Adaptive Neural Control for Bilateral Teleoperation System using

External Force Approach

Outayeb Adel Mohamed, Ferguene Farid and Toumi Redouane

LRPE Laboratory, Automatic and Instrumentation Department, U.S.T.H.B University,

BP n°32, El Alia-Bab Ezzouar, 16111 Algiers, Algeria

Keywords: Bilateral Teleoperation, External Force Control, Adaptive Control, Identification, Neural Network,

Estimation Parameter.

Abstract: The paper deals with external force control approach based on four channel scheme, that is reported in

previous paper (Outayeb et al., 2016). The problem of controlling bilateral teleoperation system under

disturbances due mainly to unknown environment, dynamic robot uncertainties and in presence of noisy

measurement of force sensors is considered. The Control Algorithms are obtained on two control strategies,

the first one consists on a force/Impedance control approach applied to the master robot, whereas the second

one consists on external force control loop combined with position control loop applied to the 3-DOF

nonlinear slave robot. A neural network (NN) compensator and online environment estimation based on

forgetting factor recursive least squares method (FFRLS) are integrated, to eliminate the effects of

uncertainties in dynamic model of the slave robot, as well as, to estimate the unknown time varying

characteristics of the environment under noisy measurements of force sensors. Numerical simulations using

Labview show the efficacy of proposed scheme to guarantee system stability and acceptable transparency

performance.

1 INTRODUCTION

Teleoperation is sometimes associated with

manipulation of environments that are too distant or

inaccessible to man, but also to interact with small

area like human body cavity to improve surgical

performances in terms of less invasive operations and

more confortable positions.

A teleoperation system consists of a teleoperated

robot (slave device) controlled by a local control

station equipped with haptic interface for the

reproduction of the effort applied at the remote site

(master device) via a telecommunication channel.

The two major issues in teleoperation are stability

robustness which may constitute a problem

especially in presence of time delays in the

communication and transparency performance which

mean that operator should feel as he is directly acting

in the remote site (Lawrence, 1993).

There exist various kinds of control schemes for

teleoperation systems. In theory and under ideal

conditions, four-channel and even three-channel

control architectures offer perfect transparency with

linear model of master and slave robots (Lawrence,

1993; Zaad and Salcudean, 1999). However in some

of these structure both position and force signals are

transmitted from one site to another. Therefore,

measurement of force in both sides is inevitable to

ensure full transparency. By consequence mounting

force sensors on robots causes some limitations such

as high expense, increasing noise and soft structure

(Ohnishi et al., 1994; Dehghan et al., 2014).

Unfortunately, an ideal transparent bilateral

teleoperation system cannot be conceived without

compromising stability, which highly depends on the

robustness of the control scheme implemented under

disturbances due mainly to unknown characteristics

of the environment, the dynamics of robots and

delays in communications (Park and Cho, 1999; Ye

et al., 2013; Artigas et al., 2011).

For this reason, in the literature a number of

control schemes have been developed based on

different criteria including the passivity, compliance,

predictive and adaptive control considering either

linear or nonlinear models of manipulators. A

comparative study based on several approaches can

be found in (Arcara and Melchiorri, 2002).

This paper is organized as follows: section 2

Mohamed, O., Farid, F. and Redouane, T.

Adaptive Neural Control for Bilateral Teleoperation System using External Force Approach.

DOI: 10.5220/0006419603090315

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 2, pages 309-315

ISBN: Not Available

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

309

presents the formulation of dynamical models of

constrained robots used in master and slave sites

respectively, specified in task space. In Section 3, we

demonstrate a control algorithms laws designed for

both master and slave stations. Moreover, neural

compensator is developed in this section, followed by

Section 4 which discusses an online estimation of

environment based on FFRLS algorithm. Finally,

simulation results are shown in Section 5 and

conclusion is drawn in section 6.

2 DYNAMIC MODELS

In this section, we consider a bilaterally controlled

teleoperator system where both the master and the

slave are 3-DOF with revolute joints, that dynamic

models are described as follows.

2.1 Dynamic Model of Slave Robot

Consider a nonlinear teleoperated manipulator

system consisting of 3-DOF with dynamics given by:

,

(1)

Where

is the inertia matrix,

,

is the

vector of Coriolis and centrifugal forces,

is the

gravity term and

is the generalized torque acting

on q. Defining the Jacobian as:

(2)

With

is the Cartesian velocity, and the acceleration

is given by

Substituting (2) and (3) in (1), and applying the

relation between the joint torque

and the

Cartesian force

at the end-effector,

,

the dynamic robot in contact with environment can

be written in Cartesian coordinates as

,

(4)

With

,

(6)

(7)

Where

is the vector of external forces appears at

the end-effector when the robot is in contact,

and

are respectively the forces due to the controlled

torque and friction.

2.2 Dynamic Model of Master Robot

The geometric form of master robot is identical to the

slave robot. Unless it is characterized by known

linear dynamic model which is represented by the

following equation:

(8)

Where

,

and

refers the impedance

characteristic of this robot in the joint

space.Reformulating this end into Cartesian space

and applying the same manner as below, the model

equation is given as :

(9)

Where

is the force applied by the operator on

end-effector master interface.

3 CONTROLLER DESIGN

This section is carried out to present a proposed

control scheme based on the Force/Impedance

controller applied at the master, and the

Force/Position control loop using external force

approach developed to the slave device.

3.1 Master Controller

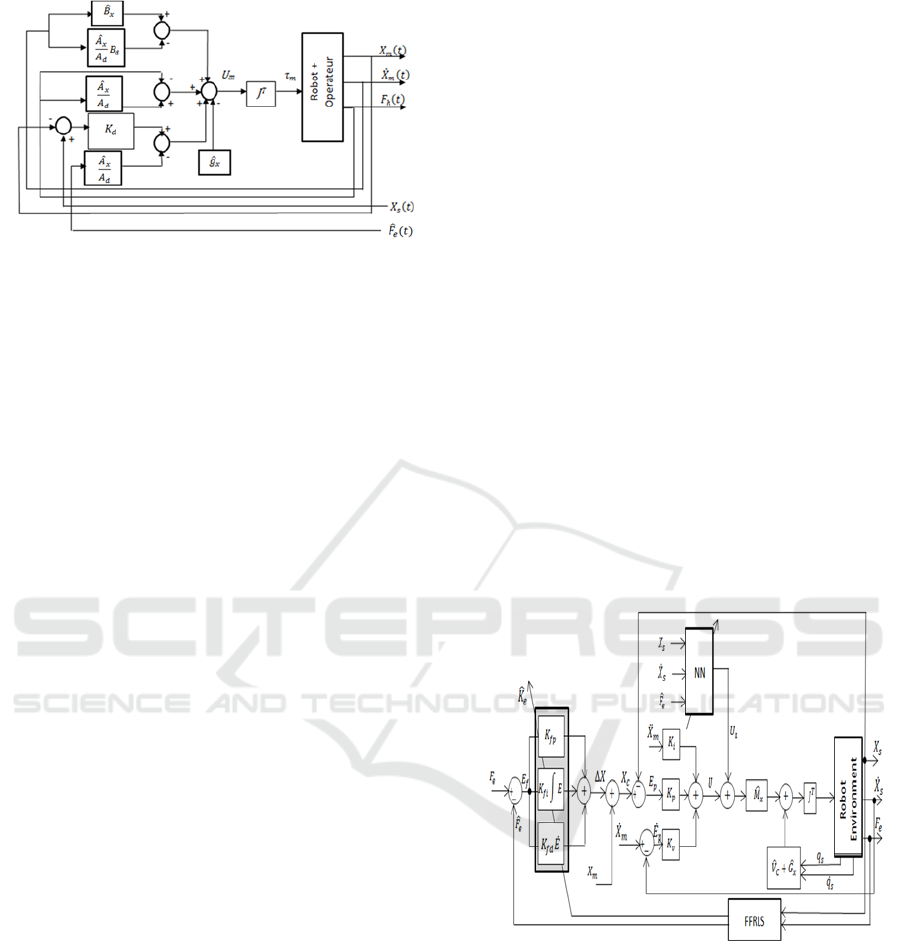

The block diagram of proposed controller is shown in

(Fig. 1), The force/impedance control is designed to

obtain desired behavior of the manipulator described

by the following relationship between end-effector

motion and applied force exerted by the operator

Where

,

represent the desired inertia and

damping respectively,

is the force recovered from

noisy force sensors measured in the remote site.

Given the manipulator dynamics and in order to

achieve the desired impedance behavior, an inverse

dynamics control law can be proposed as

1

Where the hats denote the available estimates of the

corresponding dynamic terms, this controller is

operational in either free or constrained space, by

taking account the correction of the error occurred in

the positioning of the local robot when the slave

robot is constrained by the environment.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

310

Figure 1: Force/Impedance control structure for the master

interface.

3.2 Slave Controller

An adaptive force/position control scheme is

developed in this section according to the external

force control concept proposed in literature (Schutter

and Van Berussel, 1988), where we take into account

the uncertainty dynamics of slave robot, unknown

location of the object, variable stiffness of the

environment and noisy quality of force sensor. For

this end, we have integrated two complementary

techniques based on a neural compensator and a

FFRLS method described later.

Where the hats denote the available uncertain

estimates of the dynamic terms

,

,

and

is

the signal force recovered from noisy measured

force sensor, by applying the online environment

estimation method that will be discussed in section

4.

By following the external force control approach,

is designed to assure a compliant motion by

feeding the error between desired force

and actual

force

into the force controller, this contact force

acts as correction which will modify the desired

trajectory applied to the position control loop, so:

(13)

With

∆

∆

Where ∆

presents the correction of desired

position

Namely, as (Chiaverini and Sciavesco, 1999) the

dynamic model of the slave represents a highly

nonlinear and strongly coupled system for which the

nonlinear dynamic decoupling approach can be

adopted. The closed loop dynamic equation can be

rewritten as

∆

(14)

∆

∆

∆

∆

With

∆

When ∆ denotes the uncertainty terms.

The Neural compensator output

, described

later, is trained to minimize the uncertainty terms

in14.

let

(15)

Since the control objective is to generate

to

reduce to zero. We propose here to use as the

error signal for training the neural network.

In the ideal case (

0 the output of the neural

compensator is required to be

∆

∆

∆

∆

(16)

The slave controller is schematized by the following

diagram

Figure 2: Adaptive structure of external Force controller

loop combined with FFRLS estimator and NN

compensator for the Slave manipulator.

3.3 Neural Network Compensator

Design

The network model selected in this paper in order to

implement the proposed artificial neural network

compensator is a three layer network structure (see

Fig.3) which is composed of a linear input layer I =

[X

t

X

t

F

t

], a non-linear hidden layer of

sigmoid type expressed by the following equation:

Adaptive Neural Control for Bilateral Teleoperation System using External Force Approach

311

2

1

1

(17)

And an output layer of linear processing unit.

Therefore, the input-output relationship of the

network is

2

1

∑

1

(18)

Where,

are the weights between the input layer

and the hidden layer,

are the weights between

the hidden layer and the output layer,

is the bias of

the j-th neuron in the hidden layer and

is the bias

of the k-th neuron in the output layer.

Figure 3: Structure of Neural Network Compensator

The goal is to generate an auxiliary computed

torque

altering the training signal to be zero as

either

or

, and that is based on the

minimization of a quadratic function , where is

given by:

1

2

(19)

The weight updating law is obtained by using the

back-propagation algorithm of the gradient

(Ferguene and Toumi, 2005). This algorithm

consists of modifying a variable

in the opposite

direction to the derivative function of the error,

yields the gradient of as:

(20)

Where the weight adaptation law with a momentum

term is:

∆

∆

1

(21)

With is the update rate and is the momentum

coefficient. Explicitly, the resulting algorithm can be

derived by making use of (20).

∆

0.5

1

∆

1

(22)

∆

∆

1

∆

0.5

1

∆

1

∆

∆

1

4 ENVIRONMENT DYNAMIC

In this paper, we propose a good online estimation

algorithm that have objective to track and identify the

location and dynamic characteristics of any

constraints in a robot's workspace.

The model considered is not homogeneous in the

sense that it is manifested by a time varying

stiffness

. More specifically, this environment has

the following dynamics:

0.25∗

∗sin

∗

Where

is the position of the object at rest, and

is a

33

constant diagonal stiffness matrix. In

discrete domain, the environment dynamics can be

written as (Ljung, 1987):

,

0

(24)

Where the subscript k denotes the time instant,

,

,…,

is the measurement vector,

the vector of parameters,

the modeling error

and measurement noise,

the penetration at sample

time . , the parameter is the sample time.

4.1 Estimation Method of Unknown

Time Varying Parameter

For abruptly parameter identification, the use of RLS

method with periodic initialization of estimated value

can highly capture the new values of the parameter.

However for real time varying parameter estimation,

it is necessary to apply forgetting factor to RLS

algorithm. The concept of FFRLS algorithm has the

tracking ability as the covariance ceases to exist

gradually to zero with time, Hence this method can

be viewed as giving less weight to older data and

more weight to recent data. Smaller forgetting factors

will improve the tracking ability and can affect the

stability of the algorithm (Vahidi et al., 2005). The

“loss-function” is then defined as :

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

312

,

1

2

(25)

Where is called forgetting factor and01.

Obviously, small values for λ puts greater emphasis

on recent data and can be calculated recursively

using the update equations derived as follows:

1

(26)

1

(27)

With

1

1

(28)

1

(29)

is normally referred to as the covariance

matrix of parameters

. More detailed derivation

can be found in books on parameter estimation such

as (Astrom and Wittenmark, 1994).

5 SIMULATION

To check out the efficiency of the proposed

approach, two geometric identical 3-DOF rotary

manipulators are simulated, a slave robot whose

parameters are taken from the first three links of

Puma 560 arm (Armstrong and Khatib, 1986),

whereas a linear master robot whose parameters are

assumed to be known accurately. Model uncertainties

included a 5 Kg Mechanical tool attached to the third

link, Coulomb friction and viscous friction torques

added to each joint where

0.8

0.5

. For the NN compensator we have

chosen nine input neurons

9

and seven

hidden neurons

10

. The back propagation

algorithm parameters are: 0.001, 0.9.

Weights are initially randomly selected and adjusted

every sampling time in online fashion.

On the assumption of unknown geometric

proprieties of manipulated object and in order to

calculate an online estimation of their stiffness from

poor quality force sensors measurements, we apply a

FFRLS method with

0

0,

0

15000/,

0.975, The gains of controller law and the

desired Impedance are fixed experimentally by

,

40,

800

,

40

⁄

,

40

⁄

,

0.15,

400,

8000

Task space has object with flat surface and variable

stiffness which depends on time with:

∗

∗

∗

(30)

The test bed consists of master and slave robots

situated at positions

,

0.4115,0.150,0.4331

of different sites. Initially, the operator applies

constant force

through 3 directions on the end-

effector interface to move it with respect to the

desired impedance calculated above (10), while the

slave robot starts tracking the trajectory generated by

master interface until it crashes the object situated at

unknown position (supposed in our simulation at

0.45,0.21,0.55

). At this time, the

operator pushes the interface with sinusoidal force as

given by equation (31). The slave robot is being in

constrained space, so it moves with master’s position

and controls the force of interaction on the surface of

the object according to the force applied by the

operator, in this case, the slave robot will dominate a

force action over position action. By consequence,

different positions will generated and transmitted to

the master station in order to move it with respect to

slave robot position. The input signal of force applied

by operator is given by

001

813

82∗sin

6.28∗

35

857

07

(31)

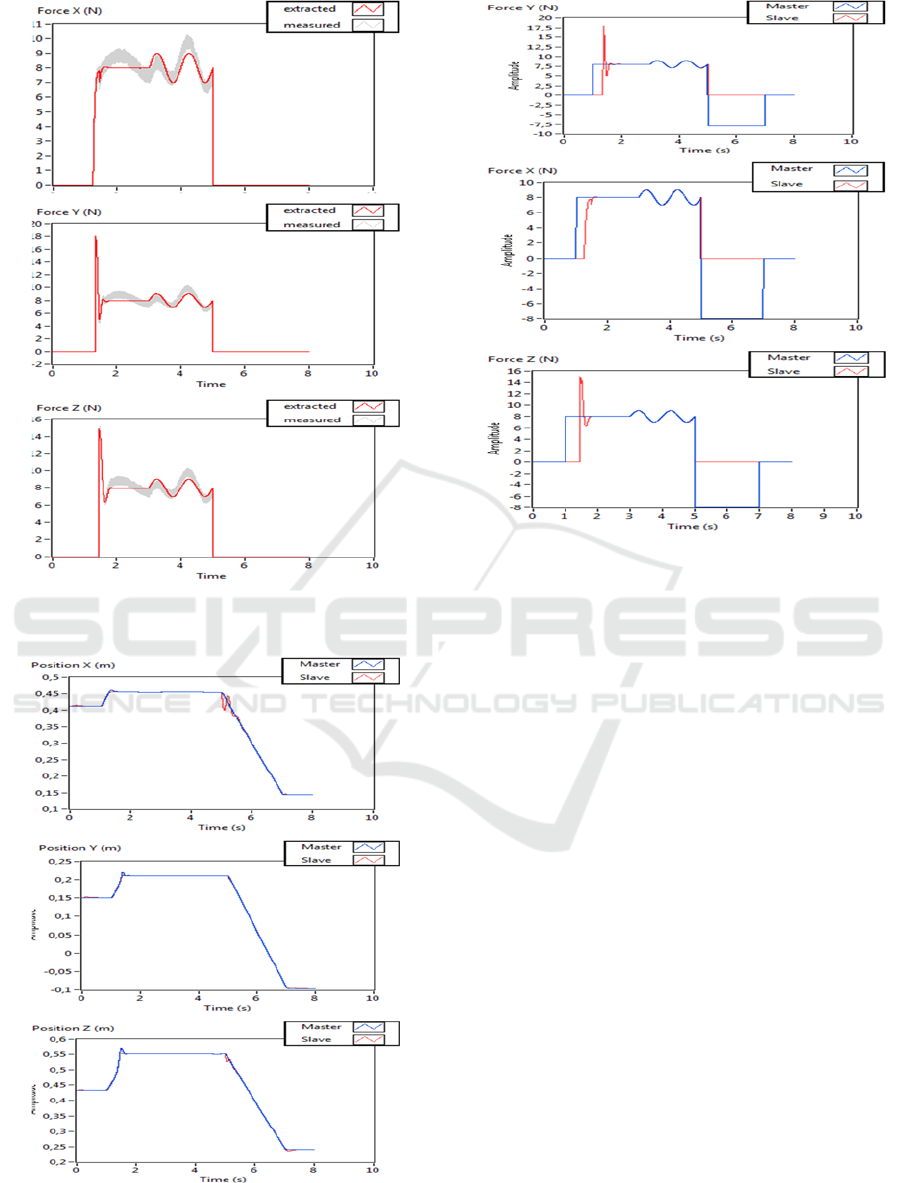

In Figure 4, it’s obviously marked the quality of

recovered signal from noisy force sensors

measurements over 3 directions, and when

interacting with environment characterized by time

varying stiffness.

In Figures (5.1) and (5.2), the responses

illustrates that the whole system is stable and

guarantees equality between the force applied by the

operator and that applied to the environment.

Moreover, it presents a good tracking of both master

and slave trajectory either in free or constrained

space.

Considering fair results obtained compared with

those obtained in previous work. We conclude the

ability to investigate with complex methods

proposed for controlling a local manipulator, to

deals with more complicated problems in

teleoperation system.

Adaptive Neural Control for Bilateral Teleoperation System using External Force Approach

313

Figure 4: The recovered force signal and noise rejected

along X, Y and Z axis.

Figure 5.1: Position Tracking along X, Y and Z axis for

teleoperation system.

Figure 5.2: Force applied along X, Y and Z axis for

teleoperation system.

6 CONCLUSION

In this work, an adaptive force/position control

algorithm in bilateral teleoperation system is

developed, using an external force control approach,

taking advantage of four channel structure that we

have presented in previous work. Our approach is

based on force/impedance controller at the master

and external force control loop, combined with a

neural compensator and forgetting factor recursive

least square estimator at the slave.

The results of simulations obtained with our

proposed scheme are convincing and similar to those

reported in (Outayeb et al., 2016).

Whole

teleoperator system stability is guaranteed with

acceptable transparency performances, even when

there are the slave robot dynamic uncertainties,

unknown and variable environment stiffness, and

poor measurements of force sensors.

Studies are remained as a proposed future work

going along with designing more robust controller,

by considering a full unknown dynamic of slave

robot and environment.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

314

REFERENCES

Arcara P., Melchiorri C., 2002. Control schemes for

teleoperation with time delay : A comparative study.

Robotics and Autonomous Systems, 38(1):49–64.

Armstrong B., Khatib O., 1986 . The explicit dynamic

model and inertial parameters of the PUMA 560 arm ,

IEEE Int. Conf. on Robotics and Automation, San

Francisco –U.S.A, pp. 510-518.

Artigas J., Ryu J., Preusche C., and Hirzinger G., 2011.

Network representation and passivity of delayed

teleoperation systems, in Proc. IEEE/RSJ Int.Conf.

Intell. Robots Syst., pp.177–183.

Astrom A., and Wittenmark B., 1994. Adaptive Control.

Addison Wesley, second edition.

Chiaverini S., Sciavesco L., 1998. the parallel approach to

force/position control of manipulators in task space

with dominance in force, in Proc,2

nd

IFAC Symp.

Robot Contr. (SYROCO’88), Karlsruhe, D, Oct. pp.

137-143

Dehghan S. A. M., Danesh M., and Sheikholeslam F.,

2014. Adaptive hybrid force/position control of robot

manipulators using an adaptive force estimator in the

presence of parametric uncertainty, Advanced

Robotics,.

Ferguene F., Toumi R., 2005. A Neural Approach to

Force/Position Parallel Control of Robotic

Manipulators Application to the Follow-up of

Trajectory in Unknown Stiffness Environment, in

Proc. International computer systems and information

technology conference Vol. N°1, pp. 247-251 ,

Algiers, Algeria.

Lawrence D.A., 1993. Stability and transparency in

bilateral téléopération. IEEE Trans. on Rob and Aut.

9(5), 624–637.

Ljung L., 1987 . System identification : Theory for the

user , Linkoping University, Sweden, PTR Prentice

Hall.

Ohnishi K., Matsui N., and Hori Y., 1994. Estimation,

identification, and sensorless control in motion control

system , Proc. IEEE, vol. 82, no.8, pp. 1253–1265.

Outayeb A., Ferguene F., Toumi R., 2016 . Bilateral

control of nonlinear teleoperation system using

parallel force/position control approach and online

environment estimation. In: IEEE Int. Conf. On

Methods and Models in automation and robotics

(MMAR’2016), pages 1110–1115, Międzyzdroje,

Poland.

Park J.H., and Cho H.C., 1999. Sliding-mode controller

for bilateral teleoperation with varying time delay. In:

IEEE Int. Conf. on Adv. Intell. Mechatronics. Atlanta,

GA.pp. 311–316.

Schutter J., Van Berussel H., 1988. Compliant robot

motion II. A control approach based on external

control loop , Int. Journal of Robotics Research, Vol.

n°4, pp. 18-33.

Vahidi A., Stefanopoulou A., and Peng H., 2005.

Recursive Least Squares with Forgetting for Online

Estimation of Vehicle Mass and Road Grade: Theory

and Experiments. Vehicle System Dynamics, vol. 43,

no. 1, pp. 31-55.

Ye Y., Pan Y.J., and Hilliard T., 2013. Bilateral

teleoperation with time-varying delay: A

communication channel passification approach,

IEEE/ASME Trans. Mechatronics, vol. 18, no. 4, pp.

1431–1434.

Zaad H.K., Salcudean, S.E., 1999. On the use of local

force feedback for transparent teleoperation. Proc. of

the IEEE Int. Conf. On Robotics and Automation

(ICRA’99), pages 1863–1869, Detroit, Michigan,

USA.

Adaptive Neural Control for Bilateral Teleoperation System using External Force Approach

315