Making and Understanding

A Vision for IoT Makerspaces

Julian Dax and Volkmar Pipek

Institute for Information Systems, University of Siegen, Siegen, Germany

Keywords: Making, IoT, Embedded Devices, End-User Development, End-User Software Engineering, Infrastructuring.

Abstract: We present a vision for the IoT makerspace of the future. Currently, makers design their spaces with a focus

on building (or making), but the core challenge they face in the IoT era is understanding. In our vision this is

archived by gathering data about the IoT devices and their environment, storing that data in a central

repository, consolidating it and making it easily accessible. We also describe the first steps we took towards

this vision.

1 INTRODUCTION

Consider the following scenario: Alice is building a

small robot in her local makerspace, which

automatically drives towards the nearest light source.

Two weeks ago, she almost got it working: It could

follow a light source, but the wheels don’t work well

on smooth surfaces. Now, that Alice has time again,

she wants to fix that. After she puts it on the big

working table in the hackspace and shines towards it

using her flashlight it does not move one bit. She is

puzzled and asks herself what she did do differently

this time.

Problems like these are quite common and

illustrate several concrete challenges makers face

every day. Software-controlled devices like the robot

behave in complex ways. Understanding the behavior

of a robot is therefore very challenging. As an IoT

device, is does not only have internal complexity; it

also reacts to the environment. In the robot's case, this

environment comprises its light sensors. In IoT in

general, it can be all kinds of sensors and also the

network. With IoT, the challenge is not building

anymore - the challenge is understanding the

behavior of the things you are building.

In this position paper, we present a vision of the

IoT makerspace (IoTMS) of the future, where the

IoTMS itself is an infrastructure which provides tools

for understanding. Concretely this means that:

The IoTMS captures and stores sensor data

automatically.

The IoTMS allows Makers to run simulations of

the developed IoT devices.

The IoTMS supports data analysis, retrieval, and

sharing.

We will also describe the first steps we took to arrive

at such a future by implementing a prototype

application.

2 REQUIREMENTS FOR AN IoT

MAKERSPACE

Back to Alice’s robot problem: After two hours of

checking the cables, debugging the source code and

replacing the motor she realizes, that when she last

worked on her project it was a Tuesday evening, and

now it is a Sunday afternoon. The lighting conditions

changed, and her algorithm has to change with them.

After some trial and error and a lot of recompilation,

she finds a setting for the light sensors which works

in the afternoon sun.

How can Alice be supported in understanding

what her robot does? At a very basic level, it is a

matter of gathering data. All sensor input and network

traffic should be directly visible to her. In general, we

derive requirement R1 from this:

The current state of the IoT device and its

environment should be visible to makers at all

times.

Fulfilling this requirement will help Alice see

previously hidden information which her robot

314

Dax, J. and Pipek, V.

Making and Understanding - A Vision for IoT Makerspaces.

DOI: 10.5220/0006094603140317

In Proceedings of the 8th International Joint Conference on Knowledge Discovery, Knowledge Engineering and Knowledge Management (IC3K 2016) - Volume 3: KMIS, pages 314-317

ISBN: 978-989-758-203-5

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

depends on. In this case, making visible the

previously invisible light sensor reading will help her

realize, that she needs to change her algorithm to

reflect the different input values. This will help with

many problems in the makerspace. However, Alice's

predicament is an exceptionally complicated one. She

can only solve it by also taking into account data from

her last visit to the space because if she adopts her

algorithm now to working in the afternoon, she also

wants to know which light sensor readings were taken

in the evening or her algorithm will not operate under

all circumstances. Abstractly, we derive requirement

R2 from this:

The past states of the IoT device and its

environment should be visible to makers at all

times.

Even if she could see the state of her robot and its

environment in past and the present, Alice would still

have a problem: She cannot test, if her updated

algorithm would work in the dark or if she just broke

it for that use-case. What would the robot do, if there

would be different lighting conditions? This question

can be addressed by allowing the simulation of

different scenarios.

We derive Requirement R3 from this:

Makers should be able to simulate environment

and device state parameters.

After she had finished her robot, Alice moved to

another city. Half a year later, Bob is interested in

building his own light-following robot. During the

project, he runs into the same problems Alice faced

before. However, he is not aware that someone in the

same makerspace built the same project as he does.

From this, we derive two requirements, R4 and R5.

Firstly, Alice should be supported in capturing

knowledge and secondly, Bob should be supported in

retrieving it:

IoTMS should help makers proactively when

they run into problems by providing information

relevant to the current context.

Makerspaces should support makers in

reviewing the gathered data and procure material

for future reference from it.

3 THE VISION

We envision an integrated hard- and software system,

which is distributed throughout and also an integral

part of the makerspace. We also see the IoTMS as one

holistic system. It is an infrastructure which provides

tools for building and understanding IoT devices.

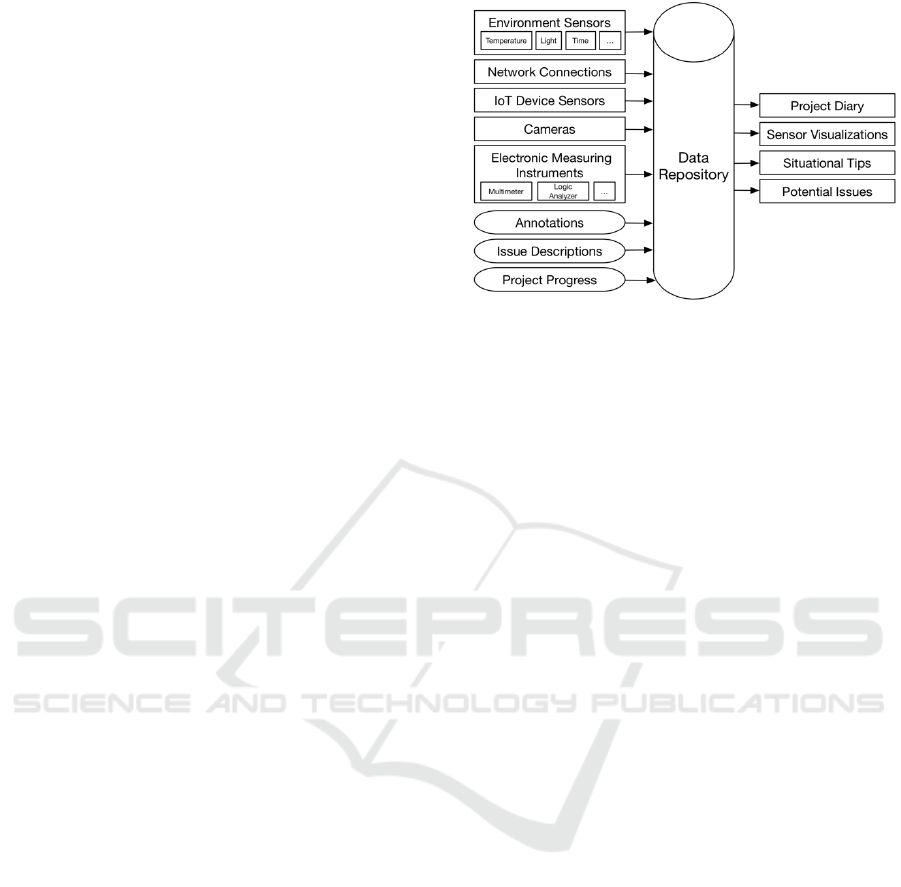

Figure 1: Overview of the data-flow through the IoTMS.

To address R1, it builds on connected sensors. For

electronics, this can be standard tools like

oscilloscopes and multimeters which transmit their

readings to a central data repository. Equally

important is reusing the already existing sensors in

IoT devices. In the robot example, the robot should

not only use the light sensor internally; it should send

all gathered data to the repository as well. Moreover,

we envision that computer vision technology can

automatically identify electronic components, like

resistors or diodes. After the sensors capture the data,

the system visualizes it. For that makers can use their

own laptops but the space also comes with projectors

or big screens. Makers should be able to visualize the

data by picking from a set of pre-defined

visualizations. The data repository and data

visualization also address requirement R2. A modern

time series database which allows quick access to all

captured information would allow makers to search

for past sensor data. To allow the simulations

described in R3, the software running on the IoT

device under development would also have to run in

the simulator. For that, the system should emulate or

simulate the microcontroller used in the IoT device.

Lastly, there would be a system for annotating the

captured data with the current project (for example

"Building a light-following robot"), project progress

and issues the maker faced. This way, a lab diary is

automatically generated. This diary can help makers

who do the same or similar projects in the future. For

this, we envision a context-dependent ambient

learning system which assists makers with their

concrete problem. The system could analyze current

sensor- and metadata data and automatically find

similar situations in the past using clustering

algorithms. Based on these past situations, the system

could then provide the maker with tips and point out

possible issues.

Making and Understanding - A Vision for IoT Makerspaces

315

4 FIRST STEPS TAKEN

As a first step towards the vision just described, we

implemented a desktop application called ‘Remotino’

(Dax et al., 2016) using web technologies (Electron,

Redux, React) which allows makers to remotely

control and instrument Arduino microcontrollers.

As shown in figure 2, Remotino allows makers to

visualize analog and digital inputs to the

microcontroller. Data from the Arduino is transferred

via USB to the desktop application using the Firmata

protocol (Steiner, 2009) . The main aim of the app is

to make the current state of the Arduino visible to the

user (R1).

Figure 2: A screenshot of the Remotino tool, showing

several analog inp ut pins and visualizing one of them.

It also provides some information about the past

state of the Arduino (R2), as the visualization uses a

sliding time window of one minute. Besides the input

visualization, Remotino also shows all available pins

and which modes these pins support (digital in, digital

out, analog in, analog out). It also recognizes which

kind of Arduino is connected. All these features aim

to make information visible and understandable

which was previously invisible.

Remotino is a first step towards the IoTMS and

currently only implements some of the aspects of a

IoTMS for a single maker. It only runs locally on a

PC and does not connect to a central repository (like

described in figure 1). It also only works with the

Arduinos it is directly connected to via USB. To

address these issues and develop it into the basis of an

IoTMS we are currently working on the first version

of the central data repository described above and on

an integration between this repository and Remotino.

Figure 3: A screenshot of the Remotino tool, showing

the two Arduinos which are automatically detected

when plugging them into the PC.

5 RELATED WORK

In our work, we draw on three research areas:

Making, Infrastructuring and End-User-Development

(EUD) (Ko et al., n.d.; Lieberman et al., 2006).

In the making and personal fabrication area,

Sheridan et al. describe and analyze current practices

in three makerspaces (Sheridan et al., 2014). Mellis

and Buechley studied DIY-communities with a focus

on online communities and electronic products. They

emphasize the need for “new Forms of knowledge

transfer" and find that in online communities about

DIY electronics text-based communication in a

question-and-answer format is very common but

ineffective (Mellis and Buechley, 2012).

In EUD, there has recently been more interest in

the development of physical objects and making.

Booth et al. identified challenges, which makers face

when building IoT devices (Booth et al., n.d.).

In infrastructure research (Star and Ruhleder,

1996) there has been interest in how to design

infrastructures, which help people in the

appropriation of technology (Ludwig et al., 2014).

We see the IoTMS as an infrastructure for

collaboratively understanding and building IoT.

KITA 2016 - 2nd International Workshop on the design, development and use of Knowledge IT Artifacts in professional communities and

aggregations. Knowledge Artifacts as resources in the maker and DIY communities

316

REFERENCES

Booth, T., Stumpf, S., Bird, J., Jones, S., n.d. Crossed

Wires: Investigating the Problems of End-User

Developers in a Physical Computing Task. ACM, New

York, New York, USA.

Dax, J., Ludwig, T., Pipek, V., 2016. Remotino: Supporting

End-User Developers in Prototyping Embedded

Devices CEUR Workshop Proceedings, Bari, Italy, pp.

7–11.

Ko, A. J., Abraham, R., Beckwith, L., Blackwell, A.,

Burnett, M., Erwig, M., Scaffidi, C., Lawrance, J.,

Lieberman, H., Myers, B., Rosson, M., Rothermel, G.,

Shaw, M., Wiedenbeck, S., n.d. ACM Computing

Surveys (CSUR) 43, 21–44.

Lieberman, H., Paternò, F., Klann, M., Wulf, V., 2006.

End-User Development: An Emerging Paradigm, in:

Lieberman, H., Paternò, F., Klann, M., Wulf, V. (Eds.),

Springer Netherlands, Dordrecht, pp. 1–8.

Ludwig, T., Stickel, O., Boden, A., Pipek, V., 2014.

Towards sociable technologies: an empirical study on

designing appropriation infrastructures for 3D printing.

ACM.

Mellis, D., Buechley, L., 2012. . Journal of the Designing

Interactive Systems Conference.

Sheridan, K., Halverson, E., Litts, B., Brahms, L., Jacobs-

Priebe, L., Owens, T., 2014. . Harvard Educ Rev 84,

505–531.

Star, S., Ruhleder, K., 1996. . Information Systems

Research 7, 111–134.

Steiner, H.-C., 2009. Firmata: Towards Making

Microcontrollers Act Like Extensions of the Computer.

pp. 125–103.

Making and Understanding - A Vision for IoT Makerspaces

317