Designing Fingers in Simulation based on Imprints

Lukas Christoffer Malte Wiuf Schwartz

1

, Adam Wolniakowski

2

, Andrzej Werner

2

,

Lars-Peter Ellekilde

1

and Norbert Kr

¨

uger

1

1

The Maersk McKinney-Moller Institute, University of Southern Denmark, Odense, Denmark

2

Department of Mechanical Engineering, Białystok University of Technology, Białystok, Poland

Keywords:

Simulation, Gripper Design, Optimization, Grasping.

Abstract:

Gripper design is nowadays an area of ongoing research activity. The problem of creating a generic and auto-

mated gripper design approach tailored for a specific task is still far from solved. In this paper, we propose a

new method of generating finger cut-outs aimed at simplifying the design process of doing so. This method

takes root in the idea of using the imprint to produce the finger geometry. We furthermore provide a verifica-

tion of our newly introduced imprinting method and a comparison to the previously introduced parametrized

geometry method. This verification is done through a set of grasping experiments performed in simulation on

two objects with geometry features based on those found in industrial setting.

1 INTRODUCTION

A large portion of industrial tasks that are (or can)

be automatized through the use of robots consists of

handling, manipulating, moving and placing of ob-

jects. There are some challenges that are associated

with strict requirements on the process quality since

the objects have to be (Honarpardaz et al., 2017):

1) grasped robustly and successfully,

2) moved rapidly in effort to reduce the cycle time,

and

3) then placed precisely.

All of this is done in presence of uncertainties,

which are due to factors like sensor calibration, im-

precise end-effectors or the flexibility of objects and

their environment. In addition, new grasping solu-

tions have to be adopted quickly, in order to respond

to changing manufacturing processes in small and

medium sized productions, often encountered in the

industry.

In typical industrial cases, the gripper solutions

are commonly implemented starting with the selec-

tion of the gripper. The fingers are then designed

by experienced engineers with the usage of heuris-

tics, guidelines, experience and trial-and-error exper-

iments. The finished designs are often produced by

the user or system integrator, using additive manufac-

turing or CNC machines. The process is cumbersome

and demanding in terms of the cost and the time re-

quired to establish a working solution.

The use of 3D printing as gripper manufacturing

technique invites the creation of smart software solu-

tions to produce and optimize the finger geometries.

The increasing computational power available and the

development of robotic frameworks (such as Rob-

Work (Ellekilde and Jørgensen, 2010)) and physical

engines, such as ODE (Smith, 2008) and RWPhysics

(Thulesen and Petersen, 2016) facilitate the use of

dynamic simulation to replace the arduous trial-and-

error design process. The automation of design with

the use of flexible software tools is indeed a current

trend in industrial manufacturing and robotics.

In our previous work (Wolniakowski et al., 2017),

a gripper design method was introduced which uses

dynamic simulation in order to provide a quality esti-

mate of parametrized grippers. This allows for the fin-

ger designs to be automatically optimized. This previ-

ously described method, while flexible and allowing

for inclusion of task context information in the gripper

optimization process, suffers from rather complex re-

quirements on the amount of set-up and user input. In

particular, the user has to provide a basic idea for the

gripper structure in form of the geometry parametriza-

tion (which is then numerically optimized). An exam-

ple of how a geometry parametrization can look like

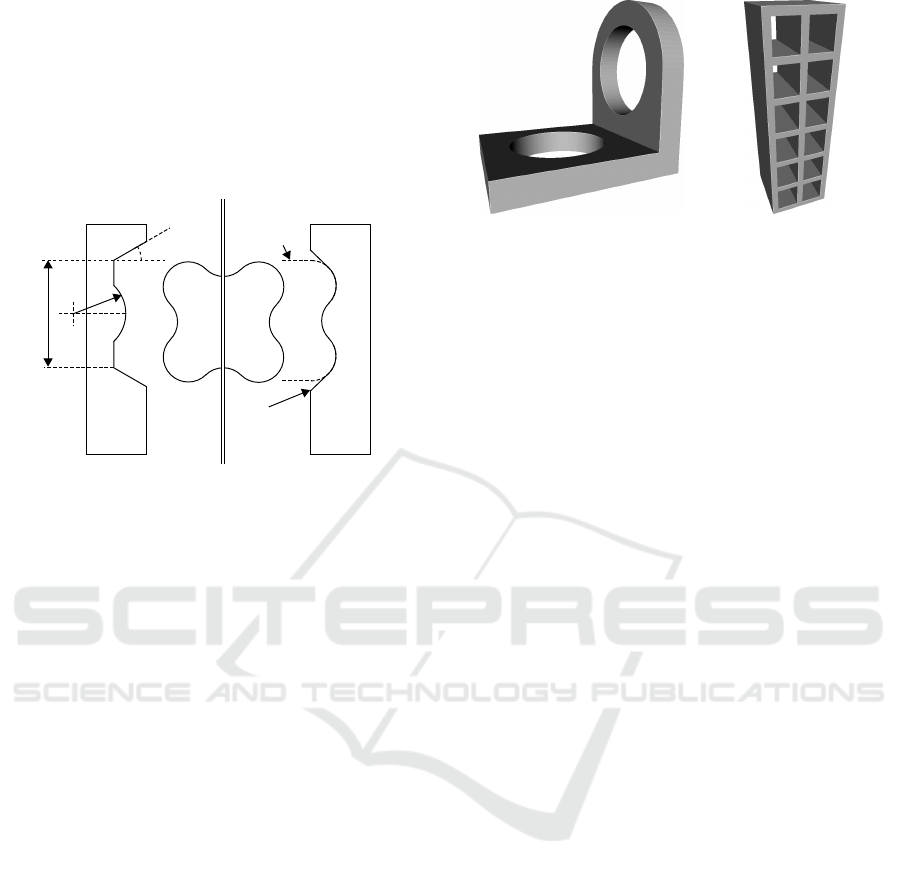

is seen as the left finger in Figure 1. This itself is

by no means trivial, and it can be easily seen that no

globally optimal gripper solution can be found when

304

Schwartz, L., Wolniakowski, A., Werner, A., Ellekilde, L-P. and Krüger, N.

Designing Fingers in Simulation based on Imprints.

DOI: 10.5220/0006441003040313

In Proceedings of the 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2017), pages 304-313

ISBN: 978-989-758-265-3

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

a insufficiently flexible parametrization is provided.

Defining the cut-out shape parametrization manu-

ally is particularly difficult and time consuming. In-

stead, the cut-out shape can be automatically gener-

ated based on the object’s imprint in the fingers. Fur-

thermore, the generated cut-out can be post-processed

in order to eliminate the grasped object’s pose uncer-

tainty (see the right finger in Figure 1).

Object

Paramatized

Imprint

imprint

post-

processing

a

w

r

d

Figure 1: The two different ways to design the fingers anal-

ysed in this work. On the left: the manual parametriza-

tion method (PFO, introduced previously in (Wolniakowski

et al., 2017)). On the right: the new imprint based method

(IFM).

In this work, we propose a method of generating

the parametrized cut-out profiles based on the grasped

object imprints. The method is an extension of the

previously presented idea (Wolniakowski et al., 2015)

that greatly reduces the user input required in setting

up the gripper optimization process. In doing so, this

development marks another step in creation of a fully

automated gripper design framework. The two finger

design methods can be used in conjunction utilizing

the synergy of the flexibility in selecting the custom

optimal finger shapes, while the cut-out shape is gen-

erated automatically to match the grasped object’s ge-

ometry.

The new cut-out shape generation method is tested

by comparing its performance with the previous

parametrized geometry optimization method in two

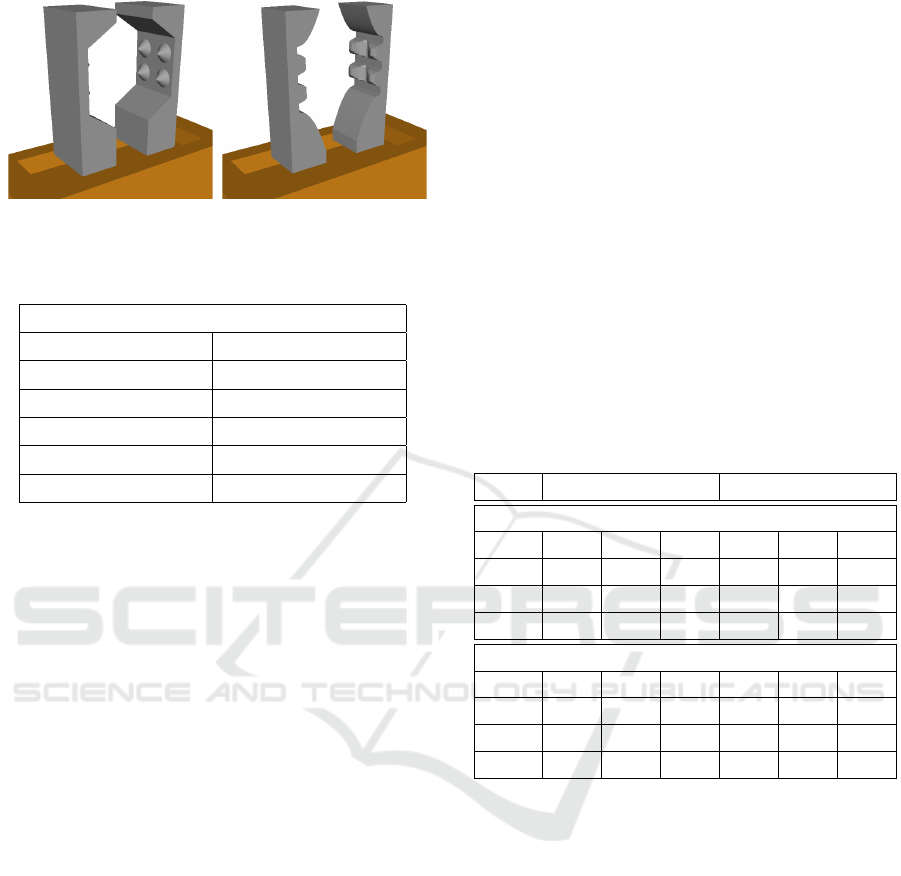

scenarios of grasping objects of complex shapes: the

bracket and the heatshield (see Figure 2). For each of

these objects, the optimized finger geometry is gen-

erated and subsequently their alignment capability is

tested in simulated grasp experiments.

The paper is organized as follows. First, in Sec-

tion 2, an analysis of the gripper design problem is

presented, summarizing the research published in the

field, and analysing several contemporary solutions

used in the industry. Next in Section 3, we present

our data-driven parametrized finger geometry genera-

tion method (Wolniakowski et al., 2017) and our new

(a) The bracket object. (b) The heatshield object.

Figure 2: The objects used in the gripper design experi-

ments.

method, based on the object imprint. In Section 4, the

performance of the two methods is compared when

designing gripper fingers for grasping two complex

objects. The fingers are then tested in simulations,

in order to determine the range of grasp uncertainties

that the designed grippers can compensate for. Fi-

nally, we present our conclusions in Section 6.

2 STATE OF THE ART

The most common gripper structure used in the in-

dustry nowadays is that of a parallel finger gripper.

A parallel finger gripper consists of a base which

provides the actuation (be it electric or pneumatic),

which is typically selected from an array of off-the-

shelf products and of two fingers. The fingers move

in a linear fashion in opposite directions until a cer-

tain position or force is achieved. The reason for the

widespread use of the parallel gripper design is its rel-

ative simplicity and flexibility. The adaptation to a

new context is usually done by designing and mount-

ing a new pair of fingers, tailored to fulfil the require-

ments of a specific task. Nowadays these fingers are

often designed and manufactured (e.g. printed) by the

system integrator or user. The process of gripper fin-

ger design is not a simple task, and an area of on-

going research.

An excellent literature review in the field of grip-

per design has been recently published by (Honarpar-

daz et al., 2017). They discuss the long-established

solutions and recent developments critically selected

from the database of thousands of articles. Other

similar reviews can be found in (Boubekri and

Chakraborty, 2002; Blanes et al., 2011).

The typical workflow involved in the design of

a new gripper solution can be described as follows

(Honarpardaz et al., 2017): 1) the requirements im-

posed on the task by the grasped object properties and

the task context is gathered, 2) a decision is then made

Designing Fingers in Simulation based on Imprints

305

on whether the grasps are performed using the force-

fit or form-fit method (Honarpardaz et al., 2017), and

3) the grasp sets are generated and analysed. The ac-

tual finger design is done after the optimal grasp has

been found, and iterated in a trial-and-error process

(testing e.g. unwanted collisions and grasp robust-

ness) until a solution is found that is good enough.

The area of gripper design research is obviously

closely connected with that of the research on grasp-

ing. As discussed above, the selection of suitable

grasps is an essential component of the design pro-

cess. In this field, contributions by (Borst et al., 2004;

Kraft et al., 2012; Li et al., 2007; Berenson et al.,

2007; Jørgensen and Petersen, 2010; Stulp et al.,

2011) can be noted, in which various quality measures

of the grasps space are considered. We make use of

these grasp quality objectives in our gripper quality

evaluation.

The process of gripper design is expensive in

terms of time, cost and the expertise required. Numer-

ous guidelines have been created, including heuris-

tics which can be applied to assist with the process.

These guidelines include, for example contributions

such as (Krenich, 2014; Causey and Quinn, 1998).

Many guidelines have been conveniently gathered in

a work concerning agility in manufacturing (Causey,

2003).

Numerous works have been published in which

the kinematic structure of the gripper that is subjected

to optimization (Cuadrado et al., 2002a; Lanni and

Ceccarelli, 2009; Cuadrado et al., 2002b; Ceccarelli

et al., 2002). In other works, modular or reconfig-

urable gripper jaws systems were proposed (Zhang

and Goldberg, 2006; Kolluru et al., 2000).

Recently, dynamic simulation has been proposed

as a tool to facilitate the replacement of a trial-and-

error process with much easier virtual experimenta-

tion. In (Ellekilde and Petersen, 2006) they proposed

the design of the gripper jaws based on the convex-

hull molding, in order to achieve robustness in terms

of grasped object pose uncertainty. The results have

been verified both in real-world experiments and in

simulation. Molding and imprinting is taken to be the

same in the cut-out generation process, the two terms

are therefore used interchangeably.

In (Wolniakowski et al., 2014), we introduced a

metric for the quality of a gripper design which takes

into account the conditions imposed by the task con-

text. We have subsequently worked on the formula-

tion of gripper design parametrization and optimiza-

tion methods (Wolniakowski et al., 2015), so that

the gripper finger design process could be automated.

This process was furthermore tested in various sce-

narios (Wolniakowski et al., 2017).

A new online tool by Schunk was recently made

available (Schunk, 2015). This tool uses the estab-

lished method of using the object molding on the fin-

ger, so that a new form-fit design can be created eas-

ily. The tool requires input from the user in terms of

the selection of a base finger shape, the expected pose

of the object and other relevant variables. This im-

plementation is protected by a patent (Schuster et al.,

2014). Molding has indeed been long used for grip-

per finger design (Velasco and Newman, 1998). The

major shortcomings of this method is the sensitivity

to uncertainties in the object shape and pose, and its

inapplicability to certain classes of objects.

In this work, a new imprinting method inspired by

the previous ideas within finger design using molds or

imprints is presented. We do not only use the profile

created by the inverse of the object’s geometry, but

also add profiles around the cut-out to facilitate the

guiding of the object into a stable position when the

pose uncertainties are present. Furthermore, simula-

tions are used as a tool to verify the designs.

3 METHODS

In this section, the gripper design optimization meth-

ods used in this work a described, starting with the

short primer on the parametrized geometry optimiza-

tion method introduced previously in (Wolniakowski

et al., 2017) (see Section 3.1). The new Imprint Fin-

ger Method (IFM) method is then introduced (see

Section 3.2), which builds upon the former by greatly

simplifying the process of finding the appropriate cut-

out parametrization for the grasped objects.

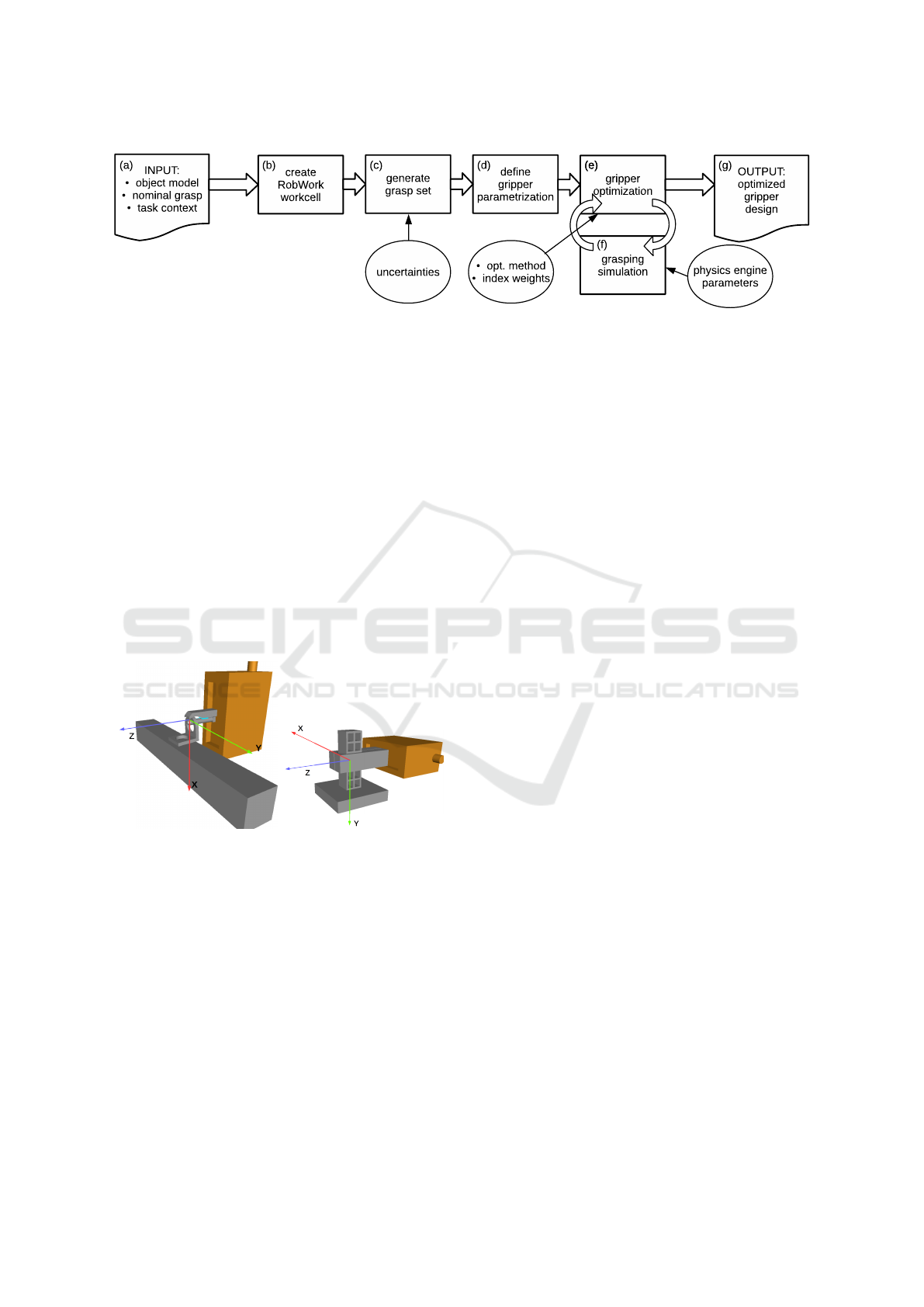

In both methods, the general workflow is similar

(see Figure 3). The common inputs required from the

user are: a 3D model of the object, the expected grasp

location (pose), and the task description (i.e. the ob-

ject position, the environment, uncertainties, gripper

structure, grasp success conditions, etc.) – see Fig-

ure 3a. In the first step, the environment representa-

tion has to be created (see Figure 3b), this was done

using the RobWork (Ellekilde and Jørgensen, 2010)

XML format. Next, the grasp set is generated by

perturbing randomly the grasp pose specified by the

user (see Figure 3c). Then, the gripper parametriza-

tion has to be provided by the user (see Figure 3d).

This can be done in the form of a OpenSCAD (Kin-

tel, 2009) script that contains a parametric model of

the finger geometry or using the hereby introduced

method (see Section 3.2). Finally, the simulation of

the generated grasps (see Figure 3f) is done repeat-

edly for different gripper designs proposed by the op-

timization procedure (see Figure 3e). The output con-

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

306

sists of the optimized gripper model (see Figure 3g).

The dynamic simulations were in both methods im-

plemented using the RobWork framework (Ellekilde

and Jørgensen, 2010) and its simulation package Rob-

WorkSim (Jørgensen et al., 2010). The physics en-

gine used in simulation is the Open Dynamics Engine

(ODE) (Smith, 2008).

Our new method allows for a significant reduction

in user input required through automating the gener-

ation of the finger geometry parametrization, thus re-

ducing the set-up time of the finger parametrization

and improving on the ease of use.

3.1 Parametrized Finger Optimization

(PFO)

In our previous work (Wolniakowski et al., 2017),

a method was introduced for computing the gripper

quality for a given task context using dynamic simu-

lation as a tool. Several Gripper Quality indices were

defined, capturing essential gripper properties neces-

sary to execute the grasping tasks successfully. These

quality measures are:

Success Index (S) which quantifies the overall suc-

cess rate of the executed grasps.

Coverage Index (C) which provides a measure of

the gripper versatility expressed as the size of the

successful approach vectors.

Robustness Index (R) defining the gripper perfor-

mance in presence of pose uncertainties.

Alignment Index (A) quantifying the size of pose

uncertainties for which the grasped object is still

forced by the gripper into a predictable pose.

Wrench Index (W) measuring the average robust-

ness of the grasps in terms of Grasp Wrench Space

metric (Ferrari and Canny, 1992).

Stress Index (T) representing structural robustness

of the gripper design.

Volume Index (V) based on the time and material

needed to produce the gripper fingers.

The details on the implementation of the quality in-

dex calculation can be found in (Wolniakowski et al.,

2017). The quality evaluation is based on simulat-

ing a number of grasps, generated either using heuris-

tic planning or generated stochastically with user-

provided uncertainty estimations.

These metrics was used in conjunction with a

gripper geometry parametrization method and an ar-

ray of numerical optimization techniques in order to

improve gripper finger designs automatically. The

objective function for the optimization is defined as

a weighted geometric average of individual indices

(Equation 1):

Q =

N

∏

i=1

q

w

i

i

!

1/

∑

N

i=1

w

i

(1)

where q = [S, C, R, A, W, T, V ] is the vector of the

seven gripper quality indices described above and the

w

1

, w

2

, ... are the respective weights.

The performance of the method was showcased

in several industry-based grasping scenarios (Wol-

niakowski et al., 2016). While this previously in-

troduced gripper design method (which will subse-

quently be referred to as the ”PFO method”) is ap-

plicable and flexible, it still requires the user to pro-

vide a lot of manual input in form of a custom ge-

ometry parametrization, decide on the weights of the

quality objective and the numerical optimization tech-

nique used. This problem is now targeted by automat-

ing the generation of the gripper cut-out, as described

in the following section.

3.2 Imprint Finger Method (IFM)

The generation of the cut-out for a finger takes basis

in the idea of pressing the object into a piece of soft

clay. Using the imprint of the object directly as a cut-

out is a poor solution since it requires a high degree

of pose certainty to place an object into its cut-out. To

improve the performance, the cut-out is modified to

get the final cut-out used to generate the finger.

4 RESULTS

In the experiments, the performance of the data-

driven gripper design and optimization methods for

grasping two different objects was compared. The

two selected objects: the bracket and the heatshield

are shown in Figure 2 . The objects were chosen as to

highlight the pros and cons of both considered meth-

ods (PFO and IFM) and to provide a reasonable de-

sign challenge. The bracket object was designed in a

fashion to make it difficult to generate the imprinted

fingers for it, due to the necessity of using the internal

grasp. The heatshield in turn poses a challenge for the

user designed cut-out parametrization: it is not a triv-

ial requirement to provide a simple (i.e. using only

a few free variables) parametrization that is flexible

enough for an object of complex geometry.

The object models were generated using the

OpenSCAD software. The bounding box dimensions

for the objects are 35 × 30 × 35 mm for the bracket

Designing Fingers in Simulation based on Imprints

307

Figure 3: The workflow in using the parametrized gripper optimization methods.

object and 30 × 30 × 100 mm for the heatshield ob-

ject respectively. For the purpose of simulation, their

masses were assigned to be m

bracket

= m

heatshield

=

50g. The friction properties of the material were set

to correspond to printable plastic, with friction coef-

ficient between the gripper fingers (also printed out

of the plastic) and the object was µ = 0.4. The grip-

per was in the simulations set to use a force of 50N for

each grasp. The simulation used the Coulomb friction

model.

The task context for grasping in both of the sce-

narios is presented in Figure 4. The objects are placed

on corresponding fixtures and a nominal grasp (illus-

trated in Figure 4) is defined for both cases. The fig-

ure additionally shows the axes, which indicate the

direction along which the grasps were offset during

the subsequent grasp alignment experiments.

(a) The bracket grasp. (b) The heatshield grasp.

Figure 4: The nominal grasps defined for the test objects.

The grasp alignment experiments were performed

in the following way. Each of the objects was grasped

repeatedly with grasps offset from the nominal grasp

along one of the major Cartesian directions: X, Y and

Z and angles θ

x

, θ

y

and θ

z

around these axes. For each

of the grasps, the grasping result was assigned one of

the three outcomes: successful – when the object was

grasped and positioned correctly wrt. to the gripper in

terms of translation and rotation, misaligned – when

the object was grasped, but the position was not cor-

rect, and failure – when the object was not grasped

(due to, e.g. collision with the fixture, the object drop-

ping out of the gripper, simulation failure etc.).

The outcome was determined automatically in

simulation, based on the object and gripper poses as

well as the contact points recorded during the simula-

tion. The grasp alignment was tested using the condi-

tion Equation 2.

max(d

ang

· w

ang

,d

lin

· w

lin

) < ε

A

(2)

where d

ang

and d

lin

are the angular and linear displace-

ments from the expected pose to the grasp pose (in

degrees and millimetres respectively). w

ang

and w

lin

are user specified weights for respectively the angu-

lar and linear displacements and ε

A

is the threshold

below which the grasp is considered to be successful.

The pose and angle weights (w

ang

and w

lin

respec-

tively) are set to 0.25 and 1, and the threshold ε

A

is

set to 1 for both objects. The data on the performance

of the grippers in object alignment was subsequently

collected and processed.

For each of the scenarios, interesting ranges in

offset space were determined during the preliminary

simulation experiment round. The sampling and the

offset bounds were subsequently defined as shown in

Table 1. Altogether, 2772 grasping experiments were

executed in simulation: 1246 for the bracket object

and 1526 for the heatshield object.

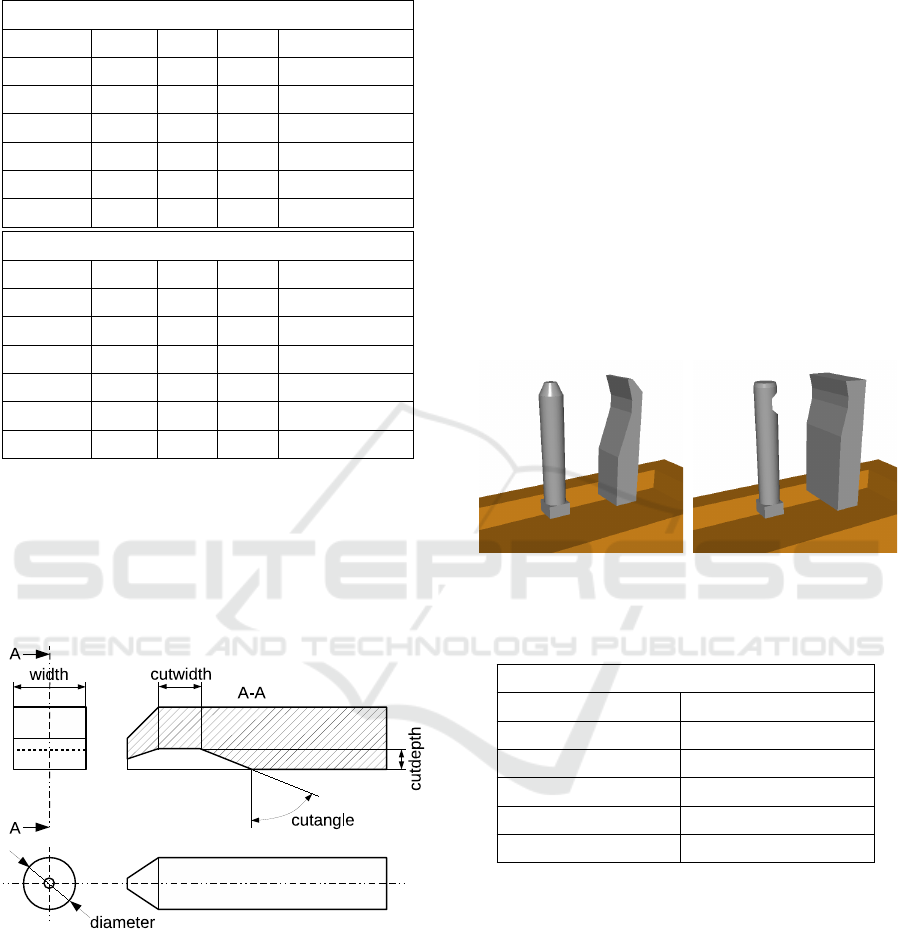

4.1 Bracket Object Scenario

The gripper design optimization for the bracket sce-

nario was performed using the predefined gripper fin-

ger shapes (a block finger with dimensions 10 × 10 ×

50 mm, wrt. the coordinate axis in Figure 4(a), and

a round finger with a width and length of 10 × 50

mm) with cut-outs designed using (a) the PFO method

and (b) the IFM. Figure 5 shows the parametrization

scheme used to design the bracket object grasping fin-

gers with the use of the PFO method.

The fingers designed using the IFM were gener-

ated specifying the bracket as the imprint object and

the nominal grasp pose shown in Figure 4(a) being the

imprint pose (see Section 3.2). When designing the

finger for the inner grasp using the IFM, the bracket

was cut open. This was done because the method con-

siders the exterior of the object and by removing the

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

308

Table 1: The sampling defined for the individual offset axes

in alignment verification experiments.

Bracket scenario

Axis Min Step Max N. of samples

X [mm] -10 0.1 5 151

Y [mm] -10 0.1 10 201

Z [mm] -12.5 0.1 12.5 251

θ

x

[

◦

] -60 0.5 60 241

θ

y

[

◦

] -60 0.5 50 221

θ

z

[

◦

] -45 0.5 45 181

Heatshield scenario

Axis Min Step Max N. of samples

X [mm] -25 0.1 25 501

Y [mm] -15 0.1 15 301

Z [mm] -15 0.1 15 301

θ

x

[

◦

] -30 0.5 30 121

θ

y

[

◦

] -40 0.5 40 161

θ

z

[

◦

] -40 0.5 30 141

part of the bracket that is not in contact with the fin-

ger during grasping, the imprint can be constructed

successfully.

The chamfering of the bracket finger was prede-

termined for the PFO method. The gripper used a 20

mm stroke for the grasping of the bracket.

Figure 5: The brackets finger geometry parametrization.

The optimization was performed with the use

of Simplex optimization method (Nelder and Mead,

1965) starting from an arbitrarily chosen point in the

parameter space. The objective function selected was

defined as a geometric average of Gripper Quality in-

dices (see Equation 1) with the weights defined as:

w

S

= 1 w

R

= 0 w

C

= 0 w

A

= 1 (3)

w

W

= 0.1 w

T

= 0.01 w

V

= 0.01 (4)

The optimization process took 60 steps for the

PFO method. The computation time was 6.5 hours

for the PFO method and 7.5 hours for the IFM. The

optimization was done using an 8-core i7-4702MQ

CPU 2.20GHz machine with 8GB of RAM. The set-

up time of the workcell and definition of the task con-

text took about 30 minutes and is identical for both the

methods. The total set-up time for the PFO method

was 1-1.5 hours and 10-20 minutes for the IFM.

Figure 6 shows the fingers designed for the

bracket object grasping scenario using both the PFO

method and the IFM. The parameters of the PFO fin-

gers before and after optimization are gathered in Ta-

ble 2. The final score of the IFM fingers was found to

be Q : 0.533. In addition to providing the basic finger

shape, the user input consists of defining 6 parameters

for the PFO method.

(a) The PFO method. (b) The IFM.

Figure 6: Optimized finger for handling the bracket object.

Table 2: The bracket fingers optimized parameters.

PFO Q: 0.134 → 0.616

diameter width

10.00 → 8.53 [mm] 10.00 → 14.50 [mm]

cutwidth cutdepth

5.00 → 4.72 [mm] 5.00 → 5.42 [mm]

cutangle

45.00 → 71.51 [

◦

]

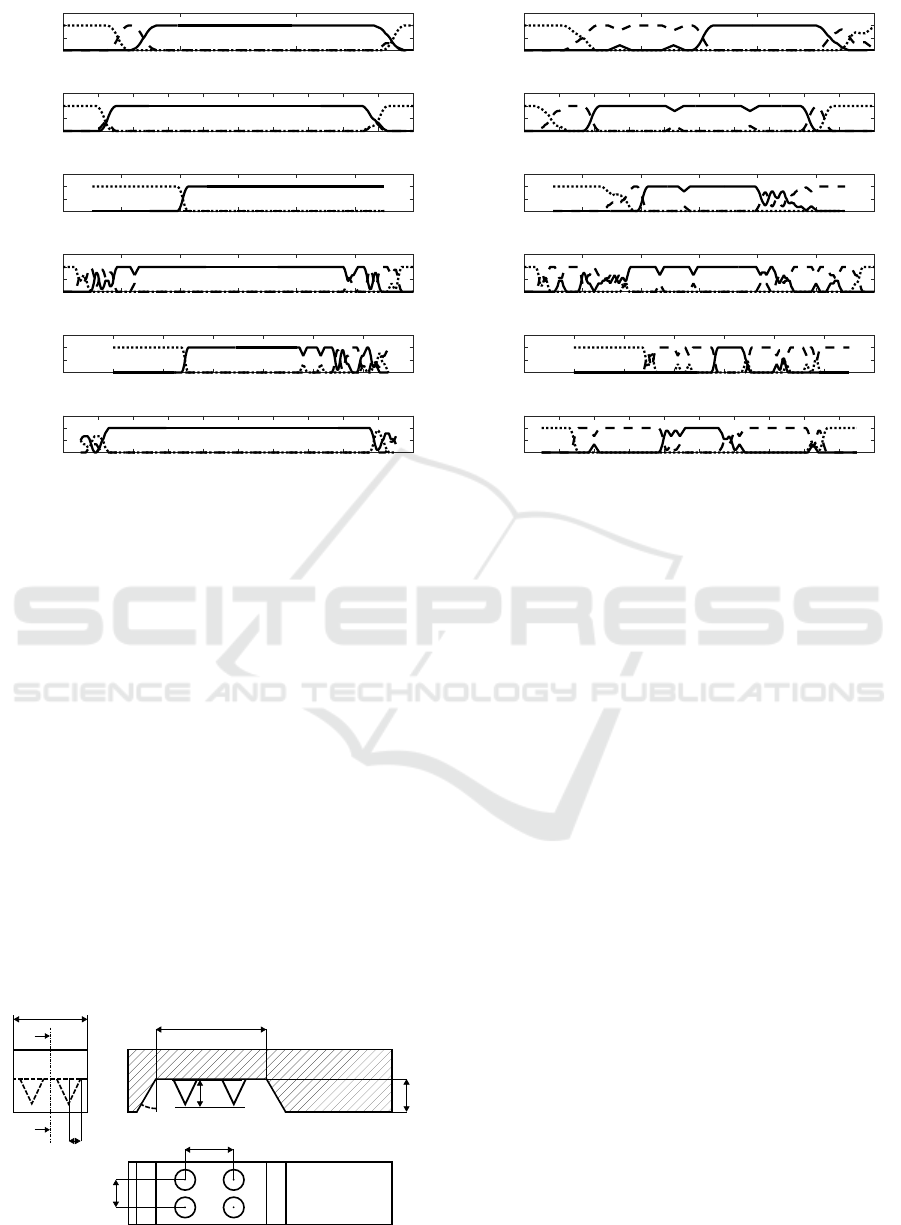

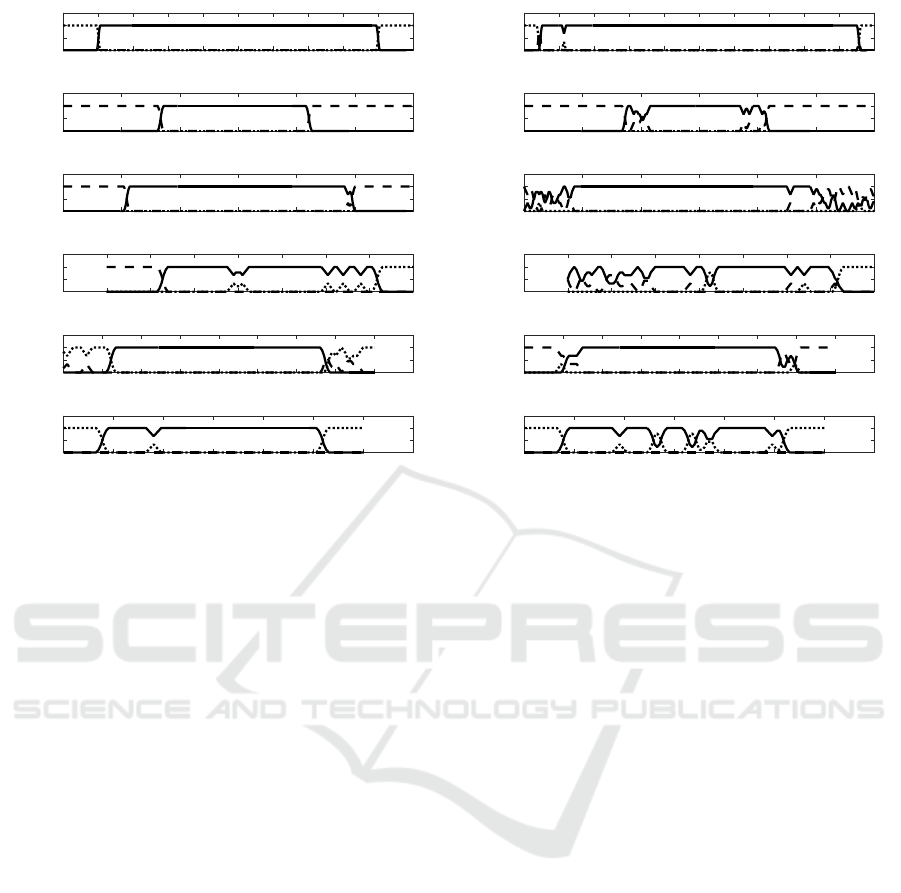

Figure 7 presents the results of grasping the

bracket object using fingers designed using PFO and

IFM methods for increasing offsets introduced in axes

defined in Section 4. It can be seen that the two meth-

ods failure regions are quite similar. However, the

success range of the IFM is smaller, along some of

the axis, than that of the PFO method. This is because

the object is able to rotate in the cut-out of the two fin-

gers and a large part of the result are hence classified

as misaligned.

The IFM method offers a great advantage in terms

of time and effort saving in the set-up phase. In

this scenario it does, however, results in lower per-

formance than that of the PFO method.

Designing Fingers in Simulation based on Imprints

309

offset [mm]

-10 -5 0 5

S/M/F

0

0.5

1

1.5

X offset (PFO)

offset [mm]

-10 -8 -6 -4 -2 0 2 4 6 8 10

S/M/F

0

0.5

1

1.5

Y offset (PFO)

offset [mm]

-15 -10 -5 0 5 10 15

S/M/F

0

0.5

1

1.5

Z offset (PFO)

offset [deg]

-60 -40 -20 0 20 40 60

S/M/F

0

0.5

1

1.5

RX offset (PFO)

offset [deg]

-80 -60 -40 -20 0 20 40 60

S/M/F

0

0.5

1

1.5

RY offset (PFO)

offset [deg]

-50 -40 -30 -20 -10 0 10 20 30 40 50

S/M/F

0

0.5

1

1.5

RZ offset (PFO)

offset [mm]

-10 -5 0 5

S/M/F

0

0.5

1

1.5

X offset (IFO)

offset [mm]

-10 -8 -6 -4 -2 0 2 4 6 8 10

S/M/F

0

0.5

1

1.5

Y offset (IFO)

offset [mm]

-15 -10 -5 0 5 10 15

S/M/F

0

0.5

1

1.5

Z offset (IFO)

offset [deg]

-60 -40 -20 0 20 40 60

S/M/F

0

0.5

1

1.5

RX offset (IFO)

offset [deg]

-80 -60 -40 -20 0 20 40 60

S/M/F

0

0.5

1

1.5

RY offset (IFO)

offset [deg]

-50 -40 -30 -20 -10 0 10 20 30 40 50

S/M/F

0

0.5

1

1.5

RZ offset (IFO)

Figure 7: The comparison of the alignment results in the bracket object scenario for the parametrized gripper (on the left) and

for the gripper designed using the imprint method (on the right). Solid line represents the grasp success rate, dotted line – the

misalignment rate, and the dashed line – the failure rate.

4.2 Heatshield Object Scenario

In the experiments performed for the heatshield sce-

nario, the gripper design optimization was performed

using the predefined gripper finger shapes (a set of

block fingers with dimensions 20 × 30 × 75 mm, wrt.

the coordinate system in Figure 4(b)) with cut-outs

designed using (a) the PFO method and (b) the IFM.

The parametrization scheme chosen for the heat-

shield object grasping fingers designed using the PFO

method is presented in Figure 8. The grasping fingers

for the IFM were designed with the heatshield as the

imprint object and the imprint pose (see Section 3.2)

was the nominal grasp pose seen in Figure 4(b).

The gripper used a 70 mm stroke for the grasping

of the heatshield. The PFO method has a predefined

cutdepth and cutwidth set to 15 and 30 mm respec-

cutwidth

width

radius

angle

cutdepth

dist

x

dist

y

height

A-A

A

A

Figure 8: The heatshield finger parametrization.

tively based on the heatshields actual size.

The finger optimization was performed with the

use of Simplex optimization method starting from a

point selected in the parameter space. The objective

function used was defined as a geometric average of

Gripper Quality indices (see Equation 1) with the fol-

lowing weights:

w

S

= 1 w

R

= 0 w

C

= 0 w

A

= 1 (5)

w

W

= 0.1 w

T

= 0.01 w

V

= 0.01 (6)

The optimization process took 53 steps for the

PFO method and 7.1 hours to computeand the IFM

took 16.7 hours of runtime in total The algorithms

were run on a Intel Core i7-3610QM CPU 2.30GHz

with 8GB of RAM, the program was run single

threaded. The total set-up time of the workcell and

task context took approximately 30 minutes. And the

time to design the fingers for the PFO method took

1-1.5 hour and less than 10 minutes for the IFM.

Figure 9 shows the comparison of the fingers de-

signed for the heatshield object grasping scenario us-

ing both the PFO method and the IFM. The param-

eters of the gripper before and after optimization are

presented in Table 3. The final score of the gripper

using the IFM was Q : 0.46. The user has to pro-

vide the basic finger shape for both of the methods.

Additionally, the required input consists of defining 6

parameters for the PFO method.

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

310

(a) The PFO method. (b) The IFM.

Figure 9: Optimized fingers for the heatshield object.

Table 3: The heatshield fingers optimized parameters.

PFO Q: 0 → 0.44

angle width

20.00 → 32.91 [deg] 30.00 → 29.99 [mm]

dist

x

dist

y

13.00 → 13.00 [mm] 13.00 → 15.81 [mm]

radius height

5.00 → 5.00 [mm] 5.00 → 5.01 [mm]

Figure 10 presents the results of grasping the heat-

shield object using fingers designed using PFO and

IFM methods for increasing offsets introduced in axes

defined in Section 4. Both the fingers found offer a

similar level of performance. The IFM has on aver-

age a larger number of successful grasps along the six

axis, but overall similar performance is obtained. The

PFO method clearly has the advantage of obtaining

its result faster than the IFM, since less than half the

simulation time is needed. However, using the IFM

does offers an advantage in terms of time and effort

saving in the set-up phase.

5 DISCUSSION

In Section 4 the experiments in simulation where pre-

sented aimed at comparing the quality of grippers pro-

duced using both methods in terms of the grasping

alignment capabilities achieved. The alignment capa-

bility of a gripper was quantified as a measure of the

degree at which it can compensate for grasping pose

uncertainty, while still achieving the predictable pose

of the grasped object wrt. the gripper.

The averaged results for both position and angle

offsets is presented in Table 4. The linear and an-

gular offsets are grouped together in the table, and

the total percentage of the grasp outcomes is shown

as well. Overall, the results are comparable for both

methods grasping the heatshield, see Section 4.2, with

the IFM performing a little better than the PFO. How-

ever, the results for the bracket are largely different.

With almost twice the success of the IFM, the PFO

method shows a significant advantage. This is due

to the unforeseen objects interaction with the cut-out

shape that allows for rotation along θ

y

in the grasp of

the IFM gripper, and the gripper performance hence

drastically falls during the tests.

It is also worth noting that the gripper designed

for the bracket using the PFO method grasps the ob-

ject at a different pose wrt. the TCP than that designed

using the IFM. This is because the PFO gripper was

parametrized with a cut-out located only on the exte-

rior grasping finger, while the IFM generates a cut-out

in both fingers. The choice of when to apply a cut-out

to a finger is an option that can be explored in further

IFM research.

Table 4: The averaged grasp experiment results for the PFO

and IFM methods used in the bracket and the heatshield sce-

narios. The columns indicate: S – the successful grasp rate,

M – the misaligned grasp rate and F – the failure grasp rate.

PFO IFM

bracket object

%S %M %F %S %M %F

Pos. 71.5 3.5 25.0 48.5 29.0 22.5

Ang. 75.0 9.0 16.0 28.3 50.3 21.4

Total 73.3 6.3 20.5 38.4 39.7 22.0

heatshield object

%S %M %F %S %M %F

Pos. 62.0 31.3 6.7 69.7 27.0 3.3

Ang. 68.7 7.7 23.7 69.0 13.7 17.3

Total 65.4 19.5 15.2 69.4 20.4 10.3

6 CONCLUSION

In this paper a new method to generate optimized fin-

ger cut-outs was presented (IFM). The method uses

the idea of using the imprint to produce the finger ge-

ometry. Furthermore the method introduces a profile

surrounding the cut-out.

The IFM was compared to a previously devel-

oped method (PFO) in terms of set-up and run time

and grasping experiments performed in simulations.

Compared to PFO, the IFM design method proved to

require considerably less set-up time, on average 15

minutes compared to 1-1.5 hours for the PFO. This is

offset by a longer computation time (on average 12.1

hours using IFM and 6.8 hours for the PFO method).

This is however not an important factor, considering

that the reduction in required man-hours greatly out-

weighs the increase in cheap computational power.

Designing Fingers in Simulation based on Imprints

311

offset [mm]

-25 -20 -15 -10 -5 0 5 10 15 20 25

S/M/F

0

0.5

1

1.5

X offset (PFO)

offset [mm]

-15 -10 -5 0 5 10 15

S/M/F

0

0.5

1

1.5

Y offset (PFO)

offset [mm]

-15 -10 -5 0 5 10 15

S/M/F

0

0.5

1

1.5

Z offset (PFO)

offset [deg]

-50 -40 -30 -20 -10 0 10 20 30

S/M/F

0

0.5

1

1.5

RX offset (PFO)

offset [deg]

-40 -30 -20 -10 0 10 20 30 40 50

S/M/F

0

0.5

1

1.5

RY offset (PFO)

offset [deg]

-30 -20 -10 0 10 20 30 40

S/M/F

0

0.5

1

1.5

RZ offset (PFO)

offset [mm]

-25 -20 -15 -10 -5 0 5 10 15 20 25

S/M/F

0

0.5

1

1.5

X offset (IFO)

offset [mm]

-15 -10 -5 0 5 10 15

S/M/F

0

0.5

1

1.5

Y offset (IFO)

offset [mm]

-15 -10 -5 0 5 10 15

S/M/F

0

0.5

1

1.5

Z offset (IFO)

offset [deg]

-50 -40 -30 -20 -10 0 10 20 30

S/M/F

0

0.5

1

1.5

RX offset (IFO)

offset [deg]

-40 -30 -20 -10 0 10 20 30 40 50

S/M/F

0

0.5

1

1.5

RY offset (IFO)

offset [deg]

-30 -20 -10 0 10 20 30 40

S/M/F

0

0.5

1

1.5

RZ offset (IFO)

Figure 10: The comparison of the alignment results in the heatshield object scenario for the PFO gripper (on the left) and for

the gripper designed using the IFM (on the right). Solid line represents the grasp success rate, dotted line – the misalignment

rate, and the dashed line – the failure rate.

The IFM requires far less manual user input, par-

ticularly in cases (such as heatshield), where it is dif-

ficult to conceive a parametrization scheme that suits

the grasping of a complicated geometrical shape. The

propose IFM therefore simplifies the gripper design

proses significantly. Even in the case of the sim-

pler objects (such as bracket), it is of great advan-

tage to have the grasping profile generated automat-

ically. The bracket object provides a challenge for the

IFM, since due to the necessity of using an internal

grasp. The general dimensions and external features

of the internal grasping finger (which is not generated

through imprinting) are of high importance in cases

like these.

Additionally, the IFM seems to produce cut-out

profiles which more closely resemble the geometry of

the object. This in turn allows for more robustness in

the grasps performed, due to larger contact surfaces.

This is also important in terms of the reduction of the

forces exerted on the objects, which is of importance

in the tasks of handling fragile and flexible materials.

It can be concluded, that using both of these meth-

ods in conjunction would utilize their synergy: the

PFO method is best suited for the choice and opti-

mization of the external finger profile (e.g. with the

parametrization chosen from a pre-defined library of

finger shapes), while the IFM is used to facilitate the

parametrization of the cut-out.

ACKNOWLEDGEMENTS

This work has received funding from the EU project

ReconCell (ICT Innovation for Manufacturing SMEs

(I4MS), project number 680431).

REFERENCES

Berenson, D., Diankov, R., Nishiwaki, K., Kagami, S., and

Kuffner, J. (2007). Grasp planning in complex scenes.

In Humanoid Robots, 2007 7th IEEE-RAS Interna-

tional Conference on, pages 42–48.

Blanes, C., Mellado, M., Ortiz, C., and Valera, A. (2011).

Review. technologies for robot grippers in pick and

place operations for fresh fruits and vegetables. Span-

ish Journal of Agricultural Research, 9(4):1130–

1141.

Borst, C., Fischer, M., and Hirzinger, G. (2004). Grasp

planning: How to choose a suitable task wrench space.

volume 1, pages 319–325.

Boubekri, N. and Chakraborty, P. (2002). Robotic grasping:

gripper designs, control methods and grasp configura-

tions – a review of research. Integrated Manufacturing

Systems, 13(7):520–531.

Causey, G. (2003). Guidelines for the design of robotic grip-

ping systems. Assembly Automation, 23(1):18–28.

Causey, G. C. and Quinn, R. D. (1998). Gripper design

guidelines for modular manufacturing. In Robotics

SIMULTECH 2017 - 7th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

312

and Automation, 1998. Proceedings. 1998 IEEE Inter-

national Conference on, volume 2, page 1453–1458.

IEEE.

Ceccarelli, M., Cuadrado, J., and Dopico, D. (2002). An

optimum synthesis for gripping mechanisms by using

natural coordinates. Proceedings of the Institution of

Mechanical Engineers, Part C: Journal of Mechanical

Engineering Science, 216(6):643–653.

Cuadrado, J., Naya, M. A., Ceccarelli, M., and Carbone, G.

(2002a). An optimum design procedure for two-finger

grippers: a case of study. IFToMM Electronic Journal

of Computational Kinematics, 15403(1):2002.

Cuadrado, J., Naya, M. A., Ceccarelli, M., and Carbone, G.

(2002b). An optimum design procedure for two-finger

grippers: a case of study. IFToMM Electronic Journal

of Computational Kinematics, 15403(1):2002.

Ellekilde, L.-P. and Jørgensen, J. A. (2010). Robwork: A

flexible toolbox for robotics research and education.

Robotics (ISR), 2010 41st International Symposium

on and 2010 6th German Conference on Robotics

(ROBOTIK), pages 1 –7.

Ellekilde, L. P. and Petersen, H. G. (2006). Design and test

of object aligning grippers for industrial applications.

In 2006 IEEE/RSJ International Conference on Intel-

ligent Robots and Systems, pages 5165–5170.

Ferrari, C. and Canny, J. (1992). Planning optimal grasps.

pages 2290–2295.

Honarpardaz, M., Tarkian, M.,

¨

Olvander, J., and Feng, X.

(2017). Finger design automation for industrial robot

grippers: A review. Robotics and Autonomous Sys-

tems, 87:104 – 119.

Jørgensen, J. A., Ellekilde, L.-P., and Petersen, H. G.

(2010). RobWorkSim - an Open Simulator for Sensor

based Grasping - Conference papers - VDE Publish-

ing House. In ISR/ROBOTIK 2010 - ISR 2010 (41st

International Symposium on Robotics) and ROBOTIK

2010 (6th German Conference on Robotics). VDE-

Verlag.

Jørgensen, J. A. and Petersen, H. G. (2010). Grasp Syn-

thesis for Dextrous Hands Optimised for Tactile Ma-

nipulation. In Proceedings for the joint conference of

ISR 2010 (41st Internationel Symposium on Robotics)

und ROBOTIK 2010 (6th German Conference on

Robotics). VDE-Verlag.

Kintel, M. (2009). Openscad.

Kolluru, R., Valavanis, K., Smith, S., and Tsourveloudis,

N. (2000). Design fundamentals of a reconfigurable

robotic gripper system. Systems, Man and Cybernet-

ics, Part A: Systems and Humans, IEEE Transactions

on, 30(2):181–187.

Kraft, D., Ellekilde, L.-P., and Rytz, J. A. (2012). Au-

tomized grasp generation and improvement for indus-

trial bin-picking. Robotics and Computer Integrated

Manufacturing. (to be submitted).

Krenich, S. (2014). Optimal design of robot gripper mecha-

nism using force and displacement transmission ratio.

Applied Mechanics and Materials, 613:117–125.

Lanni, C. and Ceccarelli, M. (2009). An optimization prob-

lem algorithm for kinematic design of mechanisms for

two-finger grippers. Open Mechanical Engineering

Journal, 3:49–62.

Li, Y., Fu, J., and Pollard, N. (2007). Data driven grasp

synthesis using shape matching and task-based prun-

ing. IEEE Transactions on Visualization and Com-

puter Graphics, 13.

Nelder, J. A. and Mead, R. (1965). A simplex method

for function minimization. The Computer Journal,

7(4):308–313.

Schunk (2015). Schunk egrip.

Schuster, A., Becker, R., and Poguntke, M. (2014). Method

for the production of customer-specific components.

UWO2014060605 A1.

Smith, R. (2008). Open dynamics engine.

http://www.ode.org/.

Stulp, F., Theodorou, E., Buchli, J., and Schaal, S. (2011).

Learning to grasp under uncertainty. In IEEE In-

ternational Conference on Robotics and Automation

(ICRA), pages 5703–5708.

Thulesen, T. N. and Petersen, H. G. (2016). RobWork-

PhysicsEngine: A new dynamic simulation engine for

manipulation actions. In 2016 IEEE International

Conference on Robotics and Automation (ICRA).

Velasco, V. B. and Newman, W. S. (1998). Computer-

assisted gripper and fixture customization using rapid-

prototyping technology. In Proceedings. 1998 IEEE

International Conference on Robotics and Automation

(Cat. No.98CH36146), volume 4, pages 3658–3664

vol.4.

Wolniakowski, A., Jorgensen, J. A., Miatliuk, K.,

Gosiewski, Z., Petersen, H. G., and Kr

¨

uger, N. (2017).

Task and context sensitive gripper design learning us-

ing dynamic grasp simulation. Journal of Intelligent

and Robotic Systems. (in print).

Wolniakowski, A., Jorgensen, J. A., Miatliuk, K., Petersen,

H. G., and Kr

¨

uger, N. (2015). Task and context sen-

sitive optimization of gripper design using dynamic

grasp simulation. In Methods and Models in Automa-

tion and Robotics (MMAR), 2015 20th International

Conference on, pages 29–34.

Wolniakowski, A., Kramberger, A., Gams, A., Chrysosto-

mou, D., Hagelskjaer, F., Thulesen, T. N., Kiforenko,

L., Buch, A. G., Bodenhagen, L., Petersen, H. G.,

Madsen, O., Ude, A., and Kr

¨

uger, N. (2016). Opti-

mizing grippers for compensating pose uncertainties

by dynamic simulation. In IEEE/RSJ Int. Conf. on In-

telligent Robots and Systems (IROS). submitted.

Wolniakowski, A., Miatliuk, K., Kr

¨

uger, N., and Rytz, J. A.

(2014). Automatic evaluation of task-focused paral-

lel jaw gripper design. In International Conference

on Simulation, Modeling, and Programming for Au-

tonomous Robots.

Zhang, M. T. and Goldberg, K. (2006). Designing robot

grippers: optimal edge contacts for part alignment.

Robotica, 25(03):341.

Designing Fingers in Simulation based on Imprints

313