An Improved Algorithm based on Constraint Programming for Job

Shop Rescheduling Problem with New Job Insertion

Peng Yun-fang

1

, Su Chen

2

1

School of management, Shanghai University, Shanghai, China

2

School of management, Shanghai University, Shanghai, China

yfpeng@t.shu.edu.cn, 774600425@qq.com

Keywords: Job Shop Rescheduling, constraint programming, new job insertion.

Abstract: Due to a variety of unexpected situations, the shop needs to make adjustments on the original schedule.

Aiming at job shop rescheduling caused by new job arrival, we build an optimal model based constraint

programming to make a reschedule to minimize the makespan. And considering the advantage of constraint

programming in solving combinatorial optimization problems, we combined constraint propagation

techniques with construction search strategy, a rescheduling algorithm based on constraint programming is

designed. Computational experiments of rescheduling problems are generated based on the benchmark of

Job shop scheduling problem. Results reveal the proposed algorithm can solve the instances in short time.

1 INTRODUCTION

Job shop scheduling problem, as a NP hard problem,

has been studied by a lot of scholars. The classical

algorithm for solving job shop scheduling problem is

generally divided into two categories: the

optimization method and the approximate method.

The optimization method includes integer

programming and branch and bound method. The

approximate algorithms mainly include the rule of

priority allocation, artificial intelligence, neural

network, Lagrange relaxation method, the

conversion of the bottleneck method, local search

method, etc. In order to get better result, many

scholars improved these algorithms, such as the

improved neural network algorithm, the improved

genetic algorithm, the improved hybrid particle

swarm algorithm, mixed integer programming

algorithm and so on. Although these classical

algorithms for static production have made great

achievements in recent decades, but in recent years,

scholars are increasingly aware that the production

workshop will face with various emergency

situations in the actual production, such as the

insertion of the new job, machine failure, operation

time change. In this dynamic environment, the

original production plan will be disturbed and the

production system cannot execute production plan,

so the production plan need to be rescheduled.

Bierwirth et al proposed a genetic algorithm to

solve rescheduling and scheduling problem in

1999(Bierwirth et al, 1999). Fang presented a

periodic and event-driven rolling horizon scheduling

strategy adapted to continuous processing in a

changing environment, and presented a hybrid of

genetic algorithms for the rescheduling problem

(Fang et al, 1997).However, periodic rescheduling

strategy cannot get very good stability solution for

this problem. In order to obtain both the stability and

effectiveness of the rescheduling problem,

Rangsaritratsamee et al proposed a local search

algorithm based on genetic algorithm ,and the

experiments show that the solution of the algorithm

compared with traditional algorithm more stable and

effective(Rangsaritratsamee, 2004).Katragjini et al

developed a rescheduling algorithms based on repair

theory to solving the problem, and proposed a

rescheduling methods to seek a good trade-off

between schedule quality and stability(Katragjini et

al, 2013).Zhang et al proposed a new rescheduling

technique based on a hybrid intelligent algorithm for

solving job shop scheduling problems with random

job arrivals, the experimental results show that the

proposed rescheduling technique is superior to other

rescheduling techniques with respect to five

objectives, different shop load level, and different

due date tightness, the results also illustrate that the

proposed rescheduling technique has a good

robustness in the dynamic manufacturing

68

68

Chen S. and Yun-fang P.

An Improved Algorithm based on Constraint Programming for Job Shop Rescheduling Problem with New Job Insertion.

DOI: 10.5220/0006443900680073

In ISME 2016 - Information Science and Management Engineering IV (ISME 2016), pages 68-73

ISBN: 978-989-758-208-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

environment(Zhang et al, 2013 ). Gao et al proposed

A two-stage artificial bee colony (TABC) algorithm

with several improvements to solve FJSP(flexible

job shop problem) with fuzzy processing time and

new job insertion constraints, and compared against

seven existing algorithms for solving five well-

known benchmarks of FJSP , the results illustrated

the competitiveness of the proposed algorithm(Gao,

2016) .

Although the optimization algorithms mentioned

above have achieved good results in solving the job

shop rescheduling problem, the solution time of

these algorithms is too long which is not good

enough to be applied in the actual production. In

actual production, decision makers often need to

make a relatively feasible decision in a short time.

Constraint satisfaction technique is an effective

method to solve the above problem. This technique

can not only simplify the complexity of the model,

but also reduce the computational complexity of the

problem by using the constraint relation between

variables. In recent decades, researchers have made

a lot of research on Constraint Satisfaction Based

Job Shop scheduling algorithm, and the constraint

programming is applied to job shop scheduling and

some excellent research results have been obtained.

For example, Nuijten, Sahraeian, Moukrim,

Lacomme and other scholars, their research results

show that constraint programming features in shop

scheduling are quickly and effectively, it can

provides a feasible scheme for the enterprise timely

and effectively(Nuijten et al, 1998)( Sahraeian et al,

2014)( Moukrim et al, 2014)( Lacomme et al, 2011).

Based on the above, this paper applies the

constraint programming to the job shop rescheduling

problem, and adopts the global rescheduling strategy

to achieve the goal of solving the shop Job

rescheduling problem with the insertion of new job

rapidly.

2 JOB SHOP RESCHEDULING

PROBLEM

2.1 Problem description

In the reality of job shop production, there are often

a lot of dynamic factors leading to the job shop need

to rescheduling, this paper focuses on the job shop

rescheduling problem of the insertion of new job.

When a new job arrives and insert into the original

schedule, some conflicts may arise and the original

schedule may not be executed. Hence, it is necessary

to reschedule in this situation. And most

importantly, the machines are available for

rescheduling only when the operations on them are

all completed. That means machines and jobs may

have different start times in the rescheduling.

In order to facilitate the establishment of the

model, we assume a new job arrives at the time of

T

b

. If o

ib

is processing on the machine b at the time

of Tb, this operation will be considered as an

operation which has been processed in rescheduling,

and the earliest start time of machine b is equal to

c

i,j

. If a machine j does not process any job, the

earliest starting time of machine j is equal to T

b

.

In this paper, all operations of original schedule

are included in the set Ω. Since the insertion of new

job, we reset n as the total jobs in the rescheduling,

and m as the total machines. All operations need

rescheduling are included in the set Ω’.

2.2 Rescheduling model

In the JSRP, each job consists of a sequence of

operations. An operation can be executed by a set of

candidate machines and each operation of a job is

processed only on one machine at a time, while each

machine can only process one operation at a time.

Minimizing the total completion time is the most

important objective of the job shop production in the

dynamic shop floor. In this paper, we use constraint

programming to establish the model, and solve the

rescheduling problem. The following notations and

assumptions are used for the formulation of JSRP.

i: job index (i=1,…,n) , a set of n jobs to be

scheduled;

j: machine index (j=1,…,m) , a set of m

machines;

c

i,j

denotes the completion time of the operation

o

i,j

;

y

i,j

denotes the start time of the operation o

i,j

;

Xiuj=1denotes job i should be processed on the

machine j after on the machine u(otherwise,

Xiuj=0);

Zikj=1 denotes machine j should process the job

i before job k (otherwise, Zikj =0);

p

i,j

denotes the processing time of o

i,j

;

M is a large enough value;

S

j

denotes the earliest starting time of machine j

in the rescheduling;

x

i,j

denotes the ending time of o

i,j

in the original

scheduling

Min C

max

(1)

s.t.

C

max

≥c

i,

j

(i =1,…,n; j=1,…,m)

c

i,

j

=y

i,

j

+p

i,

j

(i=1,…,n; j=1,…,m )

MX

iuj

+(y

i,u

-y

i,j

) ≥p

i,j

(i=1,…,n; 1≤u<j≤m )

An Improved Algorithm based on Constraint Programming for Job Shop Rescheduling Problem with New Job Insertion

69

An Improved Algorithm based on Constraint Programming for Job Shop Rescheduling Problem with New Job Insertion

69

M(1-X

iuj

)+(y

i,j

-y

i,u

) ≥p

i,u

(i=1,…,n; 1≤u<j≤m)

MZ

ikj

+(y

i,j

-y

k,j

) ≥p

k,j

(1≤i<k≤n; j=1,…,m)

M(1-Z

ikj

)+(y

k,j

-y

i,j

) ≥p

i,j

(1≤i<k≤n; j=1,…,m)

y

i,

j

≥S

j

; (i=1,…,n; j=1,…,m)

X

iuj

=0 or 1; (i=1,…,n; 1≤u<j≤m)

Z

ikj

=0 or 1; (1≤i<k≤n; j=1,…,m)

The objective C

’

max

(1) is to minimize makespan.

Eq.(2) states C

max

is the latest ending time of all the

operation in the rescheduling. Eq.(3) states the

ending time c

i,j

is equal to the ending time y

i,j

add the

duration time p

i,j

. Eqs.(4)(5) states each operation of

a job is processed only on one machine at a time.

Eqs.(6)(7) states each machine can only process one

operation at a time. Eq.(8) states the starting time of

o

i,j

should be equal or greater than the earliest time

of machine j. In the Eqs.(9)(10), the variable X

iuj

is

binary variable and the variable Z

ikj

is decision

variable.

3 RESCHEDULING ALGORITHM

BASED ON CONSTRAINT

PROGRAMMING

In this paper, a new job shop rescheduling algorithm

based on constraint programming is proposed. This

algorithm mainly uses the job shop scheduling

algorithm based on constraint satisfaction problem,

and combined with the constructive search algorithm

to solve the problem of job shop rescheduling.

3.1 The principle of rescheduling

algorithm based on Constraint

Programming

Constraint satisfaction algorithm includes repair

method and construction method. In this paper, we

use the construction method. In this algorithm, a

solution of job shop rescheduling is the processing

order of all the operation with a set of machines. The

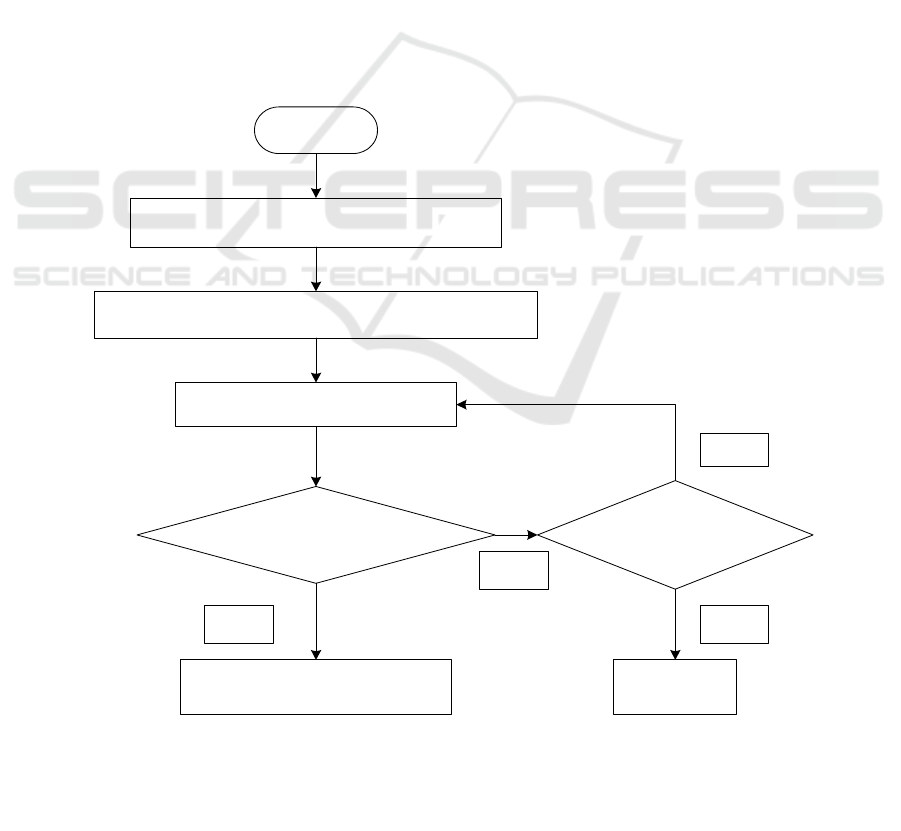

Calculate rescheduling information

Initialization

Preliminary elimination of infeasible solutions

Machines selection

Output optimal solution No solution

No Yes

N0

Is the iteration reach the

upper limit?

Does any value of the

combination violate constraint?

Yes

Figure 1: The flow chart of rescheduling algorithm

ISME 2016 - Information Science and Management Engineering IV

70

ISME 2016 - International Conference on Information System and Management Engineering

70

algorithm includes machine selection and process

selection. It will start from the machine selection,

then select a machine which hasn’t been selected to

process a job, until all the machines and all

processes are selected. If the search is failure, it will

take a backtracking strategy forward search.

Precedence constraints can be used to strengthen

the time window of all operations. The earliest start

time of all operation is updated according to Eqs.

(11) (12). The latest start time of all operations is

updated in Eqs.(13)(14). The algorithm will detect

the contradiction whenever there is no schedule can

satisfy all the precedence constraints of the problem.

est

i1

= 0 ∀i

(11)

est

i1

=max(est

i

(j

-1

)

+p

i

(j

-1

)

) ∀i,∀j

(12)

lct

i,

m

=UB ∀i

(13)

lct

i,j

=lct

i(j+1)

-p

i(j+1)

∀i,∀j∈[1,m-1]

(14)

The disjunctive constraints limit the sequence of

the operations processing on the same machine. Two

operations requiring the same machine cannot

overlap in time. As stated in Eq.(15), whenever the

earliest completion time of o

i,j

exceeds the latest start

time of oxy, o

i,j

cannot precede oxy, hence oxy must

precede o

i,j

. Once the precedence of two operations

assigned to the same machine is fixed, a new

precedence constraint is propagated based on the

rule (16)

est

i,

j

+pi,j>lstx ⇒o

x,

y

p o

i,

j

(15)

o

x,

y

p

o

i,

j

⇒ est

i,

j

+pi,j>lstx and lct

x,

y

≤lct

i,

j

-p

i,

j

(16)

3.2 The rescheduling algorithm based

on constraint programming for

JSRP

In this paper, an algorithm based constraint

programming for job shop rescheduling is proposed

to solve the scheduling problem with the objective

of minimizing the maximum completion time.

Step1. Initialization. All processes are accessed

as interval variables, and each parameter is

initialized to 0.

Step2. Calculate the rescheduling information.

Read the source file data of the information of new

job and the insert time T

b

. According to this

information, the earliest start time S

j

of machine j

will be calculated by this algorithm.

Step3. Preliminary elimination of infeasible

solutions. The initial constraint propagation removes

all values from domains that will not take part in any

solution.

Step4. Machines selection. This algorithm will

randomly chose a starting time of machine j for

operation o

i,j

by using the constructive search, the

machine j should not be selected to process a job,

until all the machines and all processes are selected.

If all the value has been chosen, there still have

conflict in the constraint, this problem has no

solution.

Step5. Consistency check. Constraint

propagation during this selection (step4) will

removes all values from the current domains that

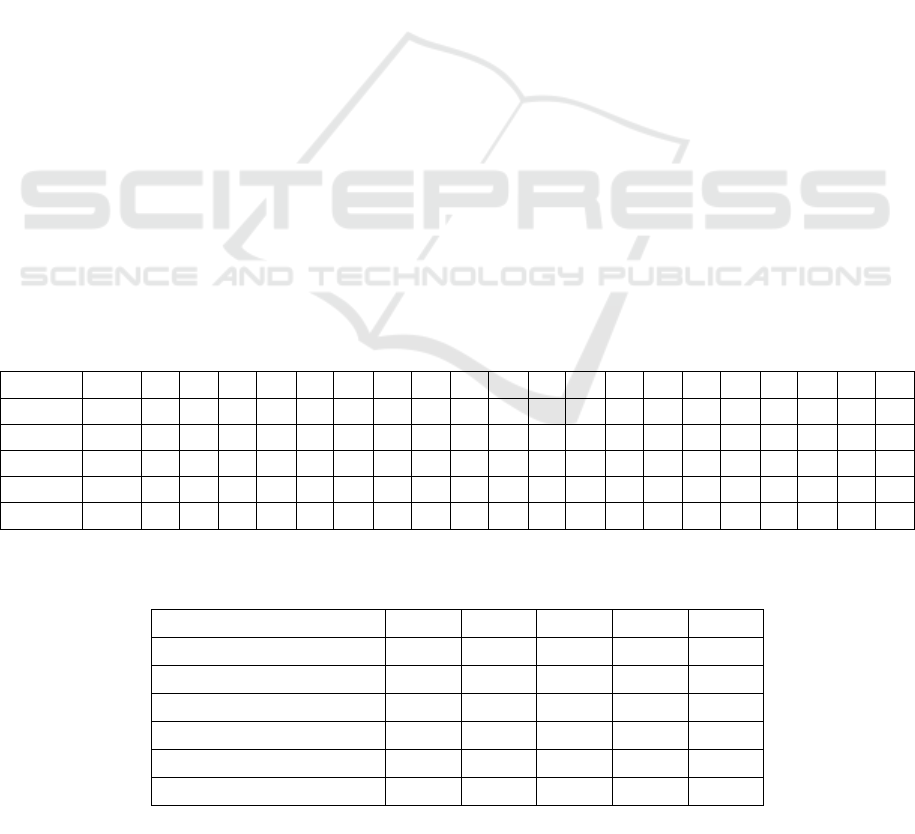

Table.1: Information of Rescheduling

Instance Time M T M T M T M T M T M T M T M T M T M T

la03 79 1 12 4 21 0 65 3 23 2 12

abz5 816 2 63 4 55 9 45 8 63 0 74 1 51 3 49 5 52 7 63 6 43

la27 103 2 45 3 18 8 29 6 42 4 32 7 87 1 11 0 28 9 26 5 25

la31 406 4 19 8 24 7 18 2 63 1 16 0 29 5 18 6 9 3 78 9 12

swv11 596 5 12 3 9 2 23 6 23 9 11 4 23 1 21 0 23 8 34 7 27

Table.2: Comparison of 6 sets of rescheduling

Type

10×5 10×10 20×10 30×10 50×10

Search limit 100000 100000 100000 100000 100000

Original scheduling objective 597 1237 1218 1784 3358

Rescheduling objective 659 1375 1279 1813 3460

Number of branches 1462 256501 118213 23040 315954

Number of fails 375 100465 37447 8999 100390

Time spent 0.09s 3.14s 1.92s 0.58s 8.03s

An Improved Algorithm based on Constraint Programming for Job Shop Rescheduling Problem with New Job Insertion

71

An Improved Algorithm based on Constraint Programming for Job Shop Rescheduling Problem with New Job Insertion

71

violate the constraints. This check will not stop in

the machine selection, until a solution is found. If

failed, it will jump to the step4, and reselect a

starting time for o

i,j

. If success, get this objective and

jump to step6.

Step6. Check iteration number. If the iteration

number is reach the upper limit, jump to

step7.otherwise, jumping to step4.

Step7. Output optimal solution. Compare all the

feasible solutions, and select the minimum objective

as the optimal solution.

4 EXPERIMENT EVALUATION

AND COMPARISONS

Since there is no standard rescheduling example for

analysis of the effectiveness of the model and

algorithm of job shop rescheduling problem, this

paper select 5 instances from OR as a basis for

rescheduling problem. We design 5 rescheduling

instances from small scale to large scale to analyse

the performance of the proposed algorithm.

In this paper, rescheduling is caused by the

100 200 300 400 500 600 700 800 900 1000 1100 1200

M10

M9

M8

M7

M6

M5

M4

M3

M2

M1

J3

J10

J5

J1J6J8 J4 J7 J2J9

J7 J9 J4J2

J8J10J1

J3

J6J5

J1J5J3 J6J7 J2

J9 J8

J4J10

J1

J5

J3

J6J7

J2

J9

J8J4 J10

J1

J5

J3

J6

J7

J2

J9

J8

J4

J10

J1

J5

J3 J6

J7

J2J9J8

J4 J10

J1

J5 J3

J6 J7

J2

J9

J8J4 J10

J1J5 J3J6 J7J2

J9

J8 J4 J10

J1

J5

J3

J6

J7

J2

J9J8 J4

J10

J1 J5

J3

J6 J7

J2J9J8 J4J10

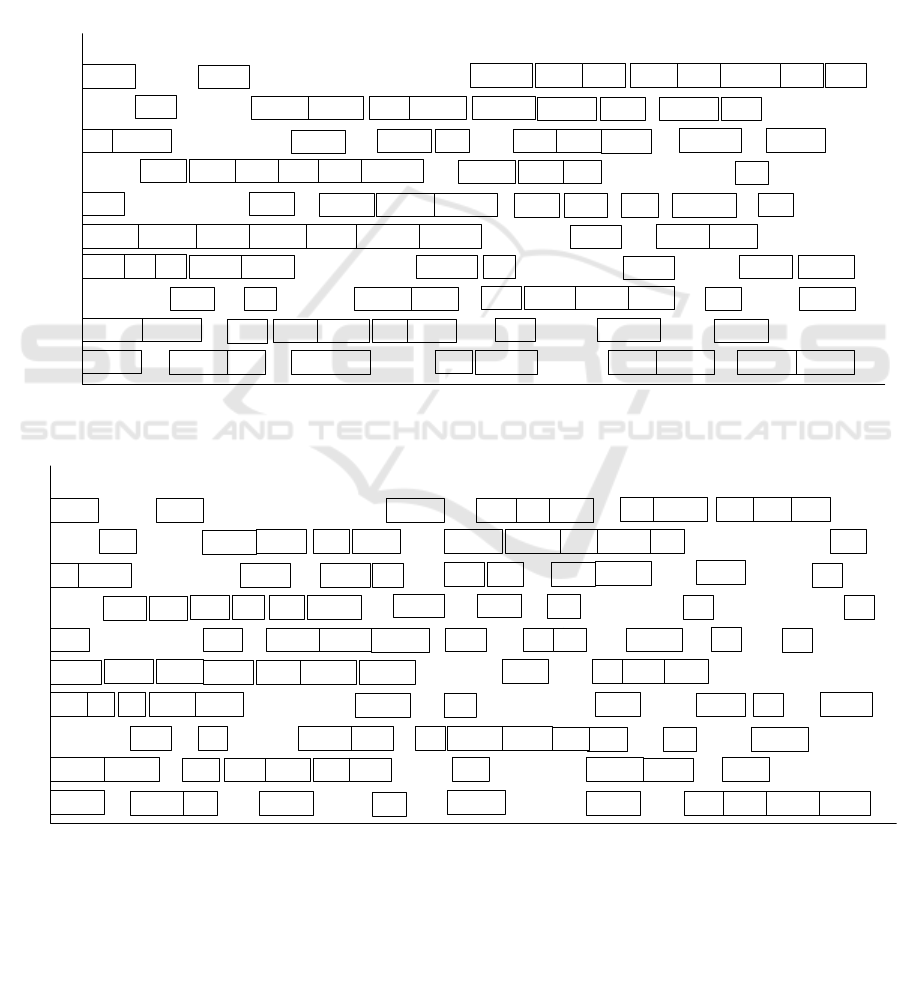

Figure 2 : 10×10 Gantt chart of original scheduling.

100 200 300 400 500 600 700 800 900 1000 1100 1200

M10

M9

M8

M7

M6

M5

M4

M3

M2

M1

J2

J5 J10

J3

J6 J1

J9 J4J7

J8

J1J2J3 J4J5 J6

J7

J8

J9

J10

J1

J2

J3

J4

J5J6

J7 J8J9 J10

J1 J2J3 J4

J5

J6 J7J8 J9J10

J1 J2

J3

J4

J5 J6

J7J8

J9 J10

J1J2 J3

J4J5

J6 J7

J8 J9

J10

J1

J2 J3 J4J5J6 J7J8 J9

J10

J1

J2J3 J4

J5J6 J7

J8 J9J10

J1J2

J3J4

J5 J6

J7

J8 J9

J10

J1J2

J3

J4 J5 J6

J7

J8 J9

J10

1300 1400

J11

J11

J11

J11

J11

J11

J11

J11

J11

J11

Figure 3 : 10×10 Gantt chart of rescheduling

ISME 2016 - Information Science and Management Engineering IV

72

ISME 2016 - International Conference on Information System and Management Engineering

72

insertion of new job, and the arrival time of new job

is selected randomly. The arrival time is

Tb=Random

1

*c, where the Random

1

value range is

[0,1], and the c is the maximum completion time of

the original scheduling. The information of new job

is created randomly.

Taking into account the feasibility of the

algorithm, this algorithm sets the upper limit to

100000. The job shop rescheduling parameters are

shown in table 1, including the insert time and the

information of new job’s operations. Table 2 is the

comparison of the results of rescheduling. Figure 2

is the Gantt chart of original scheduling (10 x 10),

and figure 3 is the Gantt chart of rescheduling (10 x

10). The values in bold in table 2 are the best

objectives of 5 job shop rescheduling problem, and

the objectives of rescheduling are closer to the

original scheduling. The last row of table 2 shows

that in solving the rescheduling, this algorithms

obtained high quality solutions in a short time for the

JSRP.

5 CONCLUSIONS AND FUTURE

WORK

This paper proposed a rescheduling algorithm based

on constraint programming for the job shop

rescheduling problem with new job arrival. This

algorithm adopted constructing search theory and

constraint propagation to minimize the maximum

completion time of all jobs. We selected 5 classical

instances released from the OR to analyse this

rescheduling problem. Experimental results showed

that this algorithms obtained high quality solutions

in a short time for the JSRP. The result showed the

proposed algorithm can be used in the practical

production and obtain more benefits for the

enterprise.

This paper focused on the job shop

rescheduling problem with new job arrive. But in the

reality, the practical production will meet more

kinds of emergency like advance delivery time and

machine breakdown. In the future study, we also

needs studied the job shop rescheduling problem

from other aspects and developed a more perfect

rescheduling algorithm.

ACKNOWLEDGEMENTS

This paper is supported by National Natural Science

Foundation of China (No.51405283).

REFERENCES

Bierwirth C, Mattfeld D C. 1999. Production scheduling

and rescheduling with genetic algorithms [J].

Evolutionary computation, 7(1): 1-17.

Fang J, Xi Y., 1997. A rolling horizon job shop

rescheduling strategy in the dynamic environment [J].

The International Journal of Advanced Manufacturing

Technology, 13(3): 227-232.

Rangsaritratsamee R, Ferrell W G, Kurz M B., 2004.

Dynamic rescheduling that simultaneously considers

efficiency and stability [J]. Computers & Industrial

Engineering, 46(1): 1-15.

Katragjini K, Vallada E, Ruiz R., 2013. Flow shop

rescheduling under different types of disruption [J].

International Journal of Production Research, 51(3):

780-797.

Zhang L, Gao L, Li X., 2013. A hybrid intelligent

algorithm and rescheduling technique for job shop

scheduling problems with disruptions [J]. The

International Journal of Advanced Manufacturing

Technology, 65(5-8): 1141-1156.

Gao K Z, Suganthan P N, Pan Q K, et al., 2016. Artificial

Bee Colony Algorithm for Scheduling and

Rescheduling Fuzzy Flexible Job Shop Problem with

New Job Insertion [J]. Knowledge-Based Systems,

109:1-16.

Nuijten W, Pape C L., 1998. Constraint-based job shop

scheduling with ILOG SCHEDULER [J]. Journal of

Heuristics , 3(4):271-286.

Sahraeian R, Namakshenas M., 2014. On the optimal

modeling and evaluation of job shops with a total

weighted tardiness objective: Constraint programming

vs. mixed integer programming [J]. Applied

Mathematical Modelling, 39(2):955-964.

Moukrim A, Quilliot A, Toussaint H., 2015. Branch and

price with constraint propagation for Resource

Constrained Project Scheduling

Problem[C]//International Conference on Control,

Decision and Information Technologies (CoDIT),

2014. IEEE,: 164-169.

Lacomme P, Tchernev N, Huguet M J., 2011. Dedicated

constraint propagation for Job-Shop problem with

generic time-lags[C]//Emerging Technologies &

Factory Automation (ETFA), 2011 IEEE 16th

Conference on. IEEE: 1-7.

An Improved Algorithm based on Constraint Programming for Job Shop Rescheduling Problem with New Job Insertion

73

An Improved Algorithm based on Constraint Programming for Job Shop Rescheduling Problem with New Job Insertion

73