The Effects of Additional Treatment of Activated Coal on the

Increase of Special Characteristics of Gas Diffused Cathods of

Aluminum-air Electrochemical Generator

Elena Alexandrovna Kiseleva

*

, Andrey Zinov’yevich Zhuk, Kleymenov Boris Vladimirovich and

Victor Petrovich Zakharov

Joint Institute for High Temperatures of the Russian Academy of Sciences, Izhorskaya st.13 Bd. 2, Moscow, Russia 125412

Keywords: Carbon materials, iron-cobalt-nitrogen-containing pyrocatalyst

Abstract: The possibility of a significant increase in the specific characteristics due to the treatment of carbon

materials with ammonia is shown in the work. In the course of the work, techniques were developed for

processing a carbon material with aqueous ammonia and pure ammonia, a procedure for the synthesis of an

iron-cobalt-nitrogen-containing catalyst. It has been established that the additional processing of carbon

materials with ammonia improves the characteristics of the experimental samples due to the deposition of

nitrogen-containing functional groups on the surface: for activated carbon from coal raw materials brand

UAF treated at 900 ° C, a current density of 0.041 mA / cm

2

is achieved at a polarization of -0.3 V. It is

shown that the application of iron- cobalt-nitrogen-containing pyrocatalyst synthesized on a activated

carbon brand UAF well catalyzes the oxygen reduction reaction.

1 INTRODUCTION

Currently, much attention is paid to solving the

problems of creating environmentally friendly

autonomous current sources with high energy

intensity for use in various portable electronic

devices, in transport and in electric power industry,

which is caused by environmental pollution by using

hydrocarbon fuels, whose share in large cities is over

90% (Zhuk et al., 2012).

Metal-air energy sources based on aluminum are

promising because they have a high theoretical and

feasible specific energy intensity (250-400 Wh / kg),

low cost, they are environmentally friendly and fire-

proof. Currently, the specific power of air-aluminum

elements is limited by the specific power of the air

electrode (gas diffusion cathode). When discharging

air-aluminum elements with an alkaline electrolyte

at a working temperature of 60 ° C, the current

density at the aluminum anode can reach 1000 mA /

cm

2

, while the current density at the gas diffusion air

cathode is several times lower (150-300 mA / cm

2

).

The most critical and complex component of an Al-

air element is a gas diffusion cathode, which is

responsible for the reduction of air oxygen, and

determines the specific power and working life of

the current source.

The reduction of oxygen can be carried out in

two parallel ways (Bidault et al., 2009; Cheng and

Chen, 2012):

a) by a four-electron reaction to a hydroxide ion:

O

2

+ 2H

2

O + 4e- = 4OH

-

E

0

O

2

/ OH- = + 0.401 V,

b) by a two-electron reaction to hydrogen

peroxide:

O

2

+ H

2

O + 2e- = HO

2

-

+ OH

-

E

0

= -0.076 V

The resulting hydrogen peroxide, depending on

the properties of the catalyst, is then either reduced

to OH

-

or decomposed into oxygen and water.

In order to intensify the process of oxygen

reduction, it is carried out in a porous,

hydrophobized electrode. The efficiency of such an

electrode is determined both by the activity of the

catalyst used and the porous structure formed during

the hydrophobization process, which should have an

optimal ratio of hydrophobic and hydrophilic pores

(Chervin et al., 2012).

In addition to the catalytically active layer, the

GDС, as a rule, contains a hydrophobic layer, the

task of which is to prevent the electrolyte from

getting wet on the back side of the cathode and to

34

Kiseleva, E., Zhuk, A., Vladimirovich, K. and Zakharov, V.

The Effects of Additional Treatment of Activated Coal on the Increase of Special Characteristics of Gas Diffused Cathods of Aluminum-air Electrochemical Generator.

DOI: 10.5220/0008185000340037

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 34-37

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

ensure diffusion of air to the active layer.

In this paper, various methods of increasing the

electrochemical activity of activated carbons used as

catalysts for the reduction of oxygen on gas

diffusion cathodes are investigated. One of such

methods is the additional treatment of activated

carbon with activated carbon from coal raw

materials brand UAF (UAF) with ammonia in order

to saturate the carbon surface with nitrogen-

containing functional groups. Another method is the

synthesis of a nitrogen-containing catalyst based on

ethylenediamine and salts of transition metal (Co,

Fe) treated with ammonia, followed by pyrolysis of

the resulting product. Figure 1 presents a

hypothetical scheme of an iron-cobalt-nitrogen-

containing pyrocatalyst.

Figure 1: Estimated scheme of iron-cobalt-nitrogen-

containing pyrocatalyst.

2 EXPERIMENTAL TECHNIQUE

A three-layer gas diffusion cathode consists of a

nickel grid, a barrier layer based on acetylene black

and an active layer based on: 1- UAF coal, 2- UAF

coal with additional treatment in ammonia at 350 °C

for 3 hours, 3- UAF coal with additional treatment in

an atmosphere of ammonia at 350 ºС for 3 hours

with the addition of the catalyst 15% TMPPCo/

Vulcan XC72.

The catalyst was synthesized by pyrolysis of

TMPPCo (tetra- (p-methoxyphenyl) -porphyrin

cobalt), adsorbed on Vulcan XC72, at 800 °C in

argon atmosphere for 1 hour. The active layer was

obtained by calendering a mixture of catalyst/

fluoroplastic (9: 1 by weight), pressing with a nickel

mesh and a barrier layer, having in its composition

35% fluoroplastic.

The test of the cathode was carried out in a three-

electrode cell. A silver chloride (Ag | AgCl)

electrode was used as a reference electrode, and 8 M

NaOH as an electrolyte. Air purified from CO

2

was

supplied to the cathode. Polarization measurements

were performed by the potentiodynamic method, the

potential sweep rate was 1 mV / s. The potential

transient was measured by the galvanostatic method

at a current density of 200 mA / cm

2

. The values of

the potentials are given in the scale of the normal

hydrogen electrode with regard to pH and

temperature. The test of the laboratory layout of the

Al-air element was carried out in a special cell

(Figure 2).

Figure 2: Electrochemical cell diagram: 1-working

electrode, 2-reference electrode, 3-thermometer, 4-

auxiliary electrode, 5-warm water supply tube, 6-heater, 7-

warm water drain tube, 8-capacitance with electrolyte.

The anode material was Al-In alloy (A99+0.45%

In), which is more stable in alkaline electrolyte than

Al. The composition Na

2

SnO

3

sodium stannate (0.1

M) was introduced with the electrolyte to reduce

chemical corrosion of the alloy. Heated to 60º C, the

electrolyte was continuously circulated through the

working space of the cell, whose width was 3 mm.

The geometric surface of the electrodes was 8 cm

2

.

3 RESULTS AND DISCUSSION

At the first stage, the dependence of polarization

curves for raw coal UAF and coal UAF treated with

water vapor and ammonia without catalyst and with

a supported catalyst was investigated (Table 1).

The Effects of Additional Treatment of Activated Coal on the Increase of Special Characteristics of Gas Diffused Cathods of Aluminum-air

Electrochemical Generator

35

Table 1: Data of open-circuit potential and current density

at different polarization for UAF coal, UAF coal

additionally treated in the atmosphere of ammonia and

coal UAF with additional treatment in the atmosphere of

ammonia with the addition of a catalyst 15% TMPPCo/

Vulcan XC72.

Active layer

material

Open-circuit

potential, V

Current

density at

0.3 V

(A /cm

2

)

Current

density at

0.4 V

(A /cm

2

)

activated

carbon UAF

-0,159

0,025

0,078

UAF treated

with aqueous

ammonia at

350 ° C for 3

hours (UAF in

NH

3

+ H

2

O 350

° C for 3 hours)

-0,131

0,048

0,074

UAF is treated

with aqueous

ammonia at

350 ° C for 3

hours +

pyrolysis of the

catalyst at 800

° C (UAF in

NH

3

+ H

2

O

350 ° C for 3

hours, at a 800

° C for 1 hour)

-0,111

0,076

0,108

Additional treatment with ammonia and

pyrolysis of the catalyst has a positive effect on the

characteristics of the open-circuit potential. For

UAF, the current-free potential is -0.159 V, and for

UAF it is treated with aqueous ammonia at 350 ° C

for 3 hours and the iron-cobalt-nitrogen-containing

catalyst pyrolyzed on it at 800 ° C is -0.111 V.

With the additional treatment of carbon material

with UAF with ammonia at 350 ° C for 3 hours, the

values of current density increase by 0.023 A / cm

2

,

as compared to untreated UAF.

The addition of a synthesized catalyst with

pyrolysis at 800 ° C to the treated coal in an

ammonia atmosphere also has a positive effect on

the current density values.

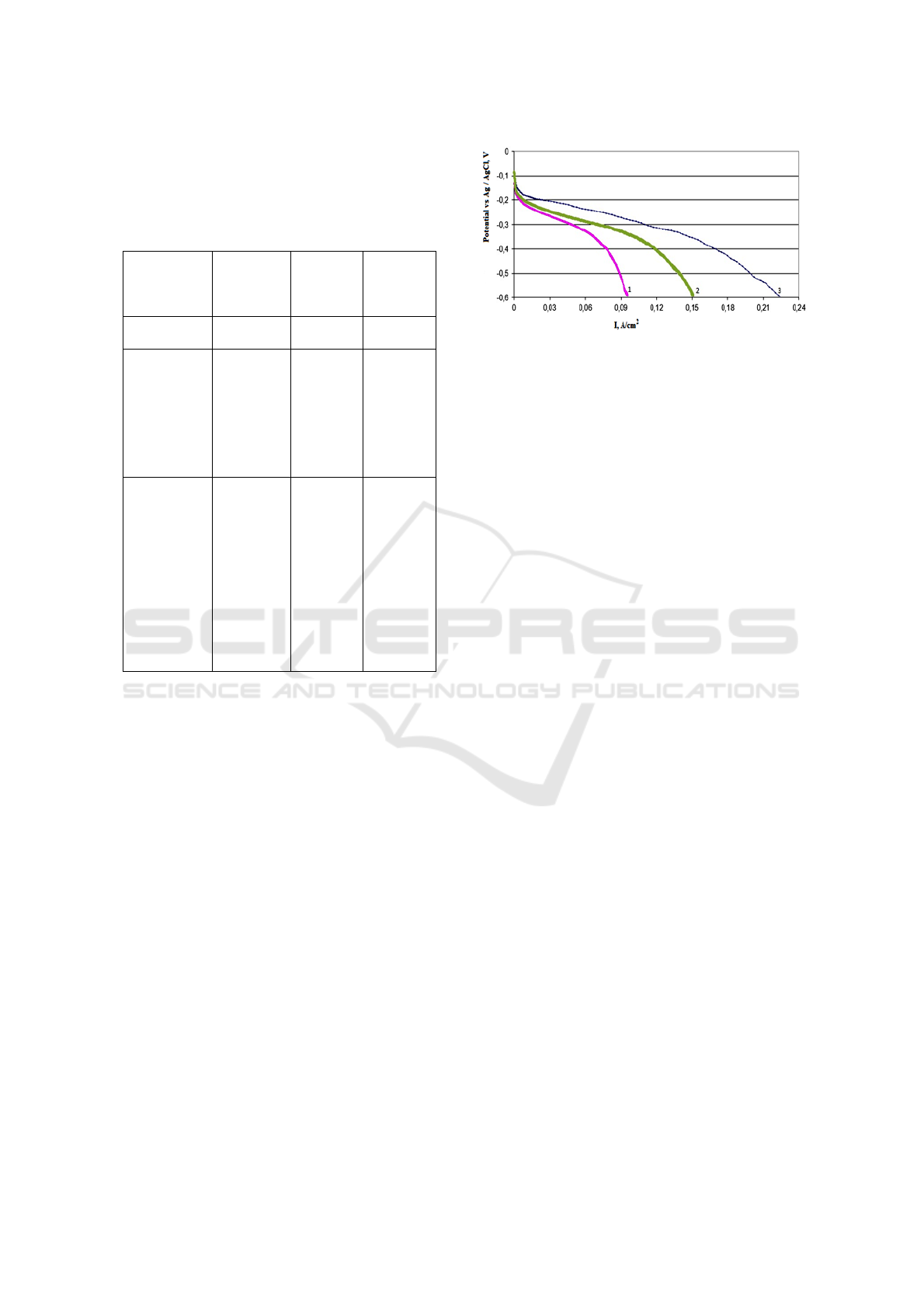

Figure 3 shows the polarization curves of air

cathodes.

Figure 3: Polarization curves of air cathodes from: 1- UAF

coal, 2- UAF coal with additional treatment in ammonia at

350 ° C for 3 hours, 3- UAF coal with additional treatment

in an atmosphere of ammonia at 350 ºС for 3 hours with

the addition of the catalyst 15% TMPPCo / Vulcan XC72.

Synthesis of catalytically active materials

produced specifically for electrocatalysis oxygen

reaction is carried out in two principally different

methods. First, the most commonly used method is

based on modifying the carbon or other carrier

precursors of various types, including metals and

nitrogen, followed by pyrolysis or without it. The

literature describes many techniques of this method

from simple precursors coadsorption before the

synthesis in pairs (Wood et al., 2008) or plasma (Olson

et al., 2013). However, regardless of the synthesis

procedure for the first method of catalytically inert

carrier is retained, but with doped surface having a

pronounced catalytic activity. The second method is

a meaningful synthesis of substantially new

catalytically active material uglepodobnogo

(Charreteur et al., 2008; Wu et al., 2011) modified by

the atoms (N, Co, Fe, etc.) Which may be included

in the alleged active centers. After introduction of

the particulate carbon in (Charreteur et al., 2008) or ion

exchange (Lefevre and Dodelet, 2012) is carried

material necessary precursor pyrolysis and deep

activation system in ammonia atmosphere to a

weight loss of 60 ÷ 80%. This method allows the

synthesis of the catalyst system with a high volume

concentration of active centers, which we got as a

result of our research work.

4 CONCLUSIONS

1. In the course of the work, methods of processing

carbon material in an ammonia atmosphere, a

method of synthesis of a pyrocatalyst, were

developed.

2. Experimental samples of air gas diffusion

cathodes were made from the obtained carbon

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

36

materials, and galvanostatic and galvano-dynamic

characteristics of experimental samples of cathodes

were investigated.

3. The analysis and comparison of the results

obtained for various groups of carbon materials

studied was carried out in order to determine the best

characteristics for gas diffusion cathodes.

ACKNOWLEDGEMENTS

The study was supported by Program no. 56 of the

Presidium of the Russian Academy of Sciences

“Fundamental principles of breakthrough

technologies in the national security interests.”

REFERENCES

Bidault, F., Brett, D.J.L., Middleton, P.H., Brandon, N.P.,

2009. J. Power Sources. V. 187. P. 39-48.

Charreteur, F., Ruggeri, S., Jaouen, F., Dodelet, J.P. 2008.

Electrochim. Acta. V. 53. P. 6881-6889.

Cheng, F., Chen, J., 2012. Chem. Soc. Rev. V. 41. P.

2172-2192.

Chervin, C.N., Long, J.W., Brandell, N.L. et al., 2012. J.

Power Sources. V. 207. P. 191-198.

Lefevre, M., Dodelet, J.-P., 2012. ECS Trans. J.-P. V. 45

(2). P. 35-44.

Olson, T.S., Dameron, A.A., Wood, K., Pylpenko, S.,

Hurst, K.E., Christensen, S., Bult, J.B., Ginley, D.S.,

O’Hayre, R., Dinh, H., Gennett, T. 2013. J.

Electrochem. Soc. V. 160 (4). P. F389-F394.

Wood, T.E., Tan, Z., Schmoeckel ,A.K., O’Neill D.,

Atanasoski, R. 2008. J. Power Sources. V. 178. P.

510-516.

Wu, L., Nabae, Y., Kuroki, S., Kakimoto, M., Miyata, S.,

2011. ECS Trans. V. 41 (1). P. 2313-2323.

Zhuk, A.Z., Kleimenov, B.V., Fortov, V.E., Sheindlin,

A.E., 2012. Electric car on aluminum fuel. Nauka,

p.171.

The Effects of Additional Treatment of Activated Coal on the Increase of Special Characteristics of Gas Diffused Cathods of Aluminum-air

Electrochemical Generator

37