Two-level Approach for Scheduling Multiproduct Oil Distribution

Systems

Hossein Mostafaei

1,2

and Pedro M. Castro

1

1

Centro de Matemática Aplicações Fundamentais e Investigação Operacional,

Faculdade de Ciências, Universidade de Lisboa, 1749-016 Lisboa, Portugal

2

Department of Applied Mathematics, Azarbaijan Shahid Madani University, Tabriz, Iran

Keywords: Scheduling, Tree-like Structure, Decomposition Approach, Batch Sequencing.

Abstract: A core component of the oil supply chain is the distribution of products. Of the different types of distribution

modes used, transportation by pipeline is one of the safest and most cost-effective ways to connect large

supply sources to local distribution centers, where products are loaded into tanker trucks and delivered to

customers. This paper presents a two-level optimization approach for detailed scheduling of tree-like pipeline

systems with a unique refinery and several distribution centers. A mixed-integer linear programming (MILP)

formulation is tackled in each level, with the upper and lower level models providing the aggregate and

detailed pipeline schedules, respectively. Both models neither discretize time nor divide a pipeline segment

into packs of equal size. Solutions to two case studies, one using real-life industrial data, show significant

reductions in both operational cost and the CPU time with regards to previous two level approaches.

1 INTRODUCTION

In today’s competitive environment, supply chain

management is a major concern for companies and

has received growing attention in recent years. The

oil supply chain deals with a complex structure and

comprises many costly stages such as: oil exploration,

refining and product distribution, with transportation

costs already surpassing 400 billion dollars in the

early eighties (Bodin et al., 1983).

Different types of distribution modes are used in

the oil supply chain where the pipeline mode is the

most reliable and cost-effective way of transporting

high volumes of oil products between refineries

(upstream) and distribution centers nearby consumer

markets (downstream). Transportation scheduling of

petroleum products via pipelines is one of the most

challenging management problems with several

operational restrictions to be considered.

Pipelines convey a variety of oil derivatives such

as heating oil, motor gasoline, jet fuel, and liquefied

gas (one after the other). The products usually move

through several pipelines before reaching their final

destinations. Since there is not a physical barrier in

between products, some mixing occurs, producing a

contaminated product that is referred to as interface

material. An effective sequence of pipeline input and

output operations can considerably reduce pipeline

operating costs.

In recent years, several authors have applied

rigorous optimization tools to pipeline scheduling

problems, relying both on discrete- (Rejowski and

Pinto, 2003, 2004; Magatao et al., 2004; Herran et al.,

2010) and continuous-time MILP formulations

(Cafaro and Cerda, 2004; Castro, 2010; Cafaro and

Cerda, 2011; Mostafaei and Ghaffari, 2014;

Mostafaei et al. 2015a). They have generally

considered two operational plans for the pipeline

systems: aggregate and detailed, depending on the

way pipeline input and output operations are

performed. Aggregate plans define the optimal batch

sizes and the sequence of batch injections during the

time horizon, while detailed plans deal with

sequencing and timing of batch removals during a

pumping operation.

Mostafaei and co-workers (Ghaffari and

Mostafaei, 2015; Mostafaei et al., 2016, 2017)

developed continuous time MILP models to tackle the

operational planning of straight pipeline networks

that permits to achieve both the aggregate and the

detailed plans in single step. Compared to a two-level

approach developed by Cafaro et al. (Cafaro et al.

2012), they achieved better detailed schedules.

150

Mostafaei H. and Castro P.

Two-level Approach for Scheduling Multiproduct Oil Distribution Systems.

DOI: 10.5220/0006196501500159

In Proceedings of the 6th International Conference on Operations Research and Enterprise Systems (ICORES 2017), pages 150-159

ISBN: 978-989-758-218-9

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Cafaro and Cerda (2010) introduced a continuous

time MILP formulation for aggregate scheduling of

tree-like pipelines. Castro (2010) and Mostafaei et al.

(2015b) developed continuous time MILP

formulations to solve the detailed scheduling of the

same problem in a single step. However, the single

level optimization framework is computationally

expensive for large-scale problems. It is the main goal

of this paper to propose a computationally more

efficient approach relying on hierarchical

decomposition to generate the detailed schedule.

In previous two level approaches for straight

pipelines (Cafaro et al. 2011, 2012), each product

delivery operation in the lower level model should be

accomplished in the time interval determined in the

upper level model. Such a decision may not avoid

unnecessarily flow restarts if a depot is alternatingly

active in the aggregate schedule. This limitation is

also relaxed in this paper.

The rest of the paper is organized as follows:

Section 2 presents a brief description of the problem

under study. Section 3 builds a hierarchically

decomposition approach for the detailed scheduling

of the tree-like pipeline networks. The efficacy of the

proposed approach is tested using two case studies,

leading to the results in Section 4. The last section

puts forward the conclusions and sums up the paper.

2 PROBLEM STATEMENT

We deal with a short-term scheduling problem where

a tree-like pipeline must convey oil derivatives from

a single refinery to several distribution centers

(depots). Such a pipeline system consists of a trunk

line known as mainline (pipeline0) and several

secondary lines emerging from the mainline at

different sites (branch points). Figure 1 shows a tree-

like pipeline network with two secondary lines

(pipelines1,2). A pipeline segment ends with a

depot and/or a branch point. The secondary line 2 in

Figure 1 has two segments and two depots.

Figure 1: Tree-like pipeline system.

Batches of petroleum products pumped at the

refinery are diverted to mainline depots or/and

branched into secondary lines. The aim is to

determine the optimal batch input and output

operations in order to meet depot requirements at

minimum total cost subject to the following rules: (1)

pipeline segments remain full at any time; (2) each

pumping operation involves at most one batch

injection at the refinery (3) pipelines work in a single

flow direction, from left to right in the diagrams, (4)

the refinery should pump product into the mainline in

admissible injection rates; (5) in the detailed level, a

pumping operation can at most have one batch input

in each pipeline and in each depot whereas the

aggregate plan relaxes such assumption; (6) pipeline

segments should operate in acceptable flowrate

ranges, whereas in the aggregate level there are no

flowrate segment restrictions; (7) the valves of active

depots and segments remain open throughout the

pumping operation while they may be turned on/off

several times in the aggregate plan.

Given are the following: (i) the number of

products to be injected by the refinery (ii) the time

horizon length measured in hours (h), (iii) the 0-1

matrix of forbidden sequences between products, (iv)

capacity of pipeline segments measured in m

3

, (v)

volumetric coordinate of depots (m

3

), (vi) volumetric

coordinate of branch points (m

3

), (vii) pump rate at

refinery measured in m

3

/h, (viii) flowrate range in

pipeline segments (m

3

/h), (ix) maximum/ minimum

volume injected to each pipeline and diverted to

depots during each pumping operation (m

3

), (x)

product inventory at refinery and product demand at

depots (m

3

).

3 OPTIMIZATION MODEL

In this section, we present a two-level approach for

the detailed scheduling of tree-like pipelines. We will

sequentially solve the aggregate (upper level) and the

detailed (lower level) pipeline scheduling models

recently developed by Mostafaei et al. (2015b). The

aggregate model (referenced hereafter as the AP

model) will focus on batch input sequencing problem

whereas the detailed schedule (DP model) will

consider batch output sequencing problem in depots.

The approach uses the common sets defined in

Mostafaei et al (2015b): (1) ∈; pumping runs (2)

∈; pipelines, (3) ∈

; depots or segments of

pipeline , (4) ∈

,

,…

; batches to move

inside the pipeline network, (5)

; new batches to

be pumped into the mainline (

⊆), (6)

∪

; batches to move in pipeline , with

indicating the batches initially inside pipeline

and

denoting the batches to be transferred within

the planning horizon; (7) ∈; oil products, (8)

Two-level Approach for Scheduling Multiproduct Oil Distribution Systems

151

⊆

; batches to be diverted into depot

,

(9)

; product contained in old batch and (10)

;

non-empty old batches in secondary line . Note that

pipeline 0 is referred to as the mainline.

Two alternative objective functions will be

explored through the optimization approach. The

objective function of the AP model will minimize the

operational cost of pipeline, including pumping,

interface and backorder costs. The DP model will

reduce the pump operating and maintenance costs

subject to fully fulfilling all product deliveries

accomplished by the aggregated plan. As stated by

Hane and Ratliff (1995), most of the pipeline energy

consumption and the pump maintenance costs are

linked to flow restarts in idle pipeline segments and

consequently it is important to minimize the number

of pipeline segments where the flow is resumed or

stopped. Restarting the flow in a segment is

equivalent to saying that the segment is active

through the current pumping run but inactive during

the previous one. The opposite condition identifies

the stop of the pipeline segment.

Note that minimizing the number of flow

stoppages brings another economic benefit to the oil

industry since the size of the interface volume

between adjacent batches inside a segment tends to

increase while it stays inoperative. Future work will

involve enforcing pipeline segments to contain a

single product when they are inactive.

Here we present the AP and DP model. The list

of model entities can be found in Mostafaei et al.

(2015b).

3.1 Aggregate Level (AP)

3.1.1 Pumping Sequence

Let

be the start time of pumping run and

be

its duration. Pumping run can start if the previous

run 1 is completed. The length of all runs must

not surpass the length of planning horizon.

, ∀ ∈

2

(1)

∈

(2)

3.1.2 Tracing the Location of Batches

The continuous variable

,,

is used to track the

upper location of batch ∈

in pipeline at the end

of pumping run . This variable is equal to the volume

of batches

pursing batch ∈

at the end of

pumping run .

,,

,,

,

∈

:

∀ ∈

,∈,∈

(3)

3.1.3 Injecting Batches from the Refinery

Binary variable

,

is equal to one if batch ∈

is

receiving material from the refinery during pumping

run . During run , batch can receive material if the

lower coordinate of the batch (

,,

,,

)

touches the origin of the mainline at the end of

pumping run . If

,

1, a positive volume of batch

will be injected into the pipeline at the acceptable

pump rate belonging to the interval [

,

].

,

∈

1, ∀∈

(4)

,,

1

,

,∀ ∈

,

(5)

,

,,

,

,∀∈

, (6)

,,

∈

,,

∈

,∀

(7)

3.1.4 Product Allocation to Batches

Batch can at most convey a single product . Binary

variable

,

is used to allocate products to batches.

The volume of batch containing product pumped

from the refinery (

,,

) should be within a given

range. If it conveys a product, new batch ∈

will

be pumped into the mainline in one or more pumping

operations. Since each batch can convey a single

product, the volume of batch containing pumped

through run is equal to

,,

.

∑

,∈

1, ∀∈

(8)

,

∑

,,

,

,∀∈

,

(9)

∑

,∈

∑

,

,∀∈

∈

(10)

∑

,,

,,

,∀∈

,

(11)

3.1.5 Batch Removal at Depots

Through pumping run , a batch ∈

can be

discharged to depot

only if: (i) its upper coordinate

has reached the output facility of depot

,

at

time

and (ii) its lower coordinate has not

surpassed

,

. If binary variable

,,,

is equal to 1,

depot

receives a certain volume of batch ∈

(

,,,

) that is bounded by

,

,,

plus the material injected to batch from the origin of

pipeline during time interval [

;

].

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

152

,,

,

,

1

,,,

,

∀ ∈

,∈

,,

(12)

,,

,

,,,

,∀ ∈

,∈

,,

(13)

,

,,,

,,,

,

,,,

,

∀ ∈

,∈

,,

(14)

,

,,

,

,,

,,

,

1

,,,

,∀ ∈

,∈

,,

(15)

The volume of batch containing product

discharged to depot ∈

will be equal to

,,,

if batch conveys product , otherwise it will be zero.

∑

,,,,

∈

,,,

,∀∈

, ∈

,,

(16)

∑

,,,,∈

|

|

,

,

,∀∈

, ∈

,

(17)

3.1.6 Material Transferred to Secondary

Lines

Through pumping run , a batch in mainline can be

diverted to secondary line (

,,

1) if its upper

and lower coordinates satisfy

,,

,,

and

,,

. It means the

upper coordinate of batch has already reached

branch point and its lower coordinate has not

surpassed the coordinate of branch point (

).

If

,,

1, a portion of batch has entered

secondary line (

,,

.

,,

1

,,

,

∀ ∈

,,0

(18)

,,

,,

,∀∈

,,0

(19)

,,

,,

,,

,

∀ ∈

,,0

(20)

Let us define binary variable

,

to identify the

existence of batch in secondary line . For non-

empty old batch ∈

we have

,

1 and for

new batches ∈

:

,

∑

,,∈

|

|

,

,∀∈

,0

(21)

3.1.7 Interface and Forbidden Sequences

Batch 1

is injected into the mainline right

after

and consequently there will always be a

contamination product at their common boundary

which is referred to as interface. The volume of the

interface material depends on the specific products

and ’ is assumed to be given by parameter

,

.

If continuous variable

,,

,

is the interface

volume between batch and its successor in pipeline

conveying products and ′, we have the following

conditions for batches in the mainline and secondary

lines, where the domain of Eq. (23) is ,

∈

,

,,

∈,0:

,,,

,

,

,

,

1,

∀ ∈

,,

∈.

(22)

,,,

,

,

,

,

,

,

∑

,

,

2,

(23)

For quality reasons, some products should not

touch each other inside the pipeline. The next

equations prevent forbidden sequences in the

mainline and secondary lines.

,

,

1

,

,

∀ ∈

,,

∈

(24)

,

,

∑

,

,

,

,

3,∀∈

,

,,

∈,0

(25)

3.1.8 Size of Batch at the End of Run

At the end of pumping run, the size of batch in

pipeline can be obtained from its size at time

(

,,

) by adding the material that has entered

pipeline and subtracting the material transferred to

its depots and split lines. The next equations compute

the size of batch in the mainline and secondary lines.

,,

,,

,,

∑

,,,∈

∑

,,

,∀∈

,1

∈

(26)

,,

,,

,,

∑

,,,∈

,∀∈

,1,0.

(27)

3.1.9 Mass Balance

The total volume entering pipeline is equal to the

volume leaving the pipeline.

∑

,,∈

∑∑

,,,∈

∈

∑∑

,,∈

,∀∈

∈

(28)

∑

,,∈

∑∑

,,,

,

∈

∈

∀ ∈ , 0

(29)

3.1.10 Material Transferred from Batch to

Mainline’ Depots and Secondary

Lines

It is possible that during the execution of a pumping

run the volume of batch in the mainline can be taken

by multiple active depots and secondary lines. In this

case, the volume from batch to these depots and

lines is limited by the following equations.

∑

,,,

∈

:

,

∑

,,

∈:´

,,

,,

1

,,

,∀ ∈

,∈,∈

(30)

Two-level Approach for Scheduling Multiproduct Oil Distribution Systems

153

∑

,

,,

∈

∑

,,

:

,

,

,,

,,

1

,,,

, ∀ ∈

,∈,∈

(31)

3.1.11 Meeting Demand

The total volume of product unloaded to depot

during the planning horizon should be as large as

,,

, the demand of product at depot

.

Note that it is possible that some demand is not

satisfied within the planning horizon. Slack variable

,,

stands for the unsatisfied demand of

product at depot

.

∑∑

,,,,∈

∈

,,

,,

,∀∈,∈

,∈

(32)

3.1.12 Objective Function of Model AP

min

.

,,

∈∈

∈

,

.

,,

,

∈

∈∈∈

,,

.

,,

∈∈∈

3.2 Detailed Level (DP)

All constraints in model AP are part of model DP

except for the interface and forbidden sequence

constraints. The remaining constraints of model DP

model are listed below.

3.2.1 Feeding Depots and Secondary Lines

In detailed level, active depots must simultaneously

receive materials while inserting a new batch from the

refinery. Such a condition enforces active depot

to

receive material from batch during run if the upper

coordinate of the batch at the end of pumping run

1 (

,,

) has reached the volumetric coordinate

of the output facility of depot

,

. Moreover, the

lower coordinate of the batch should not surpass

,

at the end of pumping run . So Eqs. (12)-(13)

need to be changed by the following.

,,

,

,

1

,,,

,

∀ ∈

,∈

,,

(33)

,,

,

,,,

,∀∈

,∈

,,

(34)

Note that in detailed plan, the product delivery to

an active depot will be accomplished from a single

batch. This is not a model restriction but a practical

fact since delivery rates may vary with products.

Active secondary lines will also receive material from

a single batch in detailed level during each pumping

operation and therefore Eqs (18)-(19) should be

replaced by the following:

,,

1

,,

,

∀ ∈

,,0

(35)

,,

,,

,∀∈

,,0

(36)

Note that Eqs (33)-(36) increase the number of

pumping runs required to find the optimal solution,

which is detrimental for computational performance.

This is one of the reasons for applying two level

approaches for detailed pipeline schedule.

3.2.2 Activated and Stopped Volume

In detailed level, it is important to detect the pipeline

segments where the flow is resumed or stopped. To

this end, we need to determine the status of pipeline

segment in two consecutive runs. Binary variable

,,

takes the value of 1 if some material moves in

segment

through pumping run.Since the

pipeline network features a unique refinery,

segment1

will be active if segment

is

active, as imposed by Eq (37). The first segment of

mainline is active if the segment is receiving products

from the refinery (

∑

,

1

∈

), and vice versa.

The first segment of a secondary line will be active

when some material is transferred to this line from the

mainline (

∑

,,

1

∈

), and vice versa. On the

other hand, depot

will be idle if segment

is idle,

as imposed by Eq (40).

,,

,,

,∀∈

,,

(37)

,,

∑

,

,

∈

∀,

(38)

,,

∑

,,

,

∈

∀,,

(39)

∑

,,,∈

,,

,∀∈

,,

(40)

The model also needs to specify the status of the

mainline segments branching into secondary lines

(segments1

and 3

in Figure 1). Since

is the

volumetric coordinated of branch point and

,

is

the volume of segment

, we have:

,,

,,

,∀,,∈

|

,

(41)

To compute activated and stopped volumes, we

first need to determine the active volume of any

pipeline at the end of pumping run through

continuous variable

,

the volume from the

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

154

origin of to the end of furthest active segment

).

The active volume of a secondary line will be zero if

its first segment is idle.

,

,,

,,

.

,

,∀,,∈

(42)

,

,

,

1

,,

,,

,∀,, ∈

(43)

,

,,

,∀,0,

(44)

Activated volume of pipeline during run

(

,

) is the idle volume of the pipeline through

run 1, while the stopped volume (

,

) is the

active volume through run 1.

,

,

,

,∀∈,∈ (45)

,

,

,

,∀ ∈ , ∈ (46)

3.2.3 Flowrate in Pipeline Segment

Aggregate plans usually prevent enforcing flowrate

constraints on pipeline segments. These are important

since segments typically have different diameters.

The detailed plan, as an operational rule, should

consider flowrate restrictions, where

,

and

,

are minimum and maximum stream flowrates

in segment

. The flowrate in segment

can be

computed by the total volume of materials moving

along , divided by the pumping run length

.Eq

(47) enforces flowrate limitations in mainline

segment whereas Eq (48) restrains flowrates in

secondary segments.

,

1

,,

∑∑

,

,,

∈

∈

∑∑

,,∈

∈

,

,

,∀∈

,∈

(47)

,

1

,,

∑∑

,

,,

∈

∈

,

,∀∈

,∈

, 0

(48)

3.2.4 Objective Function of DP Model

min

,

,

∈∈

∙

,

∈∈

4 DECOMPOSITION APPROACH

The detailed scheduling of multi-branched tree

structure pipeline networks will become an

intractable problem even for short term horizons if all

decisions related to the pipeline input and output

operations are to be made in a single step. To find the

best detailed schedule in reasonable time, we first

solve the AP model to find the optimal batch

sequence in each pipeline at minimum interface,

pumping and backorder costs. The resulting solution

helps us to identify the exact elements of sets

,

,

and

,and consequently reduce the

constraints domain. Then, after fixing the binary

variables

,

and

,

and removing the interface and

forbidden constraints, we solve the DP model to meet

demand with minimum number of flow

resumes/stoppages and pumping operations. The

proposed decomposition procedure will hereafter be

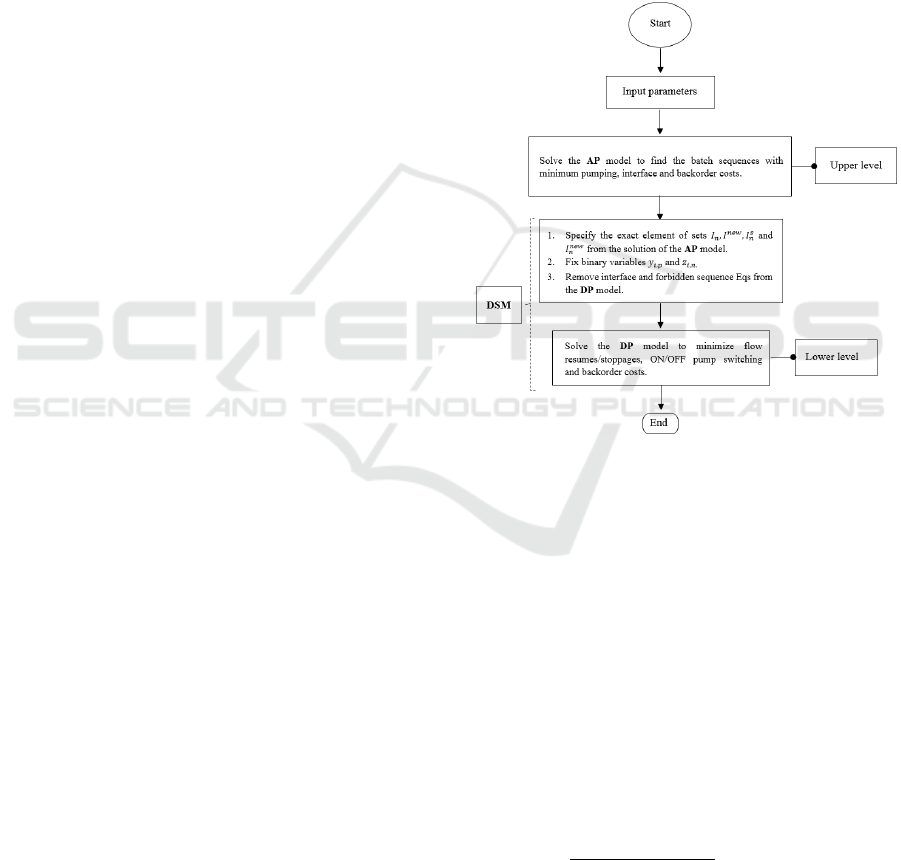

called DSM and is depicted in Figure 2.

Figure 2: Proposed DSM framework.

4.1 Optimal Number of Pumping Runs

To solve both the upper and the lower models, we

should first guess the number of pumping operations

for each step. Like previous continuous time

approaches, we use an iterative procedure to find the

optimal number of pumping operations

|

|

to be

performed. In fact, searching for the optimal solution

can be extremely costly, but if the initial guess on the

number of pumping runs is accurate, no more than

two iterations are usually required. Since all

operations may not involve the maximum volume

(

), a simple expression for the number of

pumping operations of model AP can be:

∑∑∑

,,

||

Moreover, the number of pumping operations in

the model DP cannot be greater than the number of

Two-level Approach for Scheduling Multiproduct Oil Distribution Systems

155

product deliveries in model AP (PD

) and lower

than the number of pumping runs in AP:

||

|

|

PD

4.2 Previous Two Level Approaches

Cafaro and co-workers (2012) were the firsts to

develop a two-level approach for the detailed

scheduling of straight pipeline systems. In their

approach (hereafter CC), after finding the product

sequence with minimum pumping and interface costs,

they fix the aggregate batch sizes, the starting and

completion times of each pumping operation in AP,

and solve the second stage to generate a detailed

schedule. In fact, the start and end of pumping

operations for a batch injection in the lower level

must exactly comply with the start and end times

specified for that batch injection in the upper level

model. To this end, each product delivery in the lower

level model should be accomplished in the same time

interval performed in the upper level model. Since the

solution quality for the detailed scheduling problem

depends on the sequence of product deliveries, the

CC model does not usually find cost-effective

transportation plans.

5 COMPUTATIONAL RESULTS

Two case studies, one of them using industrial data,

were solved to validate the efficiency of the proposed

two level approach. The implementations were on an

Intel® Core(TM) i5-4210U (2.7 GHz) with 6 GB of

RAM, running Windows 7, 64-bit operating system

using GAMS/CPLEX 12.6 in parallel deterministic

mode (using up to 4 threads).

5.1 Example 1

This example deals with a small network and aims to

show how we select the elements of sets

,

,

and

in the lower level model (detailed schedule).

We assume that the aggregated transportation plan in

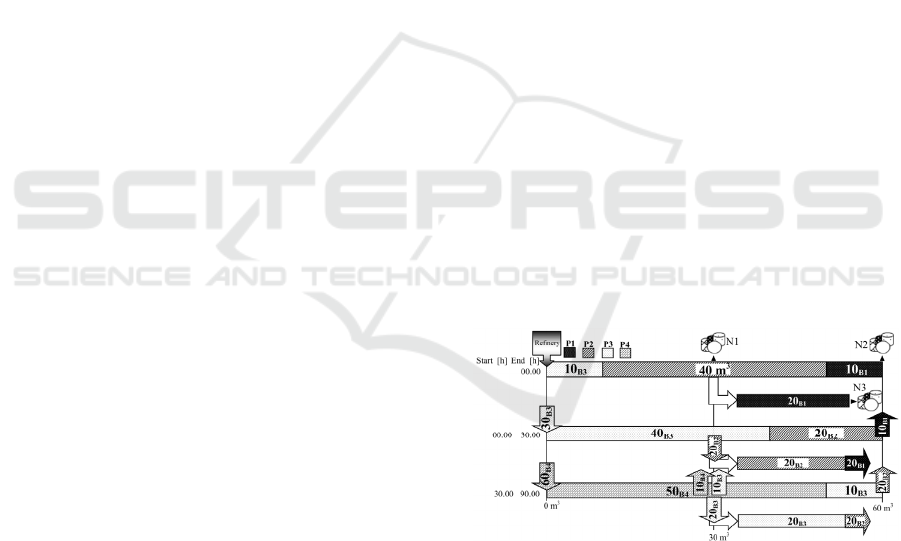

Figure 3 is already available. The pipeline topology

and its initial status at the start time of planning

horizon (time 0.00h) is depicted in the first row

of Figure 3. The flowrate in pipeline segments can

vary between 0.3 and 1.0 m

3

/h and the time horizon

has a length of 96 h (4 days). The maximum volume

input per pumping run is 60 m

3

while the minimum is

10 m

3

. The same condition holds for the minimum

and maximum batch size diverted to depots. The unit

stoppage cost is 0.4 in each segment.

The aggregate pipeline schedule contains two

pumping operations. The first operation takes place

from time 0.0 h to 30.0 h and involves increasing the

amount of product P3 in batch B3 and diverting 20 m

3

of B2 into the secondary line and 10 m

3

of batch B1

into depot N2. The second pumping operation from

30.0 to 90.0 h injects 60 m

3

of new batch B4 into the

mainline and the following delivery operations are

accomplished at depots: depot N1 receives from

batches B3 and B4; batch B2 goes to depots N2 and

N3.

To solve DP (lower level model) we should first

guess the number of pumping operations and specify

the exact elements of sets

,

,

and

. From

the aggregated plan, there are a total of 6 product

deliveries to depots and so 2

|

|

6. We will

start solving the problem with

|

|

2and keep

increasing

|

|

until no improvement is found in

the objective function.

From the solution obtained from the AP model,

we can now refine the elements of sets

,

,

and

and reduce the domain of the constraints. It

can be observed from Figure 3 that only new batch

B4 is injected into the mainline. There are three old

batches B1, B2 and B3 and so

B4,B3,B2,B1.

Two new batches B2 and B3 are injected into the

secondary line (pipeline1) and so

B3,B2.

There is only one old batch B1 inside the secondary

line and so

B1,B2,B3

. Depot N1 only

receives product from batches B3 and B4 and so

B3,B4. Similarly, we have

B1,B2

.

Figure 3: Aggregate pipeline schedule for Example 1.

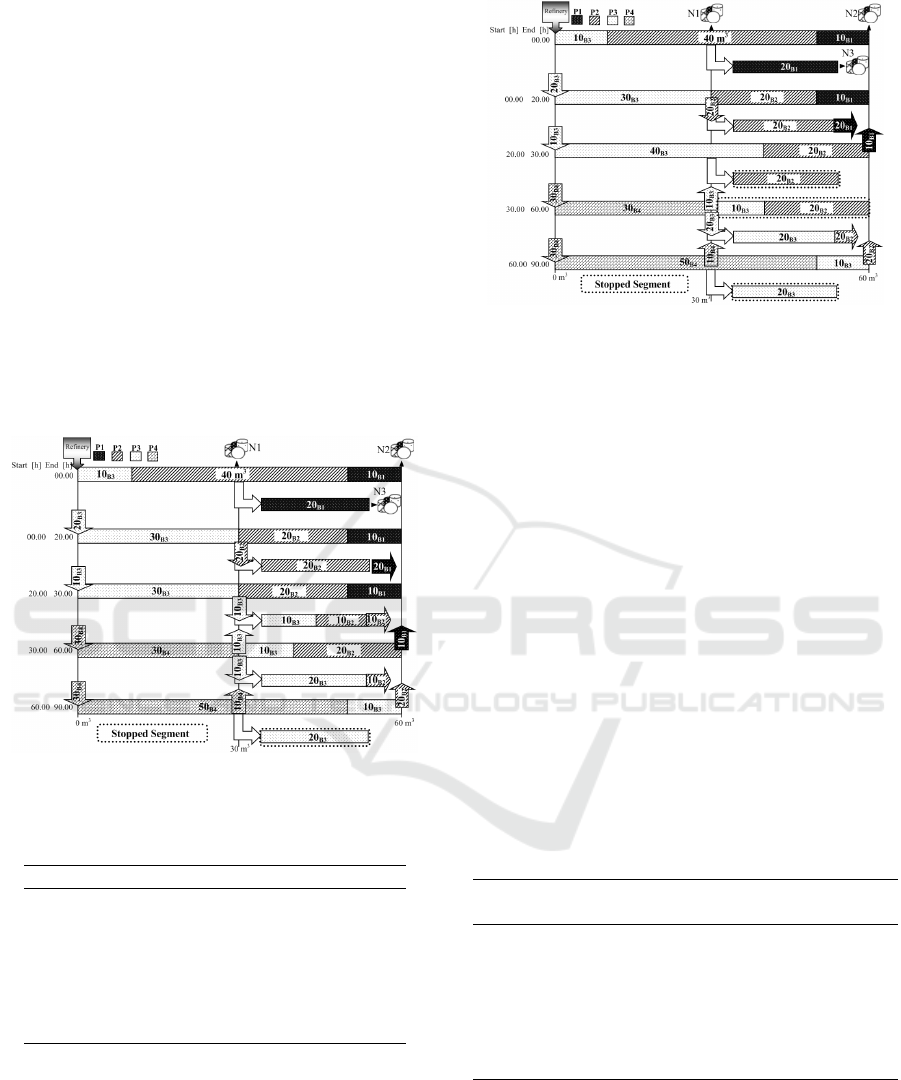

Figure 4 shows the optimal detailed schedule for

Example 1 using DSM. It contains 4 batch injections

at the refinery and 7 product deliveries to depots. The

injection of batch B3 (and batch B4) from the refinery

is now accomplished through a sequence of two short

pumping runs. There is only one segment stoppage

during 4 days that happens in the secondary line

during time interval [60.00, 90.00].

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

156

Figure 5 shows the optimal pipeline schedule for

Example 1 using CC. Like DSM, 4 batch injections

should be accomplished to fully satisfy the given

demands. Note that 10 m

3

of batch B1 are being

discharged into depot N2 during time interval [0.00,

30.00] of the aggregate plan of Figure 3. This depot

should extract the same amount of material during

time interval [0.00, 30.00] of the detailed plan. In

contrast, it remains inactive in DSM (see Figure 4).

The aggregate transportation plan enforces depot N2

to be idle during [30.00, 60.00] and to be active

during [60.00, 90.00] in CC. Such a change in the

status of depot N2 leads to a stoppage in the last

segment during the third pumping operation.

Superfluous flow shutdowns can also be observed in

the secondary line that are due to the change in the

status of depot N3 that alternatingly becomes active

and idle.

Figure 4: Detailed schedule for Example 1 using DSM.

Table 1: Computational results for Example 1.

DSM CC

# Pumping runs 4 4

# Constraints 646 646

# Binary vars 90 90

#Continuous vars 285 285

CPUs 0.47 0.42

Stop vol (m

3

) 20 70

Obj. Fun

a

($) 8 28

a

Both DSM and CC only minimize pipeline stoppage volumes.

Table 1 gives the computational results of

Example 1 for the CC, DSM approaches. Though the

number of pumping operations is the same, the

stopped volume of the pipeline in the proposed

approach decreases from 70 to 20 m

3

. Such a lower

shutdown volume in pipeline leads to cost savings of

71.42 %.

Figure 5: Detailed schedule for Example 1 using CC.

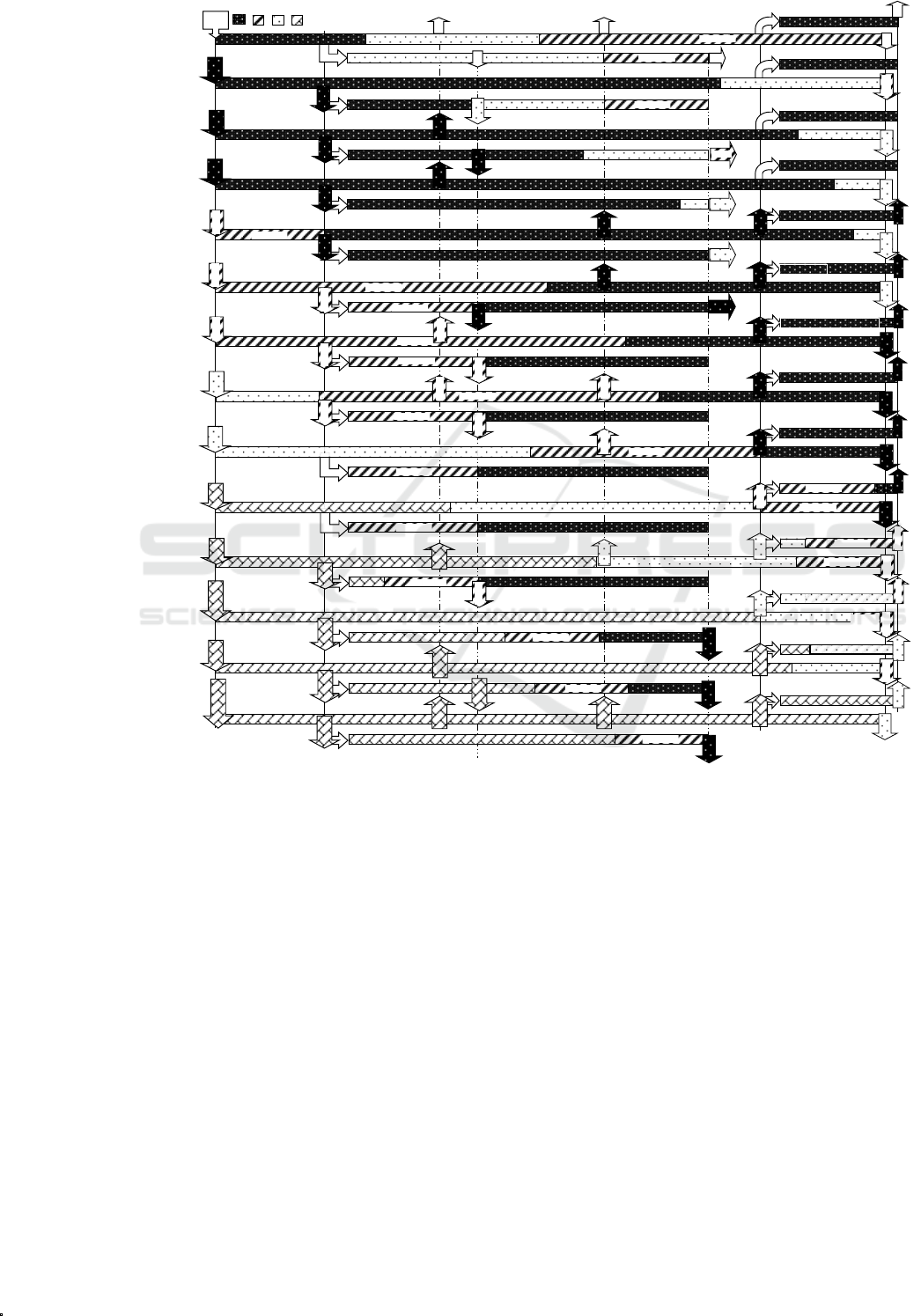

5.2 Example 2 (Real-Life Case Study)

Here we consider a large-scale real-world example

from Mostafaei et al. (2015a), involving an Iranian

tree-like pipeline with a refinery, a mainline, two

secondary lines and six depots (check first row of

Figure 6). The first secondary line with two depots

starts 3000 m

3

away from the mainline’ origin while

the other secondary line (single depot) leaves the

mainline after 15000 m

3

. Batches of four products

(P1-P4) should be conveyed and it is forbidden for P1

to touch P4. The product injection rate can vary

between 300 and 800 m

3

/h, and the time horizon has

a total length of 192 h. In both aggregated and

detailed levels, at most 13000 m

3

of each product can

be injected into the mainline during each operation.

Other data for this example, together with the

aggregate transportation plan, can be found in

Mostafaei et al. (2015b).

Table 2: Computational results for Example 2.

DSM CC Mostafaei et al.

(2015b)

# Pumping runs 13 22 12

# Constraints 5076 9090 5864

# Binary vars 671 1381 782

#Continuous vars 2500 6281 3714

CPUs 64.4 412.60 468.23

Restart vol (m

3

) 39200 118400 39200

Obj. Fun

a

($) 15680 47360 15680

a

Both DSM and CC only minimize pipeline restart volumes.

Figure 6 shows the optimal detailed schedule for

Example 2 using DSM. It contains 13 pumping

operations and 50 product deliveries to depots. Model

size and computational requirements for Example 2

are reported in Table 2.

Two-level Approach for Scheduling Multiproduct Oil Distribution Systems

157

12600

4100 4900 m

3

3800

9600

Ref

N1 N2

N3 N4

N6

N5

6000 2400

13700 4900

3000 3000

2400

3800

3800

3800

500

3000

3000

9600

13000

16137.5

4562.5

2437.5

2462.5

6000

5400 3000

3600

2400

3700

16831.25 1768.75

693.75

2368.75

7768.75

631.25 2368.75

637.5

3000

3000

8800

11800

14500 1100

668.75

631.25

8400

1200

631.25

3300

500

500

8800

9800

1100

1600 2200

1100

3000

1700

3600

1100

1300

9600

3200

3200

500

3000

3000

3000

3000

3000

5400

5400

5400

5400

5400

5400

3400

1700

500

3300

1700

6800

1300

2920

2920

9880

5800

500

500

3800

500

500

500

920

5580

8500 6500 3600

3800

1270

1270

930

3380

6500

6500 8500 3600

2900

900

2900

2900

3600

7200

1000

1000 2000

1000

10600

2100

5300 2700

2900900

900

900

900

2300

7157.143

2757.143

15000

3757.143

2000

2000

2000

2757.143

2400

3800

2900

1500

2900

9600

16200

2400

4957.143

2642.857

1442.85

1200

1200

1200 2600

12002600

2400

1200

2400

18600

6400

1200

1442.857

1442.857

11542.857

3100

2600

4800

1200

2000

00.00

Start[h] End [h]

00.00 19.20

19.20 35.45

35.45 40.07

40.07 44.02

44.02 55.02

55.02 68.02

68.02 71.67

71.67 80.97

80.97 93.97

93.97 102.97

102.97 112.64

112.64 124.64

124.64 136.07

P1

P2 P3 P4

3800

Figure 6: Detailed schedule for Example 2 using DSM.

Three interesting conclusions can be derived from

the results. The first, is that the optimal detailed

schedule by the CC approach involves 22 pump

operations against 13 by DSM. The second, is that the

solution CPU time has been reduced by a factor of 7

with regards to CC. The third, is that the objective

function value for DSM is 66.89 % less expensive

than the one for CC. This is due to substantial

reductions on shutdown volumes. Compared with the

single level approach of Mostafaei et al (2015b), the

proposed DSM approach finds the same solution in a

lower CPU time.

6 CONCLUSIONS

This paper presented a novel optimization framework

for the detailed scheduling of treelike pipeline

networks. The network consists of a refinery, a trunk

line, a set of split lines and multiple depots. A

computationally efficient two-level approach based

on a pair of MILP models has been presented. In the

upper level, the optimal sequence of batches in each

pipeline is found while the lower level deals with the

detailed plan that computes the optimal sequence of

batch removals at depots. Through the solution of two

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

158

case studies, we showed that the proposed model is

more flexible than previous hierarchical approaches

and is able to solve large scale problems in reasonable

time. Future work will involve applying the proposed

method for multi-level tree pipeline networks, with

intermediate due dates on demands over long-term

horizons.

ACKNOWLEDGMENTS

Financial support from Fundação para a Ciência e

Tecnologia through the Investigador FCT 2013

program and project UID/MAT/04561/2013.

REFERENCES

Bodin, L., Golden, B., Assad, A. and Ball, M., 1983.

Routing and scheduling of vehicles and crews. The

State of the Art. Computers &Operations Research, 10

(2), 62.

Cafaro VG., Cafaro DC., Mendéz CA., Cerdá J., 2011.

Detailed scheduling of operations in single-source

refined products pipelines. Industrial & Engineering

Chemistry Research, 50: 6240-6259.

Cafaro, D. C., Cerdá, J., 2004. Optimal scheduling of

multiproduct pipeline systems using a non-discrete

MILP formulation. Computers & Chemical

Engineering, 28, 2053-2068.

Cafaro, D. C., Cerdá, J., 2011. A rigorous mathematical

formulation for the scheduling of tree-structure pipeline

networks. Industrial & Engineering Chemistry

Research, 50, 5064-5085.

Cafaro, V. G., Cafaro, D. C., Mendéz, C. A., Cerdá, J.,

2012. Detailed scheduling of single-source pipelines

with simultaneous deliveries to multiple offtake

stations. Industrial & Engineering Chemistry Research,

51, 6145-6165.

Castro, P. M., 2010. Optimal scheduling of pipeline

systems with a resource-task network continuous-time

formulation. Industrial & Engineering Chemistry

Research, 49, 11491-11505.

Ghaffari-Hadigheh, A., Mostafaei, H., 2015. On the

scheduling of real world multiproduct pipelines with

simultaneous delivery. Optimization and Engineering,

16, 571-604.

Hane, C. A., Ratliff, H. D., 1995. Sequencing inputs to

multi-commodity pipelines. Annals of Operations

Research, 57, 73-101.

Herran, A., de la Cruz, J. M., de Andres, B., 2010.

Mathematical model for planning transportation of

multiple petroleum products in a multi-pipeline system.

Computers & Chemical Engineering, 34, 401-413.

Magatao, L., Arruda, L. V. R., Neves, F. A., 2004. A mixed

integer programming approach for scheduling

commodities in a pipeline. Computers & Chemical

Engineering, 28, 171-185.

Mostafaei, H., Alipouri, Y., Shokri, J., 2015. A mixed-

integer linear programming for scheduling a multi-

product pipeline with dual-purpose terminals.

Computational and Applied Mathematics, 34, 979-

1007.

Mostafaei, H., Castro, P. M., Ghaffari-Hadigheh, A.,

2015b. A novel monolithic MILP framework for lot-

sizing and scheduling of multiproduct treelike pipeline

networks. Industrial & Engineering Chemistry

Research, 54, 9202–9221.

Mostafaei, H., Castro, P. M., Ghaffari-Hadigheh, A., 2016.

Short-term scheduling of multiple source pipelines with

simultaneous injections and deliveries. Computers &

Operations Research, 73, 27-42.

Mostafaei, H., Castro, P.M., 2017. Continuous-time

scheduling formulation for straight pipelines. AIChE J.

doi: 10.1002/aic.15563.

Mostafaei, H., Ghaffari-Hadigheh, A., 2014. A general

modeling framework for the long-term scheduling of

multiproduct pipelines with delivery constraints.

Industrial & Engineering Chemistry Research, 53,

7029-7042.

Rejowski, R., Pinto, J. M., 2003. Scheduling of a

multiproduct pipeline system. Computers & Chemical

Engineering, 27, 1229–1246.

Rejowski, R., Pinto, J. M., 2004. Efficient MILP

formulations and valid cuts for multiproduct pipeline

scheduling. Computers & Chemical Engineering, 28,

1511–1528.

Two-level Approach for Scheduling Multiproduct Oil Distribution Systems

159