Rapid Classification of Textile Fabrics Arranged in Piles

Dirk Siegmund, Olga Kaehm and David Handtke

Fraunhofer Institute for Computer Graphics Research (IGD), Fraunhoferstrasse 5 64283, Darmstadt, Germany

Keywords:

Quality Assurance, Textile Fabrics, Pattern Recognition, Textile Classification.

Abstract:

Research on the quality assurance of textiles has been a subject of much interest, particularly in relation

to defect detection and the classification of woven fibers. Known systems require the fabric to be flat and

spread-out on 2D surfaces in order for it to be classified. Unlike other systems, this system is able to classify

textiles when they are presented in piles and in assembly-line like environments. Technical approaches have

been selected under the aspects of speed and accuracy using 2D camera image data. A patch-based solution

was chosen using an entropy-based pre-selection of small image patches. Interest points as well as texture

descriptors combined with principle component analysis were part of this evaluation. The results showed that

a classification of image patches resulted in less computational cost but reduced accuracy by 3.67%.

1 INTRODUCTION

The cleaning of textiles in manufacturing industry is

nowadays an often completely automatized task op-

erated by machines. Nevertheless the visual quality

assurance after washing and drying is mostly man-

ually operated by humans. Fabric in textiles can

include cotton, wool, polyester or a composite of

them. As human errors occur due to fatigue, an au-

tomated inspection can improve quality and reduce

labor costs. In traditional textile manufacturing, fab-

ric is inspected during the furling process and can be

considered as a continuous 2D texture. However, this

work deals with pieces of textiles on assembly-line

like environments. As there is no mechanical solu-

tion for spreading the textiles in an automatized way,

the items will be inspected in a pile-like arrangement.

Discontinuous surfaces in combination with varying

colors and weaving of different textile fibers are some

of the challenges in this task. When dealing with re-

curring items, the recognition of the item type is an

important aspect to guarantee sorting accuracy. In

this work four woven cotton textiles each with dif-

ferent fabrics were used as experimental objects. As

high processing speed is required, this work will focus

on 2D methods for fabric classification. The previous

research results in fabric classification were carried

out on spread fabrics and required a 2D patterned tex-

ture defined by an underlying lattice with symmetric

properties. Unlike other projects this work examines

the applicability of the visual descriptors LBP (Lo-

cal Binary Pattern) and SURF (Speeded Up Robust

Features) in combination with the common classifiers

SVM (Support Vector Machine) and Adaboost. All

approaches were applied on the full image as well

as on cropped patches of smaller size. The database

consists of 537 images from 196 different textiles of

four different fabrics (= textile types). As the textile

comes in used condition the type of textile is not the

only property in the quality assurance. Some images

of textiles therefore have dirt, holes or other defects,

like the ones defined by the textile industry (Coun-

cil, 2000). Because some textiles may have been

washed many times, the fiber textile may also look

different in color and appearance. There are tech-

niques for textile classification that can differentiate

between fabrics with up to 98% (Ngan et al., 2011)

(Rebhi et al., 2015) (Abou-Taleb and Sallam, 2008)

accuracy. These existing approaches require the tex-

ture surface to be a flat and spread-out 2D surface.

In quality assurance after washing and drying this is

not the case. The textiles are in a voluminous shape

and show folds, edges, and borders. Folds as well

as overlapping borders have a negative impact on the

correct fabric classification. The three dimensional

shape tends to influences the size of the weaving in

the image. This work will examine how the chosen

visual 2D descriptors and classifiers perform on these

textiles in a verification scenario and will close with a

conclusion and outlook for future investigation.

Siegmund, D., Kaehm, O. and Handtke, D.

Rapid Classification of Textile Fabrics Arranged in Piles.

DOI: 10.5220/0005969300990105

In Proceedings of the 13th International Joint Conference on e-Business and Telecommunications (ICETE 2016) - Volume 5: SIGMAP, pages 99-105

ISBN: 978-989-758-196-0

Copyright

c

2016 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

99

Figure 1: Textile in pile-like arrangement.

2 RELATED WORK

All found previous research work in fabric classifica-

tion was done on spreaded fabrics. Some approaches

utilized Artificial Neural Networks (ANN) like Kang

and Kim (Kang and Kim, 2002) who involved a

trained ANN for color grading of raw cotton. The

images were captured by a color CCD camera with

which they acquired color parameters, checked con-

nectivity and evaluated trash particles for their con-

tent, size, distribution and spatial density with a high

recognition rate compared to other methods. She et al.

(F.H. She and Kouzani, 2002) classified two kinds of

animal fibers objectively between merino and mohair.

In their approach they developed a system that uses

an ANN and image processing for this classification.

Kuo and Lee (Kuo and Lee, 2003) developed a system

to distinguish defects of fabrics like holes, oil stains,

warp-lacking, and weft-lacking. For that reason they

used a back-propagation Neural Network which gets

an image as input. They successfully determined

nonlinear properties and improved the recognition.

Srikaew et al. (A. Srikaew and Kidsang, 2011) pre-

sented a hybrid application of gabor filter and two-

dimensional principal component analysis (2DPCA)

for automatic defect detection of texture fabric im-

ages. With a Genetic Algorithm based on the non-

defect fabric images they achieved the optimal net-

work parameters. With their experiments they con-

cluded that the applied gabor filters efficiently provide

a straight-forward and effective method for defect de-

tection by using a small number of training images

but still can generally handle fabric images with com-

plex textile pattern background. Another approach

from Sun and Zhou (Sun and Zhou, 2011) used a

threshold segmentation method to identify if there are

any defects existed in the fabric. They adopted an

image feature based approach to recognize oil stain

and holes, and used training based technique to de-

tect broken ends and missing picks. They segmented

and filtered the defect image, extracted features of the

fabric defect, the classification was based on local

features and training. For automated visual inspec-

tion Ngan et al. (H.Y.T. Ngan and Ng, 2005) used a

wavelet transformation based approach. With direct

thresholding (DT) and a so-called golden image sub-

traction method (GIS) they segmented out the defec-

tive regions on patterned fabric effectively. They also

present a comparison with other methods. To address

the 3D shape of the textile in the task presented here,

this work uses the general pattern descriptor LBP and

rotation and scale invariant local features.

3 APPROACH

3.1 System Overview

The method presented in this work consists of: seg-

mentation, patch extraction, pre-selection, feature ex-

traction, classification and fusion. The individual

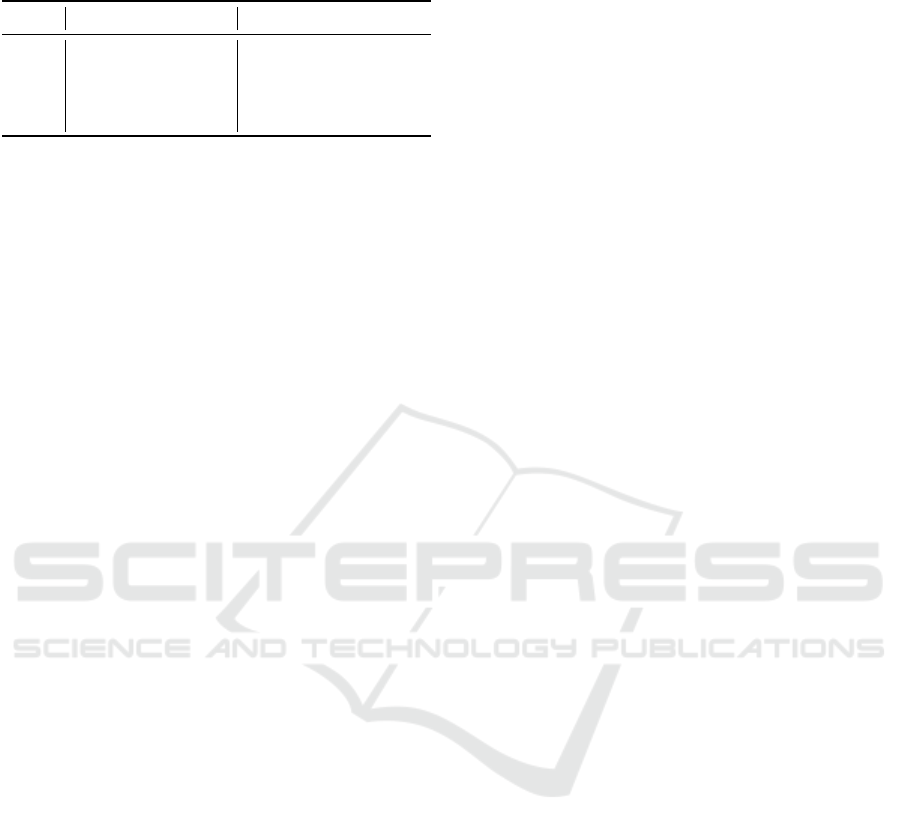

steps of the process are shown as a pipeline in Figure

2. The system has been evaluated including and ex-

cluding the steps: patch extraction and pre-selection.

For feature extraction the local interest point descrip-

tor SURF, as well as the LBP descriptor were used. In

the classification process the classifiers SVM and Ad-

aBoost were evaluated. When using patches instead

of the full image, these patches were preselected us-

ing the Shannon Entropy Value. The results of the

classification are fused in the Decision-Level-Fusion

step.

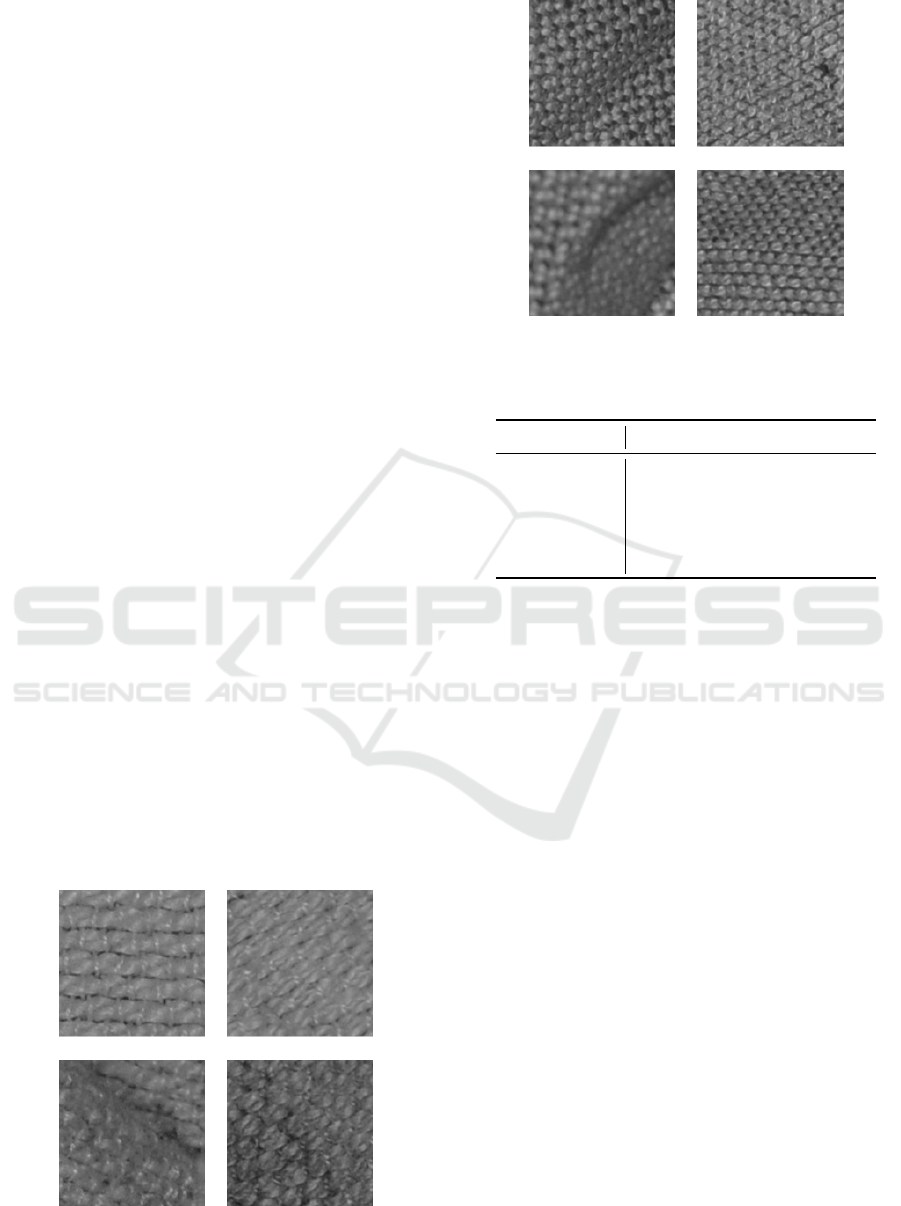

Figure 2: Program flow diagram.

3.2 Description of Methods Used

For visual distinction of the cloth quality between the

types examined in this study (see Figure 3 and 4) the

weaving of the textile is arranged differently and can

therefore be used as property. The cloth fabric can

be visually differentiated by its fineness, yarn density

and its total mixture. When there are pile-like, uncon-

trolled arrangement of textiles on the assembly line,

other properties than the fabric weaving are not al-

ways visible. The weaving pattern was therefore used

as a feature for classification. However, the evalua-

tion of this property requires a high recording quality

SIGMAP 2016 - International Conference on Signal Processing and Multimedia Applications

100

and a correspondingly high resolution. For this reason

screen tests were conducted to determine the minimal

resolution with enough features to distinguish the dif-

ferent types of fabric. Therefore, the cloth has been

divided into patches and was examined by humans on

their distinctness. The tests have shown that a resolu-

tion of 4288x2848 pixels (aspect ratio of 4:3) within a

receiving area of 30x40cm is optimal. Using the anal-

ysis of texture-spectrum or interest-points based fea-

tures, these discriminative properties can be evaluated

for a selection. To perform a classification based on

the texture of the images, different approaches were

examined. These can be differentiated by the used

image parts, the features used and the classifier. Two

different image input data formats were investigated.

First the use of the full images in high resolution of

4288x2848 pixels, secondly extracted parts of the im-

age represented in patches of the size 128x128 pix-

els. The idea behind using patches instead of the full

image relies on the assumption that pre-selecting im-

age parts which stores more discriminative informa-

tion than others will provide a more reliable classifi-

cation.

3.3 Image Acquisition

To protect the laboratory image acquisition process

from light entering from the outside, a black box was

used. On the inner side of the black box, black molton

was attached to protect the fabric from reflection of

the box. A uniform sheet of green foam rubber was

used as an underlay in order to simplify separation of

foreground and background in the segmentation pro-

cess. For a homogeneous illumination a LED ring

light with 1950 lx was used.

For image recording a camera with a CMOS DX

sensor and 35mm lens was used. In Table 1 you can

find a detailed description of the parameters used. All

Figure 3: Examined patches of textiles (left column: type 1,

right column: type 2).

Figure 4: Examined patches of textiles (left column: type 3,

right column: type 4.)

Table 1: Camera parameters.

Parameter Property

Resolution 4288x2848 pixels

Focal Length 35mm

Sensor CMOS 23,6mm x 15,8mm

Aperture F8

Exposure 1/200s

test objects were recorded in three different pile-like

arrangements. The used data format is JPEG with a

low compression rate.

3.4 Database

The database consists of 537 images from 196 differ-

ent textiles of four different fabrics (= textile types).

As the weaving properties are the only used distin-

guishing feature, the quality varies in the parameter of

yarn density and fineness. The yarn density reaches

from 9.5x6.5 fibers/cm for the most rough fabric to

26x16 fibers/cm for the finest one. The fineness of

the fibers lies in the range of 50/2 Nm x 5.2/2 Nn to

200/2 Nm x 80/2Nm. The examined textiles were in

cleaned and dry condition when they were recorded.

Nevertheless their condition varies a lot because some

of them are worn out. Most textiles show therefore

dirt, holes or others defects. Furthermore, every tex-

tile has one out of three different colors. To classify

the fabrics based on their different characteristics the

ground truth was manually determined by visual in-

spection. Table 2 gives an overview of the quantities

of examined textiles in the database. The yarn den-

sity and fineness is increasing with the type of tex-

tile weaving used. This is shown in Figures 3 and 4.

Furthermore, each type of textile can have one out of

three colors.

Rapid Classification of Textile Fabrics Arranged in Piles

101

Table 2: Quantities of examined textile images in the

database (full image).

Type #Images (#defect) #Color1/Color2/Color3

1 186(165) 87/48/51

2 177 (140) 69/66/42

3 144 (120) 66/54/24

4 30 (13) 12/3/15

3.5 Preprocessing

In the segmentation step (see Figure 2 step 2) the

background is separated from the foreground by using

a mask. The image was first converted into the HSV

color space. A color range for the ’H’ (hue) value was

used to define the background color as lying between

lowerH and upperH. Pixel in mask(I) are set to 255 if

src(I) is within the specified range and 0 otherwise.

mask(I) = lowerH(I)

0

≤ src(I)

0

≤ upperH(I)

0

(1)

The mask was inverted and then applied onto the

source image. The morphological operators erosion

and dilation were used to exclude remaining smaller

artifacts in the background from the foreground. In

the patch extraction (see Figure 2 step 3) the images

were splited into patches with the size of 128x128

pixels.

3.6 Pre-selection

In this approach, a entropy value was determined

which was used to characterizes the image quality.

Unlike a training based approach the decision was

made using a single value. The pre-selection was

therefore based on a threshold value. The so-called

Shannon Entropy Value is a value that measures the

information content in data and cam be used as a mea-

sure of image quality. Based on that, an approach for

patch selection is applied to choose the patch with

higher entropy, i.e. higher quality and information

content. The entropy of a patch I is calculated here

by summing up the entropy of each of the three chan-

nels of the image. The entropy of each image channel

is the sum of all pixel values probability p(i) multi-

plied by log

2

of those probabilities. The probability

of a pixel value p(i) is obtained by calculating a nor-

malized histogram of the possible pixel values (here,

i = {1, . . . , 2

8

}). The entropy of a 3-channel, 8-bit im-

age can be formulated as:

E(I) = −

C=3

∑

C=1

i=2

8

∑

i=1

p(i)log

2

(p(i)) (2)

The entropy values of all patches were calculated

and a number of patches with the highest entropy val-

ues selected for further processing. The number of

seven patches with the highest values were considered

as adequate in order to guarantee constant computa-

tional costs. It was furthermore observed that at least

seven patches with values higher than the threshold

could be found in every image. Patches with lower

entropy values tended to show a higher error-rate.

3.7 Feature Extraction

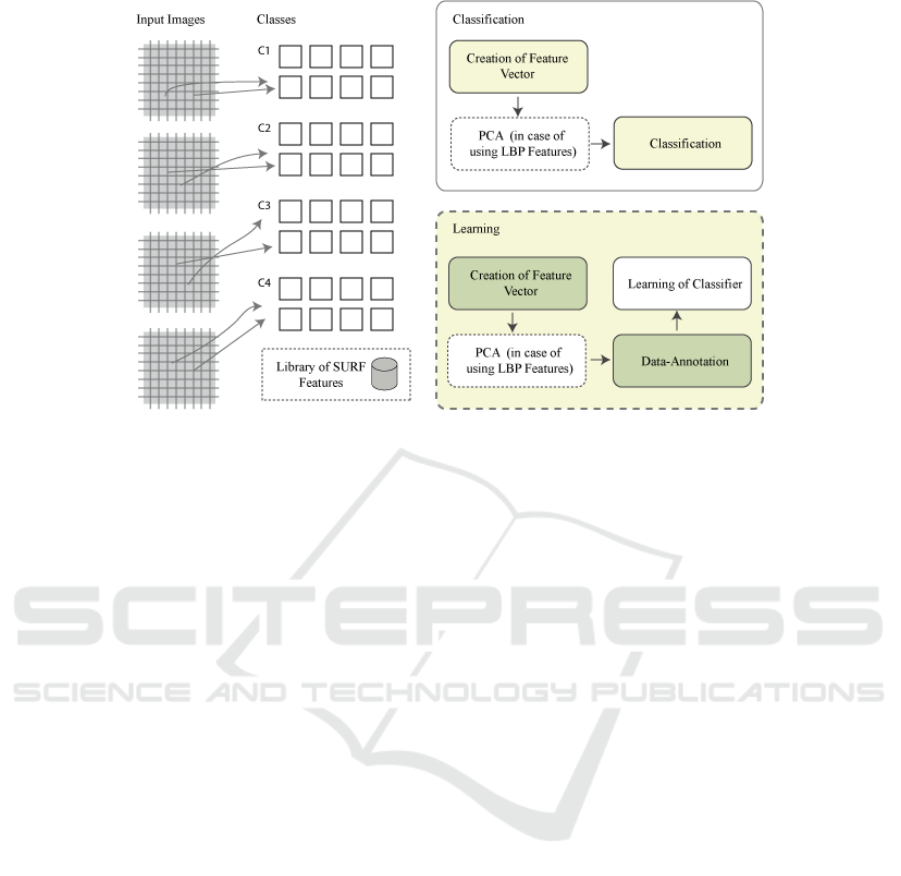

In feature extraction, the image is assigned to a class

representing a textile fabric (see Figure 5). In the ap-

proach using patches, all divided image patches de-

scribe one single class. The well-known SURF fea-

tures (Bay et al., 2006) have shown their effectiveness

in many recent papers dealing with object recognition

tasks (Yang et al., 2007). SURF Features are scale-

invariant and robust against rotation, translation and

changing lightning conditions. Therefore they are ap-

plicable for the detection of invariant features. Be-

fore feature extraction, images were converted into a

gray-scale representation and histogram equalization

was applied. A set of interest points was extracted

using the fast hessian detector. The kind of extracted

feature points was specified using manually selected

library of 120 images. These features were further

processed within a ’bag of words’ approach using a

64-dimensional vector as a descriptor. The size of

the dictionary was examined by evaluating the over-

all performance for different dictionary sizes with the

same trainings and test sets.

Local Binary Patterns (LBP) are used to analyze

texture spectra and are often used for classification in

computer vision task. Its strength is its extreme tol-

erance towards brightness changes, since only the lo-

cal gray value changes are considered. Local Binary

Patterns represent the local structure of an image and

are invariant to monotonic changes of the brightness.

They have been applied on different tasks the field

of image recognition (Luo et al., 2013) and achieved

high detection rates(Wang et al., 2009). A darken-

ing of the image (e.g. in case of shadows occurring

in folds of the textile) has therefore no negative in-

fluence to the feature vector. After gray-scale con-

version and histogram equalization the image was di-

vided into blocks of 16x16 pixels, which resulted in

64 blocks per patch or 47,704 blocks for the full im-

age. To each pixel of the gray-scale image (except

marginal areas) was assigned a new 8-bit value. This

value was calculated from 8 neighboring pixels of the

current pixel:

LBP =

7

∑

n=0

s(i

n

− i

c

) · 2

n

(3)

SIGMAP 2016 - International Conference on Signal Processing and Multimedia Applications

102

Figure 5: The left part illustrates the assignment of patches to classes based on their entropy value, the right part shows the

feature extraction, training and classification process.

For the center pixel, i

c

is the gray value of the

pixel in the gray values of adjacent pixels (contin-

uously starting left above the center pixel and then

clockwise). For each block, a normalized histogram

is calculated using the number of uniform pattern as

bins. The histograms of each block were concate-

nated to a feature vector. PCA (Principal Component

Analysis) was performed on that feature vector to re-

duce the dimensionality. As a part of it, eigenvalues,

eigenvectors and mean were calculated from a subset

of the database. By using PCA the number of com-

ponents in the feature vector was reduced by 92.03%

from 3,766 to 300 in the approach using patched. For

the full image the number of components was reduced

from 2,766,832 using the same percentage of reduc-

tion. The resulting feature vectors were used in five

fold cross validation for training and prediction.

3.8 Classification

The image classification in one of the core com-

ponents of the recognition process. The used ma-

chine learning approach requires learning a classi-

fier. Changes in the previous steps can have a high

impact on the recognition results. The previously

described features are stored as feature vectors F :

F = f

1

, f

2

, f

3

, . . . , f

7

in the patch based approach. In

the image based approach only one feature vector is

used. For further processing all feature vectors were

annotated manually and stored in form of a matrix.

The four classes C1-C4 (see Figure 5) representing

the four different textiles were used in the identifica-

tion scenario. In the verification scenario only two

classes were used in a one versus all classification ap-

proach. One representing a certain textile type (class

1) and another represents all other classes (class n).

For classification of the resulting feature vectors the

classifiers AdaBoost and SVM(Chang and Lin, 2011)

were used for supervised learning. In case of SVM

classification, C-Support Vector Classification which

allows imperfect separation of classes with penalty

multiplier and radial basis function was used. Ad-

aBoost combines the performance of many ’weak’

decision tree classifiers to produce a powerful com-

mittee(Hastie et al., 2005). The AdaBoost variante

’Gentle’(Friedman et al., 2000) was choosen because

it puts less weight on outlier data and was therefore

expected to work better with images of defect tex-

tiles. Five fold cross validation folders were used to

verify the classification results. In the approach using

patches instead of the full image, only a number of

patches with the highest entropy value were used to

create the cross validation folds. This is reasoned be-

cause it was expected that patches with a higher infor-

mation value show a lower error rate. It was further-

more expected that this approach saves computational

costs. The scores of all patches that belong to one tex-

tile were fused using mean-rule fusion-rule. Verifica-

tion and identification scenarios have been evaluated.

4 RESULTS AND EXPERIMENTS

The identification scenario was evaluated with a qual-

itative selection of image patches (patches), as well

as without such a pre-selection (full-image). The

Rapid Classification of Textile Fabrics Arranged in Piles

103

pre-selection was thereby done using the Shannon-

entropy value. The accuracy indicates the success-

ful differentiation between the 4 classes (True Posi-

tive Rate). It was tested against a data set of 537 im-

ages. The images were equally distributed over five

subsets. For each training of a classifier four subsets

were used for training and one for testing. The results

in identification show that the approach using patches

resulted in a weaker performance compared to the one

using the full image. The SURF interest point fea-

tures in a Bag of Words (BOW) approach showed a

better performance than LBP feature. This may rea-

soned in their scale and rotation invariant character-

istic. In the verification scenario the same data set

was used as for the identification scenario. As SVM

and SURF outerperformed the AdaBoost classifier by

an average of 3.67% accuracy, the verification results

are only shown for the SVM classifier and SURF fea-

tures. The results show clearly better accuracy for all

textile types and a difference of only 2.89% accuracy

between the patch based approach and the approach

using the full image was obtained. A possible rea-

son for the poor performance of the approach with

pre-selection of pieces of cloth is caused by the kind

of information excluded by the algorithm. It can be

seen that discriminative information is stored in even

patches with lower entropy. The speed of the algo-

rithm using SURF features on image patches on an

Intel Core i7 4770 is 503ms. The approach using the

full image instead of patches is 923ms.

Table 3: Classification accuracy in identification scenario.

Image Size Feature Classifier Accuracy

Full Image LBP/PCA SVM 65.52%

Full Image SURF(BOW)SVM 86.43%

Patches LBP/PCA SVM 59.9%

Patches SURF(BOW)SVM 85.41%

Full Image LBP/PCA AdaBoost 63.96%

Full Image SURF

(BOW)

AdaBoost 82.10%

Patches LBP/PCA AdaBoost 59.72%

Patches SURF

(BOW)

AdaBoost 80.33%

5 CONCLUSION

In this work, fabric patterns were classified using a

database of textiles in a pile-like arrangement. There

are multiple steps for classifying the fabrics: one in-

volves extracting the features of woven fabric im-

ages, the other involves recognizing the class of wo-

Table 4: Classification accuracy in verification scenario us-

ing SVM.

Image Size Type Feature Accuracy

Full Image 1 SURF (BOW) 94.68%

Full Image 2 SURF (BOW) 89.91%

Full Image 3 SURF (BOW) 96.56%

Full Image 4 SURF (BOW) 94.96%

Patches 1 SURF (BOW) 90.01%

Patches 2 SURF (BOW) 89.26%

Patches 3 SURF (BOW) 92.14%

Patches 4 SURF (BOW) 94.95%

ven fabrics. In order to find a solution which takes

into account speed and accuracy, an approach which

used patches instead of the full image was decided

upon. Interest points as well as texture analysis based

features were deployed and evaluated using different

classifiers. For both identification and verification, the

interest point based descriptor, SURF (in combination

with bag of words and the SVM classifier), demon-

strated the best performance. The patch-based ap-

proach reduced the calculation costs needed for pre-

diction by 46% while showing reduced 3.67% less ac-

curacy the verification. With the development of fur-

ther methods, the image automatic identification and

classification of woven fabrics could promote the de-

velopment of the textile industry.

REFERENCES

A. Srikaew, K. Attakitmongcol, P. K. and Kidsang, W.

(2011). Detection of defect in textile fabrics using

optimal gabor wavelet network and two-dimensional

pca. In Advances in Visual Computing, pages 436–

445. Springer.

Abou-Taleb, H. A. and Sallam, A. T. M. (2008). On-line

fabric defect detection and full control in a circular

knitting machine. AUTEX Research Journal, 8(1).

Bay, H., Tuytelaars, T., and Van Gool, L. (2006). Surf:

Speeded up robust features. In Computer vision–

ECCV 2006, pages 404–417. Springer.

Chang, C.-C. and Lin, C.-J. (2011). Libsvm: a library for

support vector machines. ACM Transactions on Intel-

ligent Systems and Technology (TIST), 2(3):27.

Council, H. K. P. (2000). Textile Handbook 2000. The Hong

Kong Cotton Spinners Association.

F.H. She, L.X. Kong, S. and Kouzani, A. (2002). Intel-

ligent animal fiber classification with artificial neural

networks. Textile research journal, 72(7):594–600.

Friedman, J., Hastie, T., Tibshirani, R., et al. (2000). Addi-

tive logistic regression: a statistical view of boosting

(with discussion and a rejoinder by the authors). The

annals of statistics, 28(2):337–407.

SIGMAP 2016 - International Conference on Signal Processing and Multimedia Applications

104

Hastie, T., Tibshirani, R., Friedman, J., and Franklin, J.

(2005). The elements of statistical learning: data min-

ing, inference and prediction. The Mathematical In-

telligencer, 27(2):83–85.

H.Y.T. Ngan, G.K.H. Pang, S. Y. and Ng, M. (2005).

Wavelet based methods on patterned fabric defect de-

tection. Pattern recognition, 38(4):559–576.

Kang, T. J. and Kim, S. (2002). Objective evaluation of the

trash and color of raw cotton by image processing and

neural network. Textile Research Journal, 72(9):776–

782.

Kuo, C.-F. J. and Lee, C.-J. (2003). A back-propagation

neural network for recognizing fabric defects. Textile

Research Journal, 73(2):147–151.

Luo, Y., Wu, C.-m., and Zhang, Y. (2013). Facial expres-

sion recognition based on fusion feature of pca and lbp

with svm. Optik-International Journal for Light and

Electron Optics, 124(17):2767–2770.

Ngan, H. Y., Pang, G. K., and Yung, N. H. (2011). Au-

tomated fabric defect detectiona review. Image and

Vision Computing, 29(7):442 – 458.

Rebhi, A., Benmhammed, I., Abid, S., and Fnaiech, F.

(2015). Fabric defect detection using local homogene-

ity analysis and neural network. Journal of Photonics,

2015.

Sun, J. and Zhou, Z. (2011). Fabric defect detection based

on computer vision. In Artificial Intelligence and

Computational Intelligence, pages 86–91. Springer.

Wang, X., Han, T. X., and Yan, S. (2009). An hog-lbp

human detector with partial occlusion handling. In

Computer Vision, 2009 IEEE 12th International Con-

ference on, pages 32–39. IEEE.

Yang, J., Jiang, Y.-G., Hauptmann, A. G., and Ngo, C.-W.

(2007). Evaluating bag-of-visual-words representa-

tions in scene classification. In Proceedings of the

international workshop on Workshop on multimedia

information retrieval, pages 197–206. ACM.

Rapid Classification of Textile Fabrics Arranged in Piles

105