of Lipase from

Candida rugosa on Hydrophobic and

Hydrophilic Support. Izmir Institute of

Technology, Turkey.

Pouilloux, Y., Métayer, S., & Barrault, J., 2000.

Synthesis of glycerol monooctadecanoate from

octadecanoic acid and glycerol. Influence of

solvent on the catalytic properties of basic

oxides. Comptes Rendus De LAcadémie Des

Sciences - Series IIC - Chemistry,3(7), 589-594.

Silverstein, R.M.; Bassler, G.C.; and Morrill,

T.C., 1981. Spectrometric Identification of

Organic Compounds. 4th ed. New York: John

Wiley and Sons. QD272.S6 S55

Yamamoto, K., & Fujiwara, N. (1995). The

Hydrolysis of Castor Oil Using a Lipase from

Pseudomonas sp. f-B-24: Positional and

Substrate Specificity of the Enzyme and

Optimum Reaction Conditions. Bioscience,

Biotechnology, and Biochemistry,59(7), 1262-

1266. doi:10.1271/bbb.59.1262

Synthesis of Glycerol â

˘

A¸Sâ

˘

A¸S Castor Oil Fatty Acid and Glycerol â

˘

A¸Sâ

˘

A¸S Oleic Acid Esters, as Emulsifier and Antibacterial Agent, Using

Candida rugosa Lipase

67

Zaidi, A., Gainer, J. L., & Carta, G. (1995). Fatty

acid esterification using nylon-immobilized

lipase. Biotechnology and Bioengineering,48(6),

601-605.

Zaks, A., Klibanov, A. M., 1984. Enzymatic

Catalysis in organic Media at 100

o

C. Science

224:1249-1251.

Zhao, Lei., et al., 2015. In Vitro Antibacterial

Activities and Mechanism of Sugar Fatty Acid

Esters Against Five Food-related Bacteria.

Journal of Food Chemistry 187: 370-377

BROMO 2018 - Bromo Conference, Symposium on Natural Products and Biodiversity

68