Modelling Decision Support Systems using Conceptual Constraints

Linking Process Systems Engineering and Decision Making Models

Canan Dombayci and Antonio Espu

˜

na

Chemical Engineering Department, EEBE, Universitat Polit

`

ecnica de Catalunya, Av. Eduard Maristany,

10-14, 08019 - Barcelona, Spain

Keywords:

Knowledge Engineering, Ontology Engineering, Decision Support Systems, Mathematical Programming,

Conceptual Constraint Domain, Process Systems Engineering.

Abstract:

This paper presents the use of a Conceptual Constraint (CC) Domain to systematize the construction of De-

cision Making Models (DMMs). The modelling systematics include the integration between the CC Domain

and production systems as well as an identification procedure which contains some steps aimed at constraint

identification using the CC Domain. The CC Domain consists of different modelling elements such as Concep-

tual Constraints (generic constraint types), Conceptual Components (pieces of a constraint), and Conceptual

Component Elements (pieces of a conceptual component that may be connected to production systems). In

this instance, the CC Domain is integrated with the Process Systems Engineering (PSE) Domain as a produc-

tion system domain. The PSE Domain contains information from the multi-level functional hierarchical in an

enterprise and it will be used to cover a wide range of scenarios related to hierarchical integration of DMMs.

In addition, an integration step between the CC and PSE Domains is illustrated. The focus of the work is

to show how these models should be developed in order to be properly integrated, and how they are used by

different functionalities with an identification procedure.

1 INTRODUCTION

Process Systems Engineering (PSE

1

) may be de-

scribed as the art of decision-making for engineering

disciplines such as design, operation, and control of

chemical, physical, and biological processes through

the aid of systematic computer based methods and op-

timization tools (Grossmann and Westerberg, 2000).

The PSE community uses conceptualized modelling

in order to support systematic problem solving. Re-

cently, ontological modelling has been used to build

semantic structures, while Knowledge Engineering

(KE) foundations have been implemented as a new

modelling paradigm with the purpose of supporting

chemical process engineering (Morbach et al., 2007),

managing chemical batch processes (Mu

˜

noz et al.,

2010), data reconciliation (Roda and Musulin, 2014),

pharmaceutical product engineering (Remolona et al.,

2017), etc. In addition, there are other communities

working on similar issues that PSE attempts to solve

(e.g. planning & scheduling (Palacios et al., 2016),

failure prevention (Rajpathak et al., 2001)).

Ontologies use semantic structures, which aim to

1

Complete list of abbreviations are given in Table 1.

Table 1: Abbreviations.

Abbr Explanation

BaPron Batch Process Ontology

CC Conceptual Constraint

CComp Conceptual Component

CCompEl Conceptual Component Element

DMM Decision Making Model

DSS Decision Support System

ISA88 Batch Control Standard from Inter-

national Society of Automation

KE Knowledge Engineering

PSE Process Systems Engineering

represent an abstraction of a domain as well as sup-

port KE applications in many applications such as

Decision Support Systems (DSSs), Artificial Intelli-

gence, etc. DSSs contain a big range of function-

alities and connections to different domains (Shim

et al., 2002). While the conceptualization of De-

cision Making Models (DMMs) in information sys-

tems is crucial, its systematization remains an open

research field. There are many types of DMMs that

may be used rather than mathematical programming

(e.g. dynamic programming or simulations). Addi-

Dombayci C. and EspuÃ

´

sa A.

Modelling Decision Support Systems using Conceptual Constraints - Linking Process Systems Engineering and Decision Making Models.

DOI: 10.5220/0006485201470154

In Proceedings of the 9th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (KEOD 2017), pages 147-154

ISBN: 978-989-758-272-1

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

tionally, the PSE Domain structure may vary from

multi-level hierarchical systems to other systems (e.g.

multi-scale systems, systems of systems, interwoven

systems). However, this work considers (i) multi-

level hierarchies in order to model the information

presented in production systems and (ii) DMMs based

on mathematical programming.

2 BACKGROUND

2.1 DMMs Related Background

The DSSs based on mathematical programming, have

been a topic of great interest in recent years; more-

over, mathematical programming has been used to

tackle modelling issues in the solution stage of

decision-making procedures.

Mathematical programming has been used to sup-

port strategic, tactical, and operational decisions

based on the production and distribution activities of

a production system. However, a hierarchical integra-

tive approach can represent an alternative to mathe-

matical programming. Under this approach, relevant

information is aggregated to develop proper mathe-

matical models (Bradley et al., 1977). DMMs based

on mathematical programming mainly consist of fol-

lowing items (Williams, 2013):

Sets: include indices for certain classes of variables,

indicating the size/complexity of the model to be

solved.

Parameters: coefficients of the model (defined as a

scalar or matrix).

Variables: decision variables of the model.

Constraints: relation between parameters and vari-

ables which have to be considered to ensure feasi-

bility of the proposed decision.

Objective: expression to be minimized or maxi-

mized during the decision-making procedure.

Traditionally, DMMs in production systems are con-

structed manually according to the existing data and

problem features (e.g. time horizon, decision vari-

ables and parameters, definition of constraints, and

selection of objective functions). However, there is

a lack of generic systematics for the construction of

such models (Gani and Grossmann, 2007).

The previous classification of the DMM elements

is generally used for demonstration purposes and the

systematic development of general formulations aim-

ing to solve a domain problem in a generic way. How-

ever, the connections among constraints and other ele-

ments (such as sets, parameters and variables) are not

straightforward inside a formulation and these con-

nections do not appear among different formulations.

Some of the main types of constraints are (Williams,

2013):

• productive capacity constraints or manpower,

• raw material availability,

• marketing demands and limitations,

• balance constraints (e.g. energy and material),

• quality stipulations,

• hard and soft constraints that can be violated or

can be violated by means of an extra cost,

• chance constraints related to probability, and

• simple and generalized upper bounds.

These constraints are generally used to create the

DMMs by selecting and revising according to the

analysis of the process. However, this constraint clas-

sification is not enough to support the automated con-

struction of DMMs. For this reason, the CC Domain

has been proposed and patterns of constraints are sug-

gested to be used during the conceptual modelling of

the CC Domain (Dombayci and Espu

˜

na, 2018).

2.2 PSE Related Background

Over the last decades, ontology development and

usage have been important subjects in applications

related to KE, Artificial Intelligence, Natural Lan-

guage Processing, etc. In the case of PSE, the ex-

tensive exploitation of general PSE ontologies to sup-

port the development and maintenance of models, as

well as their integration and coordination with sys-

tem/models from the related areas/domains is object

of growing interest (Morbach et al., 2007, Mu

˜

noz

et al., 2010,Roda and Musulin, 2014,Remolona et al.,

2017). The research on these application has sup-

ported the management of the great amount of infor-

mation related to the problem statement and the new

exploitations has supported development and (re)used

of conceptual models.

The need of a generic model to support PSE ac-

tivities has been recognized from the very beginning

of the PSE. A reference model for computer inte-

grated manufacturing has been developed (Williams,

1989) as a conceptual representation of the system

and it has evolved to a widely used ANSI standard

on batch control as ISA88 (ISA, 2010). The interdis-

ciplinary area of PSE and KE, different methodolo-

gies have been developed which centre on the creation

of domain knowledge. The batch process ontology

(BaPrOn) is built from the concepts of a batch control

standard (ISA88) and used in order to monitor and

control the scheduling in a pilot plant (Mu

˜

noz et al.,

2010). The intention of not just communicating but

also supporting the integration of different software

tools and exploitation of plant database information

are also considered (Mu

˜

noz et al., 2012). Addition-

ally, integration between planning and scheduling ac-

tivities in batch processes have been modelled using

ontology modelling techniques (Vegetti and Henning,

2015).

The ISA88 standard has supported the background

of the PSE Domain with the main model represen-

tations: process, procedural, and physical models.

These models contain the hierarchical representation

of production systems and connections between these

model elements. The ISA88 has also been used to

build another ontology which is a result of a system-

atic approach for the construction of domain ontolo-

gies (Dombayci et al., 2015). The methodology has

two main steps: (i) a procedure for extraction of con-

cepts and class-subclass pairs from a technical docu-

ment (Farreres et al., 2014) and (ii) a systematic pro-

cedure for solving inconsistencies and contradictions

arisen from the first step. These two steps constitute

a semi-automatic ontology construction methodology.

In addition, the semi-automatic procedure produces

a list of suggestions for improving technical docu-

ments by analysing the conceptual model that is semi-

automatically constructed from the source (Dombayci

et al., 2017). But more importantly basic concepts re-

lated to the standard are extracted and the multi-level

hierarchical structure of ISA88 has been introduced

with its concept and relations.

3 METHODOLOGY

The basic structure underlying the system and con-

cepts in CC Domain is detailed in Section 3.1. The in-

tegration of PSE Domain is suggested to enhance the

CC Domain functionalities and the integration using

ontological elements such as concepts, object prop-

erties, data properties, and instances are presented in

Section 3.1.

In addition, the general steps are introduced re-

lated to the functionalities that can be used to demon-

strate the domain applications is detailed in Section

3.3. The identification procedure related steps are in-

troduced in Section 3.3.1 and the last step related to

the identification is presented in Section 3.3.2 with a

case study.

3.1 The Conceptual Constraint Domain

The conceptualization of DMMs in a Conceptual

Constraint (CC) Domain is important for the auto-

mated building of DMMs using a knowledge-based

system. Therefore, the construction of integrated on-

tological models and their usage in order to provide

conceptualized models for the CC Domain function-

alities are studied. This work demonstrates the mod-

elling, the integration, and the connection of DMMs

and knowledge models from the PSE point of view in

order to maintain a complete DSS. The main aim is

to link these two domains together in order to develop

systematic strategies for supporting decision-making

procedures.

The basic design of the CC Domain is the abstrac-

tion of the DMMs that are constructed through con-

straints, sets, parameters, and variables; ontological

modelling techniques are adopted to model the do-

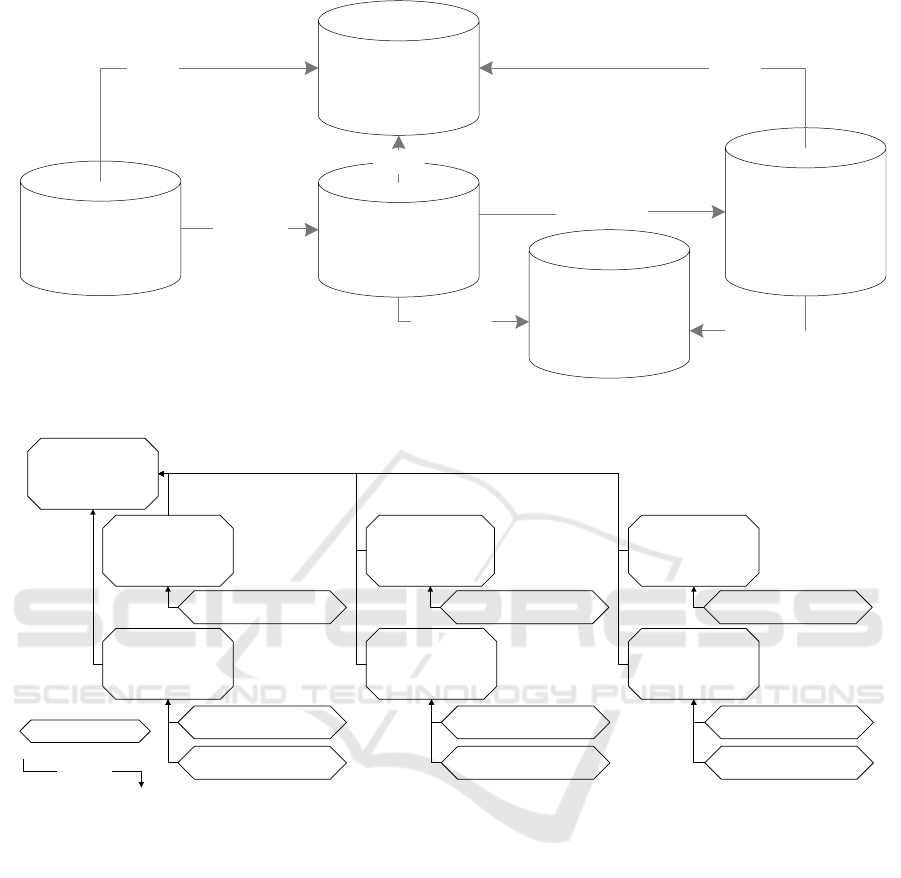

main with ontological model elements. There are 3

main types of concepts that belong to this ontological

model: the Conceptual Constraint (CC), the Concep-

tual Component (CComp), and the Conceptual Com-

ponent Element (CCompEl). A relational demonstra-

tion of these elements is shown in Figure 1 and this

figure is adapted for the case study in Figure 5(see

Section 3.3.2).

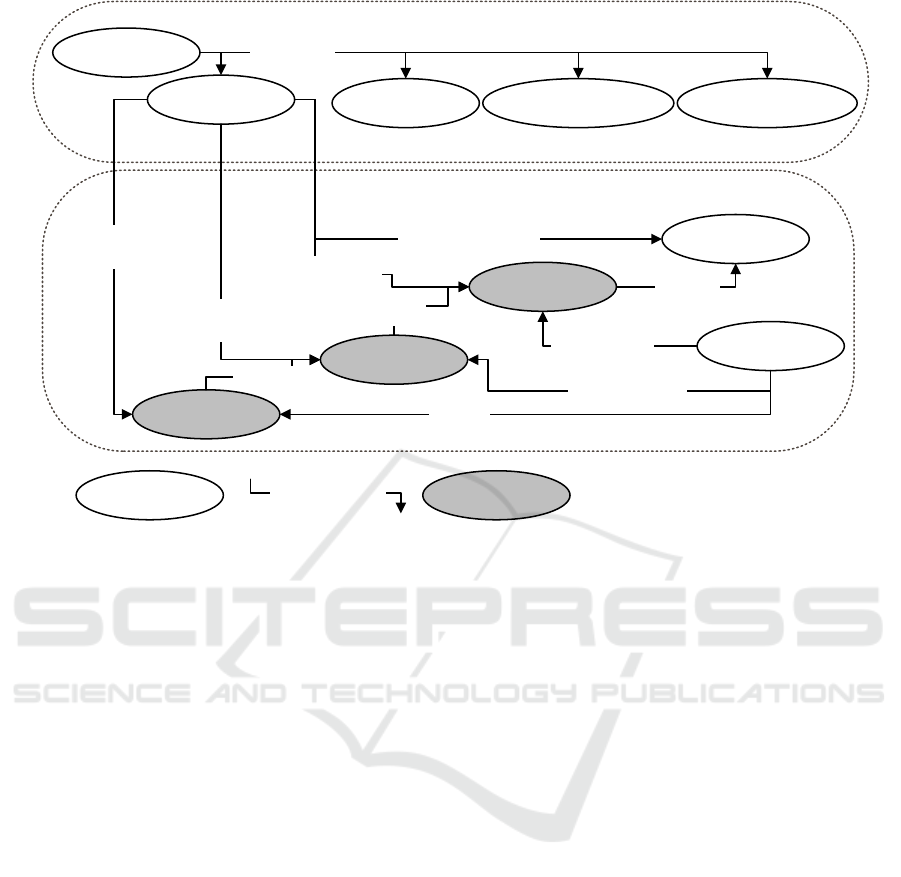

The CCs represent the semantic models of the

main types of constraints, which are built from the

main publications containing DMMs related to pro-

duction systems. The first step is to build a tax-

onomy that captures the main constraints such as

’BalanceCC’, ’ResourceAllocationCC’, ’TimingCC’,

’SizingCC’, ’SequencingCC’, and ’EconomicalCC’.

Then, the taxonomy is detailed considering these

main types of constraints, as depicted in Figure 2.

The CCs are separated into fundamental constraint

types, then the CC taxonomy is deepened with sub-

classes. For instance, the ’BalanceCC’ has the ’Mate-

rialBalanceCC’ and the ’EnergyBalanceCC’ concepts

as subclasses, which share the balancing as a com-

mon element as well as the same CComps such as the

’StoredAmount’. Depending on characteristics of the

CC the ’StoredAmount’ CComp may change from en-

ergy to material and the CCompEls that are connected

to the PSE Domain change from a concept connected

to an energy to material.

The CComps represent the concepts that construct

the CCs. The partOf relation connects CCs and

CComps in order to construct the patterns of each CC;

each CComp may be connected to more than one CC.

The elements in the DMMs (parameters, variables)

are represented through CComps. The representation

of these elements is straightforward, for example, the

Conceptual

Constraint Domain

Conceptual

Component

Conceptual

Constraint

Conceptual

Component

Element

partOf

hasCompEl

Integrated object

and data properties

(CC and PSE

Domains)

connected

hasComp

connected

partOf

partOf

Figure 1: Relations in the CC Domain.

Resource

Allocation

CC

Sizing CC Balance CC

Physical Model

Allocation CC

Sequencing

CC

Material Balance CC

Sequence Dependent

Changeover CC

Time Matching CC

Sales Sizing CC

Production Sizing CC

Timing CC

Worker Allocation CC

Economical

CC

Total Cost

Economical CC

Energy Balance CC

Conceptual

Constraint

Concept

is-a

(taxonomic

relation)

Figure 2: Part of the Conceptual Constraint Taxonomy in the CC Domain.

CComp ’ProducedMaterial’ may present a variable.

On the other hand, the ’ProducedMaterial’ CComp

may present an expression that is constructed from a

variable and a parameter. For instance, the ’Produced-

Material’ may present a proportion (parameter) of the

input material (variable).

The CCompEls represent the connections of the

CComps to the different concepts, which appear in

the conceptual domain (i.e., the PSE Domain) in order

to carry out the applications. Therefore, the CComps

are connected to the CCompEls for the definition of a

DMM. For instance, the ’ProducedMaterial’ CComp

may be defined with a unit in one DMM and with a

process cell in another DMM.

3.2 Integration of the CC and PSE

Domains

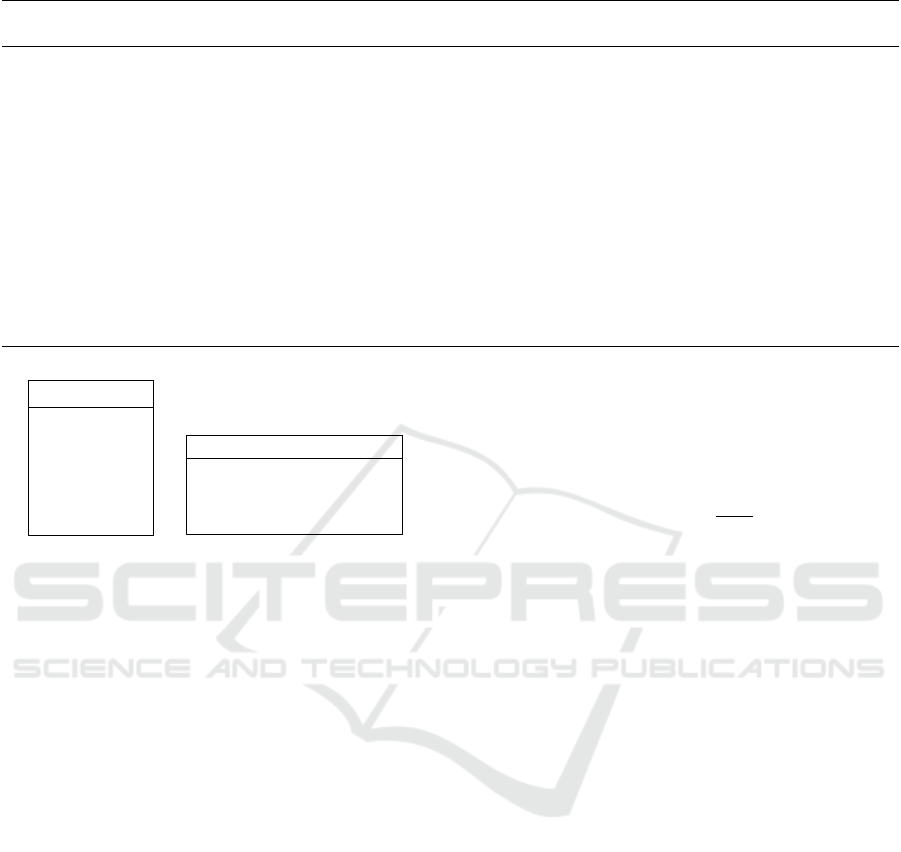

The Material Balance CC example is depicted in Fig-

ure 3 containing the ’ProducedMaterial’ CComp and

its relations. Two separate sections are used for the

CC and PSE Domains. The CC Domain section the

CCs are connected to CComps. In the CC Domain

section the CCs are connected to CComps, while the

CCompEls are connected to their specific concepts

in the PSE Domain. Then, each CComp is con-

nected to the CCompEls that exist in PSE Domain.

The example shows that ’a MaterialBalanceCC has

ProducedMaterial as a CComp’ and ’ProducedMate-

rial CComp may be linked to 4 different CCompEls

depending on the DMM-formulation (F1, F2, F3,

F4). These formulations represent different DMMs

Conceptual Constraint Domain

Process Systems Engineering Domain

Material

Balance CC

Consumed

Material

Produced

Material

Currently Available

Material

Previously

Available Material

Procedural

Model

Physical Model

Enterprise

Process Cell

Unit

linked of CCompEl

in F1

linked of

CCompEl in F2

linked of

CCompEl in F3

has Process Cell

has Enterprise

has Unit

linked of

CCompEl in F4

is part of

is part of

is part of

has CComp

Concept

Object Property

Concept

Figure 3: Connections between CC and PSE Domains.

in the multi-level hierarchies. However, these ele-

ments appear in the PSE Domain where another tax-

onomy exists. In this sense, the ’PhysicalModel’

concept has different sub-concepts and the ’Procedu-

ralModel’ is connected to these elements of physical

model through the ’ProceduralModel’. In addition, a

’partOf’ relation is depicted in the PSE Ontology that

contains the hierarchical model representation of an

enterprise.

3.3 Functionalities

The integration between the CC and PSE Domains

brings these domains together for the applications; for

example, extending the DMMs arisen in a specific hi-

erarchical level to another level or using an already

constructed DMM for a specific problem instead of

constructing a new DMM from the beginning. In this

section, 5 steps required for the constraint prediction

application are explained. The first 3 steps are the

steps that are general steps to be used in many func-

tionalities include parsing and matching from sets, pa-

rameters, variables and equations to the CC Domain

elements. Afterwards, Section 3.3.1 introduces the

fourth step that is a network construction from the

DMMs. The fourth step is required for the explana-

tion of the functionality explained in Step 5 in order

to predict the CC type.

Here, the basic steps required in order to identify a

constraint within the framework, starting from a con-

straint that is written using a high level syntax are ex-

plained:

Step 1: The first step is to parse the source con-

taining a constraint that is to be identified within the

pre-determined structure. The DMM equations are

decomposed into elements by automatically parsing a

source file into set, variable, parameter and equation

inputs.

Step 2: The DMM elements found in the previous

step are matched in a list of CComps and CCompEls.

For instance, set inputs are matched to the CCompEls,

whereas parameter and variable inputs are matched to

the CComps. The matching step can be performed in

two ways: (i) direct user interaction and/or (ii) based

on a dictionary that stores user decisions for previous

matching procedures. The information coming from a

user interaction or the dictionary are used in the Step 3

for matching the connections between equations. In-

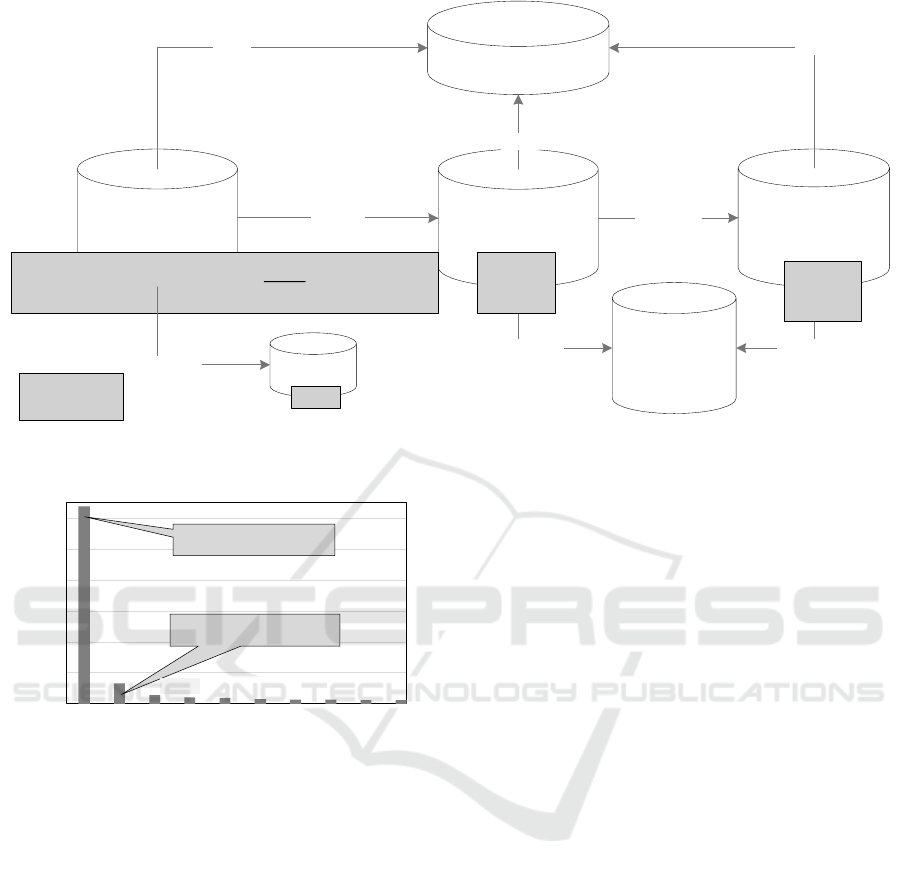

puts are stored in a structure contains IDs, explana-

tions, list of parameters and corresponding identified

fields as depicted in Figure 4(a).

Step 3: The equation inputs are connected to the CC

Domain elements (CComps and CCompEls) through

the set, parameter and variable inputs. These connec-

tions are stored as ’equation connections to the ele-

ments’ in enriched equation input structure as illus-

trated in Figure 4(b).

Table 2: Connections of Equation 1.

Symbol Explanation from the source paper CC Domain connec-

tion (CComp)

PSE Domain connection

(CCompEl)

K Set: energy storage systems (k ∈ K) PhysicalModel

TRH Set: time intervals included in the current

prediction horizon (t ∈ T RH)

Time Model

η

in

k

Parameter: charging efficiency of energy

storage system k

ChargingEfficiency PhysicalModel

η

out

k

Parameter: discharging efficiency of en-

ergy storage system k

Discharging Effi-

ciency

PhysicalModel

Ld

k,t

Variable: energy supplied to load system

k during interval t (kW h)

SuppliedDemand PhysicalModel, TimeModel

SP

k,t

Variable: energy supplied by storage sys-

tem k during interval t (kW h)

SuppliedDemand Physical Model, TimeModel

SE

k,t

Variable: electricity storage level of sys-

tem k at the end of the interval t (kW h)

CurrentlyAvailable

Amount

PhysicalModel, TimeModel

Parameter Input

ID

explanation

listOfParameters

IdentifiedField

ID

Individual

IdentifiedQuery

(a) Parameter Input.

Equation Input

ID

listOfEquation

equationExplanation

equationConnectionToELements

(b) Equation Input.

Figure 4: Enriched Input Structures.

3.3.1 The Network Construction

This section illustrates how constraint identification

is managed in the domain by exploiting the already

established connections between the CC and PSE Do-

mains. The Step 4 introduces complete and consistent

DMMs containing known constraints as input.

Step 4: A network is built through the CC Do-

main using the CC Domain model information that

was previously developed using the Machine Learn-

ing Toolbox of Matlab. A Bayesian network is build

using CComp and CCompEls as features of each class

(CCs) so that the network can be used to predict the

type of the introduced constraint.

3.3.2 The Constraint Identification and the Case

Study

The Step 5 is the core step that uses the general steps

(1-3) and network construction and predicts the type

of the constraint.

Step 5: This step combines all the connected-

identified elements of an equation and the CC Domain

network in order to predict the type of the CC in the

domain. As a result, a set of probability values are

received corresponding to the unknown constraint.

Constraint Identification Case Study: In order to

demonstrate the constraint identification, an energy

balance equation from an energy supply and demand

planning DMM is used (Silvente et al., 2015):

SE

k,t

= SE

k,t−1

+ η

in

k

∗ Ld

k,t

−

SP

k,t

η

out

k

, ∀k ∈ K, t ∈ T RH

(1)

Equation 1 has been parsed and paired through

the same procedures explained in Section 3.3 (Step

1-3). Table 2 shows the full list of symbols, nomen-

clature explanations of these symbols from the source

paper and connected elements in the CC and PSE Do-

mains. The connected elements of the sets (K and

TRH) are the CCompEls and the rest of the symbols

belong to the CComp type of concepts. Accordingly,

while sets have the same concept in the PSE Domain

column, the CComps (variables and parameters) have

connected CCompEls.

Relations in the CC Domain are shown in Figure

5. The connections of elements in the CC Domain

are depicted with the example including the relations

between the models. The demonstrative example is

used as an instance of the domain where the parsed

and matched information are shown. For instance,

Equation 1 is depicted as a ’BalanceCC’ since there

are many CComp connections with the hasCompo-

nent relation. After the implementation of Step 5, the

prediction probabilities are obtained as in Figure 6.

As a result, the constraint in Equation 1 is predicted as

a ’BalanceCC’ with 0.64 probability and an ’Energy-

BalanceCC’ with a probability of 0.07 (the remaining

predictions are less than 0.03); note that the classifi-

cation is made by evaluating 41 types of CCs. The

domain model can be continuously improved as new

formulations are reviewed. The results are expected to

have higher probability value while the domain model

Conceptual Constraint

Domain

Conceptual Component:

Currently Available

Amount

Conceptual Constraint:

Balance Constraint

Conceptual Component

Element:

Procedural Model &

Time Model

partOf

hasCompEl

hasProcedure,

hasTimeInterval

and

#currentlyAvailable

Amount

connected

hasComp

connected

partOf

partOf

,

SE

kt

&kt

Previously Stored

Amount

,1

SE

kt

,

, , 1 ,

SE =SE + Ld - , k,t TRH

kt

in

k t k t k k t

out

k

SP

hasComp

Instance of a

concept

Figure 5: Connections of Conceptual Models with the Example.

Balance CC, 0.64

Energy Balance CC, 0.07

0.03

0.00

0.10

0.20

0.30

0.40

0.50

0.60

Probability

Conceptual Constraints

Contraint identification results of the input 'equation'

Figure 6: Result of Identification of Equation 1 (x-axis rep-

resents each CC and y-axis gives the probability of being in

the same CC).

is getting more accurate and larger in terms of differ-

ent formulations introduced.

The purpose of the identification procedure is not

only to predict the type of the constraint but also to

fully identify the constraint connections to the do-

main. Therefore, all connections related to the con-

straint have been introduced to the system. The con-

straint is defined as a Balance CC with the connec-

tions to the specific physical model used but it can

be expected to be used in any extension procedure by

simply changing the connections in the PSE Domain.

4 CONCLUSIONS

This paper has presented a framework aiming to

support construction of Decision Making Models

(DMMs) using the Conceptual Constraint (CC) Do-

main. The construction of DMMs requires a proce-

dure that involves a DMM abstraction and the inte-

gration with domains connected to the main purpose.

The CC Domain contains the generic/abstract model

information of DMMs and conceptualized patterns of

constraints. Therefore, the CC Domain is adequate

for representation of constraints. A production system

domain, the Process Systems Engineering (PSE) Do-

main, containing multi-level hierarchies, is selected to

be integrated into the CC Domain to illustrate its main

features. The paper presented a procedure that allows

the identification of constraints in the CC Domain.

The procedure was demonstrated using an example

from energy systems in order to show some aspects

of the framework. This identification procedure may

be used as the basis of an integration procedure that

integrates DMMs at multi-level hierarchies. The CC

Domain is continuously improved by considering dif-

ferent DMMs; however, it is important to consider au-

tomated processing of the DMMs to improve the CC

Domain. Further developments should be devoted to

explore the potential use of classification algorithms.

ACKNOWLEDGEMENTS

Financial support from the Spanish Ministry of Econ-

omy and Competitiveness and ERDF (ECOCIS:

DPI2013-48243-C2-1-R), and AGAUR (2014-SGR-

1092-CEPEiMA and grant FI) is fully appreciated.

REFERENCES

Bradley, S. P., Hax, A. C., and Magnanti, T. L. (1977). Ap-

plied mathematical programming. Addison-Wesley

Publishing Company.

Dombayci, C. and Espu

˜

na, A. (2018). Building De-

cision Making Models Through Conceptual Con-

straints: Multi-scale Process Model Implementations.

In Fink, A., F

¨

ugenschuh, A., and Geiger, M.-J., ed-

itors, Operations Research Proceedings 2016, pages

77–83. Springer International Publishing.

Dombayci, C., Farreres, J., Rodr

´

ıguez, H., Espu

˜

na, A., and

Graells, M. (2017). Improving automation standards

via semantic modelling: Application to ISA88. ISA

Transactions, 67:443–454.

Dombayci, C., Farreres, J., Rodr

´

ıguez, H., Mu

˜

noz, E.,

Cap

´

on-Garc

´

ıa, E., Espu

˜

na, A., and Graells, M. (2015).

On the Process of Building a Process Systems Engi-

neering Ontology Using a Semi-Automatic Construc-

tion Approach. In Computer Aided Chemical Engi-

neering, volume 37, pages 941–946.

Farreres, J., Graells, M., Rodr

´

ıguez, H., and Espu

˜

na, A.

(2014). Towards Automatic Construction of Domain

Ontologies: Application to ISA88. In Kleme

ˇ

s, J. J.,

Varbanov, P. S., and Liew, P. Y., editors, Proceedings

of the 24th European Symposium on Computer Aided

Process Engineering, pages 871–876. Elsevier.

Gani, R. and Grossmann, I. (2007). Process systems engi-

neering and CAPE - what next? Proceedings of the

17th European Symposium on Computer Aided Pro-

cess Engineering, pages 1–5.

Grossmann, I. E. and Westerberg, A. W. (2000). Research

challenges in process systems engineering. AIChE

Journal, 46(9):1700–1703.

ISA (2010). Batch Control, Part 1: Models and Terminol-

ogy, ANSI/ISA-88.01-2010. ISA Committe.

Morbach, J., Yang, A., and Marquardt, W. (2007).

OntoCAPE-A large-scale ontology for chemical pro-

cess engineering. Engineering Applications of Artifi-

cial Intelligence, 20(2):147–161.

Mu

˜

noz, E., Cap

´

on, E., La

´

ınez, J., Espu

˜

na, A., and Puig-

janer, L. (2012). Ontological framework for inte-

grating environmental issues within sustainable enter-

prise: Enhancing enterprise decision-making. KEOD

2012 - Proceedings of the International Conference on

Knowledge Engineering and Ontology Development,

pages 385–388.

Mu

˜

noz, E., Espu

˜

na, A., and Puigjaner, L. (2010). Towards

an ontological infrastructure for chemical batch pro-

cess management. Computers & Chemical Engineer-

ing, 34(5):668–682.

Palacios, L., Lortal, G., Laudy, C., Sannino, C., Simon, L.,

Fusco, G., Ma, Y., and Reynaud, C. (2016). Avionics

Maintenance Ontology Building for Failure Diagnosis

Support. In Proceedings of the 8th International Joint

Conference on Knowledge Discovery, Knowledge En-

gineering and Knowledge Management (Ic3k), vol-

ume 2, pages 204–209. SCITEPRESS - Science and

and Technology Publications.

Rajpathak, D., Motta, E., and Roy, R. (2001). A generic task

ontology for scheduling applications. In International

Conference on Artificial Intelligence (IC AI’2001),

Las Vegas, USA.

Remolona, M. F. M., Conway, M. F., Balasubramanian,

S., Fan, L., Feng, Z., Gu, T., Kim, H., Nirantar,

P. M., Panda, S., Ranabothu, N. R., Rastogi, N., and

Venkatasubramanian, V. (2017). Hybrid ontology-

learning materials engineering system for pharmaceu-

tical products: Multi-label entity recognition and con-

cept detection. Computers & Chemical Engineering.

Roda, F. and Musulin, E. (2014). An ontology-based

framework to support intelligent data analysis of sen-

sor measurements. Expert Systems with Applications,

41(17):7914–7926.

Shim, J., Warkentin, M., Courtney, J. F., Power, D. J.,

Sharda, R., and Carlsson, C. (2002). Past, present,

and future of decision support technology. Decision

Support Systems, 33(2):111–126.

Silvente, J., Kopanos, G. M., Pistikopoulos, E. N., and

Espu

˜

na, A. (2015). A rolling horizon optimization

framework for the simultaneous energy supply and

demand planning in microgrids. Applied Energy,

155:485–501.

Vegetti, M. and Henning, G. (2015). An Ontological Ap-

proach to Integration of Planning and Scheduling Ac-

tivities in Batch Process Industries. In Computer

Aided Chemical Engineering, volume 37, pages 995–

1000.

Williams, H. P. (2013). Model Building in Mathematical

Programming. Wiley, 5th edition.

Williams, T. J., editor (1989). A Reference Model for Com-

puter Integrated Manufacturing (CIM): A Description

from the Viewpoint of Industrial Automation. Instru-

ment Society of America.