CdSe/ZnS (Core/Shell) Quantum Dots Multi-wallled Carbon

Nanotubes (MWCNTs) on a Stainless Steel as a Photoanode in Solar

Cells

Junthorn Udorn

1,3

, Hayashi Sachio

1

, Shengwen Hou

1

, Chaoyang Li

1,2

,

Akimitsu Hatta

1,2

and Hiroshi Furuta

1,2

1

Electronic and Photonic Systems Engineering, Kochi University of Technology, Tosayamada-cho, Kami,

Kochi 782-0003, Japan

2

Center for Nanotechnology, Research Institute, Kochi University of Technology, Tosayamada-cho, Kami,

Kochi 782-0003, Japan

3

Faculty of Engineering, Thai-Nichi Institute of Technology (TNI), 1771/1 Pattanakarn Rd. 37 Suanluang, Bangkok, 10250,

Thailand

Keywords: Multi-walled Carbon Nanotubes (MWCNTs), Quantum Dots (QDs), Quantum Dots Sensitized Solar Cells

(QDSSCs), Power Conversion Efficiency (PCE).

Abstract: Multi-walled carbon nanotube (MWCNT) forests grown on a stainless steel substrate were used as a

photoanode in CdSe/ZnS (core/shell) quantum dot (QD) sensitized solar cells (QDSSCs). QD-treated

MWCNTs on the conductive metal stainless substrate showed a higher power conversion efficiency (PCE)

of 0.014% than those grown on a doped silicon substrate with a PCE of 0.005% under AM 1.5 sunlight

intensity (100 mW/cm

2

). This higher efficiency can be attributed to the lower sheet resistance of 0.0045

Ω/sq for the metal substrate than the value of 259 Ω/sq for doped silicon. Additionally, the relationship

between the reflectance of as-grown CNT and PCE is also examined. QDSSC fabricated from CNT of lower

reflectance of 1.9 % at a height of 25 μm showed a better efficiency because the lower reflectance indicates

the scattering of light repeatedly into deeper CNT forest resulting in higher absorption which indicates a

higher surface area of CNTs to adsorb much amount of QDs on CNT forests, resulting in the higher PCE.

1 INTRODUCTION

The extraordinary mechanical, chemical, and

electronic properties of carbon nanotubes (CNTs)

make them outstanding materials for energy

applications (Iijima 1991; Dong et al. 2011; Zhu et

al. 2008). A major challenge in solar cell

applications is the development of modified CNT

structures for use as transparent electrodes (Cui et al.

2013). The modified CNT structure is expected to be

a good material for use as a counter electrode or

photo-anode (Cui et al. 2013) with semiconducting

quantum dots (QDs) in order to harvest a broader

range of light from the ultraviolet (UV) to the

infrared (IR) (Hickey et al. 2000). We have reported

a significant increase in optical total reflectance

using a structural modification of CNT honeycombs

(Udorn et al. 2016), which will increase the utility of

CNT honeycomb structures in high-efficiency solar

cells. QD-decorated CNTs exhibit efficient charge

transfer from photo-excited QDs to the CNTs

(Haremza et al. 2002). QD sensitized solar cells

(QDSSCs) have attracted considerable interest from

researchers because their power conversion

efficiency (PCE) may exceed the Shockley and

Queisser limits (Watanabe et al. 2011; Miller et al.

2012). In particular, QDs can harvest a broad range

of optical wavelengths by multiple exciton

generation (MEG), thus improving the photovoltaic

efficiency (Péchy et al. 2001; Barve et al. 2012; Mar

et al. 2011). Optical absorption by QDs fabricated

from materials such as CdS (Yu et al. 2012), CdSe

(Tian et al. 2013), and CdSe/ZnS (Baek et al. 2014)

is intrinsically tunable from the UV to the near-IR

due to the particle-size dependence of the bandgap.

A major advantage of QDs as light sensitizers

compared with conventional dyes is that electron

recombination is suppressed, thereby improving the

efficiency of QDSSCs (Hoke et al. 2012; Li et al.

158

Udorn J., Sachio H., Hou S., Li C., Hatta A. and Furuta H.

CdSe/ZnS (Core/Shell) Quantum Dots Multi-wallled Carbon Nanotubes (MWCNTs) on a Stainless Steel as a Photoanode in Solar Cells.

DOI: 10.5220/0006103801580163

In Proceedings of the 5th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2017), pages 158-163

ISBN: 978-989-758-223-3

Copyright

c

2017 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2012; Beard 2011). One dimensional (1D) wires, of

e.g., TiO2 (Zarazúa et al. 2011; Guijarro et al. 2009),

ZnO (Li et al. 2013; Zhang et al. 2009), and Si

(Takahashi 2011; Jeyakumar et al. 2013) have been

extensively used for electron transfer from QDs to

electrodes. In particular, CNTs have arisen as a

superior candidate 1D wire electrode material for

QDSSC (Dong et al. 2011; Malara et al. 2011; Peng

et al. 2011) because of their large surface area, high

conductivity, high aspect ratio, and chemical

stability. Due to their excellent electrical and

thermal conductivity, flexible metal substrates can

reduce both the sheet resistance and production cost

of solar cells (Kang et al. 2006; Miettunen et al.

2008; Ma et al. 2004). To the best of our knowledge,

there are no reports of QDSSCs in which QD-treated

CNT forest photoanodes are fabricated on a metal

substrate.

In this study, CNT forests grown on stainless

steel serving as a photoanode for CdSe/ZnS

core/shell QDSSCs are investigated as a means of

improving photovoltaic efficiency. The efficiency

was compared for samples of QDSSCs on a metal

stainless steel substrate, QDSSCs on a doped silicon

substrate, and QDSSCs with a photoanode of

randomly oriented CNT (buckypaper) films on a

metal stainless steel substrate. The relationship

between the optical total reflectance of as-grown

CNTs and the PCE was investigated.

2 MATERIAL AND METHODS

Vertically aligned multi-walled carbon nanotube

(MWCNT) forests with tube diameters of 30–65 nm

and heights of ~15 µm were prepared by a catalytic

thermal chemical vapour deposition (CVD) method

with an annealing time of 2.5 min in a hydrogen

flow of 65 sccm at 28 Pa and 730°C, followed by

CNT synthesis at 730°C with a carbon source gas of

acetylene (C2H2) gas at 54 Pa for 10 min on Fe/Al

(5/50 nm in thickness) bi-layered catalyst films on a

sheet of stainless steel SUS304 (68% iron, 19%

chromium, 10% manganese, 1% silicon, and 2%

other compounds). The Fe/Al catalyst films on the

stainless steel sheet were deposited by magnetron

sputtering under an argon flow of 10 sccm, a

pressure of 0.8 Pa, and a discharge current of 40 mA

for 21 min for Al and 2.5 min for Fe. CNT

buckypaper films were prepared by dipping

vertically aligned CNTs grown on the stainless steel

sheet into a methanol solution for 5 min, and then

drying them in air at room temperature. The

morphologies and heights of the as-grown CNT

forests and modified CNT structures were

characterized using field-emission scanning electron

microscopy (FE-SEM; JEOL JSM-5310). The total

reflectance in the UV–vis region was measured

using a spectrophotometer (HITACHI U-3900).

Solar cells were fabricated from as-grown CNT

forests and CNT buckypaper films as photoanodes,

treated with CdSe/ZnS (core/shell) quantum dots in

toluene solutions as a sensitizer with a particle size

of 3.4 nm (LumidotTM, Aldrich). Indium tin oxide

(ITO) glass with a sheet resistance of ~15 Ω/sq was

used as a counter electrode, and the 0.1-µm2 active

area between the two electrodes was filled with an

iodide electrolyte solution (I1

−

/I3

−

). The J–V

characteristics of the cells were recorded with a

computer-controlled digital source meter (Keithley

Model 2400) by applying an external potential bias

to the cell under AM 1.5 sunlight intensity (100

mW/cm

2

). All measurement was carried out at the

room temperature.

3 RESULTS AND DISCUSSIONS

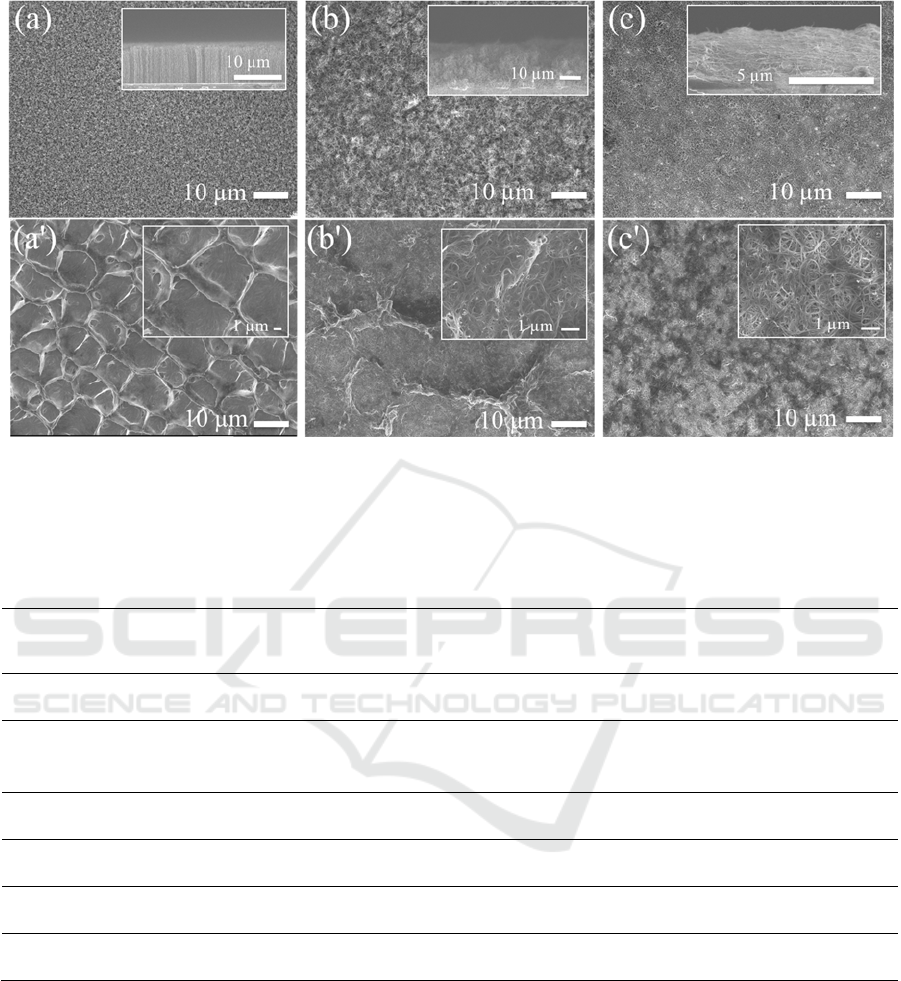

Figures 1(a), (b), (c) display a top-view of FE-SEM

micrographs of as-grown on a silicon substrate, the

stainless steel substrate, and CNT buckypaper films

on the stainless steel substrate, respectively. Inserted

images of Fig.1(a), (b) and (c) show a cross-

sectional image of as-grown on silicon substrates, on

the stainless steel, and CNT buckypaper films,

respectively. As can be seen in Figs. (a) and (b), the

as-grown CNTs on the stainless steel shows an

inconsistent

height where as-grown CNTs on the

silicon substrate shows a higher density and a

consistent height. Meanwhile, CNT buckypaper

films which were simply prepared by dipping

vertically-aligned CNTs into a methanol solution for

5 min show a highly-packed randomly oriented

CNTs as shown in an inset of Fig. 1(c). After QDs

treatment, the self-assembly patterns can be formed,

an inset of Fig. (b') shows a highly-magnified image

of highly-packed CNTs where honeycomb-like

patterns are formed on a silicon substrate as shown

in Fig. 1(a').

The performance of the different substrates,

patterns, and different heights is analysed by a sheet

resistance, a series resistance, optical total

reflectance, and power conversion efficiencies

(PCE) as shown in Table 1.

As-grown CNTs with a

height of 25 µm on a stainless steel substrate with a

sheet resistance of 0.0045 Ω/sq and an optical total

reflectance of 1.9% at 560 m exhibit the highest

PCE of 0.014%. Meanwhile, as-grown CNTs on a

CdSe/ZnS (Core/Shell) Quantum Dots Multi-wallled Carbon Nanotubes (MWCNTs) on a Stainless Steel as a Photoanode in Solar Cells

159

Figure 1: Top-view FE-SEM images of (a) as-grown CNTs on silicon substrate, (b) as-grown CNTs on stainless steel

substrate, (c) CNT buckypaper films on stainless steel substrate. The insets show cross-sectional images. CdSe/ZnS QDs-

treated on (a') as-grown CNTs on silicon substrate, (b') as-grown CNTs on stainless steel substrate, (c') CNT buckpaper

films on stainless steel substrate. The insets show high-magnification images.

Table 1: Properties of QD-treated CNTs on a silicon substrate, and CNT buckypaper films on the stainless steel substrate,

and QDs-treated CNTs on the stainless steel with various heights.

Sheet

resistance

(/sq)

Series

resistance

(/sq)

Total reflectance

at 560 nm

(without QDs)

J

SC

(mA/cm

2

)

V

OC

(V)

FF

(PCE)

QD-treated CNTs

on silicon substrate

259 33K 0.98% 0.067 0.21 38.6% 0.005%

QD-treated CNT

buckypaper films on

stainless steel

0.0046 14 K 4.3% 0.068 0.32 42.9% 0.009%

QD-treated 17-µm

CNTs on stainless steel

0.0047 13K 4.1% 0.050 0.38 56.7% 0.011%

QD-treated 25-µm

CNTs on stainless steel

0.0045 13K 1.9% 0.057 0.45 52.2% 0.014%

QD-treated 33-µm

CNTs on stainless steel

0.0043 14K 2.2% 0.049 0.40 65.6% 0.013%

QD-treated 41-µm

CNTs on stainless steel

0.0043 13K 2.2% 0.056 0.39 54.4% 0.012%

silicon substrate with a higher sheet resistance of

259 Ω/sq exhibit a PCE of 0.005%. The 2.8 times

higher PCE for the former sample can be attributed

to the higher conductance of the substrate. The PCE

for QD-treated CNTs on the stainless steel substrate

is 1.6 times higher than that for CNT buckypaper

films on the same metal stainless steel substrate,

which can be attributed to the higher number of QDs

adsorbed on the surface of the CNTs. QD-treated

CNTs on the stainless steel substrate had heights of

17, 25, 33 and 41 µm, and the PCE was the highest,

at 0.014%, for a height of 25 µm. For the taller

CNTs, the lower PCE could be explained by the fact

that the electron transport path was longer than the

electron diffusion length, leading to increased

recombination of electrons and holes (Wei et al.

2014), and hence a lower efficiency.

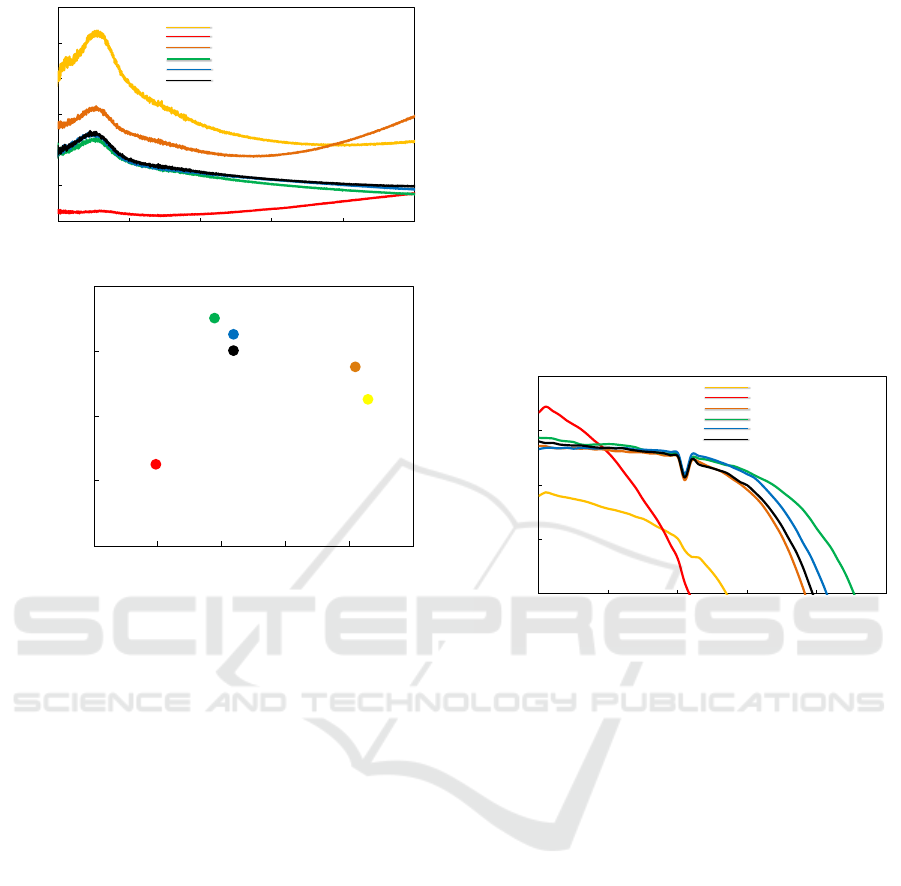

Figure 2(a) shows the total reflectance of as-

grown CNTs on a silicon substrate, a CNT

buckypaper film on a stainless steel substrate, and

as-grown CNTs of various heights on a stainless

steel substrate. For as-grown CNTs on the stainless

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

160

Figure 2: (a) Optical total reflectance of as-grown CNTs

on a silicon substrate (red), CNT buckypaper films on the

stainless steel substrate (yellow), as-grown CNTs on the

stainless steel substrate in various heights, (b) PCE vs.

total reflectance.

steel before QD treatment, the strong reflection at

wavelengths shorter than 380 nm can be assigned to

Rayleigh scattering, which provides a higher

reflectance at shorter wavelength (Yu & and Louis

Brus 2001). The bandgap of CdSe (E

g

= 2.21 eV) is

corresponded to 561 nm which is expected as an

absorption edge of QDs. The CNT buckypaper films

(black line) exhibit a higher total reflectance of more

than 5% at 560 nm due to the highly packed CNTs

serving as glassy carbon to strongly reflect light

(Shabaneh et al. 2014). As-grown CNTs on a silicon

substrate (grey line) exhibit the lowest total

reflectance of less than 2%, which can be attributed

to the higher density of CNT forests. The CNT

forest with a height of 25 µm has a lower total

reflectance of 1.9% at a wavelength of 560 nm. This

can be explained by multiple scattering of the

incident light into the bottom of the CNT forest, so-

called blackbody absorption (Mizuno et al. 2009).

Figure 2(b) shows the relationship between the total

reflectance and the PCE, which indicates that the

lower total reflectance of the as-grown CNTs on the

stainless steel gives a higher solar cell efficiency

after QDSSC fabrication. Significantly, the PCE for

QDSSCs with CNTs with heights of 25 μm on a

stainless steel substrate, with the total reflectance of

1.9% (green symbols), has a maximum value of

0.014%. Also, as can be seen in Fig. 2(b), the lower

total reflectance of 25 and 33 μm exhibits the better

PCE. The lower total reflectance due to efficient

absorption of light in CNTs leads to higher solar cell

efficiency. The low total reflectance of CNT forests,

by the mechanism of the repeated reflection of

incident light into the CNT bottom region, indicates

a higher CNT surface area, which is expected to

adsorb a larger number of QDs, resulting in a higher

PCE.

Figure 3: J–V curves of photovoltaic QDSSCs cells of

QD-treated CNTs on silicon substrate, CNT buckypaper

films on stainless steel substrate, QDs-treated CNTs with

various heights on stainless steel substrates.

Figure 3 presents J–V curves for QDSSC cells of

QD-treated CNTs on a silicon substrate, QD-treated

CNT buckypaper films on a stainless steel substrate,

and QD-treated CNTs with various heights on a

stainless steel substrate. The PCE (η) was calculated

using the equation η = (FF × J

SC

× V

OC

) / Pinput,

where FF is the fill factor and Pinput is the power

density of the incident light. It can be seen that QD-

treated CNTs with a height of 25-μm exhibit

significantly better photovoltaic performance in

terms of the current density (JSC) and the open-

circuit voltage (VOC). Compared to those on the

low-conductivity silicon substrate, as-grown CNTs

after QD treatment on the stainless steel substrate

also exhibit an improved open-circuit voltage of

0.21 to 0.45 volts (see Table 1). This is evidence that

the low resistivity of the conductive substrate gives

an increased open-circuit voltage, leading to

improved solar cell efficiency. The QD-treated

CNTs with heights of 25 μm exhibit a higher VOC

of 0.45 volts and also slightly improves the VOC

0

2

4

6

8

10

12

200 300 400 500 600 700

Total reflectance (%)

Wavelength (nm)

CNT buckypaper films on metal

CNTs on a silicon substrate

CNTs at 17-µm height on stainless steel

CNTs at 25-µm height on stainless steel

CNTs at 33-µm height on stainless steel

CNTs at 41-µm height on stainless steel

(a)

As-grown CNTs on silicon

CNT buckpaper flims on

stainless steel

CNTs at 17-µm height on

stainless steel

CNTs at 25-µm height on stainless steel

CNTs at 33-µm height on stainless steel

CNTs at 41-µm height on stainless steel

0

0.004

0.008

0.012

0.016

012345

PCE (%)

Total reflectance (%) with QDs at 560 nm

(b)

0

0.02

0.04

0.06

0.08

0 0.1 0.2 0.3 0.4 0.5

Current density (mA/cm

2

)

Bias voltage (V)

CNT buckypaper films

As-grown CNTs on a silicon substrate

As-grown CNTs at 17-µm height

As-grown CNTs at 25-µm height

As-grown CNTs at 33-µm height

As-grown CNTs at 41-µm height

CdSe/ZnS (Core/Shell) Quantum Dots Multi-wallled Carbon Nanotubes (MWCNTs) on a Stainless Steel as a Photoanode in Solar Cells

161

from 0.32 to 0.45 volts as compared with CNT

buckypaper films. In addition, the energy barrier at

the QDSSC/CNT interface can suppress interfacial

recombination, leading to an increased VOC, which

is expected for CNT forests directly grown on metal

substrates. The increase in the PCE is an indication

of improved charge collection and transport due to

introducing the CNTs forest directly grown on the

metal substrate at a significant specific height as an

electrode scaffold in the photoanode.

4 CONCLUSIONS

This study reported the first QDSSCs with

photoanodes of MWCNTs on a metal substrate, and

found that the PCE for such QDSSCs on stainless

steel substrates was three times higher than those on

a low-resistive (0.15 Ω·cm), doped silicon substrate.

A QD-treated MWCNT forest on a metal substrate

was found to have a resistance of 0.0045 Ω/sq and

exhibited a higher PCE of 0.014%, whereas QD-

treated MWCNTs on a doped silicon substrate had a

resistance of 259 Ω/sq and a lower efficiency of

0.005%. This difference could be attributed to the

fact that the very low sheet resistivity of a metal

substrate gives a higher electrical conductance

leading to a higher cell efficiency. The relationship

between the total reflectance of CNT forests and the

PCE was investigated. It was shown that the lower

total reflectance QD-treated CNT forest of 25-μm

height achieved a higher PCE of 0.014%, likely due

to the higher light absorption in the QDs. Although

the efficiency is currently low compared with that of

high-performance DSSCs or QDSSCs, the

successful incorporation of QDs with a CNT forest

on a conductive substrate as a photoanode for solar

cells has been demonstrated for the first time.

ACKNOWLEDGEMENTS

This work was supported by JSPS KAKENHI Grant

(No.24560050) and also by a grant from Japanese

Government (MEXT) Scholarship (No.132308).

REFERENCES

Baek, S.-W. et al., 2014. Effect of Core Quantum-dots

Size on Power-conversion-efficiency for Silicon Solar-

cells Implementing Energy-down-shift using

CdSe/ZnS Core/Shell Quantum Dots. Nanoscale, 6,

pp.12524-12531. Available at: http://pubs.rsc.org/en/

Content/ArticleLanding/2014/NR/C4NR02472A

[Accessed August 22, 2014].

Barve, A. V et al., 2012. Effects of contact space charge

on the performance of quantum intersubband

photodetectors. Applied Physics Letters, 100(19),

p.191107.Available at: http://scitation.aip.org/content/

aip/journal/apl/100/19/10.1063/1.4712601.

Beard, M.C., 2011. Multiple exciton generation in

semiconductor quantum dots. Journal of Physical

Chemistry Letters, 2(11), pp.1282–1288.

Cui, K. et al., 2013. Self-assembled microhoneycomb

network of single-walled carbon nanotubes for solar

cells. Journal of Physical Chemistry Letters, 4(15),

pp.2571–2576. Available at: http://dx.doi.org/

10.1021/jz401242a.

Dong, P. et al., 2011. Vertically aligned single-walled

carbon nanotubes as low-cost and high electrocatalytic

counter electrode for dye-sensitized solar cells. ACS

applied materials & interfaces, 3(8), pp.3157–61.

Available at: http://www.ncbi.nlm.nih.gov/pubmed/

21770421.

Guijarro, N. et al., 2009. CdSe quantum dot-sensitized

TiO2 electrodes: Effect of quantum dot coverage and

mode of attachment. Journal of Physical Chemistry C,

113(10), pp.4208–4214.

Haremza, J.M. et al., 2002. Attachment of Single CdSe

Nanocrystals to Individual Single-Walled Carbon

Nanotubes. Nano Letters, 2(11), pp.1253–1258.

Available at: http://pubs.acs.org/doi/abs/10.1021/

nl025799m.

Hickey, S., Riley, D. & Tull, E., 2000.

Photoelectrochemical studies of CdS nanoparticle

modified electrodes: Absorption and photocurrent

investigations. The Journal of Physical Chemistry B,

104(32), pp.7623–7626. Available at: http://

pubs.acs.org/doi/abs/10.1021/jp993858n [Accessed

June 26, 2014].

Hoke, E.T. et al., 2012. The role of electron affi nity in

determining whether fullerenes catalyze or inhibit

photooxidation of polymers for solar cells. Advanced

Energy Materials, 2(11), pp.1351–1357.

Iijima, S., 1991. Helical microtubules of graphitic carbon.

Nature, 354(6348), pp.56–58. Available at: http://

www.nature.com/doifinder/10.1038/3540560

[Accessed July 10, 2014].

Jeyakumar, R., Maiti, T.K. & Verma, A., 2013. Influence

of emitter bandgap on interdigitated point contact back

heterojunction (a-Si:H/c-Si) solar cell performance.

Solar Energy Materials and Solar Cells, 109, pp.199–

203.

Kang, M.G. et al., 2006. A 4.2% efficient flexible dye-

sensitized TiO

2

solar cells using stainless steel

substrate. SOLAR ENERGY MATERIALS AND

SOLAR CELLS, 90(5), pp.574–581.

Li, C. et al., 2013. Photovoltaic property of a vertically

aligned carbon nanotube hexagonal network

assembled with CdS quantum dots. ACS applied

materials & interfaces, 5(15), pp.7400–4. Available

at: http://www.ncbi.nlm.nih.gov/pubmed/23844806.

PHOTOPTICS 2017 - 5th International Conference on Photonics, Optics and Laser Technology

162

Li, Y. et al., 2012. Annealing Effect on Photovoltaic

Performance of CdSe Quantum-Dots-Sensitized TiO

2

Nanorod Solar Cells, 2012, pp.1-6.

Ma, T.L. et al., 2004. Properties of several types of novel

counter electrodes for dye-sensitized solar cells.

Journal of Electroanalytical Chemistry, 574(1),

pp.77–83. Available at: <Go to ISI>://

000225310800010.

Malara, F. et al., 2011. Flexible carbon nanotube-based

composite plates as efficient monolithic counter

electrodes for dye solar cells. ACS Applied Materials

and Interfaces, 3(9), pp.3625–3632.

Mar, J.D. et al., 2011. Voltage-controlled electron

tunneling from a single self-assembled quantum dot

embedded in a two-dimensional-electron-gas-based

photovoltaic cell. Journal of Applied Physics,

110(5),p.053110. Available at: http://scitation.aip.org/

content/aip/journal/jap/110/5/10.1063/1.3633216.

Miettunen, K. et al., 2008. Initial Performance of Dye

Solar Cells on Stainless Steel Substrates. Journal of

Physical Chemistry C, 112(10), pp.4011–4017.

Available at: http://pubs.acs.org/cgi-bin/doilookup/

?10.1021/jp7112957.

Miller, O.D., Yablonovitch, E. & Kurtz, S.R., 2012.

Strong internal and external luminescence as solar

cells approach the Shockley-Queisser limit. IEEE

Journal of Photovoltaics, 2(3), pp.303–311.

Mizuno, K. et al., 2009. A black body absorber from

vertically aligned single-walled carbon nanotubes.

Proceedings of the National Academy of Sciences of

the United States of America, 106(15), pp.6044–6047.

Péchy, P. et al., 2001. Engineering of Efficient

Panchromatic Sensitizers for Nanocrystalline TiO2-

Based Solar Cells. Journal of the American Chemical

Society, 123(8), pp.1613–1624. Available at:

http://pubs.acs.org/doi/abs/10.1021/ja003299u.

Peng, T. et al., 2011. Hydrothermal Preparation of

Multiwalled Carbon Nanotubes (MWCNTs)/CdS

Nanocomposite and Its Efficient Photocatalytic

Hydrogen Production under Visible Light Irradiation.

Energy & Fuels, 25(5), pp.2203–2210. Available at:

http://dx.doi.org/10.1021/ef200369z.

Shabaneh, A.A. et al., 2014. Reflectance Response of

Optical Fiber Coated With Carbon Nanotubes for

Aqueous Ethanol Sensing. IEEE Photonics Journal,

6(6), p.6802910.

Takahashi, T., 2011. Photoassisted Kelvin probe force

microscopy on multicrystalline Si solar cell materials.

In Japanese Journal of Applied Physics, 50,

p.08LA05.

Tian, J. et al., 2013. ZnO/TiO2 nanocable structured

photoelectrodes for CdS/CdSe quantum dot co-

sensitized solar cells. Nanoscale, 5(3), pp.936–943.

Available at: http://dx.doi.org/10.1039/C2NR32663A.

Udorn, J., Hatta, A. & Furuta, H., 2016. Carbon Nanotube

(CNT) Honeycomb Cell Area-Dependent Optical

Reflectance. Nanomaterials, 6(11), p.202. Available

at: http://www.mdpi.com/2079-4991/6/11/202.

Watanabe, K. et al., 2011. Si/Si 1-xGe x nanopillar

superlattice solar cell: A novel nanostructured solar

cell for overcoming the Shockley-Queisser limit. In

Technical Digest - International Electron Devices

Meeting, IEDM, pp. pp: 36.4.1-36.4.4. Available at:

http://ieeexplore.ieee.org/document/6131685/

Wei, J. et al., 2014. Modification of carbon nanotubes with

4-mercaptobenzoic acid-doped polyaniline for

quantum dot sensitized solar cells. Journal of

Materials Chemistry C, 2, pp.4177–4185. Available

at: http://xlink.rsc.org/?DOI=c4tc00021h.

Yu, K. et al., 2012. Controllable photoelectron transfer in

CdSe nanocrystal-carbon nanotube hybrid structures.

Nanoscale, 4(3), pp.742–746. Available at:

http://dx.doi.org/10.1039/C2NR11577H.

Yu, Z. & and Louis Brus, 2001. Rayleigh and Raman

Scattering from Individual Carbon Nanotube Bundles.

The Journal of Physical Chemistry B, 105(6),

pp.1123–1134. Available at: http://dx.doi.org/

10.1021/jp003081u.

Zarazúa, I. et al., 2011. Photovoltaic conversion

enhancement of CdSe quantum dot-sensitized TiO 2

decorated with Au nanoparticles and P3OT. Journal of

Physical Chemistry C, 115(46), pp.23209–23220.

Zhang, Y. et al., 2009. Surface photovoltage

characterization of a ZnO nanowire array/CdS

quantum dot heterogeneous film and its application for

photovoltaic devices. Nanotechnology, 20(15),

p.155707. Available at: http://stacks.iop.org/0957-

4484/20/i=15/a=155707.

Zhu, H.W. et al., 2008. Anthocyanin-sensitized solar cells

using carbon nanotube films as counter electrodes.

Nanotechnology, 19(46), p.5. Available at: <Go to

ISI>://000260264000007.

CdSe/ZnS (Core/Shell) Quantum Dots Multi-wallled Carbon Nanotubes (MWCNTs) on a Stainless Steel as a Photoanode in Solar Cells

163