A Domain Specific Language for Robot Programming

in the Wood Industry

A Practical Example

V

´

ıctor Juan Exp

´

osito Jim

´

enez and Herwig Zeiner

DIGITAL – Institute for Information and Communication Technologies,

JOANNEUM RESEARCH Forschungsgesellschaft mbH, Steyrergasse, Graz, Austria

Keywords:

Domain Specific Language, Functional Programming, F#, Wood Industry, Robotics.

Abstract:

Domain Specific Languages (DSL) are being used in several fields of industry. This paper shows how a DSL

can be used in the wood industry, automizing some tasks through the use of robots. In this paper we also

implement a syntax to define robot instructions inside a high-level abstraction layer to simplify these instruc-

tions and to develop a reliable tool for developers in order to avoid errors and allow for faster development.

This paper also covers considerations on how to choose the kind of DSL that best fulfills our requirements and

provides an example described in detail.

1 INTRODUCTION

Software development is causing large costs for the

manufacturers and integrators of robot technology.

Often, the volume and risk associated with software

for a new robot system exceeds the expertise and re-

sources of potential adopters in the wood manufactur-

ing industry. This might be mitigated by standardized

and reusable components or easily usable program-

ming tools for domain experts. Such a development

would help to reduce both risks and costs through co-

operative software engineering.

Current research work, especially within the sec-

tor of industrial robotics, is investigating new pro-

gramming methods for making complex tasks eas-

ier to program for standard industrial robots. Com-

mon approaches include complex offline program-

ming methods with a complete 3D model of the robot

cell and the immediate surroundings for a manual

configuration of movement and the handling of tasks.

This requires the programming of specific knowledge

and is customarily done by specialized programmers.

As a consequence, it becomes difficult to change

programs for new tasks based on new requirements,

which is needed for handling tasks with small batch

sizes.

Domain-specific modeling is used in robotics to

describe items with concepts and notations in order

to get closer to the respective domain and to raise the

level of abstraction. This results in models of the sys-

tem or parts of the system which are easier to under-

stand and to validate and in turn lowers the bar for the

skills needed to handle the system’s complexity. It

also helps increase the level of automation and makes

it easier to analyze the system. In this paper, we in-

troduce a new DSL specifically focused on the wood

industry so the advantages of this kind of program-

ming methodology can be applied here as well.

The next section gives an overview of existing and

related work in the field of DSL in the robotics field.

Section 3 explains why a DSL has been implemented

in our scenario and explains the different type of DSL

that are available to choose from. The implementation

of our solution in Section 4 explains the DSL con-

siderations and gives an example. Finally, Section 5

presents the conclusion and the future plans for this

work.

2 RELATED WORK

The implementation of Domain-Specific Modeling

and Languages is a topic which has been widely re-

searched in software development the last few years.

A good starting point for this research is this sur-

vey (Nordmann et al., 2016) in which a general

overview about tools and implementation in robotic

systems can be found. An example of a DSL usage

is given in (Thomas et al., 2013) which describes

a robot programming language using UML/P State-

charts. The work proposes a Domain Specific Lan-

guage (DSL) based on UML Statecharts. This lan-

Jiménez, V. and Zeiner, H.

A Domain Specific Language for Robot Programming in the Wood Industry - A Practical Example.

DOI: 10.5220/0006397205490555

In Proceedings of the 14th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2017) - Volume 2, pages 549-555

ISBN: Not Available

Copyright © 2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

549

guage is divided into three abstraction layers - pro-

cess, task, and skill. The process layer is intended

for users whose knowledge about programming lan-

guages is limited. The task level involves simple in-

structions for the robot. Finally, the skill level is the

lowest one, describing primitive actions for the robot.

All components that shape the DSL are modeled by

using UML diagrams. The paper also demonstrates

its implementation through a small screw example

that will be extended in future research. (Joyeux and

Albiez, 2011) explain the process of designing an Au-

tonomous Underwater Vehicle (AUV) robot. It starts

by explaining the advantages of using an embedded

DSL on this kind of system. It also presents an ex-

ample based on Ruby that details the implementation

of the system by using Rock and Orocos Real-Time

Toolkit (RTT). Another interesting use case is de-

scribed in (Maro et al., 2015), in which the implemen-

tation of both textual and graphical DSL is described,

as well as the challenges that they have solved.

One of the problems in robot programming is ex-

plained in (Herrero et al., 2015), which clarifies that

the existence of several proprietary languages renders

difficult the task of robot programming. The authors

also present a more generic architecture based on the

robotics skills. These skills could be defined as small

tasks that are a combination of primitives, while prim-

itives are the basic functions that the robot is able to

do. It also explains how the robot in question has been

modeled by using this skill based architecture and the

tests in a real environment.

Moreover, there are several research papers where

a DSL in robotic systems is used to model the sys-

tem. (Lotz et al., 2016) explains the whole process

of a robot modeling system. Meta-model, DSL, and

code generation are explained, within the tools and

framework that the authors have used for each pur-

pose. Graphical and textual representations are used

to show the advantages and disadvantages in each sit-

uation. The paper (Ramaswamy et al., 2014) talks

about SafeRobots, a Model-Driven Software Devel-

opment approach. Its framework is divided into

three parts; the Operational space, the solution space

and the problem space. The operational space col-

lects extended information about system’s analysis.

The workflow of the SafeRobots framework consists

of four parts: General Domain Knowledge Model-

ing, Problem-specific knowledge or solution model-

ing, Problem-specific concrete or operation modeling,

and executable code. The solution model is based

on functional and non-functional properties (NFPs).

These are modeled by using the DSL, Solution Space

Modeling Language (SSML). Another example can

be found in (Schlegel et al., 2009) in which another

model for robot systems is described by trying to use

existing technology to simplify the robot modeling. A

runtime can be found in (Lotz et al., 2011) to moni-

tor the robotics software components. It receives any

information from the sensors and forwards it to the

diagnose port. The black port enriches the informa-

tion it receives, i.e. adding timestamps, and thanks

to a buffer is also able to manage multiple sensors.

Finally, the diagnose port checks whether all loaded

conditions in the XML profiles are valid according the

robot model.

3 DOMAIN SPECIFIC

LANGUAGES

According to the work of (van Deursen et al., 2000), a

Domain Specific Language (DSL) is defined as a pro-

gramming language or executable specification lan-

guage that offers, through appropriate notations and

abstractions, expressive power focused on, and usu-

ally restricted to, a particular problem domain. These

abstractions and notations have to be suitable for the

stakeholders who specify the system. In most situa-

tions, the DSL are focused on limited cases and are

used as a tool for particular processes. In contrast to a

General-purpose Programming Language (GPL) such

as C# or Java, a DSL usually contains only a restricted

set of notations and abstractions specialized to one or

more particular domains.

The main goal of using a DSL is the simplifica-

tion of the development process in which a developer

does not handle complicated functions or parameters.

A DSL can also make a program easier to understand

because it usually presents a human-readable aspect.

Two well-known examples are the Cascading Style

Sheets (CSS) and Structured Query Language (SQL)

languages, which provide an abstraction layer to ease

the development instead of programming in the na-

tive language. There is also a possibility that a project

might use several DSL in various places.

There are mainly two kinds of DSL, textual and

graphical. Both implementations have their own ad-

vantages and disadvantages. A graphical DSL pro-

vides a better visualization and understanding of both

the modeling process and the final model. Unfortu-

nately, versioning is harder to implement for this no-

tation and it can occur that not all situations can be

shown when the system gets too complex.

On the other hand, textual representation increases

the speed of creation and editing but it could be harder

to understand the whole picture of the final system.

Two different types of textual DSL exist; external

DSL, which define their own syntax and semantics,

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

550

and internal DSL, which are embedded in an extensi-

ble GPL. Both extend the syntax and potentially the

semantics of the host language with domain-specific

notations and abstractions.

For external DSL, a translator is needed to convert

the DSL syntax into the host language whose code

can be executed. Most of the frameworks, such as

Xtext

1

or Visual Studio DSL SDK

2

, are able to trans-

late the DSL into a GPL, which will be used for the

implementation of the DSL. Internal DSL use a base

language, such as Lisp, F# or Haskell, to implement a

simplified abstraction for a specific domain based on

the syntax of the host language. Internal DSL are also

called embedded DSL.

In order to efficiently implement and apply a DSL

approach for the development of systems and to fully

exploit its benefits, DSL are typically used in tools

tailored to model-driven development such as the

Eclipse Modeling Project

3

or JetBrains MPS

4

. Mar-

tin Fowler (Fowler, 2010) called these language work-

benches; they offer extensive support for the develop-

ment of DSL. Domain-specific modeling languages

are themselves often modeled using the elements and

following the rules of meta-model languages. The

alternative to the use of a potentially complex meta-

model language available in a language workbench is

the use of a grammar specification formalism, which

can be used by parser generators. However, language

workbenches provide further benefits beyond the def-

inition of an abstract and concrete syntax, such as the

support for the development of textual and/or graph-

ical editors with rich code completion and dynamic

constraint checking at design time that improves the

usability for language users. Furthermore, these en-

vironments provide extension points to plug-in the

required model-to-model (M2M) and model-to-text

(M2T) transformations in order to generate a textual

representation different from system models that inte-

grate with the overall environment used for the devel-

opment of an application.

One of the main parts of designing a DSL is the

modeling of the system. A graphical model typically

provides its own custom graphic syntax, which con-

forms to a custom meta-model and requires a cus-

tomized framework for the editing and can be trans-

formed directly to allow the execution on a target plat-

form or its interpretation. It is also often used for sys-

tem analysis. Here, model checking and validation,

the setup and analysis of simulations or model-based

testing are typical tasks that can be addressed. Be-

1

http://www.eclipse.org/Xtext/

2

https://msdn.microsoft.com/en-us/library/bb126259.aspx

3

https://eclipse.org/modeling/

4

https://www.jetbrains.com/mps/

yond execution and analysis, models are often directly

suitable as documentation but can also be used to gen-

erate further visualization. Further concerns that are

highly relevant for potential DSL users are the kind of

artifacts such as source code, configuration files, etc.

that are provided for a model-based development ap-

proach and how these artifacts are used within a target

platform.

Once the modeling of the software system is com-

plete, the model has to be adapted from a generic to

a specific domain. In this part, two domain imple-

mentations have to be included, the Platform Indepen-

dent Model (PIM) and the Platform Specific Model

(PSM). The first one includes general tasks that can

be reused in other similar environments. This model

is conceived by the robotics experts who are focusing

on the functional part of the components. The PSM

includes the software functions or hardware specifica-

tions which will be used in a concrete platform or do-

main. Application experts are in charge of this model;

they have to adjust and select components as well as

the system configuration according to the PIM.

4 IMPLEMENTATION

The usage of robots in factories is a key point in the

so called Industry 4.0 or Industrial Internet of Things.

This is also a reason why more workers have to learn

how a robot should be managed to carry a task out.

The motivation behind this paper is the development

of a tool that can be used to simplify the implemen-

tation of robots for employees who have limited pro-

gramming knowledge. In such cases, the usage of a

full instructions list for the robot programming is not a

good idea because it can complicate the programming

process, while simplifying this process both avoids er-

rors and improves performance. Systems have to be

used not only by domain experts but also by people

who do not fully understand the whole system.

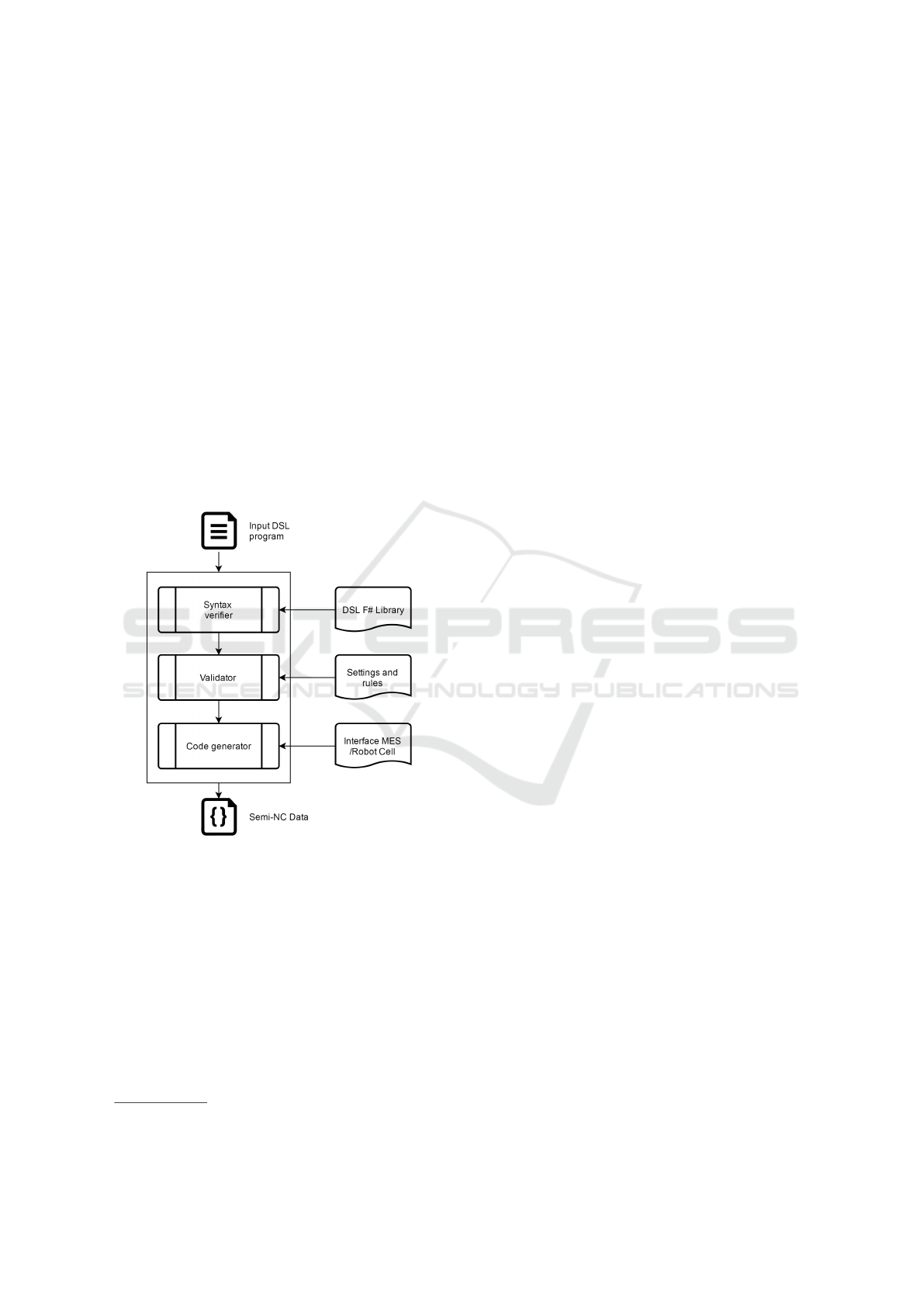

Following the guidelines given in the previous

section, the proposed DSL implementation follows

the structure depicted by Figure 1. In a first step, the

DSL syntax is validated to find if there were some er-

rors when the program was written. Once the syntax

is validated, the DSL checks that the given param-

eters are in the right range by using the predefined

rules and settings. Finally, the code is generated into

a Semi-NC data which will be used in the communi-

cation between the Manufacturing Execution System

(MES) and the robot cell.

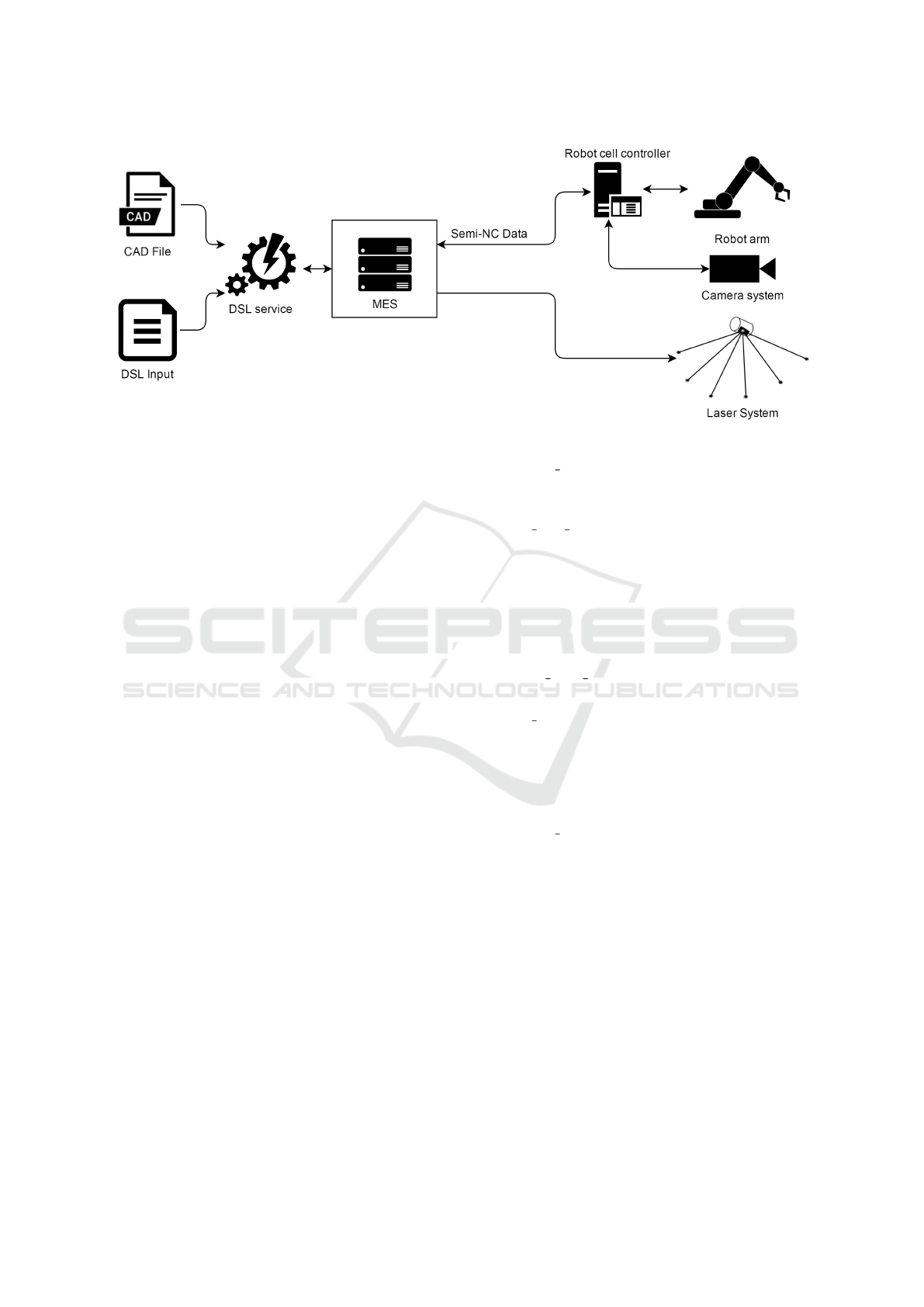

Figure 2 depicts the components of our system.

A more detailed description can be found at (Haspl

et al., 2017). Wooden prefabricated walls are manu-

A Domain Specific Language for Robot Programming in the Wood Industry - A Practical Example

551

factured in the assembly line where the robots must be

able to cut, vacuum the remains and staple clamps on

the surface of each wall without human interaction.

There are two ways to interact with the MES; the first

one is by using the CAD file which defines the pieces

and transformations. The needed information is ex-

tracted from the file to generate an output that will be

fed into the MES. Unfortunately, a more detailed ex-

planation of this process is beyond the scope of the

paper. The other possibility is by using the designed

DSL which provides a simple set of instructions to

interact with the MES.

The developed DSL is required to provide workers

an easy interface to manage the system. Once a pro-

gram is written, the interpreter translates this program

into a compatible syntax which will be used for the

MES that handles the communication with the robot

cell. The MES is provided by the company RIB SAA

5

which has designed a specific interface for this pur-

pose.

Figure 1: Structure of the proposed DSL implementation.

4.1 Selection Considerations

The choice of the DSL type has to be decided accord-

ing to our approach on flexibility, adaptation, and in-

tegration. In a first step, a textual implementation was

chosen because it provides better flexibility and inte-

gration as well as a clear human-readable syntax.

One of the main points that have been considered

in choosing the DSL type is the compatibility with

the .NET language stack which is widely used by the

project partners. Therefore, the election of a differ-

ent language stack, such as Java, may present major

5

http://www.saa.at/es/

compatibility issues in a later integration and would

require more maintenance efforts. At this point, the

usage of either an external or an internal DSL was dis-

cussed. Three main options were considered for the

DSL. The first one was to design an external DSL and

then to translate the code to C#. Another possibility

was to use an internal one based on the C# language.

The third one was the implementation of an internal

DSL based on the F# programming language.

For an external DSL, we can set a simple and clear

syntax which can be used within the communication

process of domain experts, while a code generator

must be implemented to translate our syntax into a

program for external DSL. The syntax in this kind of

DSL is a key issue because users have to learn how

the DSL works and its behavior. This means that the

learning curve has to be considered. The most rele-

vant issue in our selection process is the integration

of the DSL in the .NET language stack and its follow-

ing integration in a future platform. For these reasons

we have decided to choose an internal DSL because

we are able to implement our approach in a more af-

fordable way. Therefore, the first option of writing an

external DSL was rejected.

Once an internal DSL is chosen, the election of

F# against C# has some advantages. Functional-

programming languages, like F#, avoid changing-

state and mutable data, meaning that the results of

a functional programming function only depends on

the arguments that are input to the function. There-

fore, a function with the same input arguments al-

ways gives the same result. This kind of language fits

very well for reactive systems, which are the systems

that respond to external events, similar to robots. For

all these aspects, the F# programming language was

chosen to build our DSL. The reason that we use F#

instead of other functional programming languages

such as Lisp or Haskell, is that there is a good integra-

tion available in the .NET runtime stack. F# is fully

supported in Microsoft Visual Studio, which provides

some compatibility with C# and can be used as a li-

brary in C# programs.

4.2 Code Generation and Validation

When a program is written by operators using the

DSL syntax, the validation and code generation

should follow. Here, the program has to be validated

in two aspects, the DSL syntax, and the domain val-

idation. The domain experts carry out this task in

which they have to decide the settings and the limi-

tations of our scenario which will afterwards be in-

cluded in the DSL. For example, developers have to

make sure that the coordinates where the robot arm

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

552

Figure 2: System overview and components interconnection.

would be moving are in reach before the code is gen-

erated. After the program is validated, it will be trans-

lated into a code that is able to be used in the MES

system.

4.3 Example

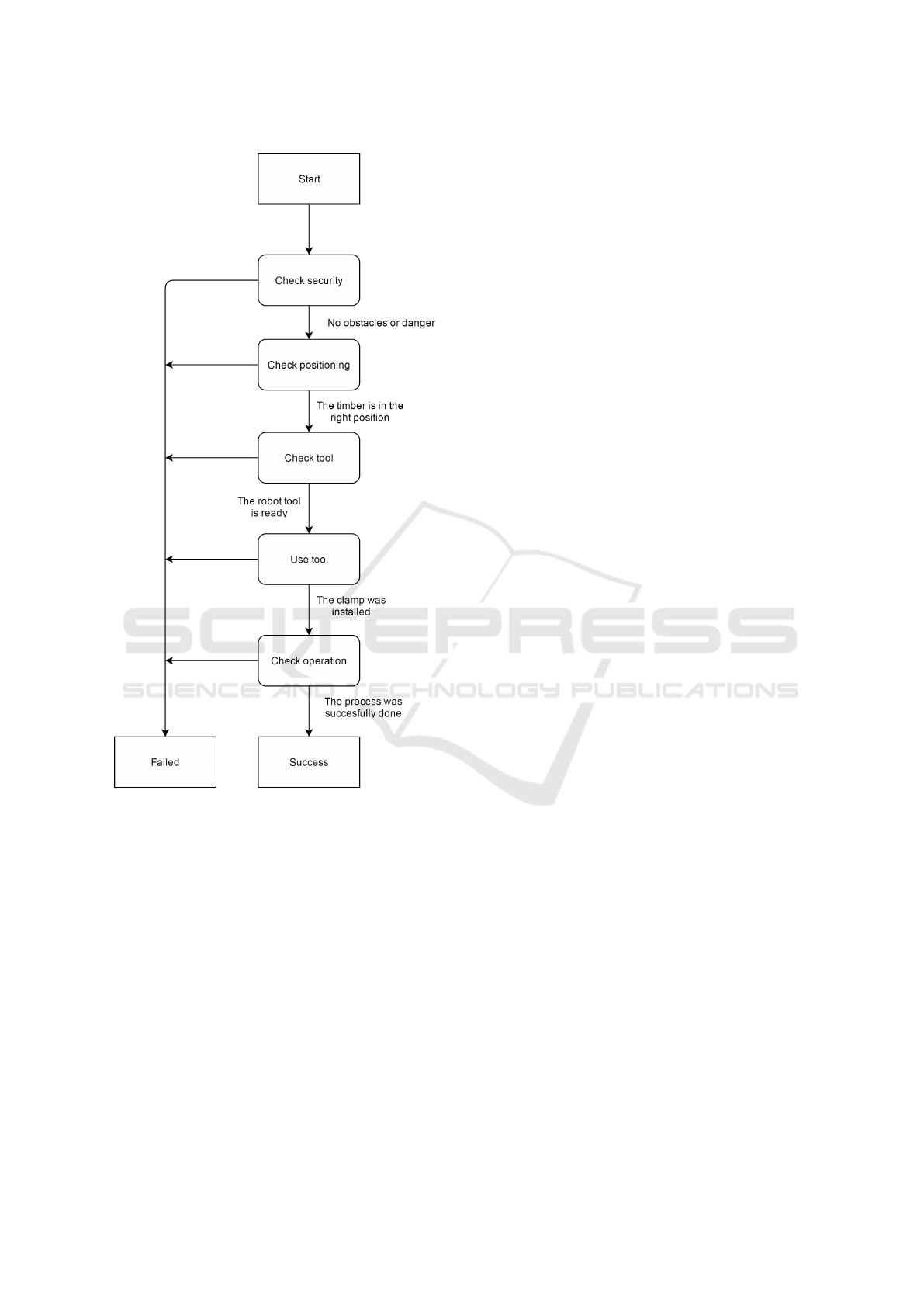

A small example of the DSL can be found in this sub-

section. For this purpose, the process, in which the

clamps are stapled onto the surface wall, is described.

In this process, the robot arm uses the specific tool to

staple the clamps as can be seen in Figure 3 where

the whole process is shown. This process can also

be described as a combination of high-level buildings

blocks, as listed below:

1. Check security: the robot cell checks that there are

no obstacles which could complicate the process

or put someone in danger.

2. Check positioning: this operation uses the laser to

check that the timber is laid down on the table in

the correct position.

3. Check tool: this operation checks which tool is

currently equipped in the robot to know if the

robot has to switch the tool.

4. Use tool: the robot uses the selected tool to do the

operation.

5. Check operation: there is a camera system which

checks the set clamp. The location and the quality

of the staple process are verified. The camera is

able to perceive the surface of the wall and the

height of the clamp.

At the same time, the process above can also be

defined as a small set of tasks in which every step

includes predefined settings. If this model is used,

every process is described as below:

• CHECK SECURITY: This operation checks that

there are no objects in the robot cell which could

interfere in the execution of the process.

• USE

EXT PERIPHERALS ”toolName” PARAM-

ETERS ”p1”, ”p2”, ”p3”, : This command uses

external peripherals that can be connected to the

cell to extend the functionality of the system. For

example, a laser has been used to check that the

panels are in the correct position. PARAMETERS

are used to set the behavior controlling how this

added peripheral will work.

• MOVE ARM TO ”x”,”y”,”z”: The command

moves the robot arm to the defined coordinator.

• USE TOOL ”toolName” PARAMETERS ”p1”,

”p2”, ”p3”,...: The robot arm uses its equipped

tool with the provided parameters. Each tool has

its own set of parameters. In this example, the sta-

pler uses two parameters, the coordinates and the

length of the staples.

• CHECK QUALITY ”parametersToCheck” PA-

RAMETERS ”p1”,”p2”, ”p3”...: This operation

checks whether the final process has been success-

fully executed. The parametersToCheck defines

which element will be checked, and the parame-

ters determine the precision of verification.

This way, the process is already in a pseudocode

that is easy to understand. The next step will be the

adaptation of this process to the proposed DSL syn-

tax. Finally, the code would be like below:

process "staple"

task "check security"

use "laser"

parameters "7477;1633,

7522;1633,

7522;1876,

7477;1876"

A Domain Specific Language for Robot Programming in the Wood Industry - A Practical Example

553

Figure 3: Staple process diagram.

use "arm"

parameters "7477;1683;213"

use "stapler"

parameters "7499,5;1683;213"

task "check quality"

parameters "highPrecision"

The program above shows an easy syntax for the

clamps process. In it, three main instructions can be

explained; process, task and use.

• process: this instruction creates the set of instruc-

tions for the new project . The name of the process

is given as a parameter.

• task: this instruction calls a small task which has

already been modeled in the system.

• use: this instruction is used when a peripheral is

called. Each peripheral includes its own specific

settings. For example, if the robot arm is used, the

parameters are the goal coordinates.

Every program in our DSL begins with a process

instruction which starts and designates the program.

Next, the task security is called, in which the robot

cell is checked to avoid obstacles during the execu-

tion. In the next instruction, the laser tool is used.

This laser checks whether the wood plate is laid down

in the right place. The parameters used for this task

are the coordinates where the plate has to be located.

The coordinates use this syntax:

use "laser"

parameters "minX;minY,

maxX;minY,

maxX;maxY,

maxX;maxY"

All coordinates are given as a double variable

which represents the distance to a reference point

in millimeters. In the next instruction, the robot is

moved to the location defined in the parameter.

use "arm"

parameters "X";"Y";"Z"

The stapler is used to staple the clamp onto the

surface of the plate and, at this point, instead of just

one clamp, a series of clamps, defined by the coordi-

nates, can be stapled.

use "stapler"

parameters "X1;Y1;Z1"

"X2;Y2;Z2"

"X3;Y3;Z3"

To finish the process, the camera checks if all

clamps were successfully stapled. In this instruction,

an optional parameter can be set to define the preci-

sion of the verification.

task "check quality"

parameters "precision"

Once the code is set, the validator checks that ev-

ery task is valid and also that the given parameters of

the tools are correct and in reach. For example, if a

destiny coordinator is not reachable for the robot arm,

a warning message will be sent by the software com-

ponent to notify workers.

As can be seen, we are able to model a process

with a relatively human-readable and minimal syntax.

Thanks to F#, we are able to reach this goal through

simple functions which can be declared for easy use.

5 CONCLUSION

This paper gives an overview of the usage of Domain

Specific Languages (DSL) in robot systems, and ex-

plains the fundamentals of model-driven approaches.

ICINCO 2017 - 14th International Conference on Informatics in Control, Automation and Robotics

554

It also describes the design of a DSL to be used in a

wood factory. The design process was explained in

detail in order to arrive at a DSL that could be used

for the company to model manufacturing processes

with little effort. This is an important issue for work-

ers without profound programming language knowl-

edge, with a minimal and human-readable syntax as

key points. The choice of a DSL based on F# was

made because it fulfilled the requirements of having

a library compatible with the .Net environment, and

it is also a functional-programming language, which

perfectly suits a reactive system like this. This docu-

ment also includes some examples to help understand

how this DSL implementation works.

In our future work, the implementation of this

DSL library in the system will be extended to em-

brace new scenarios in which more complex rules are

needed.

ACKNOWLEDGEMENTS

The RobWood project is partially funded by the Aus-

trian Research Promotion Agency (FFG) and the Aus-

trian Ministry for Transport, Innovation and Technol-

ogy (bmvit).

The authors are grateful to the institutions funding

the RobWood project and wish to thank all project

partners for their contributions.

REFERENCES

Fowler, M. (2010). Domain Specific Languages. Addison-

Wesley Professional, Boston, USA.

Haspl, T., Capovilla, C., Rinnhofer, A., Exp

´

osito Jim

´

enez,

V. J., Maier, S., V

¨

olkl, M., Zarnhofer, M., J

¨

obstl,

R. A., Pretterhofer, E., Dieber, B., and Zeiner, H.

(2017). Robwood - smart robotics for wood industry.

In OAGM and ARW Joint Workshop 2017 on Vision,

Automation and Robotics.

Herrero, H., Outn, J. L., Esnaola, U., Sall, D., and de Ipia,

K. L. (2015). Development and evaluation of a skill

based architecture for applied industrial robotics. In

2015 4th International Work Conference on Bioin-

spired Intelligence (IWOBI), pages 191–196.

Joyeux, S. and Albiez, J. (2011). Robot development: from

components to systems. In 6th National Conference

on Control Architectures of Robots, page 15 p., Greno-

ble, France. INRIA Grenoble Rh

ˆ

one-Alpes.

Lotz, A., Hamann, A., L

¨

utkebohle, I., Stampfer, D., Lutz,

M., and Schlegel, C. (2016). Modeling non-functional

application domain constraints for component-based

robotics software systems. CoRR, abs/1601.02379.

Lotz, A., Steck, A., and Schlegel, C. (2011). Runtime

monitoring of robotics software components: Increas-

ing robustness of service robotic systems. In 2011

15th International Conference on Advanced Robotics

(ICAR), pages 285–290.

Maro, S., Stegh

¨

ofer, J.-P., Anjorin, A., Tichy, M., and Gelin,

L. (2015). On integrating graphical and textual edi-

tors for a uml profile based domain specific language:

An industrial experience. In Proceedings of the 2015

ACM SIGPLAN International Conference on Software

Language Engineering, SLE 2015, pages 1–12, New

York, NY, USA. ACM.

Nordmann, A., Hochgeschwender, N., Wigand, D., and

Wrede, S. (2016). A Survey on Domain-Specific

Modeling and Languages in Robotics. Journal of Soft-

ware Engineering for Robotics (JOSER).

Ramaswamy, A., Monsuez, B., and Tapus, A. (2014). Safer-

obots: A model-driven approach for designing robotic

software architectures. In 2014 International Con-

ference on Collaboration Technologies and Systems

(CTS), pages 131–134.

Schlegel, C., Hassler, T., Lotz, A., and Steck, A. (2009).

Robotic software systems: From code-driven to

model-driven designs. In 2009 International Confer-

ence on Advanced Robotics, pages 1–8.

Thomas, U., Hirzinger, G., Rumpe, B., Schulze, C., and

Wortmann, A. (2013). A new skill based robot pro-

gramming language using uml/p statecharts. In 2013

IEEE International Conference on Robotics and Au-

tomation, pages 461–466.

van Deursen, A., Klint, P., and Visser, J. (2000). Domain-

specific languages: An annotated bibliography. SIG-

PLAN Not., 35(6):26–36.

A Domain Specific Language for Robot Programming in the Wood Industry - A Practical Example

555