Process Optimization for Cutting Steel-Plates

Markus Rothe, Michael Reyer and Rudolf Mathar

Institute for Theoretical Information Technology, RWTH Aachen University, Kopernikusstraße 16, 52074 Aachen, Germany

Keywords:

Two-Stage Three-Dimensional Guillotine Cutting, Residual Bin-Packing Problem, Mixed Integer Program-

ming Model, Reuseable Leftovers.

Abstract:

In this paper, we consider the two-stage three-dimensional guillotine cutting stock problem with usable left-

over. There are two properties that distinguish our problem formulation from others. First, we allow the items

to be rotated. Second, we consider the case in which leftover material is to be reused in subsequent production

cycles. Third, we solve the problem in three dimensions. The optimization problem is formulated as a mixed

integer linear program. To verify the approach, several examples show that our formulation performs well.

1 INTRODUCTION

In many areas of industrial production large or long

pieces of material need to be cut into smaller ones.

E.g., it needs to be decided from which reel of raw

material a cable of a specific length will be produced.

This is an example for a one-dimensional problem.

An example for a two-dimensional problem is to cut

patterns from pieces of large leather. In our case, we

want to cut items out of slabs of steel. This is a three-

dimensional problem.

The cutting stock problem is similar to the bin

packing problem and the knapsack problem. In the

bin packing problem objects of different sizes must be

packed into a finite number of bins. The classical bin

packing problem minimizes the number of bins that

are used. For the knapsack problem, there is only one

bin of a certain volume and the objects to pack have

a value and a volume. Then, the objective is to maxi-

mize the value of the packed objects. Both problems

are, in general, NP-hard problems.

In this paper, we formulate a problem that is simi-

lar to the above mentioned problems and solves the

cutting stock problem. The problem is formulated

such that the optimization program becomes linear

and we can find an optimal solution according to our

objective function.

The general problem of cutting stock is explored

widely in the literature. The earliest work we found,

that minimizes scrap material, is (Kantorovich, 1960).

We cite the English translation, which is, to the best

of our knowledge, a translation from the original Rus-

sian publication from 1939. (Kurt Eisemann, 1957),

and (Gilmore and Gomory, 1961), utilize linear pro-

gramming to solve cutting stock problems. P. Gilmore

and Gomory investigate the one dimensional prob-

lem of cutting items from stock of several standard

lengths. They devise the method of column gener-

ation in their work. P. Gilmore and Gomory con-

tinued their work in (Gilmore and Gomory, 1965).

Here, they extend their formulation to multistage cut-

ting stock problems of two and more dimensions.

(Farley, 1988), adapt the approach of (Gilmore

and Gomory, 1961), with some practical adaptations.

In particular, they introduce guillotine cuts, which

will be explained in detail in the following section.

Solutions not utilizing linear programming have

also been published, e.g., tree-search algorithms,

(Christofides and Whitlock, 1977). The survey (Hinx-

man, 1980), summarizes many more publications.

(Dyckhoff et al., 1985), give a detailed catalog of cri-

teria for characterization of real-world cutting stock

problems (Dyckhoff et al., 1985). (Yanasse et al.,

1991), describe heuristics for the cutting stock prob-

lem. (Carnieri et al., 1994), formulate the cutting

stock problem as a Knapsack algorithm and also give

heuristics to enhance computational efficiency.

(Kalagnanam et al., 2000), formulate the problem

for the steel industry, without considering the depth

of the slabs. (Martello et al., 2000), present a three-

dimensional bin packing problem, while allowing ar-

bitrary, i.e., non-guillotine, cuts. (Morabito and Are-

nales, 2000), focus on a simplified cutting pattern. In

their book Operations Research: Applications and Al-

gorithms, (Wayne L Winston and Jeffrey B Goldberg,

2004), summarize and extend some of the aforemen-

Rothe M., Reyer M. and Mathar R.

Process Optimization for Cutting Steel-Plates.

DOI: 10.5220/0006108400270037

In Proceedings of the 6th International Conference on Operations Research and Enterprise Systems (ICORES 2017), pages 27-37

ISBN: 978-989-758-218-9

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

27

tioned as well as many more methods.

(Silva et al., 2010), consider waste, but lack the

third dimension in their problem formulation. They

also mention the value of the surplus material on a

conceptual level, but do not show it in their problem

formulation. (Burke et al., 2011), present an iterative

packing methodology based on squeaky wheel opti-

mization. (Furini and Malaguti, 2013), make similar

formulations as previously found in the literature, but

focus on the run-time of the solution.

The recent results from (Andrade et al., 2013),

lay the foundation for our problem formulation.

(Andrade et al., 2013), investigate two-stage two-

dimensional guillotine cutting stock problems with

usable leftover. We will extend their formulation for

two-stage three-dimensional guillotine cutting stock

problems with usable leftover. The term “stage” will

be explained when we describe the constrains that are

imposed by our production machinery.

There are three properties that distinguish our

problem formulation from others. First, we allow the

items to be rotated.

Second, we consider the case in which leftover

material is to be reused in subsequent production cy-

cles. I.e., after one production cycle, leftover material

is added to the set of slabs.

Third, we solve the problem in three dimensions.

On the one hand, this is needed to calculate the

weight, which is required in our objective function.

On the other hand, this opens up for the possibility to

cut an item from a slab that is thicker than necessary,

if the value of the leftover material permits or even

dictates this decision.

The remainder of the present paper is organized

as follows. In Section 2, we present the problem we

want to solve and the model we use. In Section 3, we

propose an optimization program to solve the prob-

lem. In Section 4, we discuss some examples and

their solutions. Finally, we summarize our results in

Section 5.

2 PROBLEM FORMULATION

AND MODEL DESCRIPTION

The overall goal is to fulfill customer orders of blocks

of steel. We call the ordered blocks of steel items.

These items are cut from larger slabs of steel. As the

size of an item is defined by the customer, the size is,

in general, different and arbitrary from item to item.

The problem we solve in this work is the decision

which item is cut from which slab and how items are

geometrically placed on each slab. Due to the produc-

tion process, or technical and economic restrictions,

(a) (b) (c)

Figure 1: Guillotine cutting in (b) and (c).

these problems can have an abundance of constraints.

It is not important that the material we are working

with is steel. However, the machines that are used

for cutting the slabs create certain constraints in our

problem formulation.

In general, when items are cut from slabs, the orig-

inal slab is cut up into items and surplus material. The

surplus material can either be useful in the future or it

is so small that it is thrown away. If it is kept we call

it leftover material and it will be placed in the set of

slabs for future usage. If it is thrown away we call it

scrap material.

One of our goals is to use surplus material more

frequently than new slabs. Otherwise, the slabs in

stock could increase over time. Our solution for this

problem is to attach a value per kilogram to all the

slabs. The less a slab weights in total, the smaller its

value per kilogram.

The machines cutting the slabs can only do full

straight cuts, parallel to the edges of the slab and not

stop halfway through the material. This is called guil-

lotine cutting.

Figure 1a shows how the blue item can not be cut

from the gray slab if it is placed in the bottom left cor-

ner. The item has either to be cut as seen in Fig. 1b or

Fig. 1c. Leftover material will have different shapes,

not only depending on the exact geometrical place-

ment of the item on the slab, but also depending on the

exact cuts being made. Currently, in order to calculate

the dimensions of the surplus material, the problem

formulation assumes a strict cutting order, which will

be explained shortly.

Our model follows (Lodi and Monaci, 2003), in

using the notion of shelves, as does (Andrade et al.,

2013). Shelves are a way to connect the restriction on

guillotine cutting and geometric placement of items.

Figure 2 shows the general layout of items and shelves

on a slab.

In this figure, item 1 and item 2 are on the same

shelf, while item 3 is on a separate shelf. To make this

clear, a shelf is just a notion to group and place items

on a slab. Further, shelf ν is opened by item ν. The

height of all items, that are placed in this shelf after

item ν must be less than or equal to the height of item

ν. I.e., the height of shelf ν is equivalent to the height

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

28

Figure 2: Shelves.

(a) (b)

Figure 3: Positions of leftover material.

of item ν. An item is either placed in an existing shelf

or opens a new shelf. As a result, if item

ˆ

ν was placed

in an existing shelf, then shelf

ˆ

ν does not exist.

As was mentioned earlier, the size and form of

the surplus material depends on the order in which

cuts are made. Therefore, our problem formulation

assumes a specific order of the cuts. This is neces-

sary to calculate the precise dimensions, and hence

the value, of the surplus material. The result of the

cuts is depicted in Fig. 3.

The figure is ambiguous about the depth of V

C

il

,

which is the leftover material filling the height above

item i on slab l. It has the same depth as the slab,

which is clear from the following cutting order.

1. Slabs are cut in the direction of “width” such that

shelves are cut out.

2. Each shelf is cut in the direction of “height” such

that the widths of items are correct.

3. V

C

il

are trimmed from the items.

4. V

T

il

are trimmed from the items.

Trimming in this context means to cut unwanted

pieces from the items, e.g., separating V

T

il

from the

item.

(Andrade et al., 2013), describe their model as

having “two stages”.

In the first stage, parallel longitudinal (hor-

izontal) guillotine cuts are produced on a

plate, without moving it, to produce a set of

strips. In the second stage, these strips are

pushed, one by one, and the remaining parallel

transversal (vertical) guillotine cuts are made

on each strip. ((Andrade et al., 2013, p. 2))

(a) Exact case. (b) Non-exact case.

Figure 4: Two-stage cutting patterns.

(a) (b)

Figure 5: Measuring the leftover material.

Further, (Andrade et al., 2013), distinguish between

the exact and non-exact cases of matching items to

shelves. Figure 4a shows the exact case. Here, all

items in the same shelf have the same height. On the

other hand, Fig. 4b shows the non-exact case. Here,

trimming is necessary, because items in the same shelf

might have a different height. Recall that (Andrade

et al., 2013), only account for two dimensions. They

do not treat trimming as a separate stage.

Our formulation matches items to slabs in three

dimensions considering the non-exact case. Items are

trimmed at most two times, but items are not stacked

in the third dimension. So we call our problem a two-

stage three-dimensional non-exact guillotine cutting

stock problem.

The objective function of our optimization prob-

lem will maximize the value of the surplus material,

accounting for the lost value of cut slabs. A value

needs to be attached to the volumes of the pieces of

surplus material. In order to calculate the volumes,

the measures depicted in Fig. 5 are used.

As we mentioned earlier, the value of each piece

of surplus material is a function of its weight. The

weight of each piece is calculated by simply mul-

tiplying its volume by the weight per volume unit.

The constants g

e

l

define the boundaries of the weight

classes. α

e

l

is the value relative to the value of the slab

the piece originates from. l denoting the slab, e denot-

ing the weight class. Explicit example values for g

e

l

and α

e

l

are given in Table 1. E.g., the value per kilo-

gram of a piece of surplus material weighting between

2.1 kg and 5 kg is 0.5 times the value per kilogram of

the slab it originates from.

Surplus material is considered waste if one of its

sides is too small. See d

W

min

l

, d

H

min

l

, d

T

min

l

in Table 1.

Process Optimization for Cutting Steel-Plates

29

We allow items to be rotated in the width-height-

axis. This is done by copying each item and rotating

the copy. We then restrict placement such that only

one of these items is produced. More on this in the

optimization program itself.

Further, we require items to be sorted by decreas-

ing height, i.e., h

i

≥ h

i+1

. This is a result of how the

height of shelves is determined in our optimization

problem. The first item to be placed in a shelf defines

its height. Only items with a larger index are allowed

to be put into this shelf. So all items following the

first item must have the same or a smaller height, such

that they can be placed on any of the existing shelves.

Therefore, items are sorted by decreasing height be-

fore given an index.

3 THE OPTIMIZATION

PROGRAM

Below is the complete optimization program, which

will be explained afterwards.

Define F

N

= {1, . . . , N} for any N ∈ N. Unless

otherwise mentioned, the constraints apply to ∀i ∈ F

n

,

∀k ∈ F

n

, ∀l ∈ F

p

. n and p are number of items and

number of slabs, respectively, see Table 1.

The main variables are x

ikl

, i.e., it is one if item i

is placed in shelf k on slab l.

maximize

n

∑

i=1

i

∑

k=1

p

∑

l=1

w

i

h

i

t

i

G

l

p

i

x

ikl

(1)

−

p

∑

l=1

M

l

P

l

u

l

(2)

−

p

∑

l=1

(P

0

l

− P

l

)R

l

(3)

+

|V|

∑

j=1

F

j

(4)

subject to all conditions in Table 2 ,

p

∑

l=1

i

∑

k=1

∑

i∈c

i

x

ikl

= 1 ,

∀c

i

= { j | j = i or j is rotated version of i} , (5)

n

∑

k=i+1

p

∑

l=1

x

ikl

= 0 , (6)

u

l

≥

1

n

n

∑

i=1

n

∑

k=1

x

ikl

(7)

b

kl

= W

l

x

kk l

−

n

∑

i=k

w

i

x

ikl

,

∀k ∈ F

n

, ∀l ∈ F

p

, (8)

b

k

=

p

∑

l=1

b

kl

, (9)

s

l

= H

l

u

l

−

n

∑

k=1

h

k

x

kk l

, (10)

q

i

=

p

∑

l=1

i

∑

k=1

(h

k

− h

i

)x

ikl

, (11)

a

i

=

p

∑

l=1

i

∑

k=1

(T

l

−t

i

)x

ikl

, (12)

s

l

≥ d

H

min

l

−

ˆ

H(1 − z

H

l

) , (13)

s

l

≤

ˆ

Hz

H

l

+ d

H

min

l

, (14)

V

H

l

≤ s

l

W

l

T

l

G

l

, (15)

V

H

l

≤ H

l

W

l

T

l

G

l

z

H

l

, (16)

b

k

≥

p

∑

l=1

d

W

min

l

x

kk l

− (1 − z

S

k

)

ˆ

W , (17)

b

k

≤

ˆ

W z

S

k

+

p

∑

l=1

d

W

min

l

x

kk l

, (18)

G

l

V

S

kl

≤ M

l

z

S

k

, (19)

V

S

kl

≤ b

k

h

k

T

l

G

l

, (20)

V

S

kl

≤ W

l

h

k

T

l

G

l

x

kk l

, (21)

q

i

≥

p

∑

l=1

i

∑

k=1

d

H

min

l

x

ikl

− (1 − z

C

i

)

ˆ

H ,

(22)

q

i

≤

ˆ

Hz

C

i

+

p

∑

l=1

i

∑

k=1

d

H

min

l

x

ikl

, (23)

G

l

V

C

il

≤ M

l

z

C

i

, (24)

V

C

il

≤ w

i

q

i

T

l

G

l

, (25)

V

C

il

≤ w

i

H

l

T

l

G

l

i

∑

k=1

x

ikl

, (26)

a

i

≥

p

∑

l=1

i

∑

k=1

d

T

min

l

x

ikl

−

ˆ

T (1 − z

T

i

) ,

(27)

a

i

≤

ˆ

T z

T

i

+

p

∑

l=1

i

∑

k=1

d

T

min

l

x

ikl

, (28)

G

l

V

T

il

≤ M

l

z

T

i

, (29)

V

T

il

≤ w

i

h

i

a

i

G

l

, (30)

V

T

il

≤ w

i

h

i

T

l

G

l

i

∑

k=1

x

ikl

, (31)

R

l

= M

l

−

n

∑

i=1

i

∑

k=1

w

i

h

i

t

i

G

l

x

ikl

| {z }

assigned items

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

30

Table 1: Inputs and Identifiers.

Input or Identifier Description

w

i

, h

i

,t

i

Width, height and depth of item i, with i = 1, . . . , n.

p

i

Value of item i per kilogram.

W

l

, H

l

, T

l

Width, height and depth of slab l, with l = 1, . . . , p.

G

l

Weight per volume unit of slab l, e.g., 7.85 · 10

−6

kg

mm

3

.

M

l

= W

l

H

l

T

l

G

l

Weight of slab l.

ˆ

W = max

l=1,...,p

{W

l

} Greatest width of slabs.

ˆ

T = max

l=1,...,p

{T

l

} Greatest height of slabs.

ˆ

H = max

l=1,...,p

{H

l

} Greatest depth of slabs.

P

0

l

Purchase value of slab l per kilogram.

P

l

Current value of slab l per kilogram.

g

e

l

Boundaries of weight classes, specific to slab l,

e.g.,

g

1

1

g

2

1

g

3

1

g

4

1

= g

m

1

=

0 2.1 5.1 10.1

.

α

e

l

Relative value for weight classes, specific to slab l,

e.g.,

α

1

1

α

2

1

α

3

1

α

4

1

= α

m

1

=

0.2 0.5 0.6 1

.

d

W

min

l

, d

H

min

l

, d

T

min

l

Minimum width, height, and depth before leftover

material is considered waste, e.g., d

W

min

l

= d

H

min

l

= d

T

min

l

= 10 cm

−

n

∑

k=1

V

S

kl

−

n

∑

i=1

V

C

il

−

n

∑

i=1

V

T

il

−V

H

l

, (32)

V :=

V

H

l

> 0 | l = 1, . . . , p

∪

V

S

k

> 0 | k = 1, . . . , n

∪

V

C

i

> 0 | i = 1, . . . , n

∪

V

T

i

> 0 | i = 1, . . . , n

, (33)

z

R

je

g

e

l( j)

≤ V

j

,

∀ j ∈ F

|V|

, ∀e ∈ F

m

, (34)

V

j

< g

e+1

l( j)

+ M

l( j)

(1 − z

R

je

) ,

∀ j ∈ F

|V|

, ∀e ∈ F

m−1

, (35)

m

∑

e=1

z

R

je

= 1 , ∀ j ∈ F

|V|

, (36)

F

je

≤ V

j

P

0

l( j)

α

e

l( j)

,

∀ j ∈ F

|V|

, ∀e ∈ F

m

, (37)

F

je

≤ M

l( j)

P

0

l( j)

α

e

l( j)

z

R

je

,

∀ j ∈ F

|V|

, ∀e ∈ F

m

(38)

In the following, the objective function and the con-

straints will be discussed in detail.

The objective is to maximize the profit from the

production of one batch of items. In general, the profit

is calculated by subtracting the costs from the rev-

enue. The costs, on the one hand, consist of the slabs

that are used for production, see Eq. (2), and the scrap

material, see Eq. (3). The revenue, on the other hand,

consists of the produced items, see Eq. (1), and the

reusable leftover material, see Eq. (4). Note that the

objective function is linear in the variables x

ikl

, u

l

, R

l

,

and F

j

, c.f., Table 2.

From Eq. (5) and Eq. (6) we see that all items have

to be produced. This means Eq. (1) of the objective is

constant and does not influence the optimal solution.

However, we will simplify that for the solver.

If we use a slab, it decreases the revenue. I.e., its

value is subtracted in Eq. (2). The production will re-

sult not only in items that we want to produce. There

will also be surplus material. As discussed earlier this

can either be leftover material or scrap material.

The scrap material originates from a slab with a

purchase value P

0

l

and this is the value we lose if we

throw it away. As we have already accounted for the

current value in Eq. (2), we need to compensate for

that in Eq. (3).

The leftover material is a kind of positive revenue.

It is not being paid for by a customer at this moment,

but it might be in future production cycles. So this

value is added to the objective, and thereby to the rev-

enue, in Eq. (4).

The constraints are described in the following.

Equation (5) describes that each item should only be

produced once. Usage of the set c

i

prevents that both,

the original and the rotated version of an item, are

produced.

Equation (6) means that an item i can only be

placed in shelves 1 to i. In other words, an item can

open a shelf or be placed in an existing one. As items

are sorted by height, this ensures equivalence to the

case where the height of a shelf is not determined by

Process Optimization for Cutting Steel-Plates

31

Table 2: (Auxiliary) Variables.

Variable Description

x

ikl

∈ {0, 1} Set to 1 if item i is placed in shelf k on slab l.

u

l

∈ {0, 1} Set to 1 if slab l is used.

b

kl

≥ 0 Remaining width in shelf k on slab l, see Fig. 5a.

b

k

≥ 0 Remaining width in shelf k, see Eq. (9).

s

l

≥ 0 Remaining height above top shelf on slab l,

see Fig. 5a, Eq. (10).

q

i

≥ 0 Remaining height above item i in its assigned shelf,

see Fig. 5a, Eq. (11).

a

i

≥ 0 Remaining depth above item i in its assigned shelf,

see Fig. 5b, Eq. (12).

V

S

kl

≥ 0 Weight of leftover material filling the width of shelf

k on slab l, see Fig. 3. A shelf is located on exactly one slab, so it is 6= 0

for exactly one combination of k and l or all are 0 if the leftover material

is waste.

V

S

k

=

∑

p

l=1

V

S

kl

≥ 0 Weight V

S

of shelf k.

V

C

il

≥ 0 Weight of leftover material filling the height above

item i on slab l, see Fig. 3. It is 6= 0 for only one combination of i and l

or all equal 0 if waste.

V

C

i

=

∑

p

l=1

V

C

il

≥ 0 Weight V

C

above item i.

V

T

il

≥ 0 Weight of leftover material filling the depth above

item i on slab l, see Fig. 3. It is 6= 0 for only one combination of i and l

or all equal 0 if waste.

V

T

i

=

∑

p

l=1

V

T

il

≥ 0 Weight V

T

above item i.

V

H

l

≥ 0 Weight of leftover material on the top of slab l,

see Fig. 3.

z

S

k

, z

C

i

, z

T

i

, z

H

l

∈ {0, 1} Set to 0 if associated weights are waste.

V

j

≥ 0 , ∀ j ∈ F

|V |

An element from the set V, see Eq. (33).

z

R

je

∈ {0, 1} , ∀ j ∈ F

|V |

Set to 1 if weight j is in class e.

F

je

Value of leftover material j in weight class e.

Not equal 0 for one weight class.

F

j

=

∑

m

e=0

F

je

≥ 0 , The value of weight j.

∀ j ∈ F

|V |

R

l

Weight of leftover material that is waste.

the first, but highest item.

Equation (7) sets u

l

to one if slab l is used.

Equation (8) and Eq. (9) set the variable b

k

which

describes the remaining width in shelf k, see also

Fig. 5. Equation (10), Eq. (11), and Eq. (12) set s

l

,

q

i

, and a

i

, respectively. See also Fig. 5.

Equation (13) and Eq. (14) set the variable z

H

l

to

zero if the associated weight V

H

l

is waste. V

H

l

is con-

sidered waste if s

l

< d

H

min

l

. In that case, z

H

l

in Eq. (14)

can either be 0 or 1, but with Eq. (13) it has to be 0.

Then again, if s

l

≥ d

H

min

l

, z

H

l

in Eq. (13) can either

be 0 or 1, while Eq. (14) sets it to 1.

The weights, which are calculated to get the value

of the leftover material, are best understood by look-

ing at Fig. 3. The weight V

H

l

is calculated in Eq. (15)

and Eq. (16). The latter one is set to zero if it is con-

sidered waste. This is done so that no value is added

for it in the objective function.

In Eq. (17) and Eq. (18) z

S

k

is set to 0 if V

S

kl

is scrap

material. Otherwise, z

S

k

is set to 1. In both equations,

the summation over l “picks” the correct slab as x

kk l

can only be one for one l. Beside of that, it works

analogously to Eq. (13) and Eq. (14).

The next three equations, Eq. (19), Eq. (20), and

Eq. (21), set the weight V

S

kl

. It is set to its actual

value if it is usable, otherwise it is set to 0. To

be more precise, the equations set the upper limit

of the weight and the objective indirectly maximizes

the weight such that the upper limit will be reached.

Equation (19) limits V

S

kl

to the weight of the slab or

sets it to 0 if it is scrap material. Equation (20) and

Eq. (21) need to be interpreted in conjunction. Equa-

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

32

tion (20) limits V

S

kl

as if shelf k is on slab l, which is

not necessarily true. Equation (21) then limits V

S

kl

to 0

if x

kk l

equals 0, i.e., only the correct combination of k

and l lead to a value unequal 0.

Equation (22) and Eq. (23) set z

C

i

in a similar way

as Eq. (17) and Eq. (18) set z

S

k

. The sum to find the

correct d

H

min

l

needs to be a sum over x

ikl

. This is be-

cause an item, not being the first item in a shelf, can

be located on any shelf.

The next three equations, Eq. (24), Eq. (25), and

Eq. (26), set the weight V

C

il

in the same way as

Eq. (19), Eq. (20), and Eq. (21) set V

S

kl

. Equation (26)

has an additional sum, compared to the calculation of

V

S

kl

. The argument here is similar to the one above.

Item i can be located on any shelf, so we sum over the

shelves k in order to pick the correct x

ikl

.

Equation (27) and Eq. (28) set z

T

i

in the same way

as z

C

i

is set. Equation (29), Eq. (30), and Eq. (31)

define the weight V

T

il

in the same way as V

C

il

is defined.

R

l

is the sum of the weight of scrap material from

slab l. It is calculated in Eq. (32) as the remainder

from substracting produced and reusable items from

the slab weight. I.e., everything that is not an item or

reusable leftover is scrap material.

Equation (4) uses the set V , which is defined in

Eq. (33). V is the set of all weights not of size zero.

Recall that these weights are only those that are asso-

ciated to reusable material.

The rest of the constrains are used to finally cal-

culate the value of the reusable material. z

R

je

denotes

if weight j is in the weight class e. Let l( j) denote

the slab on which weight j is located. l( j) is linear,

because V

j

= V

S

k

: l( j) = l ⇔ V

S

kl

> 0, analogously for

C, T. Then, z

R

je

shall equal 1 if g

e

l( j)

≤ V

j

< g

e+1

l( j)

. This

is accomplished by Eq. (34), Eq. (35), and Eq. (36).

Equation (35) will set z

R

je

to zero if V

j

is lighter than

the boundary g

e

. Equation (34) will set z

R

je

to zero if

V

j

is heavier than g

e

. Both these equations allow z

R

je

to be either 0 or 1 if the above inequality holds. In

that case Eq. (36) forces z

R

je

to be 1 and we have our

desired behavior.

With this information we can finally calculate F

je

,

which is the value of V

j

. As the name suggests, it is

non-zero only for one specific value of e. Unfortu-

nately, we cannot multiply V

j

by z

R

je

as we want our

problem to stay linear. Therefore, Eq. (37) sets the up-

per limit of its value regardless of z

R

je

. Then, Eq. (38)

sets an even larger upper limit, but only if z

R

je

equals 1.

Otherwise, it sets it to 0, which is what we want if V

j

does not lie in this specific weight class. In our ob-

jective function, the sum is above F

j

, not F

je

. This is

explained in Table 2.

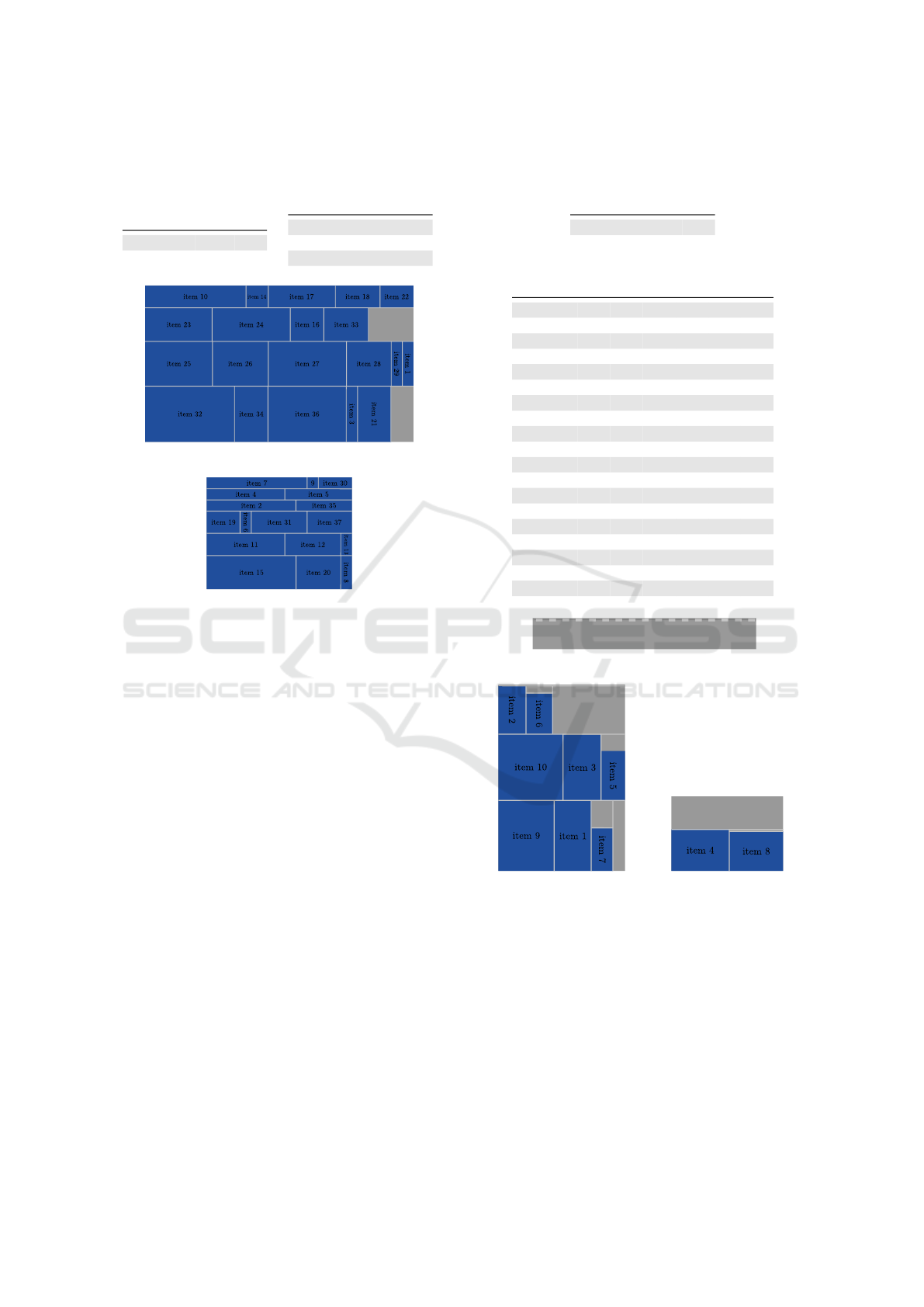

(a) Our solution.

(b) Solution from (Andrade

et al., 2013).

Figure 6: Example 1, input data No. 1, Table 3.

Table 3: Input data No. 1.

(a) Slabs in stock

ID W H T

1 500 700 45

(b) Items in order

ID w h t

−3 150 400 45

−1 100 300 45

−2 100 300 45

3 400 150 45

1 300 100 45

2 300 100 45

4 EVALUATION

The optimization program was implemented using

CVX, which is an add-on for MATLAB. CVX allows

a high level description of the program, which is close

to the description in Section 3. CVX can use several

solvers. The solver we use is Gurobi ((Gurobi Opti-

mization, Inc., 2016)) as it can solve binary integer

linear programs.

In all examples, the boundaries and relative values

of the weight classes are the ones from Table 1. Also,

the weight per volume is given there.

Please note that some of the slabs had to be drawn

incomplete in order to keep the page size down. This

was done only in areas where no items are placed and

is denoted by a dotted line at the top of the slab.

Example 1

We compare our solution to the one named M

L

1

in

(Andrade et al., 2013), which is also implemented in

CVX/Gurobi. As mentioned earlier, the solution in

(Andrade et al., 2013), solves the problem in two di-

mensions. Therefore, in our example, the thickness of

the ordered items matches the thickness of the slabs in

stock.

Later, we will also show an example where the

thickness between slab and items is different.

Process Optimization for Cutting Steel-Plates

33

Table 4: Input data No. 2.

(a) Slabs in stock

ID W H T

1 350 650 40

2 300 300 40

(b) Items in order

ID w h t

1 200 330 40

2 150 300 40

3 150 300 40

The data from Table 3 produces the solutions

shown in Fig. 6. The table shows the rotated items,

where the item with identifier −i denotes the rotated

version of the item with itentifier i. We will omit these

in later tables. The items in this specific table are also

ordered by height as needed for in our problem for-

mulation.

We denote a cut which should not be necessary in

the final cutting procedure with a dashed line. Our

solution results in two quite large pieces of surplus

material. The solution from (Andrade et al., 2013),

results in a solution with three smaller pieces of sur-

plus material. We also rotated all items before feed-

ing the input to the algorithm from (Andrade et al.,

2013). Still, its solution was to put all three items

side by side, i.e., also creating three pieces of surplus

material. Subjectively, two larger pieces of surplus

material are better than three smaller ones.

Putting the solution from (Andrade et al., 2013)

into our objective function, we get a smaller, i.e.,

worse, objective value. That means, according to our

valuation, we have a better overall value of items and

slabs, compared to the algorithm from (Andrade et al.,

2013). It is also shown that the rotation of items is of

importance.

Example 2

This example, see Fig. 7, underlines how our opti-

mization problem finds really good solutions if slabs

can be filled. There is no leftover material on slab 2,

so slab 1 produces a nice large piece of leftover ma-

terial in addition to a smaller one. The smaller one is

just slightly above the size limitations of scrap mate-

rial, so it is put back to the set of slabs for the next

run, too.

Assume, we rotate item 1 on slab 1. The values

of the used slabs, as well as the value of the produced

items stays the same. Still, the value of the objec-

tive function decreases, because the sum of the values

of the surplus material decreases. Note that, the sum

of the weights of the surplus material stays also the

same. The value of the surplus material decreases,

because the function, described by g

e

l

and α

e

l

, is a

concave function. This function is essential for the

performance of the optimization program.

(a) Slab 1 (b) Slab 2

Figure 7: Example 2, input data No. 2, Table 4.

(a) Input data No. 3 (b) Input data No. 4

Figure 8: Ex. 3, data No. 3 and 4, Tables 5 and 6.

Example 3

Two slightly different variations of input data is exam-

ined in this example. Table 5 shows input data no. 3,

while Table 6 shows input data no. 4. The only differ-

ence is the size in the direction of x of the slab.

Figure 8 shows both solutions. Again, it is all

about the value of the leftover material. It is clear

the solution with the highest value of the leftover ma-

terial is optimal, because all of the items have to be

produced according to the objective function.

With input data No. 4, if the items would be

placed as seen in Fig. 8a, then the value of the leftover

material would be less than is shown. This directly

depends on the weight groups. As a result the weight

groups have to be empirically adjusted, according to

the slab sizes and items ordered.

Table 5: Input data No. 3.

(a) Slabs in stock

ID W H T

1 330 650 40

(b) Items in order

ID w h t

1 200 330 40

2 150 300 40

3 150 300 40

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

34

Table 6: Input data No. 4.

(a) Stock

ID W H T

1 350 650 40

(b) Order

ID w h t

1 200 330 40

2 150 300 40

3 150 300 40

(a) Slab 1

(b) Slab 2

Figure 9: Example 4, input data No. 5, Table 7.

Example 4

In Fig. 9 we show the result of an optimization which

barely fits on the slabs and where items have many

similar dimensions. This is where the optimization

problem really shines and a manual solution would

be really time consuming if you would even find one.

Example 5

Compared to the last example, Fig. 10 shows the re-

sult of items, which don’t have many similar sizes.

The result does not look as nice and dense as the pre-

vious one, but it still produces many larger pieces of

surplus material. Note that slab 1 is not used, i.e.,

smaller blocks of steel are used first, because they

have a smaller value. This is exactly what we want.

Example 6

Figure 11 is a slight variation of the previous example.

The sizes of slab 2 and slab 3 are decreased. As a

result not all items fit on these two slabs.

As can be seen from the figure, item 7 is put on

slab 1, but it would neatly fit into the upper right cor-

Table 7: Input data No. 5.

(a) Stock

ID W H T

1 240 140 10

2 130 100 10

(b) Order

ID w h t ID w h t

1 40 10 10 20 40 30 10

2 80 10 10 21 50 30 10

3 50 10 10 22 20 30 10

4 70 10 10 23 60 30 10

5 60 10 10 24 70 30 10

6 20 10 10 25 60 40 10

7 90 10 10 26 50 40 10

8 30 10 10 27 70 40 10

9 10 10 10 28 40 40 10

10 90 20 10 29 10 40 10

11 70 20 10 30 10 30 10

12 50 20 10 31 20 50 10

13 10 20 10 32 80 50 10

14 20 20 10 33 30 40 10

15 80 30 10 34 30 50 10

16 30 30 10 35 10 50 10

17 60 20 10 36 70 50 10

18 40 20 10 37 20 40 10

19 30 20 10

(a) Slab 1

(b) Slab 2 (c) Slab 3

Figure 10: Example 5, input data No. 6, Table 8.

ner of slab 3. The optimization problem can’t find this

solution, because it makes strict assumptions about

the layout of the items. Further investigation about

cutting patterns and their application to the formula-

tion of the optimization problem might be a direction

of future research.

Example 7

In previous examples, the thickness of items matched

Process Optimization for Cutting Steel-Plates

35

Table 8: Input data No. 6.

(a) Stock

ID W H T

1 300 300 45

2 170 250 45

3 150 100 45

(b) Order

ID w h t

1 94 50 45

2 65 37 45

3 51 88 45

4 78 56 45

5 32 66 45

6 54 36 45

7 58 29 45

8 53 72 45

9 95 75 45

10 89 87 45

(a) Slab 1

(b) Slab 2 (c) Slab 3

Figure 11: Example 6, input data No. 7, Table 9.

the thickness of the slabs. Now, we show that our

formulation can give unexpected results if there are

several slabs with different thicknesses to pick from.

In Fig. 12, we show the results of our formulation

with input data no. 8, Table 10. One might assume

that producing the item on slab 2, which matches its

thickness, is the best option. As you can see, our for-

mulation places the item on slab 1, which is consider-

ably thicker than it needs to be. Simply put, the value

Table 9: Input data No. 7.

(a) Stock

ID W H T

1 300 300 45

2 150 220 45

3 120 100 45

(b) Order

ID w h t

1 94 50 45

2 65 37 45

3 51 88 45

4 78 56 45

5 32 66 45

6 54 36 45

7 58 29 45

8 53 72 45

9 95 75 45

10 89 87 45

(a) Slab 1 (b) Slab 2

Figure 12: Example 7, input data No. 8, Table 10.

Table 10: Input data No. 8.

(a) Stock

ID W H T

1 500 700 25

2 500 700 15

(b) Order

ID w h t

1 400 400 15

of the leftover material dictates this placement.

Cuts that trim the thickness can take a long time,

because the area to cut can be quite large compared

to the other cuts. If these trims were not desired, the

optimization problem could either be extended by a

penalty for these cuts or items and orders could sim-

ply be matched in thickness before given to the opti-

mization program.

Runtime and Quality

Besides example 4, the runtime of our examples was

always below one minute, which is a reasonable run-

time to collect and place orders. Example 4 took

about 5000 seconds, which is considerable more than

the other solutions. Limiting the time allowed by the

solver for Example 4 to 60 seconds, we still got a fea-

sible solution. I.e., while not as dense as the solution

shown in Fig. 9, all items were placed on the slabs.

5 SUMMARY

In this paper, we developed an optimization program

that solves the problem of cutting steel-plates, where

only guillotine cuts are allowed. We consider surplus

material as a form of value. Our solution is mod-

eled in three dimensions in order to assign a value

to the surplus material. We use the notion of shelves

to model the placement of items on slabs and allow

items to be rotated.

As has been shown in the examples, our problem

formulation gives subjectively good results, i.e., the

problem is apparently well solved. We have shown

that preferable few, big leftovers are created and small

slabs are used first, see Examples 1 and 6 respectively.

ICORES 2017 - 6th International Conference on Operations Research and Enterprise Systems

36

Example 4 showed that our formulation allows

the tradeoff between runtime and quality. Example 5

showed good performance, even for items of random

size.

In some cases, the placement using shelves might

not be optimal and a more advanced placement might

yield better results in the case of sparser placements.

Consider Example 6, item 7 could fit on slab 3 with

a proper cutting order. Although, modeling and find-

ing optimal solutions of placements not following the

notion of shelves is much more difficult.

Including the third dimension is necessary to

achieve optimal solutions, see Example 7. Our results

are strongly dependent on the choice of weight classes

and their values, see Examples 2 and 3. A proper opti-

mization of these could be the topic of future research.

Although, the values from Table 1 produce good re-

sults for the sizes we used in our examples.

In the future, the number of cuts or a penalty for

using many different slabs could be incorporated eas-

ily into the objective function. But these considera-

tions should be justified by concrete requirements of

a factory.

REFERENCES

Andrade, R., Birgin, E., and Morabito, R. (2013). Two-

stage two-dimensional guillotine cutting stock prob-

lems with usable leftover.

Burke, E. K., Hyde, M. R., and Kendall, G. (2011). A

squeaky wheel optimisation methodology for two-

dimensional strip packing. Computers & Operations

Research, 38(7):1035–1044.

Carnieri, C., Mendoza, G. A., and Gavinho, L. G. (1994).

Solution procedures for cutting lumber into furniture

parts. European Journal of Operational Research,

73(3):495–501.

Christofides, N. and Whitlock, C. (1977). An Algorithm

for Two-Dimensional Cutting Problems. Operations

Research, 25(1):30–44.

Dyckhoff, H., Kruse, H.-J., Abel, D., and Gal, T. (1985).

Trim loss and related problems. Omega, 13(1):59–72.

Farley, A. A. (1988). Practical adaptations of the

Gilmore-Gomory approach to cutting stock problems.

Operations-Research-Spektrum, 10(2):113–123.

Furini, F. and Malaguti, E. (2013). Models for the two-

dimensional two-stage cutting stock problem with

multiple stock size. Computers & Operations Re-

search, 40(8):1953–1962.

Gilmore, P. and Gomory, R. (1961). A Linear Programming

Approach to the Cutting-Stock Problem. Operations

Research, 9(6):849–859.

Gilmore, P. C. and Gomory, R. E. (1965). Multistage Cut-

ting Stock Problems of Two and More Dimensions.

Operations Research, 13(1):94–120.

Gurobi Optimization, Inc. (2016). Gurobi Optimizer Refer-

ence Manual. http://www.gurobi.com/.

Hinxman, A. I. (1980). The trim-loss and assortment prob-

lems: A survey. European Journal of Operational Re-

search, 5(1):8–18.

Kalagnanam, J. R., Dawande, M. W., Trumbo, M., and

Ho Soo Lee (2000). The Surplus Inventory Match-

ing Problem in the Process Industry. Operations Re-

search, 48(4):505–516.

Kantorovich, L. V. (1960). Mathematical Methods of Or-

ganizing and Planning Production. Management Sci-

ence, 6(4):366–422.

Kurt Eisemann (1957). The Trim Problem. Management

Science, 3(3):279–284.

Lodi, A. and Monaci, M. (2003). Integer linear program-

ming models for 2-staged two-dimensional Knapsack

problems. Mathematical Programming, 94:257–278.

Martello, S., Pisinger, D., and Vigo, D. (2000). The Three-

Dimensional Bin Packing Problem. Operations Re-

search, 48(2):256–267.

Morabito, R. and Arenales, M. (2000). Optimizing the cut-

ting of stock plates in a furniture company. Interna-

tional Journal of Production Research, 38(12):2725–

2742.

Silva, E., Alvelos, F., and Valério de Carvalho, J. M. (2010).

An integer programming model for two- and three-

stage two-dimensional cutting stock problems. Euro-

pean Journal of Operational Research, 205(3):699–

708.

Wayne L Winston and Jeffrey B Goldberg (2004). Op-

erations Research: Applications and Algorithms.

Duxbury press Belmont, CA.

Yanasse, H. H., Zinober, A. S. I., and Harris, R. G. (1991).

Two-dimensional Cutting Stock with Multiple Stock

Sizes. Journal of the Operational Research Society,

42(8):673–683.

Process Optimization for Cutting Steel-Plates

37