Sensor Fusion of a 2D Laser Scanner and a Thermal Camera

Johanna Gleichauf, Christian Pfitzner and Stefan May

Technische Hochschule N

¨

urnberg Georg Simon Ohm, Kesslerplatz 12, Nuremberg, Germany

Keywords:

Sensor Fusion, Calibration, 2D Laser Scanner, Thermal Camera.

Abstract:

In order to increase the robustness of localisation and victim detection in low visibility situations it is necessary

to fuse several sensors. The most common sensor used in robotics is the 2D laser scanner which delivers

distance measurements. In combination with a camera the gained information can be supported by visual

information about the environment. Thermal cameras are ideal for finding objects with a certain temperature,

but they do not deliver distance information. The difficulty in fusing these two sensors is, that a correspondence

between each distance measurement and its corresponding pixel within the thermal image needs to be found.

As the laser scanner only displays one plane, this is not an intuitive task. A special triangular calibration

target, covering all six degrees of freedom and being visible for both sensors, was developed. In the end

the transformation between each laser scan point and its corresponding thermal image pixel is given. This

allows for assigning every laser measurement within the field of view a corresponding thermal pixel. The final

application will enable detection of human beings and display the distance required to reach them.

1 INTRODUCTION

For allowing robust localisation and victim detection

sensor fusion of several sensors with different proper-

ties is needed. As the aim is to find possible victims in

for example environments with great smoke emission,

sensors applicable for this situation are required. The

proposed sensor fusion system is made up of a ther-

mal camera, a Short Wave Infrared (SWIR) camera, a

laser scanner and a radar sensor. Laser scanners have

limits in poor visibility situations. That is why radar

sensors are a robust alternative.

So far a laser scanner and a thermal camera are

used on the rescue robot Schroedi. In a fire drill

with the firefighters in Nuremberg, Germany, it was

demonstrated how victims could be found with the

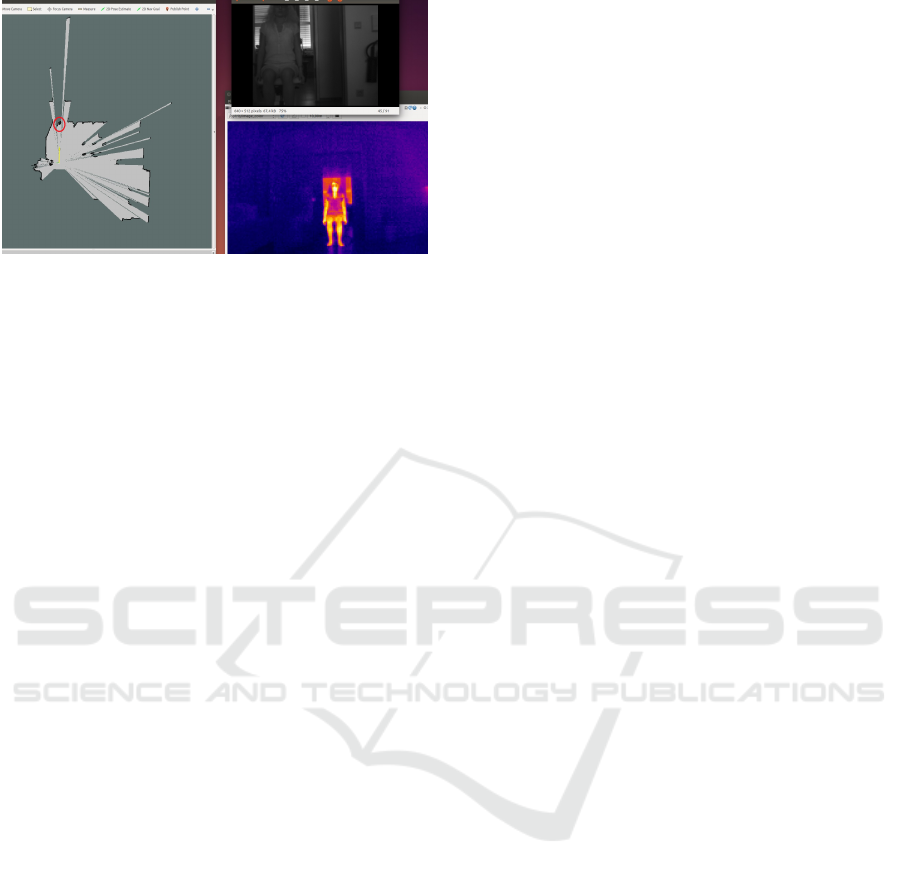

help of Schroedi (see Figure 1). At present, Schroedi

can be steered into a room filled with smoke by a hu-

man and the victim detection is based on the opera-

tor’s perception of the thermal images. For a human

the detection of victims within an image is intuitive.

If a robot had to detect the exact position and orienta-

tion of a possible victim, the operation becomes more

complicated.

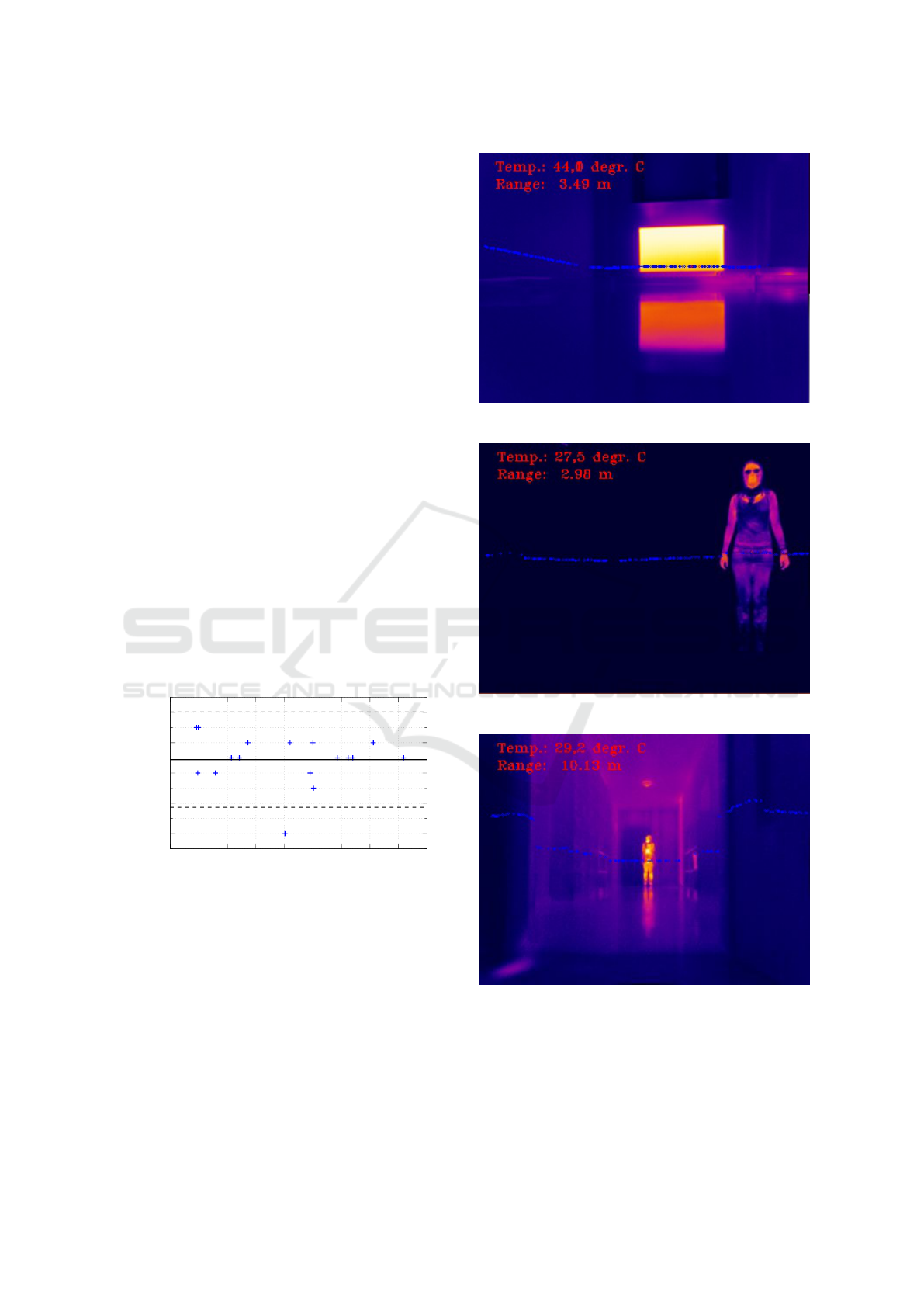

As part of a stationary test, sensor data was taken

with a laser scanner, a thermal camera and a SWIR

camera. The result is displayed within Figure 2 show-

ing a human sitting within a room. A human is ca-

pable of identifying the human’s position within the

Figure 1: Rescue robot Schroedi at a fire drill (Source: A.

Bergmeister).

map (red circle) by eye. The robot needs to be taught

to automatically combine the different data types and

understand the information.

The aim of this project is to implement the first

part of the sensor fusion system, fusing a thermal

camera with a laser scanner. Later on the laser scanner

can be replaced by a radar sensor such that a robot is

capable of detecting victims in a poor visibility situa-

tion such as a house fire. This requires the calibration

of the thermal camera with a 2D laser scanner. The

difficulty is that distance data (3D data) has to be pro-

jected onto the 2D image plane of the thermal camera

image.

This paper is structured as follows: section 2 in-

troduces existing calibration methods, section 3 de-

398

Gleichauf, J., Pfitzner, C. and May, S.

Sensor Fusion of a 2D Laser Scanner and a Thermal Camera.

DOI: 10.5220/0006397303980405

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 1, pages 398-405

ISBN: 978-989-758-263-9

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 2: Laser scan map, thermal and SWIR image.

scribes the new approach and finally the conclusion

and future work can be found in chapter 4.

2 STATE OF THE ART

Sensor fusion between several sensors is popular in

robotics. Approaches of fusing a laser scanner with

a thermal camera to combine the advantages of dis-

tance measurements and image information have been

made. Most of these methods use a 3D laser scanner

instead of a 2D one. Approaches combining an RGB

camera with a 2D laser scanner are mentioned in this

chapter, too, as the underlying method would be sim-

ilar for an infrared camera.

2.1 Fusion of a Thermal Camera with a

3D Laser Scanner

In his Bachelor thesis Tom-Marvin Liebelt describes

the sensor fusion between a 3D laser scanner (a ro-

tated SICK LMS100 2D scanner) and a thermal cam-

era. Both sensors are placed in a fixed position such

that the z-axis of the camera lies on the scan plane

of the laser scanner. Different types of calibration

patterns (a printed pattern, a pattern using light bulbs

and one using resistance wire) were compared in this

project. It was decided to use resistance wire which

delivers good thermal images and allows the resulting

pattern to be used for both the intrinsic and extrinsic

calibration. (Liebelt, 2013)

As part of the Smokebot project the calibration

and fusion between a far infrared camera and a 3D

laser scanner were performed. Their calibration pat-

tern is of trihedral shape such that its edges can be

clearly seen within the laser point cloud. (Zeise,

2016)

2.2 Fusion of a Thermal Camera with a

2D Laser Scanner

An approach using an infrared camera is used for fast

moving object detection. The extrinsic calibration

between the two sensors is not precise. Zeng et al.

(2015) approximated the extrinsic transformation by

finding agreement between the horizontal axes. The

difference in the vertical axis (i.e., z) was then mea-

sured manually. For their project this low precision

calibration was sufficient to be able to locate the Re-

gion of Interest (ROI).

2.3 Fusion of a Camera with a 3D Laser

Scanner

Several fusion applications can be found using dif-

ferent types of cameras and a 3D laser scanner. Un-

nikrishnan et al. (2005) introduce the usage of a

Laser-Camera Calibration Toolbox, based on a Mat-

lab graphical user interface. Their calibration pattern

is a leaning chessboard.

For mapping infrared data onto a terrestrial laser

scanner for 3D models of buildings a ”bi-camera” sys-

tem made up of a thermal camera and a RGB cam-

era was created. The aim is to overcome drawbacks

such as time consuming methods caused by classic

approaches where direct registration between the ther-

mal camera and the 3D laser scanner is taking place

using space resection or homography. Furthermore

a low-cost NIR camera is integrated into the system.

For the calibration between the ”bi-camera” system

and the 3D laser scanner, the recognition of common

features between RGB images and the laser intensity

is suggested as in (Meierhold et al., 2010) (this is a

manual task if no targets are used). (Alba et al., 2011)

A similar work was proposed by Borrmann et al.

(2013) with the exceptions that calibration patterns

are used, a printed chessboard pattern for the optical

camera and attached lightbulbs for the infrared cam-

era. The position of the points within these patterns

needs to be detected within the laser scan.

An arbitrary trihedron can be used as calibration

pattern, too. The calibration is based on a non linear

least square problem formulated in terms of geometric

constraints. (Gong et al., 2013)

Pandey et al. (2010) fuse a 3D laser scanner with

an omnidirectional camera. Their calibration method

is based on the approach introduced by Zhang (see

below), with the difference of using an omnidirec-

tional camera instead of a classical camera. A pla-

nar checkerboard pattern is required and needs to be

observed from both, the laser scanner and the camera

system from at least three points of view.

Sensor Fusion of a 2D Laser Scanner and a Thermal Camera

399

2.4 Extrinsic Calibration of a Camera

with a 2D Laser Scanner

Within the research area of pedestrian detection a 2D

laser scanner and a Far Infrared camera are fused. The

calibration is based on the least mean square (LMS)

algorithm. This algorithm takes a sample sequence

with a single pedestrian such that the person can be

detected within both sensor modalities. The coef-

ficients to convert the coordinates from the camera

to the laser scanner coordinate system is calculated.

(Garcia et al., 2010)

Alternatively there are approaches fusing a stan-

dard camera with a 2D laser scanner using different

calibration patterns.

Wasilewsky and Strauss use a rectangular folded

target with one side being black and the other one

coloured white. This allows a clear differentiation be-

tween the two halfs using the camera. The laser scan-

ner produces a triangular scan line - two lines inter-

secting in one point. Hereby the point of intersection

is clearly visible within the laser scan and the camera

image. (Wasielewski and Strauss, 1995)

Zhang and Pless propose a calibration using a sim-

ple checkerboard and solve all geometric constraints

for the transformation under the assumption that the

laser scan points must lie on the camera (calibration)

plane (Zhang and Pless, 2004). This method is im-

plemented within the automatic matlab tool by Kassir

and Peynot (Kassir and Peynot, 2010).

A further approach uses a black line on a white

sheet as calibration target. A created polynomial sys-

tem is solved and the laserscan point which is normal

to the plane is derived (Naroditsky et al., 2011).

Most of the suggested calibration methods for 2D

laser scanners have disadvantages due to a lack of de-

grees of freedom. Six degrees of freedom (transla-

tion in X, Y and Z direction and rotation around these

axes) are necessary to exactly determine the extrinsic

transformation.

As described by Dong and Isler for the meth-

ods suggested by Zhang (Zhang and Pless, 2004),

Wasielewski (Wasielewski and Strauss, 1995) and

Naroditsky (Naroditsky et al., 2011) there are miss-

ing degrees of freedom (Dong and Isler, 2016). This

means that either turning or shifting the calibration

target in different directions would still deliver the

same scan points or line even though it has a com-

pletely different position and it should be possible to

distinguish between the scans.

Dong and Isler developed a calibration target

made up of two triangles which are positioned at an

angle of 150

◦

to each other. Using this target for cal-

ibration, all six degrees of freedom are covered. A

complex algorithm using different planes and vectors

solves all constraints for the extrinsic transformation.

(Dong and Isler, 2016)

This overview showed that no precise extrinsic

calibration method exists for the fusion of a 2D laser

scanner and a thermal camera. Therefore a new

method has to be introduced. Due to the fact that the

calibration pattern proposed by Dong and Isler covers

all degrees of freedom it was decided to use a simi-

lar calibration target with the difference that it must

be visible for the thermal camera instead of a RGB

camera. This new approach also uses a third sensor to

help with the fusion.

3 APPROACH

The chosen approach will be described in detail in this

chapter. The laser scanner and the thermal camera are

combined with a NoIR camera.

3.1 Sensor Set Up

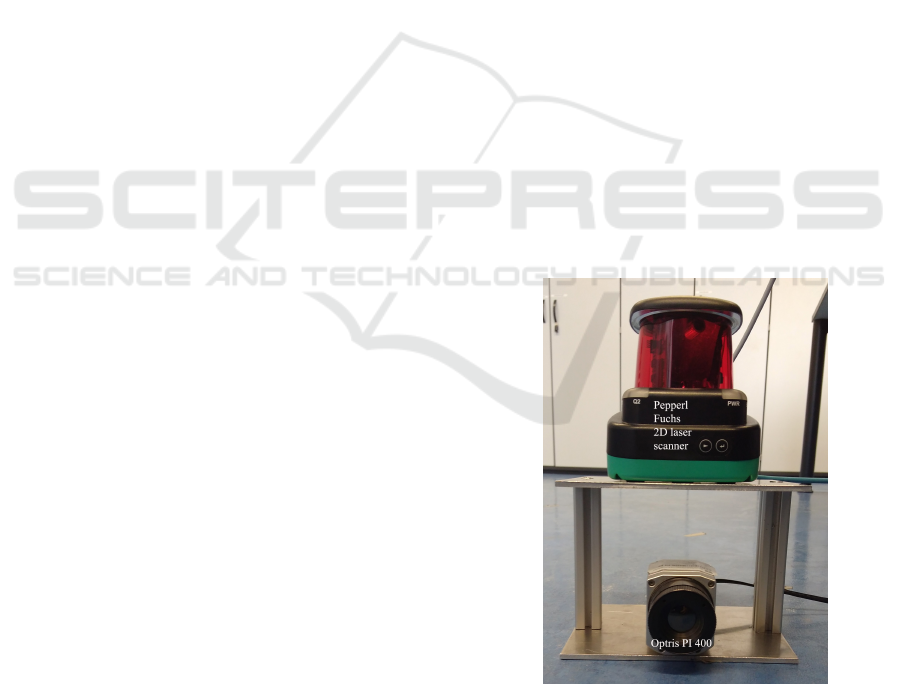

Both sensors are fixed on top of each other (see Fig-

ure 3). This is necessary to stop a parallax error oc-

curing. Otherwise the sensors would ’look’ sideways

onto each other which leads to an ambiguity. A NoIR

camera is fixed on top of the thermal camera to help

with the calibration and is removed afterwards.

Figure 3: Sensor set up.

The 2D laser scanner in use is the R2000

ODM30M designed by the company Pepperl und

Fuchs. It has a wavelength of 905 nm, a resolution

of 1 mm and an angular resolution of 0,014

◦

. The

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

400

ROS package pepperl fuchs r2000 supplies a driver

for this type of laser scanner. In this project a scan

rate of 50 Hz and 3600 scan samples was chosen. The

laser scanner delivers range and intensity data of the

measurements 360

◦

around itself.

The thermal camera in use is the Optris PI 400. It

has an uncooled detector and delivers a temperature

sensitivity of up to 0.8 K. Its spectral range lies be-

tween 7.5 and 13µm. The ROS package optris drivers

is used as interface for the camera.

Additionaly to the main sensors a Raspberry Pi

camera is applied to help with the calibration between

the laser scanner and the thermal camera. Further

details can be found in the later chapters. The No

Infrared (NoIR) camera (camera module v1) is con-

nected to a Raspberry Pi computer. NoIR implies

the lack of an infrared filter such that infrared light

can be detected. This camera is capable of seeing the

laser scan line. The Raspberry Pi runs with the 16.04

Ubuntu mate version. The ROS package raspicam is

the driver used to run the camera.

3.2 Intrinsic Calibration of the Thermal

and the NoIR Camera

The ROS package camera calibration is used for the

intrinsic calibration of both the thermal camera and

the NoIR camera. The intrinsic calibration is neces-

sary to rectify the image and to remove distortions.

It relates to the projection of the chip plane onto the

image plane of the camera sensor such that the trans-

formation between the sensor’s pixel coordinates and

the world coordinate frame is given. Both cameras

can be modelled as a pinhole camera represented by

this formula:

u

v

1

=

f

x

0 u

0

0 f

y

v

0

0 0 1

X/Z

Y /Z

1

where (u, v) are the distorted image coordinates, f

x

and f

y

are the focal length, u

0

and v

0

are the coordi-

nates of the center of the camera sensor. X, Y and Z

make up the 3D coordinate within the world coordi-

nate system.

Images of the heated calibration pattern with 9x6

circles with a distance to each other of 3.75 cm are

computed by the calibration tool. The images need to

be taken from all different orientations, distances and

at varying degrees of skewness so that the tangential

and radial distortion coefficients can be precisely cal-

culated. The distortions are removed by applying the

following formula to the pixel coordinates:

u

00

v

00

=

u

0

· k + 2p

1

v

0

+ p

2

· (r

2

+ 2u

02

)

v

0

· k + 2p

1

· (r

2

+ 2v

02

) + p

2

u

0

with

k = (1 + k

1

r

2

+ k

2

r

4

+ k

3

r

6

)

where k

1

, k

2

and k

3

are the radial distortion coeffi-

cients and p

1

and p

2

are the tangential distortion co-

efficients. r is the Euclidean distance of u

0

and v

0

with

u

0

= u − u

0

and v

0

= v − v

0

.

The camera matrix and the distortion factors are saved

within a yaml file which is called by the camera driver

when starting it.

The same calibration target has a black and white

pattern on its backside which delivers a good contrast

for the calibration of the Raspberry Pi camera. The

calibration package camera calibration was installed

and run on the Raspberry Pi itself. The calibration

procedure is the same as for the thermal camera.

3.3 Extrinsic Calibration

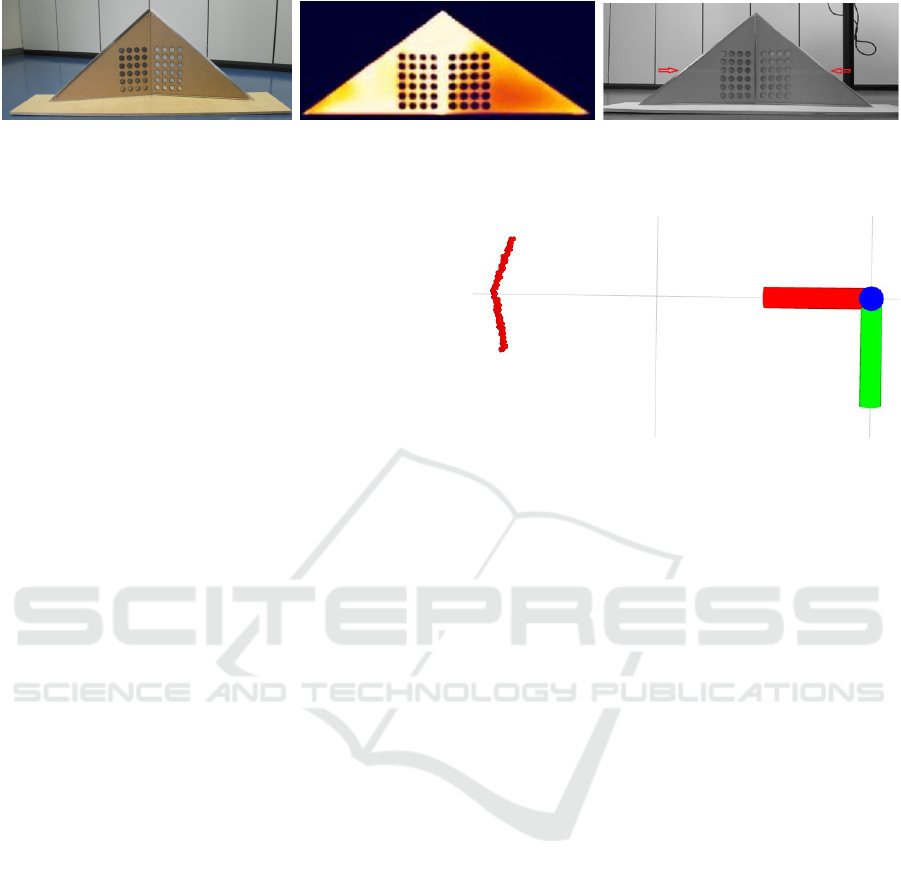

A special calibration target was developed for the ex-

trinsic calibration of the laser scanner and the thermal

camera (see Figure 4 left).

The basic principle is based upon the publication of

Dong and Isler (Dong and Isler, 2016). In their pa-

per they describe the extrinsic calibration of a cam-

era and a 2D laser scanner. Their approach allows

a direct calibration covering all six degrees of free-

dom. In their paper two triangles are positioned to

each other at an angle of 150

◦

. When using a thermal

camera instead of an RGB camera the target needs to

be heated so that a clear temperature gradient can be

detected. For this reason two triangular shaped alu-

minium plates were produced. As only the edges of

the triangle are of major interest, two slightly smaller

triangles made of high density fibreboard (HDF), are

placed in front. The whole calibration target is fixed

on a wooden board so that it remains in an angle of

150

◦

, with the two triangles being connected by a

metal hinge.

The first test to check whether useful images and

sensor data can be generated was done by heating the

target with a hot air blower. The calibration target was

clearly visible in all different sensor images. Surpris-

ingly the edges of the aluminium triangles were not

visible within the thermal image. It became apparent

that the aluminium cools down much faster than the

HDF boards so that the whole wooden plane was ac-

tually visible within the thermal image (see Figure 4

middle). For this reason the calibration target had to

be adjusted. So far the aluminium was forming the

edges of the triangular target. As the aluminium is

not visible, the wooden triangles were moved towards

the middle, so that the middle edge is visible.

In order to calculate the extrinsic transformation

including translation and rotation between one laser

Sensor Fusion of a 2D Laser Scanner and a Thermal Camera

401

Figure 4: Special calibration target (le.), Calibration target within thermal camera image (mid.) and Laser scan line within

NoIR image (ri.).

scan point and one thermal image pixel, the following

steps had to be followed.

The intersection points between the scan line and

the edges of the triangle need to be identified in both

the laser scan data and the thermal camera image. The

laser scan data needs to be filtered so that only the

scan points displaying the calibration target remain.

Furthermore reflections caused by the laser scan line

interfering with the target’s edges need to be removed.

The scan points belonging to the calibration target’s

edges need to be detected. The Raspberry Pi camera

without an infrared filter, helps to detect the actual

laser scan line (see Figure 4 right). First the trans-

formation between the NoIR image and the thermal

camera image needs to be calculated using the trian-

gle corner coordinates within both images. The next

step is to find the corresponding pixels within the ther-

mal image by applying the transformation on the in-

tersection points within the NoIR image such that they

are given within the thermal camera image. Once the

scan points and the thermal image points of the inter-

section are known, they need to be inserted into an

algorithm which calculates the extrinsic transforma-

tion out of them. The used function is the SolvePnP

function by OpenCV.

3.3.1 Laser Data

The laser scan data holds all measurements which

are placed 360

◦

around the scanner with a maximum

range of 100 m. For the calibration only measure-

ments corresponding to the calibration target are re-

quired - the triangular line within Figure 5 - that is

why filtering is needed. The colourful axes represent

the laser scanner.

Only angles between -31 and 31

◦

within the laser scan

data are accepted. This is because the thermal camera

only has a field of view of 62

◦

. A distance filter is

applied, too, such that all distances further and closer

than the calibration target are eliminated. Artefacts

caused by reflections at the edges of the object are

filtered out by comparing the distances to the neigh-

bours. If they exceed a threshold value, the laser scan

is set to ”not a number”. Additionally only scans

of a certain intensity are accepted. The laser scans

Figure 5: Relevant laser data.

are furthermore converted to 3D-coordinates as the

solvePnP function needs the objectPoints in this for-

mat. As last step the search for the edge scan points is

implemented so that the relevant values are returned.

The edge point in the middle is the laser scan value

with the greatest distance, if the target is positioned

such as within Figure 5. The outer intersection points

are the first and the last point within the scan.

3.3.2 Raspberry PI Camera Data

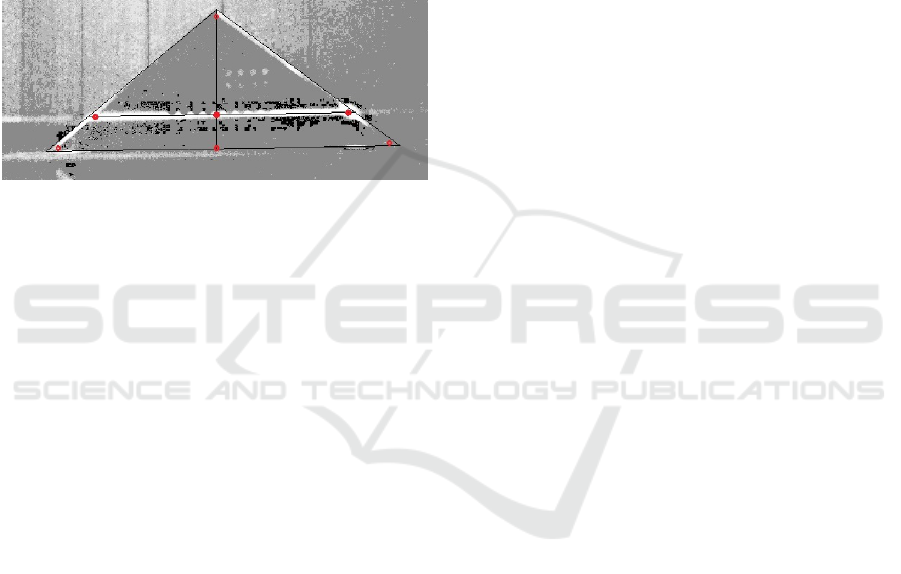

The pixel coordinates of the wooden triangles need to

be found within both the Raspberry Pi camera image

and the thermal camera image. As the NoIR image

was taken in complete darkness so that the laser scan

line appears brighter, histogram equalisation is neces-

sary.

First of all image processing methods were con-

sidered to segment the laser scan line within the im-

age. The image was supposed to be binarised at first

after which an appropriate threshold was to be found

so only the scan line remains. As the laser scan line is

broad due to the distance from which the image was

taken this was not possible. So even when applying

the Canny operator to detect the edges or different im-

plementations of a thinning algorithm by Zhang and

Suen, no suitable result was gained. Another option

would be the Hough Transform which detects lines

within images. Unfortunately the laser scan line is not

a constant line because of the laser cut holes within

the calibration target so that none of the mentioned

approaches led to satisfying extraction.

In the end it was decided to determine the coor-

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

402

dinates of the (wooden) triangle corners as well as

the intersection points with the laser scan line manu-

ally using OpenCV3. The triangle corner coordinates

were found within the thermal camera image and the

NoIR image. One frame of the recorded bagfile is

used and by drawing in lines around the triangular

shape and through the middle of the laser scan line

the significant points are determined and the correct-

ness is checked at the same time. The intersection

points with the laser scan line were determined within

the NoIR image, too. The triangle corner coordinates

within both images were used to calculate the trans-

formation between them.

Figure 6: Points selected within the NoIR image.

Four points from both modalities were first selected

and inserted into the function OpenCV findHomogra-

phy . This function is supposed to deliver the transfor-

mation between the thermal and Raspberry Pi camera

image pixels. Unfortunately this function returned an

incorrect transformation matrix so an alternative func-

tion was required. The OpenCV function getAffine-

Transform fulfills this task. This transformation was

applied on the intersection points (transform) such

that they are known within the thermal camera image.

To gain more accuracy this was done for the two sub-

triangles halfs seperately as they correspond to two

different planes.

3.3.3 Calculation of the Extrinsic

Transformation Matrix

To be able to finally calculate the extrinsic transfor-

mation between the laser scanner and the thermal

camera, the laser 3D coordinates and the correspondig

pixel values within the thermal image are both pro-

cessed by the solvePnP function which returns the ro-

tation and the translation as 3x1 vectors.

SolvePnP. Using several corresponding laser and

thermal points, the extrinsic transformation is calcu-

lated using the function solvePnP from OpenCV. This

implementation is based on the publication by Zhang

(Zhang, 2000).

The function estimates the object pose given a set

of 3D laser points (object points) and their corre-

sponding thermal pixels (image projections), taking

the camera matrix and the distortion coefficients into

account. If the points lie on the same plane it inter-

nally calls the function findHomography which finds

the perspective transform between two planes, and re-

fines it by applying Levenberg-Marquardt approxima-

tion, which is an optimisation algorithm based on the

least squares method. If the points lie on different

planes the Direct Linear Transform (DLT) algorithm

is used. It calculates the matrix A which projects the

3D laser points (y

1

,y

2

,y

3

) onto the thermal 2D plane

(x

1

,x

2

) such that:

x

1

x

2

=

a

11

a

12

a

13

a

21

a

22

a

23

y

1

y

2

y

3

The function solvePnP returns the required rotational

and translational vectors which represent the extrinsic

transformation.

In order to apply this transformation on all laserpoints

a reprojection has to take place. This was done manu-

ally at first. In order to get a 4x4 matrix which can be

applied on each laser point coordinate, a rotation ma-

trix was formed using the Rodrigues function. This

function returns a 3x3 rotation matrix. (Rodrigues,

2017) The transformed laser points within the ther-

mal image have the unit m. The conversion to the

pixel value coordinates is done by taking the field of

view (FOV) of the thermal camera into account. The

FOV in the x-direction is of 62

◦

, into the y-direction

the FOV is of 49

◦

. The width and height of the image

in meters depends on the distance the image was taken

from. It turned out that this method lead to erroneous

values so that the more precise function projectPoints

was used instead. This function projects 3D points

onto the image plane.

The transformation is applied to all laserpoints

and projected into the thermal camera image. The

aim is to display the human’s temperature and the dis-

tance to them. The first approach was to find the most

common temperature of the laser scan line and get

the corresponding average distance. Only tempera-

tures within the human’s skin temperature range are

of interest.

Results. The relevant temperature range is made

flexible by finding the maximum temperature value

of the laser scan line. The minimum value is set as

the maximum - 3

◦

C (t

min

= t

max

− 3

◦

C).

The distance found is now the minimum distance

as the closest person has to be found first. This auto-

matically filters out too large values.

The sensors have to be positioned on top of each

other so that no parallax error can occur (see Fig-

ure 3). If the sensors were positioned next to each

Sensor Fusion of a 2D Laser Scanner and a Thermal Camera

403

other they would have different field of views. This

leads to the effect that the thermal camera is looking

sideways onto the laser scan measurements. The par-

allax error has an impact on the short but not long dis-

tances. The results, if the sensors are placed on top of

each other, for the closest values as well as the further

ones are then accurate.

It was also found out that the thermal emission of

the body leads to the effect that the thermal camera

detects pixels with the same temperature even though

they are not part of the body and the laser scanner

returns too long distances. These values need to be

filtered out.

Additionally it has to be made sure that a distance

of at least 35 cm is kept to the sensor system. Other-

wise the laser scan line is not within the measurement

field of the thermal camera. The camera’s optic has to

be taken into account. Half the height of the measure-

ment field has to be greater than the distance between

the laser scanner and the thermal camera in vertical

direction (about 16 cm). Using the optic’s calculator

by optris this leads to a minimum distance of 35 cm.

As final test a person was positioned with differ-

ent distances to the sensor system and the distance

was measured with a reference laser measurement and

with the sensor system. The reference measurement

had an accuracy of 1-2 cm. The data is visualised

within a Bland-Altman plot and shows that with the

exceptance of one outlier the accuracy of the sensor

fusion system is high (see Figure 7).

-0.06

-0.04

-0.02

0

0.02

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

error in m

distance in m

Figure 7: Bland-Altman plot.

The following images present the results of the sensor

fusion system.

It was found out that the greater the distance the

more inacurrate the calibration. This is due to the res-

olution of the thermal camera. Distances up to 10 m

can be determined with great accuracy. For the in-

tended aim this distance is sufficient as a flat should

not have greater dimensions.

Figure 8: Temperature and distance to a radiator.

Figure 9: Human with a distance of about 3 m.

Figure 10: Human with a distance of about 10 m.

4 CONCLUSIONS

It was shown that it is possible to fuse a 2D laser scan-

ner with a thermal camera using a special triangular

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

404

calibration target and a NoIR camera to help. This

new calibration method covers all six degrees of free-

dom. The sensor set up has to be such that the sensors

are placed on top of each other so that no parallax er-

ror occurs. Furthermore a distance greater than 35 cm

has to be kept to the sensor system. Otherwise the

laser scan line does not lie within the thermal cam-

era measurement field. It was verified that this system

works for distances up to 10 m (see Figure 10).

In the future this system can be improved by using

a thermal camera with a higher resolution. This will

make it applicable for greater distances. Additionally

it can be considered to use image processing and ob-

ject detection algorithms for detecting more than one

person within the image at a time. Furthermore the

existing system can be expanded by a SWIR camera

and a radar sensor to allow localisation under poor

visibility conditions.

REFERENCES

Alba, M. I., Barazzetti, L., Scaioni, M., Rosina, E., and Pre-

vitali, M. (2011). Mapping infrared data on terrestrial

laser scanning 3d models of buildings. Remote Sens-

ing, 3(9):1847.

Borrmann, D., Elseberg, J., and N

¨

uchter, A. (2013). Ther-

mal 3D Mapping of Building Fac¸ades, pages 173–182.

Springer Berlin Heidelberg, Berlin, Heidelberg.

Dong, W. and Isler, V. (2016). A novel method for extrin-

sic calibration of a 2-d laser-rangefinder and a camera.

CoRR, abs/1603.04132.

Garcia, F., Olmeda, D., Armingol, J., and de la Escalera, A.

(2010). Hybrid fusion schemer for pedestrian detec-

tion based on laser scanner and far infrared camera. In

Proceedings of 2010 IEEE Intelligent Vehicles Sympo-

sium, San Diego, USA.

Gong, X., Lin, Y., and Liu, J. (2013). 3d lidar-camera ex-

trinsic calibration using an arbitrary trihedron. Sen-

sors, 13(2):1902.

Kassir, A. and Peynot, T. (2010). Reliable automatic

camera-laser calibration. In Proceedings of Aus-

tralasian Conference on Robotics and Automation,

Brisbane, Australia.

Liebelt, T.-M. (2013). Fusion von 3D-Laserscanner-

Daten mit 2D Thermal-Bilddaten. Bachelor thesis,

Westf

¨

alische Hochschule Gelsenkirchen.

Meierhold, N., Spehr, M., Schilling, A., Gumhold, S., and

Maas, H. (2010). Automatic feature matching be-

tween digital images and 2d representations of a 3d

laser scanner point cloud. International Archives of

Photogrammetry, Remote Sensing and Spatial Infor-

mation Science, Newcastle upon Tyne, UK, 38:446–

451.

Naroditsky, O., Patterson, A., and Daniilidis, K. (2011).

Automatic alignment of a camera with a line scan

lidar system. In Proceedings of 2011 IEEE In-

ternational Conference on Robotics and Automation

(ICRA), Shanghai, China, pages 3429–3434.

Pandey, G., McBride, J., Savarese, S., and Eustice, R.

(2010). Extrinsic calibration of a 3d laser scanner and

an omnidirectional camera. IFAC Proceedings Vol-

umes, Lecce, Italy, 43(16):336 – 341.

Rodrigues (2017). Rodrigus. http://docs.opencv.org/2.4/

modules/calib3d/doc/camera calibration and 3d

reconstruction.html#rodrigues. Accessed on 04 May

2017.

Unnikrishnan, R. and Hebert, M. (2005). Fast extrinsic cal-

ibration of a laser rangefinder to a camera. Technical

Report CMU-RI-TR-05-09, Robotics Institute, Pitts-

burgh, PA.

Wagner, M., Heß, P., Reitelsh

¨

ofer, S., and Franke, J. (2015).

Data fusion between a 2d laser profile sensor and a

camera. In Proceedings of 12th International Con-

ference on Informatics in Control, Automation and

Robotics (ICINCO), 2015, Colmar, Alsace, France,

volume 02, pages 159–165.

Wasielewski, S. and Strauss, O. (1995). Calibration of a

multi-sensor system laser rangefinder / camera. In

Proceedings of the IEEE Xplore Conference: Intelli-

gent Vehicles ’95 Symposium., Detroit, USA.

Zeise, B. (2016). Smokebot deliverable 3.2: Software

toolkit indoor surface temperature mapping. http://

aass.oru.se/Research/mro/smokebot/deliverables/

SmokeBot D3 2.pdf. Accessed on 14 November

2016.

Zeng, L., Ding, M., Zhang, T., and Sun, Z. (2015). A

fast moving object detection method based on 2d laser

scanner and infrared camera. In Proceedings of SPIE

9675, AOPC 2015: Image Processing and Analysis,

Beijing, China.

Zhang, Q. and Pless, R. (2004). Extrinsic calibration of a

camera and laser range finder (improves camera cal-

ibration). In Proceedings of IEEE/RSJ International

Conference on Intelligent Robots and Systems, 2004.

(IROS 2004), Sendai, Japan.

Zhang, Z. (2000). A flexible new technique for camera cali-

bration. In Proceedings of IEEE Transactions on Pat-

tern Analysis and Machine Intelligence, volume 22,

page 13301334.

Sensor Fusion of a 2D Laser Scanner and a Thermal Camera

405