Various Approaches to the Application of Answer Set Programming in

Order-picking Systems with Intelligent Vehicles

Steffen Schieweck

1,2

, Gabriele Kern-Isberner

1

and Michael ten Hompel

2

1

Chair 1 Computer Science, TU Dortmund, Otto-Hahn-Str. 12, Dortmund, Germany

2

Chair of Materials Handling and Warehousing, TU Dortmund, Joseph-von-Fraunhofer-Str. 2-4, Dortmund, Germany

Keywords:

Answer Set Programming, Multi-agent Systems, Application, Hybrid Systems.

Abstract:

Intelligent, self-driving vehicles on public roads are widely noted in the media nowadays. In warehouse and

production systems, such vehicles have been common for a number of years, even though their intelligence

has only come to awareness in the recent years. Those systems are especially tailored to work in volatile

environments which change (to some degree) every few weeks or months. Thus, programming is required to be

as flexible as possible while still providing high efficiency. Answer set programming is a well known paradigm

which has received remarkable attention in the recent years. In this paper several approaches are presented

and evaluated to apply answer set programming to an order-picking system with intelligent vehicles. The

interconnected planning tasks are the dispatching of vehicles to driving jobs and the assignment of customer

orders to picking stations.

1 INTRODUCTION

The currently established continuous conveying sys-

tems are tailored to work in environments where

steady and well-predictable demand occurs. Intelli-

gent, self-driving vehicles are the answer to a global

market which has become highly unpredictable and

fast-moving. However, the intelligence of those ve-

hicles is restricted by the tasks and solutions the de-

signer and programmer initially envisaged. As a re-

sult, more costly programming has to be conducted

whenever a new task or solution is introduced. An-

swer set programming (ASP) is well known for its

simplicity and efficiency for programming and find-

ing optimal solutions and thus serves an ideal tool

for the systems mentioned above. In this paper we

discuss several approaches to the fusion of intelligent

vehicles for order-picking with ASP and approach the

question if this might be beneficial.

The planning task which is implemented with

ASP has the restriction of not requiring any physical

adaption of the system. Still, we aim for a significant

increase of performance. A combinatorial problem

for such order-picking systems is vehicle dispatching,

meaning the assignment of driving jobs to vehicles.

In the specific context of order-picking systems, the

question arises to which picking station a customer

order is assigned. All of the items of a customer order

must be transported to the same picking station which

have limited capacity. Thus, due to limited capacity

a driving job may not be able to select (see section 3)

which makes the decisions interconnected. Also, they

must be completed at the same time and raise poten-

tial for a holistic optimization of the system, e.g. con-

cerning the utilization of the picking stations.

2 FUNDAMENTALS

In the following we will provide some fundamentals

of the presented work. The concept of answer set pro-

gramming will be introduced briefly (further details

may be found in e.g. (Dovier et al., 2009) and (Geb-

ser, 2013)). After that, cellular transport systems are

described. A (more) formal definition of the planning

task is presented in chapter 3.

2.1 Answer Set Programming

An answer set program P consists of a number of

rules of the form

r : H ← A

1

, ..., A

n

, not B

1

, ..., not B

m

. (1)

where H, A

1

, ..., A

n

, B

1

, ..., B

m

are literals and ”not” is

a so-called default negation operator. H is head(r)

Schieweck S., Kern-Isberner G. and ten Hompel M.

Various Approaches to the Application of Answer Set Programming in Order-picking Systems with Intelligent Vehicles.

DOI: 10.5220/0006489300250034

In Proceedings of the 9th International Joint Conference on Computational Intelligence (IJCCI 2017), pages 25-34

ISBN: 978-989-758-274-5

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

and A

1

, ..., A

n

, not B

1

, ..., not B

m

is body(r), respec-

tively. H holds if pos(r) = A

1

, ..., A

n

is true and

neg(r) = B

1

, ..., B

m

are false or not known. A rule

without body is called a fact and holds without any

precondition. A rule without head is a constraint and

excludes the set defined in body(r) from the answer

set.

An encoding of an answer set program contains

a number of such rules which may (and will) inter-

connect. A valid answer set satisfies all of the given

rules. While the most basic structure of a rule is as

described, rules may look differently to achieve spe-

cific grounding and solving behaviors (Gebser, 2013).

With todays ASP-grounders and -solvers, one may

specify objective functions to select an optimal an-

swer set from the set of valid ones.

A set S of literals is a model (an answer set) of

P , if H ∈ S whenever pos(r) ⊆ S and neg(r) ∩ S =

/

0

for every r ∈ P . S is a stable model of P , if S is

the ⊆-minimal model of P

S

where P

S

is the reduct

of P relative to the set S as defined by (Gelfond and

Lifschitz, 1988; Gelfond and Lifschitz, 1991)

P

S

:= {H ← A

1

, ..., A

n

|

H ← A

1

, ..., A

n

, not B

1

, ..., not B

m

∈ P ,

{B

1

, ..., B

m

} ∩ S =

/

0}

(2)

A rational agent can gain knowledge from P . He con-

siders any literals P

S

true and the remaining literals

false.

2.2 Cellular Transport System

In the domain of facility logistics, cellular transport

systems received considerable attention in the recent

years. They are the embodiment of multi-agent sys-

tems for the purpose of in-house transport of goods

and handling units such as pallets, bins or cartons.

Cellular Transport Systems consist of structural and

functional elements like racks, picking stations and

lifts and a number of conveying units. The trans-

port units are intelligent and self-organizing which

enables them to decide and act autonomously. They

may be manifested by single continuous conveying

units which are able to work upon ”plug-and-play”

by detecting the meta-structure of the conveying sys-

tem and collaborate to achieve conveying objectives

(Mayer, 2009). In this paper, a manifestation in form

of a fleet of intelligent vehicles is considered which

operate in an order-picking system.

The Cellular Conveyor System has been devel-

oped jointly by Fraunhofer-Institute for Material

Flow and Logistics IML and Dematic GmbH. Its

unique feature is the vehicles capability of moving on

the various levels of rack as well as on the ground

Figure 1: Example of routing graph.

floor. The system consists of one (or multiple) racks,

picking stations, article bins, order bins, vehicles and

lifts which transport the vehicles vertically. The arti-

cle bins are stored in the rack(s). If a specific stock

keeping unit (sku) is ordered, the related article bin

is retrieved by a vehicle and transported to one of

the picking stations. The system is automated by a

large degree. Nonetheless, as in most order-picking

systems, the isolated pick-and-put procedure of skus

from the article bins to the order bins is conducted by

workers (order pickers) who are located at the picking

stations. After picking has been completed the vehi-

cle transports the bin back into the rack and stores it.

The lifts are required to reach the various levels of the

rack. They are located at the beginning and the end of

an aisle. The vehicles move on dedicated virtual paths

which compose to a graph (see Figure 1). The edges

of the graph are unidirectional. Thus, no reservation

procedure for edges is necessary. As an additional

consequence, one of the lifts is dedicated for the up-

bound transport of the vehicles and the other lift for

the downbound transport.

The control architecture of the vehicles consists

of three layers which are connected by UDP-sockets.

The sensor and actuator layer is at the lowest level and

responsible for tasks which are strongly coupled to

the hardware and time-critical (e.g. position control,

safety, sensor data acquisition). The operational layer

is on the mid-level and responsible for tasks like lo-

calization, path planning and collision avoidance. The

autonomous behavior is located at the strategical level

and implemented via software agents. Those agents

are capable of communicating with other agents in the

system (Kamagaew et al., 2011).

Currently, such an external system is responsible

for job management (aka dispatching) (Kamagaew

et al., 2011). Dispatching is conducted using the FIPA

protocol (Foundation for Intelligent Physical Agents

FIPA, 2002). The external system releases a broadcast

to all vehicles once a new order-line arrive. The avail-

able (idle) vehicles bid for the order-line and the high-

est bidder is assigned the offered driving job. Hence,

if the system runs under full utilization (which is de-

sirable for economical reasons), the operation results

in a simple first-come-first-served (FIFO) procedure.

2.3 Related Work

The assignment of driving tasks to vehicles has been

studied intensely in the domain of operations re-

search. The vehicle scheduling problem decides

when, where and how any vehicle in a system shall

act. Routing is included in this problem. The problem

may be tackled online or offline. The offline prob-

lem can theoretically be solved to optimality using

a multiple traveling salesman model which has NP-

complexity. Real-life scenarios require online solv-

ing due to uncertainty of the environment states. This

may be realized with a rolling horizon, in which the

planning is conducted for a limited future timespan

(Le-Anh and de Koster, 2006).

Vehicle dispatching strategies only assign driving

jobs to vehicles. Often, the planning horizon has a

timespan of zero. This results in simple rules from

which the assignment is made. Especially in multi-

agent systems, the choice weather the decision is

made central or distributed is of interest (Vis, 2006).

Existing research dealing with the theoretical

foundations is diverse. Among them are optimiza-

tion models (Yang et al., 2004), heuristics (Bartholdi

and Platzman, 1989), disposition strategies (de Koster

et al., 2004) but also more complex methods such as

fuzzy logic (Benincasa et al., 2003) and ant colony

algorithms (Saidi-Mehrabad et al., 2015) are used.

Cellular transport systems are a rather new field

of research. Therefore, publications are sparse and

mainly engage with the physical design of the sys-

tems (Guizzo, 2008; Kamagaew et al., 2011). To our

knowledge, no publications from other authors exist

which deal with the combination of ASP and cellular

transport systems.

3 TASK DEFINITION

An order-picking system has the purpose of the as-

sembly of customer orders. In a warehouse, a set

M of skus is held in inventory. A customer order

O ⊂ M consists of a number n

P,O

of skus which are

condensed to n

O

≤ n

P,O

order-lines l in which skus

with the same identity compose to one order-line

1

.

The system has a number of picking stations S, stor-

age positions R and vehicles F. The picking sta-

tions have equal capacity c

S

. The incoming customer

orders are stored in a list of orders L. Given the

time t

O

of an order O the orders are sorted such that

t

1

≤ t

2

≤ ... ≤ t

q−1

≤ t

q

.

The vehicles move on a graph G = (V, E) with a

set of nodes V and a set of edges E. V = {V

R

;V

S

;V

W

}

where V

R

are nodes which identify storage locations

in the rack, V

S

are nodes which identify picking sta-

tions where bins need to be delivered to and V

W

are

waypoints without further functionality. The edges

are unidirectional. On G, the vehicles need to travel a

distance d to fulfill the systems purpose.

The planning task is the assignment l

v

= (v, l) of

a vehicle v to an order-line and the related assign-

ment o

s

= (O, S) of an order to a picking station. We

aim to maximize the number of satisfied order-lines

per time N

l

:

z

1

: max N

l

(3)

Also, a balanced utilization u

s

between the picking

stations is favored:

z

2

: min

∑

S

|

u

avg

− u

s

|

(4)

with

u

avg

=

1

S

S

∑

i=1

u

i

(5)

One vehicle can only transport one bin at a time. The

capacity c

S

of a picking station may not be exceeded

by the number of orders O assigned to the same pick-

ing station at a time.

For the planning task, the agents are given a hori-

zon H with size n. Informally speaking, they are

given the opportunity to select an order-line from a

pool which consists of the next n unfulfilled order-

lines of L. Note that, if the same article is part of

multiple orders in H, the vehicle may approach mul-

tiple picking stations between retrieval and storing to

satisfy multiple order-lines with one cycle. Thus, we

define a driving job j which is selected from H. Every

unique storage position is one Pos ∈ H. Every job j

has one pickup node V

p

∈ V

R

, one or multiple deliv-

ery nodes V

d

⊆ V

S

and one storing node V

r

= V

p

. If

1

E.g. if a customer orders 500 business cards, n

O

= 1.

j has multiple delivery nodes it will be referred to as

an eos-job (economy of scale). The latter definition of

the storing node implies that bins are transported back

to the same location from which they were extracted.

Practically speaking, we assume a fixed storage pol-

icy. Finally, we define that all of the order-lines l of

a customer-order O must be transported to the same

picking station

V

d,l

1

= V

d,l

2

= ... = V

d,l

n

∀l

i

∈ O (6)

4 SYSTEM DESIGN

The developed approaches are tailored to work in a

realistic scenario and will be evaluated as such (see

section 5). To cope with the complexity real-life sce-

narios provide, the implemented planning agents op-

erate with limited knowledge.

First, the rating of the order-lines l ∈ H will be

based on the driving distance d

p

⊂ d to the pickup

nodes V

p

. The remaining steps to complete the driv-

ing task are not considered for the rating as they do

not depend on the assignment of the vehicle. Also,

every order-line needs to be completed at some point

of time. As a consequence, those steps have no influ-

ence on the overall system performance. We assume a

strong correlation between driving distance and driv-

ing time. Second, for the assignment of orders to

picking stations only orders are assumed to reserve

capacity

• for which at least one driving job has been

started yet and

• which have unsatisfied order-lines remaining.

The first assumption is trivial, as no order bin is re-

quired at the picking station before the first order-line

has been delivered. The second assumption implies

that any driving job which has already been started

will reach a possibly capacity-critical picking station

before the currently assigned one. Otherwise, the cur-

rently assigned will have to start a new attempt for

delivery as no capacity for its order bin is available.

A new attempt will result in a detour on G such that

other vehicles may reach the picking station and some

time passes until the current vehicle reaches the pick-

ing station again.

For all of the implementations, a blackboard ar-

chitecture has been implemented for the multi-agent

system. The blackboard contains information about

the incoming customer orders (denoted as L). Also,

information about the status of the order-line and the

corresponding order are published on the blackboard.

Depending on the approach, specific agents have read

and write privileges for the blackboard. For example,

an agent may annotate for an order-line to be com-

pleted and add an assignment o

S

.

In this paper three approaches are described and

evaluated:

• distributed planning with hybrid encoding

(section 4.1)

• distributed planning with numbering concept

(section 4.2)

• central planning with hybrid encoding

(section 4.3)

For all of the implementations the ASP grounder and

solver clingo (Gebser et al., 2014) in version 4.5.4 of

the Windows build has been used.

4.1 Distributed Planning

Some versions of the distributed approach with hybrid

encoding have been discussed in (Schieweck et al.,

2016). We will describe the superior version of the

encoding and its operation in the overall system in the

following.

The implementation follows the trend towards dis-

tributed systems by increasing the vehicles auton-

omy and enabling them to take their own decision.

This approach has been selected due to its high anal-

ogy to the current systems architecture, its flexibil-

ity and low expected computing times. As soon as

a vehicle completes a driving task it requests a new

driving job. Assuming full utilization of the system

(which is the most critical state) a number of driv-

ing jobs is available. At that point of time, the vehi-

cle makes the assignments for both l

v

and o

S

, if re-

quired. The vehicles planning agent extracts the rel-

evant information from the blackboard and translates

them to an ASP-instance (see Listing 1). The instance

contains information about the available order-lines

(order pos/3), the current assignments of orders to

picking stations (order pickst/2) and the vehicles

position (veh position/2).

In the encoding the driving jobs (pos/2) are ex-

tracted in line 8. After, we ensure that the vehi-

cle is assigned exactly one driving job in the atom

pos veh/2. In line 10 existing assignments of orders

to picking stations are transferred to the new atom

as order pickst/2 to differ between new and ex-

isting assignments. If a driving job j is selected, at

least one of its corresponding order-lines l must be

assigned to the vehicle (line 11). The selection of the

order-line requires assignment of the related order, if

no assignment exists already (line 12). The assign-

ment is then conducted in lines 13 and 14 with respect

to the capacity restriction c pickst of the picking sta-

tions.

1 instance

2 orde r_ po s (69 , 33 ,43 6 ) . ord er _p os (70 ,3 4 ,322) . o r d e r_ po s ( 7 6 ,36 , 2 41) . or de r_ p o s (82 , 39 ,44 6 ) .

3 orde r_ po s (83 , 39 ,12 4 ) .

4 ord e r _ p ic ks t (3 3 , 2 ) . o r d e r _ p i ck st (34 ,3) . or de r_ pi c k s t (36 ,1) . or d e r _ p i c ks t (39 ,8 ) .

5 veh _ p o s it io n ( 4 ,573) .

6

7 encoding

8 pos ( P ) :- o rd er _ p o s (_ , _ ,P ) .

9 1{ pos _v e h (P , V ) : p o s ( P) }1 : - veh ( V ) .

10 as _o r d e r_ pi c k s t (O , S ) : - o rd er _p i c k s t (O , S ) , pi cks t ( S ) .

11 1{ job _v e h (Ix , V ) : o r d er _p os ( Ix , _ ,P ) } :- p os _ ve h ( P , V ) .

12 as _ or de r ( O ) :- j ob _v e h (Ix , V ) , o rd er _p os ( Ix , O ,_ ) ,

not or de r_ p i c k s t ( O , _ ) .

13 1{ as _ o r de r_ p i c ks t (O , S ) : pic k st ( S) }1 :- a s_ o r d er ( O ) .

14 :- pic k st ( S ) , c _ p ic ks t +1{ a s _o r d e r _ pi c k s t ( O , S ) }.

15

16 dis t (A , B , @d is ta n c e ( A ,B ) ) :- v eh _ po s ( _ , A ) , pos ( B ) .

17 pos _v e h (P , V ,C ) :- p os _v e h (P , V ) , ve h_ p o s i t i o n ( V , A ) , dist ( A ,P , C ) .

18 num Jo b s ( K ) :- K =# cou n t { Ix : jo b _v eh ( Ix , V ) }.

19 nu mO r d e r P ic ks t ( X ) :- pic k st ( S ) , X =# coun t { O : a s_ o r d er _p i c k st ( O ,S ) }.

20 ma x N u mO rd e r P ic k s t ( Y ) : - Y=# max { X : n u m O rd er P i c k s t (X ) }.

21

22 # m in im iz e { C@3 : p o s_ ve h ( P ,V , C ) }.

23 # m ax im iz e { K@1 : n u mJ ob s ( K ) }.

24 # m in im iz e { Y@2 : m a x N um O r d er P i c ks t ( Y ) }.

Listing 1: Excerpt of encoding for distributed planning with exemplary instance (n = 5).

In line 16 to 20 the rating of the driving jobs

is implemented. Note that in line 16 we use the

@-directive to compute the distance of the vehicle to

the various bins with a Dijkstra-Algorithm (Dijkstra,

1959). The Windows build of clingo allows for the in-

clusion of Lua scripts in the ASP-encoding. Thus, hy-

brid programming is implemented. Some tests were

conducted comparing the Dijkstra-algorithm with the

A*-algorithm. For the prevailing structure, Dijkstra

provided lower calculation times. The distance to

the bins position is minimized with highest priority.

Then, the maximum of the number of orders assigned

to all picking stations is minimized, resulting in a lev-

eled utilization. To be able to use eos-jobs properly

the number of order-lines l completed with this single

driving job j is maximized.

4.2 Location Numbering

The proposed approach is an evolution of the one de-

scribed in section 4.1, resulting from first tests and

insights to the aforementioned approach. While in

the previous approaches hybrid programming is used,

we try to eliminate the routing algorithm in the cur-

rent approach. This is due to the high expected

calculation time of the routing algorithm, especially

when it comes to scalability. ASP is tailored for

combinatorial, complex problems. The routing prob-

lem however, has been investigated many times and

existing algorithms are expected to be superior to

the implementation of the routing problem in ASP

2

.

Thus, a different approach has been developed which

makes use of the unidirectional structure of the rout-

ing graph. By testing and implementing we hope to

find a good approximation of the optimal solution.

Also, we hope to gain insights on how costly the rout-

ing algorithm is for the current planning task.

As a matter of fact, every driving job starts and

ends in the rack. All of V

R

are given names such

that simple comparison yields an estimation for the

ranking of the driving jobs with shortest traveling dis-

tance d

p

. An example of the numbering for one rack

is given in Figure 2. As a consequence, the multi-

agent system is extended by a numbering agent which

reassigns the names according to the concept. The

numbering agent also has an ASP-encoding imple-

mented which requires information about the length

of the rack, the number of rack levels and the po-

sition of the rack entries and generates the 2-tuple

t = (id

old

, id

new

).

E2

102

103

E1E3104

203202201 206205204 207

303302301 306305304 307

E2

102

103

E1E3104

203202201 206205204 207

303302301 306305304 307

101101

Figure 2: Example of numbering concept.

2

Again, tests were conducted to indicate this.

1 le ve l_ po s ( N , P / 100 ) :- or d e r _p os (N ,_ , P ) .

2 le ve l_ ve h ( V , P / 100 ) :- ve h_ po s i t i o n ( V , P) .

3 n um Pi ck s t ( Max ) : - Max =# m a x { S: pi ck st _n od e (S , _ ) }.

4

5 % c a s e 1 % c ase 2 % c ase 3

6 po ss ib le P o s 1 ( N ) : - ... po ss ib le P o s 2 ( N ) : - ... po ss ib le P o s 2 ( N ) : - ...

7 se le ct ed B i n 1 ( N ) : - ... se le ct ed B i n 2 ( N ) : - ... se le ct ed B i n 3 ( N ) : - ...

8

9 s el ec t e d B i n ( N ) : - s e l e ct ed Bi n1 ( N ) .

10 s el ec t e d B i n ( N ) : - s e l e ct ed Bi n2 ( N ) .

11 s el ec t e d B i n ( N ) : - s e l e ct ed Bi n3 ( N ) , n o t s e le ct ed Bi n 2 ( _ ) .

12

13 po s _v e h (B , V ) : - s el e c t e d B i n ( N ) , o r d e r_ po s (N ,_ , B ) , v eh _ p o s i t i on (V , _ ) .

Listing 2: Excerpt of encoding for distributed planning with numbering concept.

The vehicles planning agent has an encoding sim-

ilar to Listing 1. Lines 16 and 18 are substituted by

Listing 2. Also, the optimization statement in line 22

is no longer necessary. First, the rack levels of the

order-lines l ∈ H are calculated in lines 1 and 2. The

number of the picking stations is expressed in the

atom numPickst/1 in line 3. Afterwards, the cases

1. the vehicle is not in the rack,

2. the vehicle is in the rack and at least one driving

job j ∈ H starts on the same level in driving direc-

tion of v and

3. the vehicle is in the rack and a driving job j ∈ H

is available.

If case I applies and the capacity restriction

for at least one job of the position is fulfilled

an atom possiblePosI/1 is created. Multiple

possiblePosI/1 may exist for each I. The minimum

number has the lowest traveling distance d

p

and is

transferred to selectedBinI/1. While case 1 ex-

cludes the other cases, 2 and 3 may occur in the

same instance. Then, selectedBin2/1 is assigned

because the bin can be picked up on the way to the

outside of the rack (line 10 and 11). Line 13 is

the interface to the existing encoding and translates

selectedBinI/1 to pos veh/2.

4.3 Central Planning

The distributed approaches fit into the existing trend

towards local decision making of intelligent units.

However, multi-agent systems rarely exist without

any central agents which have the ability to coordi-

nate the overall system (see e.g. section 2.2 with the

current architecture). As described in chapter 2.2 the

existing system contains a central entity for dispatch-

ing. A global optimum for a planning problem is ex-

pected to have an objective value at least as good as

multiple local optima. On the other hand, the search

for a global optimum raises higher complexity. The

following approach has been developed to test the im-

pact of the global optimum and the capability of ASP

to find the optimum with satisfiable computing times.

An exemplary situation in which a central plan-

ning approach is superior to a distributed approach is

depicted in Figure 3. Vehicle 1 requests a new driving

task and has bin a and b available. Bin b induces a

shorter distance and will be selected in the distributed

approach, even though the difference between a and

b is comparatively small. For vehicle 2 bin a remains

for which it has to travel through the whole rack and

use the lifts twice. A central planning approach can

minimize the overall traveling distance for all vehi-

cles. In this case, vehicle 1 is assigned bin a with a

slightly larger traveling distance. As a consequence,

vehicle 2 can reach bin b which induces considerably

less traveling distance.

For the current approach a central dispatching

agent is added to the multi-agent system. Just like

in the previous implementations the agent has a hori-

zon H of order-lines available from which it conducts

the assignments l

v

and o

S

. Once a vehicle completes

a driving job it tries to find a new driving job which is

assigned for itself on the blackboard. If no assignment

2

b

DistributedCentral

1

a

b

2

b

1

a

b

Figure 3: Distributed vs. central planing.

1 :- p o s ( P ) , 2{ po s_ v eh (P , V ) }.

2 sp o s i t i on (V , Pos ) : - oc cu p ie d (V , P o s ) .

3 sp o s i t i on (V , Pos ) : - ve h _ p o s i t io n (V , P o s ) , not oc c u p ie d ( V , _ ).

4 dist ( SPos , TPos , @d i st an ce ( SPos , TP o s ) ) : - spo si ti on (_ , SPos ) , pos ( TPos ) .

5 ve h _d ri ve (V , D ) : - p os _v e h (P , V ) , sp os it io n ( V , S Pos ) , d ist ( SPos ,P ,D ) .

6

7 # m in im iz e { D@3 : v eh _ d r i v e (V , D ) }.

Listing 3: Excerpt of encoding for central planning.

can be found a new planning cycle is initialized

3

. At

that point of time, the planning agent creates a plan

for all of the vehicles v in the system and assigns ex-

actly one j for each v and publishes the result on the

blackboard. The agent requires the additional infor-

mation about the status of each vehicle. The status is

defined by the occupation and if an occupation exists,

the final vehicle position induced by driving job j.

For the comparability of the implementations, n

is redefined. Note that a minimum of F order-lines

must be available in H to allow for one assignment l

v

for each vehicle v. Also, the amount of undesirable,

unassigned order-lines in H shall stay the same. Thus,

the central planning agent has a number of

n

cen

= n + F − 1 (7)

order-lines available.

The central planning agent has a similar encoding

as the distributed agents in Listing 1. The differing

lines are displayed in Listing 3. In line 1 we ensure

that each vehicle receives only one driving job. If a

vehicle is occupied, the atom occupied/2 is added

to the problem instance and the starting point for the

next job is defined with sposition/2 (line 2). If the

vehicle is not occupied, we assume that it does not

move until the next driving job starts (line 3). The

necessary distances are computed in line 4. Again, a

routing algorithm is used. If an assignment is made

the vehicle has to travel the distance D which is noted

in the atom veh drive/2 (line 5). The overall travel-

ing distance to the starting positions is minimized in

line 7.

5 EVALUATION

The approaches which are described in section 4 are

evaluated in the following. First, the experimental de-

sign is described (section 5.1). Second, the results are

described and interpreted (section 5.2).

3

The planning procedure may be started even before.

This is the protocol which has been implemented to the sim-

ulation.

5.1 Experimental Design

For the evaluation a Demo3D simulation model has

been created. The simulation model has the pur-

pose of a development and evaluation environment.

For being able to validate the functionality of the ap-

proaches, their behavior inducted by the encodings

could be tested instantly. Also, an interface between

the simulation environment and the employed ASP-

grounder and -solver clingo 4.5.4 has been created.

Demo3D was selected due to its programming struc-

ture which is close to agent-based systems. Single

entities are assigned proprietary C#-scripts which ex-

change information with messaging protocols. Thus,

the simulation could be implemented similarly to a

real-world application. The level of abstraction of the

simulation is relatively low. Just like the real vehicles,

their digital replications possess proximity sensors

which slow the vehicle down (proximity < 3 m) and

let it come to an halt eventually (proximity < 1 m).

Working towards comparable results not only the

approaches described in section 4 were implemented

but also counterparts with classical (imperative) pro-

gramming as well as the FIFO approach. The qual-

ity of the implementations is in the following quanti-

fied by their improvement compared to the FIFO ap-

proach and indicated by ∆. The experimental design

consists of a basic system from which single parame-

ters are varied. The basic system has one rack with a

capacity of 500 bins, S = 5 picking stations, F = 5 ve-

hicles, uniformly distributed demand among the skus

Table 1: Data of simulated system.

Parameter Value Unit

Vehicle

Speed floor 1 m/s

Speed rack 2 m/s

Acceleration/Deceleration 0,5 m/s

2

Time loading/unloading 4,5 s

Lift

Speed 2 m/s

Acceleration/Deceleration 2 m/s

2

Picking time per order-line 5 s

0,01

0,1

1

10

100

3 4 5 6 7 8 9 10 11 12 13 14 15

Size n of horizon H

11

12

13

14

15

16

17

18

19

20

Driving tasks/

vehicle/hour

0,001

0,01

0,1

1

10

100

1000

1 3 5 7 9 11 13 15 17 19

Computing time

[sec]

Number of vehicles F

16

17

18

19

20

asp_dij asp_num imp_dij imp_num Zasp FIFO

Casp

2 4 6 8 10 12 14 16 18 20

10

0

10

1

10

2

10

3

10

-1

10

-2

10

-3

10

0

10

1

10

2

10

-1

10

-2

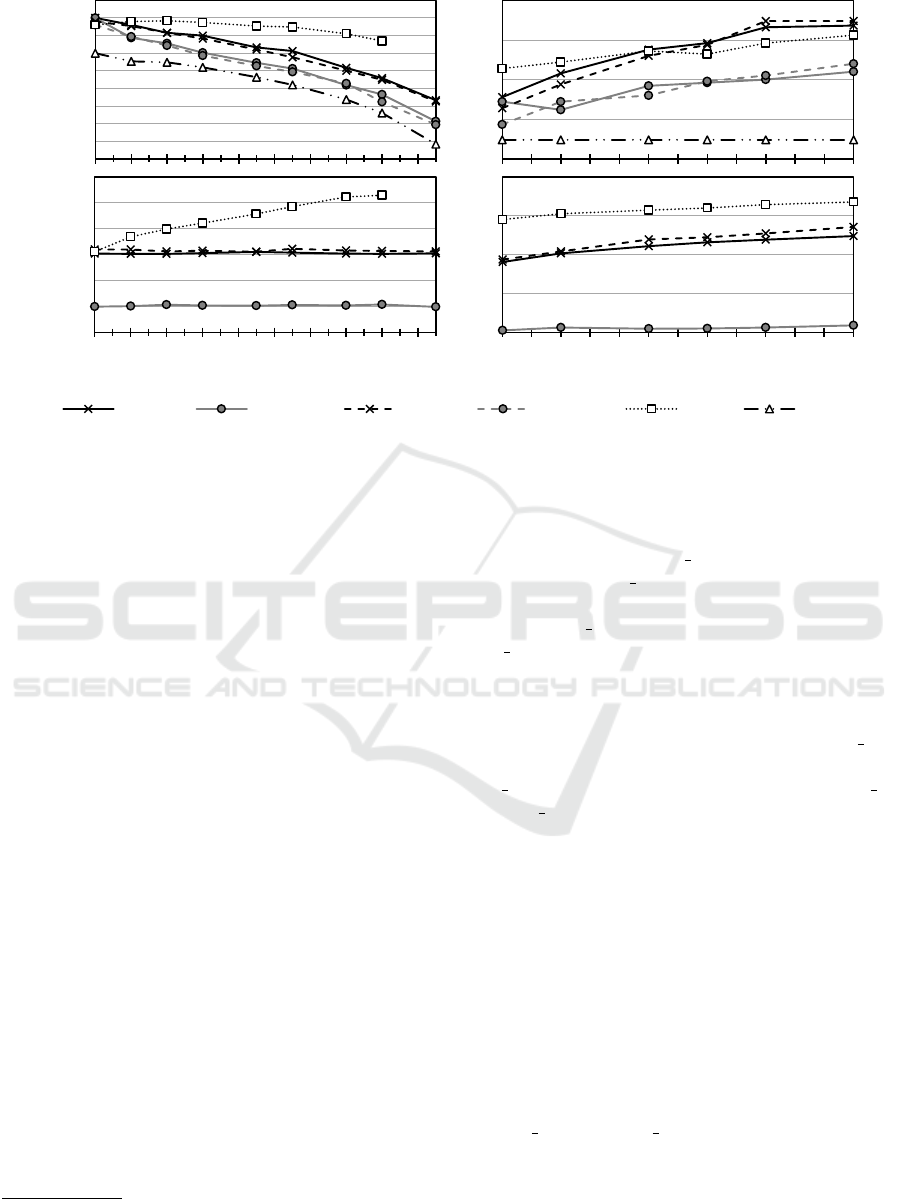

Figure 4: Evaluation of the approaches.

and a horizon with n = 5 order-lines. The parame-

ter variations were tested for five hours of simulation

time each. The central and distributed planning agents

are granted a computing time of 200 seconds to find

the optimal solution

4

. After this time, three options

may occur:

• An optimal answer set has been found and the

computation has been terminated at a time < 200

seconds.

• The solver has not terminated the computation

procedure yet and

– an answer set has been found. The answer set

may or may not be optimal.

– no answer set has been found.

If no answer set has been found the simulation run

was terminated.

5.2 Experimental Results

Some key results of the simulation runs are depicted

in Figure 4. Note that the computing time (bottom)

is presented with a logarithmic y-Axis. We define

the number of driving tasks which have been com-

pleted by one vehicle per hour on average as the per-

formance.

Generally, the performance of a vehicle decreases

with a growing number of vehicles in the system (top

left). This is due to blocking and congestion of the

vehicles on the routing graph. For the variation of the

4

This is the time a vehicle needs approximately for one

driving task.

number of vehicles the highest average performance

was achieved by the central approach (Casp, ∆19%).

The distributed approaches with hybrid programming

achieve ∆13% (ASP, asp dij) and ∆12% (classical

programming, imp dij). With the distributed ap-

proaches with numbering concept an improvement of

7% (ASP, asp num) and 6% (classical programming,

imp num) is achieved. For the distributed approaches

the computing time (bottom left) is constant with in-

creasing vehicle number as the instance of every sin-

gle planning agent is independent of this parame-

ter. No measurable computing times for imp num

and FIFO were recorded. The computing time for

asp num was 0.01 seconds on average. For asp dij

and imp dij the times were on average 1.13 and 1.45

seconds, respectively. The increase is caused by the

routing algorithm. Separate experiments revealed that

the average computing time for the routing on the

graph of the basic system is roughly 0.2 seconds. The

computing time of the central approach increases al-

most exponentially with the number of vehicles. As

a consequence, the experiments with 20 vehicles did

not produce results due to the 200 seconds limit.

With growing size n of the horizon H the perfor-

mance (top right) of the vehicles increases. For all of

the simulation runs, the central (∆13%) and the dis-

tributed, hybrid approaches (∆13% ASP, ∆12% im-

perative) achieve the highest performance followed

by asp num and imp num (∆6% each). Remark-

ably, the performance of Casp increases by a smaller

amount than the other approaches, even though a cen-

tral approach is expected to be superior. The limited

knowledge has an impact in those scenarios. While in

the distributed approaches the planning is conducted

exactly at the time needed, the central planning agent

has to take a wider look into the future. However,

the limitation of the knowledge stays the same due to

rapidly growing complexity of the problem (e.g. in

an state-action encoding with consideration of time

points). Thus, in the central approach a capacity of

a picking station may be considered as occupied by

the time of the planning while in real-life operation

it has been released in due time. The computing time

(bottom right) grows steadily for all of the approaches

which use the routing algorithm. The highest increase

is noted for Casp due to the redefinition of the hori-

zon size n

cen

. For the distributed approaches the in-

crease is roughly constant to the 0.2 seconds which

are required to compute the distance to every l ∈ H.

The computing time of asp num only increases from

0.009 seconds to 0.011 seconds with a horizon size of

3 and 15, respectively.

Generally, a slight decrease of performance oc-

curs from the ASP implementations to their impera-

tive counterparts. At this point, the flexible structure

of the ASP encodings proves to be advantageous. In

the ASP approaches it is possible to prioritize the eos-

jobs such that, if two driving jobs induce the same

distance and utilization, the driving job which com-

pletes the most order-lines will be selected. The im-

perative implementations have a less flexible structure

in which first an order-line is selected and if possible,

more order-lines with the same bin are added:

1. Setup of horizon H.

2. Calculate distances d

p

.

3. Choose minimum distance order-line l

min

.

4. Search eos of l

min

in H with d

p,eos

= d

p,min

.

5. Assign station(s) o

S

with respect to c

S

and u

avg

.

6.(a) If no o

S

could be assigned, eliminate l

min

from

H, clear o

S

∀ l

min

and go to (2).

(b) Else, assign order-line(s) l

v

.

In the case mentioned above weather the order-line

with or without eos-job is selected is random. Also,

one might note that the priority of eos-jobs is third in

the ASP approaches and they are searched for second

in their counterparts. This is due to the fixed sequence

in imperative programs. In this case, all of the poten-

tial l must be found to verify possible c

S

.

Furthermore, the computing time of the ap-

proaches with the numbering concept is remarkably

low. Unfortunately, the performance of the ap-

proaches is low as well, even though an improvement

compared to the FIFO experiments could be achieved.

We find the reason for this in the rating of the stor-

age positions on different levels. While the hybrid

approaches always select the positions which are the

easiest to reach, asp num and imp num prefer the po-

sitions on the lower levels because they have lower

numbers (see Figure 2). As a final note, the comput-

ing times of the imperative counterparts are certainly

induced by some degree by the simulations interface

to the routing algorithm. Generally, we expect a well

programmed imperative code to be faster than a gen-

eral purpose ASP solver. However, especially for sys-

tems which are designed to work in volatile environ-

ments the flexibility and comfort of programming is

key which is remarkably good for ASP. This can be

elucidated with the small length of the encodings in

this paper as well as the small adaptions necessary

between the approaches.

6 CONCLUSION AND OUTLOOK

The presented work combines answer set program-

ming with the innovative field of application of intel-

ligent vehicles in an industrial setup. The approaches

are tailored to work in a real-life environment and are

evaluated as such. The general approach of allow-

ing the planning agents to select driving jobs from a

horizon achieves a considerable improvement of per-

formance without any physical adjustment of the sys-

tem. The approaches to the planning task do not cause

an immense complexity. However, for operational

planning even seconds become valuable. For most

cases, central planning achieved a higher performance

than the distributed approaches. The limited knowl-

edge plays a critical role for the performance, espe-

cially when the planning horizon is large. Answer set

programming as a method promises great capabilities

in systems which are made to work in changing and

volatile environments. This is due to good computing

times and especially easy modeling and high flexibil-

ity.

For future steps we recommend the evaluation of

further planning tasks to be implemented with ASP

and combinations of those. As a final step, the most

promising approaches should be implemented and

tested with existing vehicles.

REFERENCES

Bartholdi, J. J. and Platzman, L. K. (1989). Decentralized

control of automated guided vehicles on a simple loop.

IIE Transactions, 21(1):76–81.

Benincasa, A. X., Morandin, O., and Kato, E. R. R. (2003).

Reactive fuzzy dispatching rule for automated guided

vehicles. In IEEE International Conference on Sys-

tems, Man and Cybernetics, pages 4375–4380.

de Koster, R. B., Le-Anh, T., and van der Meer, J. (2004).

Testing and classifying vehicle dispatching rules in

three real-world settings. Journal of Operations Man-

agement, 22(4):369–386.

Dijkstra, E. W. (1959). A note on two problems in connex-

ion with graphs. Numerische Mathematik, 1(1):269–

271.

Dovier, A., Formisano, A., and Pontelli, E. (2009). An

empirical study of constraint logic programming and

answer set programming solutions of combinatorial

problems. Journal of Experimental & Theoretical Ar-

tificial Intelligence, 21(2):79–121.

Foundation for Intelligent Physical Agents FIPA (2002).

Fipa contract net interaction protocol specification.

Gebser, M. (2013). Answer set solving in practice. Morgan

& Claypool, San Francisco, CA.

Gebser, M., Kaminski, R., Kaufmann, B., and Schaub, T.

(2014). Clingo = asp + control: Extended report.

Gelfond, M. and Lifschitz, V. (1988). The stable model se-

mantics for logic programming. Journal of Symbolic

Logic, 57(1):274–277.

Gelfond, M. and Lifschitz, V. (1991). Classical negation in

logic programs and disjunctive databases. New Gen-

eration Computing, 9(3-4):365–385.

Guizzo, E. (2008). Three engineers, hundreds of robots, one

warehouse. IEEE Spectrum, 45(7):26–34.

Kamagaew, A., Stenzel, J., Nettstrater, A., and ten Hompel,

M. (2011). Concept of cellular transport systems in

facility logistics. In 5th International Conference on

Automation, Robotics and Applications, pages 40–45.

Le-Anh, T. and de Koster, R. B. (2006). A review of de-

sign and control of automated guided vehicle systems.

European Journal of Operational Research, 171(1):1–

23.

Mayer, S. H. (2009). Development of a completely decen-

tralized control system for modular continuous con-

veyor systems. Dissertation, Karlsruhe University,

Karlsruhe.

Saidi-Mehrabad, M., Dehnavi-Arani, S., Evazabadian, F.,

and Mahmoodian, V. (2015). An ant colony algo-

rithm for solving the new integrated model of job shop

scheduling and conflict-free routing of agvs. Comput-

ers & Industrial Engineering, 86:2–13.

Schieweck, S., Kern-Isberner, G., and ten Hompel, M.

(2016). Using answer set programming in an order-

picking system with cellular transport vehicles. In

IEEE International Conference on Industrial Engi-

neering and Engineering Management, pages 1600–

1604.

Vis, I. F. A. (2006). Survey of research in the design and

control of automated guided vehicle systems. Euro-

pean Journal of Operational Research, 170(3):677–

709.

Yang, J., Jaillet, P., and Mahmassani, H. (2004). Real-time

multivehicle truckload pickup and delivery problems.

Transportation Science, 38:135–148.